pressure transmitters for mud pump factory

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Viatran has been designing and manufacturing pressure sensing instruments for the Oil & Gas Industry for over 50 years, we are intimately familiar with the demanding performance, reliability and adaptability requirements for drilling, secondary recovery, offshore and land-based production.

Viatran"s Hammer Union Pressure Transmitters offer superior construction and the rugged performance that we have built our reputation on. Our new generation of Hammer Union Pressure Transmitters incorporate more user-friendly features and optional add-on features than ever before.

Potential applications include Drilling, Acidizing, Choke Manifolds, Extraction, Fracturing and Cementing, Mud Pumps, New Well development, Nitrogen Injection, Service and Cement Trucks, Standpipe, Stimulation and Well head measurement.

Want to get a great deal on wholesale wholesale mud pressure sensor online? The good news is that you have landed on the right marketplace. Browse through a wide range of pressure sensors including oil pressure senders, pressure transducers, pressure differentials, wireless pressure sensors, digital hydraulic pressure gauges, differential pressure sensors, and many more on Alibaba.com. Our comprehensive collection gives you the freedom to find the ideal product that matches your requirements. In addition to quality products, you"ll also enjoy discounts when buying differential pressure sensors during our numerous promotional campaigns. Finally, consider filtering the items with features such as complimentary shipping and returns, so you get the full value of your time spent shopping online!

Are you looking for customized wholesale mud pressure sensor? Besides the fact that our piezoresistive sensors and digital pressure sensors offer customizability, Alibaba.com offers a wide range of wholesale pressure sensors at your convenience. Pressure sensors are aimed at measuring the temperature and convert the pressure into a Voltage (V) signal. This voltage output is generally buffered to meet the demands of industry standardized outputs. Additionally, they can supply soft millivolt (mV) releases that feature greater overall frequency response and reduced energy usage, and higher susceptibility to electrical noise thus, being ideal for any applications. Browse through our collection of pressure measuring devices, and let yourself be spoiled by our international wholesalers" deals. Start your search with confidence here on Alibaba.com.

The field adjustable Model 470 WECO® Hammer Union Pressure Transmitter from GP:50 is ruggedly designed and engineered to effectively address demanding shock and vibration and installation challenges within the oilfield environment. Units are directly compatible with WECO® 2”-1502, 2202, 2002 or 602 wing union fittings. The field adjustment option provides for zero and span adjustments as well as rangeability. This field adjustable option eliminates the need to rescale your panel meter when replacing transmitters and allows for fewer pressure ranges to stock. Learn More

The Model 136/236/336-AI/AF from GP:50 is a family of highly accurate, digitally compensated differential pressure transducers. Model 136/236/336-AI/AF measures differential pressure ranges as low as 20” WCD and line pressures up to 1000 PSID (69 BAR) in a compact size. Customers may also choose from among multiple accuracy, digital output, process and electrical connections. Please consult the factory for details. Learn More

The Model 136/236/336-AI/AF from GP:50 is a family of highly accurate, digitally compensated differential pressure transducers. Model 136/236/336-AI/AF measures differential pressure ranges as low as 20” WCD and line pressures up to 1000 PSID (69 BAR) in a compact size. Customers may also choose from among multiple accuracy, digital output, process and electrical connections. Please consult the factory for details. Learn More

Model 7100 flight-heritage, low level pressure transducer from GP:50 is designed to provide high-accuracy measurements of up to ±0.1% FSO. Its flight heritage, spanning 25 years, makes it ideal for use within demanding aerospace and defense applications, including those in which higher shock and vibration levels may be present. Its compact and lightweight design facilitates ease of installation within space constrained environments. Learn More

The Model 7202 is one of the smallest and light weight aerospace designs GP:50 offers. It provides very high accuracy and improved thermal performance. The 7202 will withstand some of the most severe aerospace or military applications, including higher shock and vibration environments. Learn More

The industry exclusive Model 170/270/370 WECO® Hammer Union Pressure Transmitter from GP:50 is ruggedly designed and engineered to effectively address demanding shock and vibration and installation challenges within the oilfield environment. Units are directly compatible with WECO® 2”-1502, 2202, 2002 or 602 wing union fittings. They are also available in multiple outputs, ranges, electrical connections, and area approvals to meet specific requirements. Buy OnlineLearn More

The Model 8200 series from GP:50 is a flight heritage, high level pressure transducer. Digitally corrected to provide high-accuracy pressure measurements with a proprietary sensor design for added zero stability for commercial aviation, military, aerospace, UAV, satellite, and defense

automation, test stand, and OEM applications. Its rugged stainless steel design offers high corrosion resistance in pressure ranges from 0-25” WC (69 Mbar) to 30K PSI (2068 bar). Learn More

