pond mud pump free sample

Patented design protects your pump from the crushing forces of rock and water with a structurally tough injection-molded housing. Durable snap-fit enclosure is easy to assemble and contains no moving parts. Multiple uses for irrigation, rain collection, drainage, and lift-pump applications. Handles flow up to 15,000 gph. (Pump not included).Undoubtedly the hardest working gardening product in your pond, the Savio Skimmerfilter® dramatically reduces pond maintenance while blending seamlessly with the surrounding landscape. Combining four types of filtration for superior pond water clarity - its all-in-one approach reduces plumbing and eliminates the need for extra plumbing and equipment. All four systems work in harmony, in one easy-to-install unit that saves you time and money.

The “pond” is actually a man made dam which covers an area of about 40ha and has rockfill embankments of up to 53m high along the southern side that forms the impoundment. It initially constructed in 1959 to act as a tailings pond to take the bauxite residue (red mud) from the Ewarton Plant situated about 5km away and 300m lower. The red mud was pumped as a slurry comprising about 20% solids to the pond over a period of about 32 years up to 1991 when the pond was replaced by the Charlemount Mud Stacking and Drying Facility. During this period the pond embankments (referred to as dams), were raised up to 7 times providing a final crest elevation of 472m. The pond was however never filled to its final design capacity and the mud beach level remained at about 469m and the central area about 458m leaving a concave depression which held about 1.4mil m3 of water with elevated pH and some caustic content.

The remediation plan for the pond includes the removal of the ponded water and then the regrading of the mud surface to be free draining so that it can be stabilised and vegetated. About 500,000 m3 of mud will need to be moved over a distance of up to 1km in order to create the required profile. Due to the very soft nature of the surface muds (shear strength of less than 3kPa) its bearing capacity is less than 20kPa hence it is not accessible using even modified earthworks equipment. In addition, the muds are thyrotrophic and under any vibration or shear loading, rapidly liquefy resulting in significant reduction in shear strength and loss of bearing capacity. Using conventional earthmoving equipment would therefore require extensive “floating” haul roads with a high risk of machinery getting stuck or entire plant loss and risk to personnel. It was therefore decided to investigate the possibility of pumping the in-situ red mud.

A mud pumping trial was undertaken to assess the feasibility of using this technique to do the bulk mud moving. Pumping red mud is not unusual and the muds were initially pumped up to Mt Rosser Pond. However, the muds are usually pumped at a solids content of 30% or less. Once deposited, they can take years to reconsolidate and firm up sufficiently to allow access for light earthworks and agricultural plant.

In addition to the mud pumping, the trial included infilling three small scale geotubes to assess their performance as these may be needed as part of the regrading works.

The main aim of the pump trial was to determine if the muds could be pumped in their insitu state, and if not, what amount of water is required and how the variations in water content affect pump rates.

The mud pumping trial was undertaken using a 4” EDDY Pump. This pump was recommended due to its ability to handle variable solids and robust operating mechanism. The pump unit incorporated a hydraulic drive and cutter head. The unit was mounted onto the boom of a JCB 220 excavator which also supplied the hydraulic feed to power the pump for the required range of 30-40 GPM at 3,500 to 4,000 psi (2428MPa). The cutter head was powered by a standalone hydraulic power unit capable of providing the required 30gpm at 200psi (1.9 l/s at 13.8MPa). If mounted on a 30-ton excavator with a System 14 hydraulic system and dual auxiliary feeds to the boom, all necessary hydraulic power for the pump and cutter head can be supplied by the excavator. This equipment was however not available at the time in Jamaica.

In addition to the pump mounted on the excavator a Long Reach excavator (CAT 325) was used to move muds towards the cutter head but also to loosen up the muds and mix in additional water to facilitate pumping. Water was added by pumping it directly from the pond using a 3” diesel water pump.

Prior to pumping the muds, the mud pump would operate in recirculation mode in order to prime the pump. When in recirculation (re-circ) mode, the material pumped would be diverted to a short discharge pipe mounted on the pump directed back parallel to the cutter head. This action would help agitate and stir the muds.

A geotechnical soils investigation was undertaken on the muds within Mt Rosser pond in 2004. It showed the material to be predominantly clayey silt with approximately 13% sand, 29% clay and 58% silt using conventional sieve analysis and hydrometer. Atterberg limits indicate that the material is an intermediate to high plasticity clay. The muds do however vary across the lake and also vertically. This is mainly as a consequence of the deposition process and discharge location. Close to the discharge location the courser materials would settle out first and the finer materials would disperse furthest and to the opposite end of the pond. The results are presented in figure 4.1.

Earlier this year, additional mud samples were tested as it was evident that standard soil mechanics tests did not provide an accurate assessment of this fine material. This was particularly evident in tests done with dry sieving which shows the material as well-graded sand (see results for samples 5300, 5301, 5302 on figure 4.2). When dispersed in water, even with an agent, the ‘yield-pseudo-plastic’ rheology of the muds appeared to affect the hydrometer results with large variations between tests (see results of samples PFT4&5 taken during mud pumping trials on figure 4.2).

The additional testing comprised of undertaking gradings using a Laser Particle Analyzer. The results indicated that the muds are predominantly Silt although the silt % varied from 30% to 80% with the material being either more sandy or more clayey (up to 15% clay). See results of samples ending in “L” on figure 4.2 below.