Model 241/341 from GP:50 is our most accurate pressure transducer. Designed specifically for aerospace and automotive test stand applications, it is 5x tighter through temperature than standard industrial transmitters with a 0.20% FSO / 100 °F thermal stability. More than 25 years of field expertise went into the design of our pressure transducer for exceptional reliability. The compact, corrosion-resistant, all-welded stainless steel design of the Model 241/341 offers ease of installation within space constrained environments. Static accuracy is available to ±0.05% FSO, with a total thermal error of 0.25% FSO over the compensated temperature range. Learn More

Model 241/341 from GP:50 is our most accurate pressure transducer. Designed specifically for aerospace and automotive test stand applications, it is 5x tighter through temperature than standard industrial transmitters with a 0.20% FSO / 100 °F thermal stability. More than 25 years of field expertise went into the design of our pressure transducer for exceptional reliability. The compact, corrosion-resistant, all-welded stainless steel design of the Model 241/341 offers ease of installation within space constrained environments. Static accuracy is available to ±0.05% FSO, with a total thermal error of 0.25% FSO over the compensated temperature range. Learn More

Model 40 Series from GP:50 incorporates over 25 years of oil field proven design in a 1” diameter package. The 40 Series provides a rugged solution for hazardous approved areas, especially where space constraints are a concern. Its all-welded stainless steel design will provide years of reliable service in some of the harshest environments. Learn More

The Model 136/236/336 from GP:50 is a family of highly accurate, digitally compensated differential pressure transducers. Model 136/236/336 measures differential pressure ranges as low as 20” WCD and line pressures up to 1000 PSID (69 BAR) in a compact size. Customers may also choose from among multiple accuracy, digital output, process and electrical connections. Please consult the factory for details. Learn More

Model 536 CAN Bus from GP:50 is a compact, high-accuracy, digital output differential pressure transducer. This Model measures differential pressure ranges as low as 0-20” WCD (50 mbar) and line pressures up to 1000 PSID (69 BAR) in a compact size with improved thermal performance to meet the demands of the automotive, medical and laboratory test markets. The CAN Open protocol allows for multiple devices on a single bus, reducing installation time and cost. Learn More

Model 536 CAN bus from GP:50 is a compact, high-accuracy, digital output differential pressure transducer. This Model measures differential pressure ranges as low as 0-20” WCD (50 mbar) and line pressures up to 1000 PSID (69 BAR) in a compact size with improved thermal performance to meet the demands of the automotive, medical and laboratory test markets. The CAN open protocol allows for multiple devices on a single bus, reducing installation time and cost. Learn More

The Model 1002/1003 OEM Industrial Grade Pressure Transmitter from GP:50 is a family of lower cost, industrial grade OEM pressure transducers, featuring corrosion-resistant, all stainless steel wetted parts and housings. Series transducers are ideal for higher volume pressure monitoring applications, particularly where lower costs are required, yet where the need for precision measurement accuracy remains. Units are available with choice of 4-20 mA, 0 to 5 Vdc or 0 to 10 Vdc output, as well as various electrical connection and pressure port options. Typical

costs are required, yet where the need for precision measurement accuracy remains. Units are available with choice of 4-20 mA, 0 to 5 Vdc or 0 to 10 Vdc output, as well as various electrical connection and pressure port options. Typical applications for the Model 1002/1003-CA include off-road vehicle, HVAC/R, hydraulic and pneumatic control systems, pumps and compressors, and industrial engine pressure monitoring. Learn More

The Model 111/211/311 from GP:50 is a family of industrial grade pressure transducers. These strain gauge-based sensors are expressly designed to withstand the shock, vibration and pressure spikes common to most hydraulic and pneumatic control systems.

The highly rugged, all-welded stainless steel design of the Model 111/211/311 offers high corrosion resistance, making the sensors an ideal choice for demanding oil & gas, steelworks, rolling mills and process control applications. Units are further available with optional 10X proof pressure for extended worry-free service life within challenging environments. Learn More

The Model 216/316 from GP:50 is a family of low range, high line, differential pressure transducers. Their compact design incorporates GP:50’s own digital correction circuit technology, for high accuracy and extended service life across a variety of applications.

GP:50 model 540 CAN Bus digital output pressure transducer provides high resolution, accuracy, and improved thermal performance to meet the demands of the automotive, medical and laboratory test markets. The CAN Open protocol allows for multiple devices on a single bus reducing installation time and cost. Learn More

The Model 541 series is our most accurate CAN based pressure transducer. Designed specifically for test stand applications, the CAN Bus protocol provides high resolution, reduced noise and improved thermal performance. The compact, all-welded stainless steel design of the Model 541 offers ease of installation within space constrained environments. Static accuracy is available to ±0.05% FSO, with a total thermal error of 0.25% FSO over the compensated temperature range. Learn More

The Model 541 series is our most accurate CAN based pressure transducer. Designed specifically for test stand applications, the CAN Bus protocol provides high resolution, reduced noise and improved thermal performance. The compact, all-welded stainless steel design of the Model 541 offers ease of installation within space constrained environments. Static accuracy is available to ±0.05% FSO, with a total thermal error of 0.25% FSO over the compensated temperature range. Learn More

GP:50 Model 741 provides RS485 digital data transmission used in serial communication protocols standard for Industrial Control Networks and Data Acquisition Systems. High static accuracy, thermal performance and lack of EMI makes the 741 ideal for the auto and aircraft manufacturing floor. Learn More

GP:50 Model 741 provides RS485 digital data transmission used in serial communication protocols standard for Industrial Control Networks and Data acquisition systems. High static accuracy, thermal performance and lack of EMI makes the 741 ideal for the auto and aircraft manufacturing floor. Learn More

Model 188/288/388 from GP:50 is a family of all welded stainless steel miniature flush diaphragm pressure transducers. Their unique design incorporates a specialty flush process connection. This allows the transducer to effectively support higher viscosity fluid pressure measurements without port clogging or plugging. Their compact size allows for ease of installation within space constrained environments. Learn More

Model 188/288/388 from GP:50 is a family of all welded stainless steel miniature flush diaphragm pressure transducers. Their unique design incorporates a specialty flush process connection. This allows the transducer to effectively support higher viscosity fluid pressure measurements without port clogging or plugging. Their compact size allows for ease of installation within space constrained environments. Learn More

The Model 340T temperature transducer is essential where reliable and accurate process temperatures are required. With a large range of temperature ranges and probe lengths available, the Model 340T is adaptable for most temperature applications or processes. The compact size provides easy installation for on-board vehicles used in the oil and gas industry. Learn More

The Model 340T/AI/AF/AN Hazardous Location Temperature Transmitter is essential where reliable and accurate process temperatures are required. With a large range of temperature ranges and probe lengths available the Model 340T/AI/AF/AN is adaptable for most temperature applications or processes. The compact size provides easy installation for on-board vehicles used in the oil and gas industry. Learn More

The Model 1003T economical temperature transmitter series from GP:50 offers the most common industrycalibrated temperature ranges, process ports, and electrical connection. The 1003T Series provides for better lead times and lower unit cost while delivering a reliable, accurate, temperature measurement. Learn More

The Model 243AI/AN / 343AI/AN Series from GP:50 is an all-stainless steel, dual pressure and temperature transducer with 4-20 mA and 0-5 V output. Its compact design reduces I/O and insertion points where size and weight are considerations. Units are available in a variety of pressure and temperature ranges. Learn More

Developed from 20+ years of aerospace experience, the 42 Series was designed with aerospace criteria for industrial applications. The compact all-welded construction offers higher accuracies and a broad thermally compensated range. The 42 Series has all the performance and durability of an aerospace grade unit, but with industrial grade pricing. Learn More

GP:50’s Model 540-IM Series offers CAN Bus protocol in a flush faced sensor design. GP:50’s CAN Bus protocol provides high resolution, reduced noise and improved thermal performance. The flush Inconel diaphragm provides maximum corrosion resistance and limits plugging associated with viscous media. Learn More

GP:50’s model 540-IM series offers CANbus protocol in a flush faced sensor design. GP:50’s CANbus protocol provides high resolution, reduced noise and improved thermal performance. The flush Inconel diaphragm provides maximum corrosion resistance and limits plugging associated with viscous media. Learn More

The Spike Series from GP:50 is a family of pressure transducers, specifically designed to withstand high-amplitude, high-frequency spikes that commonly occur in hydraulic pressure sensing applications. A proprietary sensor design provides increased over pressure protection as high as 10x. Learn More

eliminating the need for recessed tee’s or dead ended process connections. This design removes the possibility of trapped media or contamination and allows for a clean out-of-place (COP) device, providing for a sanitary, in-line solution. Learn More

eliminating the need for recessed tee’s or dead ended process connections. This design removes the possibility of trapped media or contamination and allows for a clean out-of-place (COP) device, providing for a sanitary, in-line solution. Learn More

Models 280/380 & 283/383 from GP:50 are a family of food and beverage grade tri-clamp process connection pressure transmitters. Their rugged design also meets 3A sanitary standards for dairy applications. Tri-clamp fitting sizes as small as 3/4” are available to provide reduced surface area exposure. The Model 383 is also available with optional high-temperature

compensation to +400 °F (+204 °C). Standard models feature all 316L stainless steel construction. Optional Inconel or Hastelloy wetted parts may be substituted for improved corrosion resistance. An optional vented quick disconnect cable provides a barometric reference on lower ranges while providing a NEMA 4X rating. Learn More