Moisture content tests on the muds taken from within the mud pond but below the ponded water ranged from 100% to 150% (50% to 40% solids). The muds at the pump test location were 137% (42% solids).

Shear strength was generally very low ranging from 1kPa to 6kPa increasing with depth. Dynamic probes previously undertaken indicated that the muds are “very soft” to 5m increasing in strength slightly to “soft” at a depth of 9m after which they increase to firm becoming stiff.

The pH of the muds ranged from 10.3 to 11.7, (ave 11.2). Previous testing indicated that the surface muds have the lower pH although once through the crust, the pH tends to be higher. When doing the trials, the muds up to a depth of about 2.5m was intermixed, hence any stratification in pH could not be determined.

Initially, pumping was problematic mainly due to the excavator being underpowered. This was diagnosed as a hydraulic pump problem and the excavator was replaced. The cutter head (which also acts to protect the intake) tended to blind with mud (Photo 5.1) and was also not providing enough agitation to liquefy the muds. This was partly resolved by adding “stirrers” (2 steel loops welded either side) to the rotating cutter head and also a “comb” (Photo 5.2) to keep the gaps within the cutter head open.

Mud pumping rates varied from 21 l/s to 52 l/s (332 – 824gpm) and it was clearly visible that the more liquid the muds were the higher the pump rate was. Samples were taken at different discharge rates and moisture content and percent solids determined by laboratory testing. The results are plotted in Figure 5.1 and although scattered, do give an indication of the effects of solids content on flow rates. The natural moisture content of the muds (insitu) at the test location was 137%, or 42% solids. This is shown in Figure 5.1 as a vertical line. Pumping muds close to the percent solids was achieved although flow rates were low.

As mentioned previously, the long reach excavator was used to loosen up the muds. Water was pumped from the pond using a 3” pump into the excavation and the long reach would then work the muds to mix the water in. The mud pump would then be used in recirculation mode to further mix the muds into a more consistent state. Even with this mixing and agitation, the water tended to concentrate on the surface. This aided the initial process of priming the pump and once primed thicker muds at 1m to 2m below the surface could be pumped. However, it was found that the deeper muds tended to be lumpy and this would significantly reduce or stop the flow requiring the pump to be lifted into thinner muds or having to go back into re-circ mode or having to fully re-prime. The pump discharge was therefore very inconsistent as the suction intake position constantly needed adjustment in an attempt to get adequate discharge but also pump the thickest muds possible.

Discharge of the pumped muds was through 30m of flexible hose then 60m of 4” HDPE pipe which had an internal diameter of about 87mm (3.5”). The muds were discharged onto the original mud beach which lies at a gradient of about 9%. On deposition the muds slowly flowed down gradient. At times the flow would stop and the muds would build up then flow again in a wave motion. The natural angle of repose would therefore be a few degrees less than this – probably 5% to 6%.

Although the muds have very low shear strength, and on agitation liquefy, the sides of the excavation had sufficient strength to stand about 2m near vertical. Even overnight, there was limited slumping and the bank could be undermined by about 0.5m with the cutter head/agitator before collapsing.

On termination of pumping, in order to flush the pipeline, thin watery muds were pumped until the line was clear. A “T” valve system was then used to connect the 3” water pump line and this was then used to flush the pipe with water.

Three geotubes (1m x 6m) were filled with red muds pumped using the 4” Eddy pump. Fill rates were about 30 to 40l/s although it was difficult to assess as the flow and mud consistence was not visible.

Tube 1 was filled initially with more runny mud and then thicker muds as the pump operator got a better feel for conditions. The tube was filled until firm. The second tube was filled with thicker muds and filling continued until the tube was taut. These two tubes were positioned on the sloping beach in order to form a small “U” impoundment area that would later be filled with pumped muds. Although the area was prepared, the sloping ground caused the first tube to rotate through about 20 degrees. The tube was staked and the downslope side backfilled. A more defined bed was created for the second tube and the same rotational issue was limited. The two filled tubes with the ponded mud are shown in Photos 5.7 and 5.8. Other than a small leak at the contact between the two geotubes, the ponding of the muds was successful.

The third tube was positioned on level ground. It was filled with medium runny (but consistent thickness) muds and was filled until the tube was taut.

In all three cases, there was very little mud loss or seepage from the tubes. When stood on, some red water would squeeze out around the pressure area. Once filled taut, the entire bag would have small red water droplets form on the outside (visible in Photo 5.11) , but the seepage was in general nominal.

The tubes have been monitored and the most recent photo’s taken on 10 October 2011 (6 weeks after filling) show how the tubes have reduced in volume due to the dewatering of the contained muds. Volume loss is estimated to be around 30%. The anticipated moisture content would therefore be about 90% and the solids around 53%.

The muds pumped into the trial pond behind the geotubes were medium thick to thick, probably in the order of 37 – 40% solids. After 6 weeks the mud has not only firmed-up but had dried out significantly with wide and deep surface cracks as are evident in Photo 5.14 and 5.15.

The muds can be pumped at close to their insitu moisture content and most likely at their in-situ moisture content if they were agitated more and the pipeline system was designed to reduce friction losses.