Models 280/380 & 283/383 from GP:50 are a family of food and beverage grade tri-clamp process connection pressure transmitters. Their rugged design also meets 3A sanitary standards for dairy applications. Tri-clamp fitting sizes as small as 3/4” are available to provide reduced surface area exposure. The Model 383 is also available with optional high-temperature

compensation to +400 °F (+204 °C). Standard models feature all 316L stainless steel construction. Optional Inconel or Hastelloy wetted parts may be substituted for improved corrosion resistance. An optional vented quick disconnect cable provides a barometric reference on lower ranges while providing a NEMA 4X rating. Learn More

The Model 250/350 AI/AN from GP:50 is a flow-thru pressure transmitter with a unique one-piece design. This flow-thru design provides a zero internal dead volume eliminating the need for piping tees or dead ended process connections. This design removes the possibility of trapped media or contamination and allows for a Clean In Place (CIP) device, providing for a sanitary, in-line solution for the pharmaceutical market especially rated for high pressure homogenization systems. Learn More

The Model 250/350 AI/AN from GP:50 is a flow-thru pressure transmitter with a unique one-piece design. This flow-thru design provides a zero internal dead volume eliminating the need for piping tees or dead ended process connections. This design removes the possibility of trapped media or contamination and allows for a Clean In Place (CIP) device, providing for a sanitary, in-line solution for the pharmaceutical market especially rated for high pressure homogenization systems. Learn More

The Model 311-IM from GP:50 is a flush mounted, hazardous location approved pressure transducer, designed to provide added reliability within slurry or thick process media applications. Their rugged, all-welded flush mounted design facilitates accurate measurements of corrosive or higher viscosity media, in applications where non-flush port sensors are otherwise

provides protection from water ingress and is designed for the extremes associated with food and beverage processing. An optional high temperature version provides reliable operation in CIP processes to

provides protection from water ingress and is designed for the extremes associated with food and beverage processing. An optional high temperature version provides reliable operation in CIP processes to

The GP:50 Model 210/310 series provides a high accuracy, low pressure sensor with high proof pressure. With ranges as low as 0 to 5” WC the standard unit provides proof pressures to 500 PSI with an optional ±0.05% FSO static accuracy. Learn More

The Model 313L from GP:50 is a line of highly accurate and reliable submersible level transmitters. The corrosion-resistant 316L stainless steel construction, and an integrated hydrophobic breather vent help provide years of maintenance free service. Learn More

The Model 313L from GP:50 is a line of highly accurate and reliable submersible level transmitters. The corrosion-resistant 316L stainless steel construction, and an integrated hydrophobic breather vent help provide years of maintenance-free service. Learn More

Model 313L-NI utilizes an all-titanium design to provide long term stability and continued performance under the harshest conditions, including corrosive and hazardous chemical applications. The slim design and high media resistance perform exceptionally well in downhole applications that often have tight space constraints and caustic environmental conditions. Learn More

Model 313L-NI utilizes an all-titanium design to provide long term stability and continued performance under the harshest conditions, including corrosive and hazardous chemical applications. The slim design and high media resistance perform exceptionally well in down-hole applications that often have tight space constraints and caustic environmental conditions. Learn More

installation space. All GP:50 submersible level transmitters are built with a rugged leak-proof stainless steel construction, lightning surge protection and an integrated hydrophobic filter to provide accurate level measurement with years of corrosion free service for all types of level applications. Learn More

limited installation space. All GP:50 submersible level transmitters are built with a rugged leak-proof stainless steel construction, lightning surge protection and an integrated hydrophobic filter to provide accurate level measurement with years of corrosion free service for all types of level applications. Learn More

Model 413 from GP:50 is a line of field rangeable, highly accurate and reliable submersible level transmitters. The field adjustment option provides for zero and span adjustments as well as rangeability, eliminates the need to rescale your panel meter when replacing transmitters, and

allows for fewer units to stock due to rangeability options. Their corrosion-resistant 316L stainless steel construction and an integrated hydrophobic

Model 413 from GP:50 is a line of field rangeable, highly accurate and reliable submersible level transmitters. The field adjustment option provides for zero and span adjustments as well as rangeability, eliminates the need to rescale your panel meter when replacing transmitters, and

The Model 1112/1113 from GP:50 is a family of submersible level transmitters, designed to provide high-accuracy measurements at a competitive price point. They are offered with an all stainless steel sensor