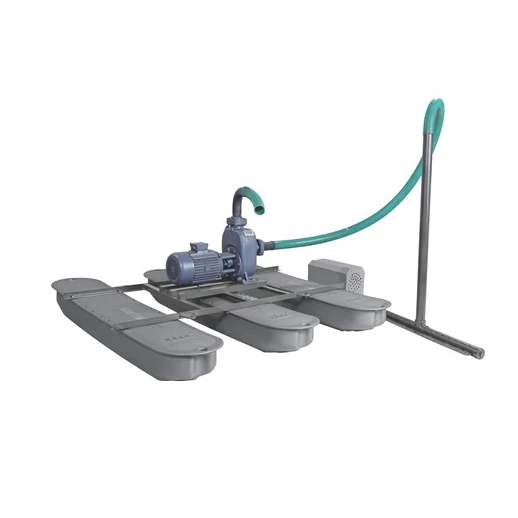

Be able to access the mud surface and move around efficiently and safely. The suggestion is to have the pump mounted on a pontoon that is positioned using high strength rope (dynema) or steel cable. The pump system should be remotely controlled as this would limit regular movement of personnel on the muds.

Have sufficient power and volume capacity to pump the muds at close to or at in-situ moisture content and discharge them about 1000m through a flexible pipeline.

It was also evident from the trials that the muds do not slump and flow readily. It will therefore be necessary to have an amphibious excavator to loosen up the muds in the area around the pump head. This weakened and more liquid mud would also aid the movement of the pump pontoon. To also limit the amount of movement the pontoon will need to do, the amphibious excavator could also move muds towards the pump location.

Using the capacity of the 4” mud pump, mud moving would take about 1.5 to 2 years, the pump will however need to be more suited to the task. A target period of 1 year however seems reasonable. However, prior to this, equipment will need to be procured and imported into Jamaica. The 6 and 10 inch Excavator Dredge Pump Attachments are also being considered as an option for higher GMP and a more aggressive completion timeline. A preliminary programme is as follows:

Similar to soil, Sludge and Sediment can also be Sampled, Monitored, Filtered and Treated. If you need to sample from a reservoir or in a pond or simply remove all excess water from your sludge we just may have what you are looking for.

The All-New PondMAX Bacta-Pak’s, combine BactiMAX+ & SludgeMAX to deal with all the muck and sludge buildup in ponds. Why muck around, when this combo pack gives your pond the jump start it needs? Offered in two sizes to treat water features up to 8,000 gallons.

About 7 years ago I started developing various water features, both garden ponds and water falls. As part of my research I found consistent comments like the following: you can’t make a natural pond using a pond liner without pumps and filters. The use of the word ‘natural’ here refers to the pond filtration system, not the esthetic look of the pond. I’ll deal with esthetics in a future post on how to build ponds.

In a natural pond the water, soil, plants, and animals all live in harmony. No one comes along to clean the pond or to aerate it. There is no big man-made filtration system that keeps the water clean. The common advice is that a pond liner is artificial and a pond built with it will never reach a natural state where the water, plants, and animals live in harmony the way they do in a natural pond. If you don’t filter such an unnatural pond it will become full of algae and the water will be dirty and smelly. The only way to have a pond with a liner is to add aeration and filtration.

This blog post is the second most popular post ever on this site. Lots of people comment and are interested in more information about building natural ponds, so I have started a public Facebook Group to make it easier for people to discuss this hot topic. Please join the group at https://www.facebook.com/groups/1760349757565562/

In a natural pond animals (insects, fish, etc) eat, poop, sleep and die. Both the poop and dead animals add nutrients to the water. Some is added immediately, and some is added over time as the material is degraded by various micro-organisms.

Plants also add nutrients when they die. In fall all kinds of leaves and other dead plant material is blown into the pond, and as this material is decomposed by micro-organisms it also increases the nutrient level.

Algae is a plant that grows best with high light and high nutrient levels. When the nutrients get high enough, the algae takes over the pond and chokes everything else out.

Why does the algae not take over natural ponds? The answer is higher order pond plants (not including algae). Plants also use nutrients and as long as the plants in the pond use up the nutrients as fast as they are produced, algae has trouble getting a foot hold.

The other important part of a natural pond is the presence of micro-organisms. They are everywhere; in the soil, on rocks, and attached to plants. Think of these micro-organisms as the ‘cleaning machine’ of the pond. They take rotting, smelly animal and plant material and turn it into nutrients that plants and algae can use. The micro-organisms keep the water clean, and keep it from smelling.

A man-made pond made with a pond liner has no soil – so one source of micro-organisms is missing, especially if you keep cleaning the pond liner. Most ponds have few stones and few plants reducing the number of micro-organisms even further. Without microbes or filtration, the dead animals and plants just sit in the bottom, making the water cloudy and smelly. But it does not have to be this way – read on.

The picture shows a pond at Aspen Grove Gardens during installation. The black pond liner is in the deep part and the planting shelves are covered in carpet (white/gray areas). The liner will be pulled up to cover the carpet.

A poorly designed man-made pond does not have enough plants, and it does not have enough places for micro-organisms to live. As a result, dead stuff accumulates on the bottom. As this dead stuff starts to rot it uses up oxygen, and the water at the bottom becomes depleted in oxygen, which in turn causes anaerobic bacterial to grow. This type of bacterial loves the smelly mess and they thrive with low levels of oxygen. This seems like a good thing, and environmentally it is a good thing. The problem for us is that as they digest the rotting stuff, they make the water smell. We don’t like smelly ponds even if they are natural.

Aeration is recommended for ponds so that they don’t smell and that works quite well. The problem is that without anaerobic bacteria, the sludge on the bottom degrades very slowly and so you also need to clean the bottom of the pond on a regular basis.

Sure they do. It is quite normal to find this in a pond where a lot of animal or plant material falls into the water. You don’t normally smell it because the water is not stirred up enough to move the smells to the surface. Dig around with a shovel or step into it from a canoe and you’ll find the smell. The smelly sludge on the bottom is natural.

My man-made water features have sludge and anaerobic bacteria in the bottom. If I don’t disturb them, they degrade dead plant material, and produce nutrients for growing plants. In my ponds I don’t stir up the water so I don’t smell them.

As mentioned above, the lack of soil in the bottom of the pond and the lack of rocks and plants results in an environment that houses few micro-organisms when compared to a natural pond. The solution is to provide a man-made place for the microbes to live. Most filtration systems contain some type of surface for the micro-organisms to live on. This can be sand, wool, small pieces of plastic – it doesn’t really mater. What is important is that there is a lot of surface area. Microbes like to attach themselves to a surface and then ‘eat’ plant and animal bits as they float by in the water. So the filter replaces the natural places were microbes live–on soil, rocks and plants.

The above information should give you some background to understand both natural and man-made ponds. If you think about it for a while you will realize that a properly designed pond, with enough pond plants and homes for microbes, should work just as well as a natural pond. When I was planning to build my ponds I spent a lot of time trying to find a reference for a man-made pond that worked without pumps and filters – I found none. Every reference I found said that such a pond will not work.

The following is not the result of good research or the opinions of experts. It is the result of my experience with two ponds over a 6 year period. In this blog I am not describing how to make a pond but I will do that in another blog entry–some day. I will provide the key points to consider.

Based on the information above, a pond design needs two things which are lacking in most designs. It needs lots of pond plants. Plants will use up the excess nutrients and keep the algae in control. It also needs lots of little homes for microorganism – they will help keep the water clean.

2) Soil is not used for the plants. Pond plants don’t need a substrate, except to hold them down, and the pond certainly does not need more nutrients from soil. The plants should be using the nutrients produced by the micro-organisms and not the nutrients in soil . Instead of soil, I use small rocks – 1/2 inch or so. I just use all the small rocks I collect as I make new flower beds. Don’t fertilize your plants.

The garden pond in the pictures was built 5 years ago and it is only now that the planting shelves are starting to be full of plants. Wild bull rushes seeded themselves the second year. Irises have been added and are spreading. The pond has never been drained, and the bottom is never cleaned. It has no pump and no filter. Wind is the only thing that might provide some aeration as it ripples across the surface of the water. There are several large trees around the pond that add fall leaf drop – which is left to settle in the pond.

For the first 4 years the pond plants increased in number each year. During this time, I did have string algae, but it mostly had a spring bloom and by mid summer it was under control. The water was very green showing the presence of lots of one celled algae, but the water was clean, and it did not smell. The fish that were added the first year did not over winter but since year two they have overwintered and keep breeding. Herons and racoons help to keep numbers in check.

From a naturists point of view the pond is very healthy with lots of frogs and dragon flies breeding each year. Larger mammals, including deer use it as a water source.

It is now nearing the end of summer 2013 and the pond has been extremely clean–much clearer than the picture below from 2012. In fact it is too clean. You can now see the pond liner in the deeper sections of the pond. There was no string algae this year and almost no one celled algae. It has been a strange year weather wise which may account for some of this, but I think it is mostly due to the fact that the planting shelves are now very full of hungry plants which are out-competing the algae.

After 5 years I conclude that aeration and filtration are ‘probably’ not required. I’ll need to wait another 5 years or so to be absolutely certain of this. It is possible that in a few more years the stuff at the bottom will overwhelm the pond and may need to be removed. I doubt it!

From an environmental point of view there is nothing wrong with water that contains algae. In a natural pond it might indicate that too much fertilizer has leached into the pond which is not good. But this is not usually a problem in a man-made garden pond. If your pond water is green with algae it is probably healthy.

In Japan, garden ponds are treasured and it is common to buy a dye to color the pond water. Why do they do that? When the water is colored it reflects light much better. The shadows and reflections are considered to be very desirable. So next time someone comments about your green water, just tell them that you do it on purpose to better enjoy the reflections.

If you have further questions about building natural ponds or about your existing pond please post them in our new face book group called Building Natural Ponds.

A pump is like the heart of your pond, it circulates the water and moves it through your filtration unit, spitter, or waterfall. Selecting the right pump for the job will ensure that your water is filtered properly, and your water feature is looking its best. When doing your shopping, here are some things to consider:

Waterfalls require a few more calculations to determine the size needed. See below for more information on sizing a waterfall pump. We have a wide variety of Waterfall Pumps available to get the flow you want.

UV Clarifiers or Pressure Filters typically have a recommended pump size for optimal use. Check your manual or the product page to determine what pump size is recommended but note that head pressure will come into play (see below)

Water needs to circulate through the filter at least once every 2 hours. This means that if you have a 1,000-gallon pond, you need a pump that can produce at least 500 gallons per hour or GPH. If you have fish, then it is best to double the pump"s capacity to ensure that your water stays clean. A common misconception is that pump size is only related to pond size; however, the size of a waterfall, stream, or fountain is typically the deciding factor for which pump will be best in your feature.