The Model 411-M351 from GP:50 is a submersible lift station and sludge level transmitter with field adjustability. It’s all stainless-steel design incorporates a 3-inch diameter clog-resistant sensing diaphragm and corrosion resistant protective baffle plate. These features facilitate high accuracy level measurements, even in heavy sludge conditions. The field adjustment option provides for zero and span adjustments as well as rangeability. This field adjustable option eliminates need to rescale your panel meter when replacing transmitters and allows for fewer units to stock due to rangeability options. This combination of durability and accuracy, coupled with over 25 years of proven field service have helped make the GP:50 Model 411-M351 an industry gold standard for water and wastewater

accuracy over its standard ranges of 500 to 20K PSID (35 to 1,379 BAR D). Improved accuracy is available to +0.20%. Their rugged, compact design incorporates a unique, non-filled strain gauge sensing technology. These attributes allow the Model 114/214/314 to effectively support high-cycle pressure measurement requirements, even in space constrained environments. An all stainless steel construction, without seals or o-rings, provides high-corrosion resistance. Optional intrinsically safe versions are also available for extreme applications. Learn More

compact, proprietary sensor design provides added zero stability required for commercial aviation, military, aerospace, UAV, satellite, and defense applications. Learn More

The Model 8300 series from GP:50 is a flight heritage, differential pressure transducer, providing high reliability with high accuracy. The compact, proprietary sensor design provides years of reliable measurement required for commercial aviation, military, aerospace, UAV, satellite, and defense applications. Learn More

demanding aerospace environments. Its flight heritage, spanning 25 years, makes it ideal for use within demanding aerospace and defense applications, including those in which higher shock and vibration levels may be present.

GP:50’s 7800 series temperature transducer provides reliable temperature measurement from -100 °F to +500 °F (-73 °C to +260 °C) while withstanding the harsh conditions associated with space exploration. The compact size and rugged design are an excellent choice for on-board space

Model 7900 series is a light weight flow-thru pressure transmitter designed for flight propulsion systems. The flow thru design is engineered to measure up to 0.1% of full scale pressure flow across the sensor and will stand up to the rigorous conditions associated with propulsion applications. Learn More

-320°F (-196 °C) within a rugged, all-stainless steel package. Remotely mounted electronics provide a high-level signal output of either 4-20 mA; 0 to 5 Vdc; or 0 to 10 Vdc, as well as choice of RS232 or RS485 for improved cryogenic measurement accuracy and higher resolution. Stainless steel

GP:50’s 7790 High Temperature series transducer provides pressure and temperature measurement up to +350 °F (+177 °C). The remote electronics provides a high level output of 4-20 mA or 0 to 5 Vdc while reducing the overall footprint by integrating pressure and temperature measurement in one device. Learn More

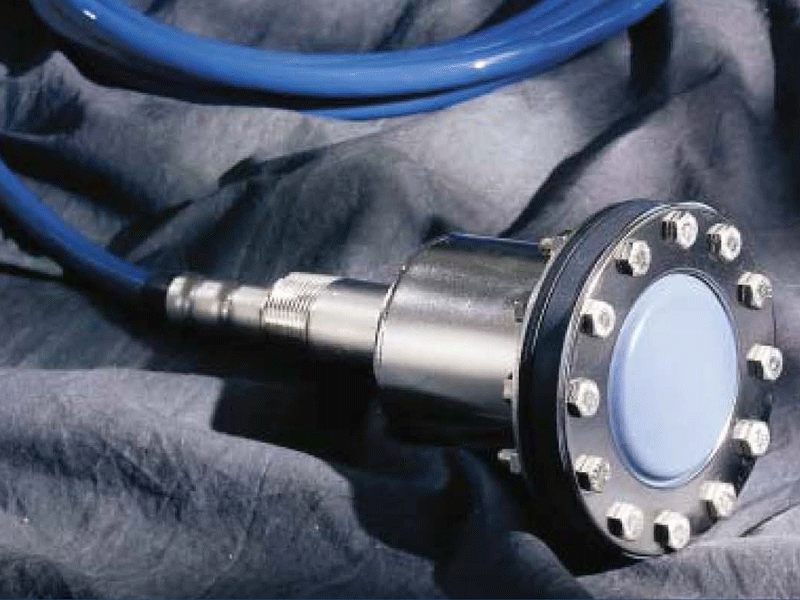

The Model 7500 from GP:50 is a rugged, sub-sea rated pressure transducer, tested to 30,000 FT sea water. The highly corrosion resistant design meets the tough environmental challenges of offshore oil and gas, Naval and

The 7500-M254 from GP:50 is a subsea pressure transducer, designed for use within remote or unmanned vehicles. Its open reference provides for sea depth pressure. When used in a non-conductive fluid bladder, the transducer also provides a gauge process pressure. In addition to ROV applications, the compact size and sea rated construction of the 7500-M254 make it ideal for the effective monitoring of subsea oilfield wellhead control systems. Learn More

Model 7500-M254 from GP:50 is a subsea pressure transducer, designed for use within remote or unmanned vehicles. Its open reference provides for sea depth pressure. When used in a non-conductive fluid bladder, the transducer also provides a gauge process pressure. In addition to ROV applications, the compact size and sea rated construction of the 7500-M254 make it ideal for the effective monitoring of subsea oilfield wellhead control systems. Learn More