Head pressure and desired flow rate will influence the pump needed to power your water feature. Head pressure refers to the friction created when water is pumped uphill or over long distances. Flow rate will determine how much water moves through the feature. Below are some tips for

Flow Rate: The average amount of water moving over a waterfall is 1,500 GPH for every 1" of width. Therefore, a waterfall that is 2" wide would need a 3,000 GPH pump. If you are looking for a heavier flow, calculate your flow using 2,000 GPH per foot.

Putting It Together: You may have noticed that our pumps have the flow rates listed different head pressures, so you just have to match up the numbers. In our example, if you wanted your feature to have a heavy flow then you would need a pump that can produce about 4,000 GPH at 5" of head pressure. The Pond Guy RapidFlo – 4,000 GPH would be the perfect fit because at 5" of head pressure, this pump produces 3,900 GPH.

There are two classes of pumps, submersible and external. For ponds, submersible pumps are preferred because they can be hidden easily and used in skimmer boxes. There are several varieties of pumps available, so below is guide to help you determine which one is right for you.

Mag-Drive: Ideal for small to medium applications, such as spitters and small in-pond filtration units. The Pond Guy MagFlo and other pumps of this style operate by a magnetic impeller. These are usually long-lived and generally only a new impeller is needed to refresh the pump.

Asynchronous and Hybrid: These have a higher flow rate at lower head pressures and are perfect for medium to larger applications. Asynchronous and hybrid pumps, like the Atlantic Tidal Wave3 TT-Series and Blue Thumb IllumiFlow, have a long life span, performing like direct drives, but energy efficient like mag-drives.

Direct Drive: The ShinMaywa Norus Submersible and other direct drive pumps are designed for features with a high head pressure and flow rate. Most models require oil or lubrication changes to keep the impeller shaft moving properly. These pumps have fewer moving parts, making them more economical to purchase; however, they have a shorter lifespan than the other style of pumps.

Sludge, slurry and sewage—three topics that aren’t a subject of everyday “pleasant” conversations. Any of these words conjures images of yucky goo, germs, and debris. But dealing with these fluids is a fact of life, and you need the right kind ofsubmersible pumpto handle the heavier load.

Having the right pump helps considerably with handling sludge and slurry safely. But with many brands and types of pump on the market, what kind of heavy-duty pump do you need to handle the workload?

Sludge pumps and slurry pumps are often considered interchangeable, but they do have slightly different functions. Both sludge and slurry are fluids with a high percentage of solids, but sludge is softer and thicker. Slurry is thinner and flows through the pipes more easily.

This article explains everything you need to know about sludge and slurry pumps, including the difference between a sludge pump and a slurry pump, and when you might need one.

Sludge has a thick texture that may be very viscous or sticky, making it difficult to pump. However, with a higher percentage of solids, it is more compact and can facilitate the disposal of waste products.

Being easier to pump, slurry is the preferred output where waste needs to be transported in liquid form. Being distributed in a liquid suspension, slurries can make it easier to relocate and dispose of waste products in the mining and construction industries.

Both sludge and slurry are mixtures of liquid and pulverised solid waste, but they are not the same. Sludge has a heavier consistency, like thick mud, while slurry is thinner and less viscous.

The main difference between sludge and slurry is the texture, rather than the composition of the fluid. Both slurry and sludge contain solids such as sand, mud, metals, sediments, and other particles within the liquid. They may be organic (like sewage) or non-organic.

Sludge is a thick and viscous fluid, and may be sticky, while slurry is thinner and flows more easily. This means that pumping requirements can vary significantly between these two fluids, and is also influenced by the type of particles found in the material.

The purpose of the sludge pump is to move sludge through sewer lines or other systems. Sludge can be heavy and often abrasive and corrosive; therefore, these pumps need to be high-powered. The heavier the sludge, the more horsepower that is required.

Centrifugal pumpsare commonly used thanks to their ability to pump effluent reliably. A centrifugal pump consists of a rotating impeller that converts electrical energy from the motor into kinetic energy. The kinetic energy is then converted to pressure, which creates the flow of the sludge through the pump.

These pumps can handle particles up to the size of sand, and flow rates can go as high as thousands of litres per second. However, these pumps cannot generate pressures higher than 1000 psi.

Positive displacement pumps work differently. While centrifugal pumps use continuous energy to increase the sludge flow, positive displacement pumps work by intermittently adding energy to increase pressure. They can generate more pressure than centrifugal pumps, but their flow rate can only go up to nine hundred and fifty litres per second.

There are two designs for the positive displacement pumps: either reciprocating (such as the plunger and piston design) or rotary (progressing-cavity pumps and rotary vane vacuum pumps being examples).

Slurry pumps are the type of pumps that are appropriate for pumping slurry. Choosing the suitable pump will depend on the size and types of solids in the slurry liquid and how corrosive the slurry mixture is. The larger and more corrosive the slurry is, the more heavy-duty the pumps would need to be.

Centrifugal pumpsare mainly used for slurry at concentrations less than seventy percent solid by weight; and come in various appearances, such as horizontal, submersible, and vertical.

Positive displacement slurry pumps are more limited when it comes to capacity, but they are better for pumping slurry with higher concentrations of solid material.

Centrifugal pumps, such asBianco Vulcan centrifugal pumpare above ground pumps that can be added to existing pump lines to add more power and suction force to the set up. In comparison,submersible drainage pumpssuch as theNova submersible pumpare powerful pumps ideal for removing water from an area, either on a daily basis or in case of emergencies.