The Model 7540 from GP:50 is a highly rugged differential pressure transducer, designed to address the tough environmental challenges of subsea and other marine service environments. It is designed for applications in which higher shock and vibration levels may be present providing high-reliability within extreme environments. Learn More

The Model 7540 from GP:50 is a highly rugged differential pressure transducer, designed to withstand the tough environmental challenges of subsea and other marine service environments. It is designed for applications in which higher shock and vibration levels may be present providing high-reliability within extreme environments. Learn More

The 7540-9000 Series from GP:50 is a high-accuracy subsea rated pressure transmitter with sea depth sensing reference offering more than 15 years of fieldproven pedigree. This Series features an API flanged process connection with Inconel inlay and all stainless steel housing with full seawater compatibility to 30K (9,144 M). The sea depth reference port provides either a differential output between the process pressure and sea depth, or a dual output between the process pressure and sea depth. A temperature output is also available. Learn More

5,000 PSI. Differential ranges as low as 0-2.5” WCD and a 500 PSI proof pressure are standard on all ranges. A custom subsea rated design allows operation to 23,000 FT SW. Learn More

The Model 7400 from GP:50 is a high-line, high-pressure, aerospace grade differential pressure transducer. Its true wet-wet all stainless steel design allows it to effectively measure both corrosive fluid and industrial gas pressures to high degrees of accuracy and repeatability.

Its optional 10X proof pressure and 10K PSI (689 BAR) line rating also facilitates its use within demanding aircraft engine and hydraulic systems. In addition to expanded ranges, a variety of pressure ports, electrical connections, outputs, and wetted part materials are available. Please consult the factory

The Model 543 Series from GP:50 is an all-stainless steel, dual pressure and temperature CAN Bus output transmitter. Its compact design reduces I/O and insertion points where size and weight are considerations. Units are available in a variety of pressure and temperature ranges, with support for both CAN Bus J1939 and CAN Open protocols. Learn More

GP:50’s Model 370-QX series is designed for High Pressure High Temperature (HPHT) well applications. This series is designed to fit the standard WECO® 2”- 1502 or 2”- 2002/2202 unions and operates at

a continuous process temperature to +350 °F (+177 °C). It offers reliable service in high shock and vibration applications such as cementing, fracturing and drilling mud pressure measurement. Learn More

Model 112/212/312 from GP:50 is an ultra high-pressure transducer, offered in a single piece sensor design with no welds or seals. All stainless steel construction and industry standard highpressure coned process connections are available in both English and Metric sizes. Learn More

The Model 375 Series from GP:50 is an API flanged pressure transmitter, offering over 10 years of fieldproven pedigree. This Series features a robust design with all stainless steel housing and optional Inconel wetted parts. The compact design provides a highly reliable and accurate transmitter that provides years of trouble-free use. There is an optional redundant sensor

design that provides backup in case of primary sensor failures. Optional HART communication protocol is available for field adjustment options. Learn More

The Model 7500-9000 Series from GP:50 is a high accuracy pressure and temperature transmitter, offering more than 15 years of field-proven pedigree within subsea wellhead applications. The Series features a robust design with all stainless steel housings and wetted parts, full seawater submersibility to 30K ft (9,144 M) and an API flanged process connection. An optional redundant sensor provides backup pressure and temperature outputs, in the case of prime element failures or cabling issues. Optional HART communication protocols are available for remote measurements. Learn More

The Model 7500-9100 Series from GP:50 is an API flanged, subsea pressure transmitter with over 20 years of field heritage. This Series features pressure ranges up to 20K PSI, seawater rating to 30K ft (9,144 M) and

optional HART protocol allowing for field configuration. A removable sensor assembly option allows for field repairs as well as redundant sensors that provide field backup in case of a primary sensor failure. Learn More

The 7501-9000 Series from GP:50 is a high-accuracy subsea rated pressure transmitter offering more than 15 years of field-proven pedigree. This Series features an API flanged process connection with Inconel inlay and all stainless steel housing with full seawater compatibility to 30K ft (9,144 M). Pressure ranges available from 0-500 through 0-30,000 psi with 4-20mA output or optional digital protocols. Learn More

The Model 411, 411X/P from GP:50 is a SMART rangeable pressure transmitter incorporating a 4-20 mA output with digital HART protocol. Units are offered with both CSA and FM approval options, as well as a

variety of process and electrical connections. Improved accuracy provides for a stable measurement throughout the total compensated temperature range. Learn More

The Model 913 from GP:50 is a high-accuracy submersible level transmitter. It features an asynchronous serial communication output (SDI-12-v 1.3), typically used to monitor environmental data. This also allows for communication with compatible data loggers or data acquisition

systems. The incorporation of a hydrophobic breather vent ensures extended trouble-free service within demanding applications. These features, combined with the low power requirements of the Model 913, make it particularly ideal for remote well monitoring applications. Learn More

The Model 913 from GP:50 is a high-accuracy submersible level transmitter. It features an asynchronous serial communication output (SDI-12-v 1.3), typically used to monitor environmental data. This also allows for communication with compatible data loggers or data acquisition

systems. The incorporation of a hydrophobic breather vent ensures extended trouble-free service within demanding applications. These features, combined with the low power requirements of the Model 913, make it particularly ideal for remote well monitoring applications. Learn More

The Model 1171 Series from GP:50 is a rugged, hermetically sealed pressure transmitter which features magnetic coupling adjusts for full field calibration with 5:1 turndown ratio. Their compact, corrosion-resistant,

The Model 40-IM Series from GP:50 is a flush face mounted industrial pressure transmitter. It is expressly designed for higher viscosity media, particularly where such media can otherwise clog or damage traditional

non-flush port sensor designs. The rugged, all-welded, Inconel design of the 40-IM series allows for greater compatibility with corrosive media. No zero offset is caused during sensor installation. Buy OnlineLearn More

The Model 40-IM series from GP:50 is a flush face mounted industrial pressure transmitter. It is expressly designed for higher viscosity media, particularly where such media can otherwise clog or damage traditional

non-flush port sensor designs. The rugged, all-welded, Inconel design of the 40-IM series allows for greater compatibility with corrosive media. No zero offset is caused during sensor installation. Buy OnlineLearn More

The Model BCH2000 Cable Hanger from GP:50 is designed to eliminate unnecessary stresses on the transmitter while installed in the application. Affordably priced, the BCH2000 Cable Hanger is designed for easy installation within a variety of environments. Learn More

Our Engineering team continues to lead the industry with innovative pressure and temperature measurement options including USB, and SDI-12 transmitters as well other well-established digital protocols such as CAN bus and HART. These digital protocols can be provided on most of our current line of analog output pressure and temperature transducers. Learn More

The Model BD300 digital indicator from GP:50 offers multi-pump alternation control. Universal 85-265 VAC, or 12/24 VDC Input Power Models. Large Dual-Line 6-Digit Display, 0.60″ & 0.46″ Learn More

Blue Ribbon is an Affiliate of GP50 and offers pressure gauges suited for water treatment applications. Whether for line pressure or our Poly-isolated version for caustic or alkaline media. Blue Ribbon has a gauge for your application.Learn More

Designed for direct pipe mount via its flush process pipe connection the Model 340 series can handle the pressure and harsh media found on Frac blender trucks.

The Model 340 transmitter offers a compact, all welded, rugged design with a flush faced sensor that resists clogging found with conventional pipe mounted transmitters. With at least 5 times proof pressure, and a machined stainless steel sensing diaphragm, it can withstand erosion from aggregate and survive high pressure spikes typically found in blender applications.

With a proprietary sensor design there is zero installation offset, typically found with flush NPT process devices. Available in 4-20mA, 0-5 VDC or Canbus J1939 outputs and pressure ranges from 0-75 thru 0-1,000 PSI.

Hydraulic data transmission requires sensitive pressure sensors capable of enduring high pressures. This is particularly true when used in measurement while drilling (MWD) applications.

MWD has become a standard application, especially for offshore directional drilling. Real-time data collection is essential for measuring the trajectory of the hole as it is drilled. For this purpose, various sensors are mounted on the drill head to provide information about the drilling environment in real time. Inclination, temperature, ultrasound and also radiation sensors are used. These various sensors are physically or digitally connected to a logic unit that converts the information into binary digits. The downhole data are transmitted to the surface via mud pulse telemetry. In addition to monitoring and controlling the drilling process, the data are used for further aspects, including:

Mud pulse telemetry is a binary coding transmission system used with liquids. This is achieved by a valve that varies the pressure of the drilling mud within the drill string and thus converts the recordings of the sensors mounted on the drill head into pressure pulses. The pulsations reach the surface via the drilling mud. The pressure pulses are measured on the surface by a pressure transmitter and converted into an electrical signal. This signal is transmitted to a computer and digitized.

STS provides offshore directional drilling companies with analog pressure transmitters optimized for mud pulse telemetry. The sensors have to meet high demands: They must be extremely sensitive in order to reliably register even the smallest pressure differences. At the same time, the sensors must withstand pressures of up to 1,000 bar. Very high pressures are required to power the drill head in very deep drill holes. The pressure transmitters used for mud pulse telemetry on the surface are also exposed to these forces.

In addition to the high sensitivity, very fast response times are required to ensure good data communication in real time. In order to exclude falsified measurement results, the measuring instrument should be low-noise. The mud pumps in particular can cause the most signal noise in drilling applications. The drive of the drill is another source of interference. For this reason, analogue sensors with a 4 – 20 mAoutput signal are the best solution for mud pulse telemetry.