Positive displacement slurry pumps are more limited when it comes to capacity, but they are better for pumping slurry with higher concentrations of solid material.

Water pumps differ from slurry or sludge pumps. The viscosity and composition of these fluids mean they need much higher pressure and hydraulic capacity than water pumps. Finally, water pumps cannot withstand potential chemical corrosion and particle abrasion.

Sludge and slurry both contain solid particles, including (but not limited to) sand, gravel, and metals; the difference lies in their consistency. Furthermore, while the liquid in sludge and slurry can indeed be water, it can also contain other types of liquid such as petroleum and various acids.Due to the difference in viscosity and composition of slurry and sludge, installing and using the correct type of pump is imperative.For pumping slurries, a centrifugal pump or heavy-duty drainage pump is used.For pumping sludges, positive displacement pumps such as diaphragm pumps, lobe pumps, and Moyno pumps are best.

A sludge or slurry pump can be used to pump out sewage from sewage lines. The most common type of pumps used for sewage are centrifugal pumps. These pumps can effectively push sewage and can be installed in pits and sumps.

Due to their higher starting costs and complex maintenance, reciprocating pumps are less common than centrifugal pumps. Reciprocating pumps are used in specialised cases when a larger-than-normal quantity of sewage needs to be pumped.

If you are dealing with a small amount of sewage that doesn’t justify the need to construct a pumping station, you can use air pressure pumps or pneumatic ejectors. Unlike other pumps with spinning impellers or pistons, these pumps use compressed air to move sewage. These small-capacity pumps are quieter, have fewer moving parts, and develop blockages less frequently. However, they are the least efficient among the pumping options available.

Because there are several conditions where a slurry pump or a sludge pump is called for, there are three types of installations to consider: dry installation, semi-dry installation or wet installation, which involves fully submerging the pump.

First is a dry installation where the bearings and the pump drive are kept out of the sludge or slurry. The wet end—which may include the impeller, suction liner, shaft sleeve, and shell—is free-standing and out of the way of any liquid. Horizontal slurry pumps are mostly dry installations.

The second method is semi-dry installation. The operator floods the wet end and the bearings but keeps the drive dry. This installation is often used for dredging with horizontal pumps.

The final method is wet installation. Using this method, the slurry pump and drive are fully submerged. Wet installation is often reserved for underwater operations, cement plants, dyeing and printing plants, and similar industries. The pumps used are oftenvertical centrifugal pumpswith semi-open impellers.

A pump is cavitating when the liquid in the pump turns to vapour at low pressure. Cavitation happens when voids (or bubbles) form within the slurry because the pressure rapidly decreases below the vapour pressure.

Sewage ejector pumps can pump high volumes of sewage to a maximum of about230 metres. Septic grinder pumps are better for low volumes but can pump sewage a much longer distance.

The type of pump needed depends on the type of wastewater that needs to be pumped. Centrifugal pumps are good for sludge wastewater with less particulates or solids. Rotary lobe pumps are great for thicker or more viscous fluids. Progressive cavity pumps and the air-operated diaphragm pumps are also suitable for sludge.

While it is possible to pump mud, it’s difficult and complex, so it requires specialised equipment. A reciprocating piston-driven or plunger-driven pump specially made to pump mud is needed for the task, and these can be expensive.

It’s best to have a pump professionally installed by a licensed specialist. Slurry pumps are intricate systems that won’t work correctly if not installed properly. To avoid issues with your slurry pump system, we always recommend getting it professionally installed.

There are many different ways to drill a domestic water well. One is what we call the “mud rotary” method. Whether or not this is the desired and/or best method for drilling your well is something more fully explained in this brief summary.

One advantage of drilling with compressed air is that it can tell you when you have encountered groundwater and gives you an indication how much water the borehole is producing. When drilling with water using the mud rotary method, the driller must rely on his interpretation of the borehole cuttings and any changes he can observe in the recirculating fluid. Mud rotary drillers can also use borehole geophysical tools to interpret which zones might be productive enough for your water well.

The mud rotary well drilling method is considered a closed-loop system. That is, the mud is cleaned of its cuttings and then is recirculated back down the borehole. Referring to this drilling method as “mud” is a misnomer, but it is one that has stuck with the industry for many years and most people understand what the term actually means.

The water is carefully mixed with a product that should not be called mud because it is a highly refined and formulated clay product—bentonite. It is added, mixed, and carefully monitored throughout the well drilling process.

The purpose of using a bentonite additive to the water is to form a thin film on the walls of the borehole to seal it and prevent water losses while drilling. This film also helps support the borehole wall from sluffing or caving in because of the hydraulic pressure of the bentonite mixture pressing against it. The objective of the fluid mixture is to carry cuttings from the bottom of the borehole up to the surface, where they drop out or are filtered out of the fluid, so it can be pumped back down the borehole again.

When using the mud rotary method, the driller must have a sump, a tank, or a small pond to hold a few thousand gallons of recirculating fluid. If they can’t dig sumps or small ponds, they must have a mud processing piece of equipment that mechanically screens and removes the sands and gravels from the mixture. This device is called a “shale shaker.”

The driller does not want to pump fine sand through the pump and back down the borehole. To avoid that, the shale shaker uses vibrating screens of various sizes and desanding cones to drop the sand out of the fluid as it flows through the shaker—so that the fluid can be used again.

Some drillers use compressed air to blow off the well, starting at the first screened interval and slowly working their way to the bottom—blowing off all the water standing above the drill pipe and allowing it to recover, and repeating this until the water blown from the well is free of sand and relatively clean. If after repeated cycles of airlift pumping and recovery the driller cannot find any sand in the water, it is time to install a well development pump.

Additional development of the well can be done with a development pump that may be of a higher capacity than what the final installation pump will be. Just as with cycles of airlift pumping of the well, the development pump will be cycled at different flow rates until the maximum capacity of the well can be determined. If the development pump can be operated briefly at a flow rate 50% greater than the permanent pump, the well should not pump sand.

Mud rotary well drillers for decades have found ways to make this particular system work to drill and construct domestic water wells. In some areas, it’s the ideal method to use because of the geologic formations there, while other areas of the country favor air rotary methods.

To learn more about the difference between mud rotary drilling and air rotary drilling, click the video below. The video is part of our “NGWA: Industry Connected” YouTube series:

Letting weeds and muck build up can cause problems for any lake or pond. Besides just looking ugly, these nuisances can lower property value, lessen visibility, and inhibit fishing and swimming by making it easier to slip and fall. If left unchecked, they can even throw off your waterbody’s ecosystem. Excess weeds and muck make it hard for larger fish to find food, and they keep water from flowing, creating places for mosquitos, leeches, and other pests to breed. Worst of all, muck and dead plants use up valuable oxygen as they decompose, resulting in fish kills. Muck also promotes the growth of bacteria that emit toxic ammonia, methane, and hydrogen sulfide gas — the source of that infamous “rotten egg” smell.

Healthy ponds and lakes need some muck and weeds, but if they’ve started taking over, you may need to intervene. Thankfully, there are plenty of options you can choose from to both remove muck and weeds and stop more from accumulating.

These manual tools won’t remove all muck and weeds, making them best for routine maintenance on small ponds or personal lakefront areas. They’re cheap, straightforward, and portable, but using them can be physically demanding — all that tossing, pushing, and pulling against water resistance can be tiring.Manual Lake Rakes, Cutters & Rollers

Although muck blowers take away most of the exertion, they also come with flaws. Blowers can be decently effective for moving muck, but they don’t usually work well for removing rooted weeds. Additionally, blowers don’t actually remove muck, they just push it somewhere else. This may be fine as a temporary way to get rid of excess muck, for example on waterfront property along a large lake or pond. For smaller ponds, though, there’s no reason to have a muck blower, since there’s not as much space for the muck to go. You’ll also need to be careful not to blow muck towards any neighbors’ property. Finally, in some areas, using muck blowers on the bottom is restricted, since they can create troughs that severely damage plant and animal habitats.Lake Muck Blowers

In terms of automated, electrical tools, water vacuums may be the most economical choice for removing muck and floating weeds from small private ponds. These devices typically consist of a wheeled holding tank with a vacuum nozzle and a discharge tube. Essentially big mobile pumps, water vacuums suck water at rates that usually fall between 1,500 and 2,000 GPH. After passing through a mesh-like bag that collects large debris, the mucky water sits in the holding tank until it’s pumped out via the discharge tube. To maintain optimal suction, you’ll need to clean the collection bag periodically.

Water vacuums usually have fairly long suction and discharge hoses (over 30 feet in some cases), allowing users some control over where they send the dirty water. Most brands don’t recommend returning this water to the pond, since it contains the small particles of muck, algae, and other debris that you were probably trying to remove in the first place. Some may include a very fine filter bag to put over the discharge hose that strains out fine particles, but even then, this may be counterintuitive unless your area is experiencing a water shortage. As a result, you’ll need to find someplace for the discharge to go. Luckily, the dirty water is full of nutrients, making it great for fertilizing your lawn or garden.

Water vacuums do have a few significant shortcomings. The first is that they’re not very practical for large waterbodies, with most having maximum operating depths of 4 to 6 feet. These tools are best for ponds smaller than 3,000 gallons, where everything is easy to reach. Another issue is that water vacuums aren’t very effective against rooted weeds. They should be able to suck up most loose or drifting plants, but they’re rarely able to pull out vegetation by the roots, which is key to making sure weeds don’t regrow in the future.Water Lake Vacuums

Pond owners often put a lot of thought into the pump they choose, but usually very little into which size tubing to use. Pond tubing is an often overlooked piece of pond equipment, but if you choose tubing that it too small, it will significantly decrease the flow of your pump.

A pump must have the power to not only push water vertically up to the top of your waterfall or filter, but also overcome the friction created inside the tubing or pipe. Pumping 2000 GPH of water through a 1 1/2″ tubing creates very little friction inside the pipe. However, if you pump the same 2000 GPH through 1″ pipe, the water will travel much faster through the pipe and create more friction. More friction creates more pressure on the pump and reduces the flow.

While a pond can be a wonderful feature for any property, there’s no denying that keeping the water healthy and the pond looking its best can take some work. If you’ve been wondering how to clean a pond, there are some easy steps you can take that will reduce the amount of labor needed.

Whether you have a small decorative pond, a koi pond, a larger pond or even a small lake, aerating and/or agitating the water definitely help keep your pond clean. Why does aeration matter? Let’s take a look at what happens if your pond water becomes stagnant.

Pond water contains a certain amount of oxygen. When a pond is stagnant the oxygen floats to the surface of the pond and the bottom water layer loses oxygen. When you aerate the pond water, this adds oxygen to the bottom layer and ensures that all of the water has a proper amount of oxygen. Low oxygen levels often lead to fish death, and aerating can prevent this from occurring.

Aerating can prohibit algae overgrowth and even reduce the amount of muck (decomposing matter) that builds up along the bottom of your pond. This much is made up of plant waste, fish waste and other materials. This muck not only reduces water clarity and reduces oxygen levels, but it can also create some unpleasant odors and aeration can go a long way to preventing muck from building up.

When it comes to aeration, you have several choices. For a fairly deep pond, bottom diffusion aeration can be a great option. This diffuses the water from the bottom, forcing the water up toward the surface where it can access more oxygen. If your pond is six feet or deeper, a bottom diffusion system is recommended.

A bottom diffuser also can be a good option if you live in an area where the top layer of your pond freezes over. When too much of the surface of a pond freezes, then very little light can reach into the water, and this leads to fish death. With a properly-installed aeration system, you can prevent these “winterkill” issues.

For a shallower pond, you might consider surface aeration, such as a waterfall. Not only will this help agitate the water, but it’s also lovely to look at, which is another bonus. There are other types of surface aerators aside from fountains, but we can’t deny that these look lovely as well as providing that much-needed aeration. Again, if your pond may freeze over in winter, a bottom diffuser might still be necessary.

Ok, we know this article’s title suggests that we are providing “easy” tips, but raking your pond can be a great way to remove algae and debris, as well as for removing muck. If you have a larger pond, consider heading out with your rake once per week and removing the debris. A pond rake is inexpensive and while it’s time-consuming to rake out the pond, if you make time once per week, it needn’t take an excessive amount of time to remove debris.

For a small decorative pond or koi pond, spend a few minutes each day removing dead leaves, twigs and other debris. Spending just 10 minutes per day removing some debris (you may not even need a rake for a smaller pond) can go a long way to keeping your pond water and your fish healthy. With these small ponds, a skimmer might be all you need to get out the debris.

One quick koi pond tip: Be wary of over-feeding your fish. Over-feeding is a very common mistake people make with their koi ponds. Not only is too much food bad for your koi, the excess food will just rot in your pond and create a situation ripe for algae growth.

Adding plants can be a great option for any pond. Plants can help keep water temperatures cooler and provide much-needed shade for fish and other aquatic life during the hotter months of the year.

Adding floating plants can be a great option. Not only are these beautiful, but they also restrict the growth of algae and eat up some of the nutrients that algae need in order to grow. Some plants even add extra oxygen to your pond water. We highly recommend that you speak with a pond expert and discuss the best types of plants for your pond.

As a side note, if your pond is stocked with fish, it is crucial that you keep this fish population under control. When there are too many fish in the water, they must compete for oxygen. An overstocked pond, after all, raises the water temperature and the amount of waste from these fish becomes excessive. When water temperatures rise and there is too much waste, oxygen levels drop and this leads to fish death.

If you are aerating and raking and vacuuming, but your pond’s water color isn’t as attractive as you like, you might be scratching your head and wondering how to clean a pond and restore the water to a beautiful condition. After all, you might pass by a golf course or park and see a beautiful sparkling pond and wonder what are they doing to that you aren’t doing.

The answer could be as simple as adding colorant to the water. It might seem like adding dye to your pond water is a bad idea, but it can be very beneficial for a pond. Colorants typically are made from the same dyes that are used in our food, so they are considered safe for your fish, as well as livestock and humans. You just want to ensure that you purchase food-grade dye and that your dye is veterinarian-approved.

Colorants not only enhance the color of pond water, they also can lower the temperature of a pond. Hotter temperatures drive up the temperature of pond water, which lowers the oxygen levels in your pond. Not only can low oxygen levels harm fish, this also encourages algae growth. The darker water also acts as a shield from predators that might be hoping to eat your fish.

When you combine colorants with aeration, you can achieve a very healthy pond, and adding colorants is a relatively simple process, you just need to make sure you wear protective gear as the concentrated dyes can stain your skin and clothing.

When one searches for “how to clean a pond,” you probably hear a lot about adding bacteria. One of the easiest ways to reduce excess nutrients is to simply add beneficial bacteria to your pond. The bacteria will eat away at the green organic material and sludge, improving water quality and clarity.

Often adding biodegradable bacteria packs once per month is all you have to do to keep the water clean and healthy. Beneficial bacteria combined with an aeration system can make pond maintenance extremely easy. In some cases, especially in areas prone to temperature spikes or very high summer temperatures, you may need to treat monthly and add a supplement to maintain a clean pond.

To add the beneficial bacteria, you just calculate the approximate number of gallons in your pond and add the appropriate amount of biodegradable bacteria packs. You cannot over-treat the water, but you can undertreat, so if you add a little more product that you absolutely need, this will not harm the water. Be sure to read the package directions carefully, and select products that are veterinarian-approved and safe for fish, wildlife, livestock and humans.

In general, that’s how to clean a pond. Preventative steps such as aeration, adding bacteria and some basic maintenance should keep your pond water healthy for your fish although certain circumstances might necessitate additional treatment or steps. At Healthy Ponds, we have an assortment of products that can help with pond maintenance, and if you are sure which products are the best fit for your pond, you can give us a call, email us or contact us via live chat.

8613371530291

8613371530291