Acadiana Mud Pump Pressure is committed to providing total customer satisfaction by manufacturing and delivering high-quality products and unparalleled service.

With a broad line of instrumentation products and a dedicated staff of over 30 employees, the company was proving to be very successful. In 2005, SCF Partners approached Acadiana Oilfield Instruments with a proposition to purchase the fast-growing company. SCF acquired the company, and Acadiana Oilfield Instruments became part of the Forum Oilfield Technology family, in the drilling division.

Travis stayed employed with Forum as the General Manager of the instrumentation product line working for another 9 years before departing after 2015. Shortly thereafter, he elected to start up Acadiana Oilfield Instruments.

Offering a 4 to 1 resolution for indicating the smallest pressure changes, Acadiana Oilfield Instruments’ compound pointer pressure gauge system precisely measure and indicate pump pressures for several different operations including, acidizing oil pay, down-hole cementing and high-pressure hydraulic fracturing. This gauge system is comprised of a gauge protector, a 6″ liquid filled pressure gauge, and a high-pressure hose.

Used to help expose mud pump operation complications, Acadiana Oilfield Instruments’ gauge is very versatile and can be mounted on the mud pump, in the driller’s console, or in a weight indicator box.

Product&Reapir: Crown block(TC225 TC250 TC315 TC450 TC585), Travelling block(YC225 YC250 YC315 YC350 YC450 YC450S YC585), Hook(DG225 DG250 DG315 DG350 DG450 DG585 DG675), Rotary table(ZP175 ZP205 ZP275 ZP375 ZP975AS ZP495), Swivel(SL225 SL250 SL450 SL585), Drawworks(JC20 JC30 JC40 JC50 JC70B JC90DB), Mud pump (F-500 F-800 F-1000 F-1300 F-1600 F-1600HL F-2200 F-2200HL 3NB500C,3NB1000C 3NB1300C 3NB1600 SL3NB-1000 SL3NB-1300A SL3NB-1600A),BOP(FH,FZ,Cameron,Shaffer), Control System for Surface Mounted BOP Stacks(FKQ,FKDQ),Disc brake (PS,PSZ, DBS), Bladder accumulator (NXQ), Drilling rig(ZJ40/2250DZ ZJ50/3150DZ ZJ70/4500DZ ZJ90/6750DZ), Workover rig (XJ40,XJ60, XJ80,XJ100,XJ12,ZJ15,ZJ20,ZJ3,XJ350, XJ450, XJ550,XJ650,XJ750), BPM Top drive((DQ120BSC, DQ90BSD, DQ90BSC, DQ80BSC, DQ70BSD, DQ70BSE, DQ70BSC, DQ50BC, DQ40BC, DQ40BSG, DQ40BCQ, DQ40YR, DQ30Y) Make: Bomco, Lanzhou LS,LSPE, SJ Petro, RG Petro, Sichuan Honghua, CPTDC, Beijing BPM, Shanghai Shenkai, Kingdream, CCDC, SJS Serva, DFXK, LS-NOV, Beijing PSK, Gold basin, Renqiu Boke,Guangdong Dongsu.(Guangshi), XBSY.,Tiehu, Rongsheng (HBRS), TSC. Replacements:Mission magnum/Halco centrifugal pump, Cameron FC gate valve,Cameron R check valve, Demco mud valveE( 3K&5K ), Demco butterfly valve,BJ varco handling tools (SDXL, SDML, SDS,DCS,SSC,SSD,YT, HYC, LYT, MP,MYT, MG, RGG, HGG, MGG, TA, SJ), MI SWACO / Mongoose / Derrick / /Brandt / King cobra shale shaker screen (FLC2000,FLC503,Derrick 626), M/D & OTECO Gauge(Type F,Type D,Model 6,Model 7,Model 8), Twin disc,WPT, Eaton clutch & friction disc, National (10-P-130,12-P-160 ,14-P-220 ,8-P-80 ,9-P-100), Gardner denver (PZ-7,PZ-8,PZ-9,PZ-10,PZ-11), EMSCO FB1600.International Brand: Moog, CCS, ATOS, Rexroth, Eaton, Flowrox, Italvibras, Martin, Norgren, Parker, Siemens, Vickers, 3M.Standard:API Spec 4F, API Spec 6A,API Spec 6D,API Spec 600, API Spec 7K, API Spec 8A, API Spec 8C,API Spec 16A, API Spec 16C, API Spec 16D

Universal Flow Monitors, Inc was incorporated in 1963. It is a closely held company owned and run by Erik and Lars Rosaen. This family owned business started out making variable area flow switches for the automotive market. They were used largely for lubrication flow, cooling water and paint and this remains true today.

Over the years, Universal has added flow indication and flow transmitters to the basic design platform. We have also added the Insite® and FlowStream® product lines. Insite® is a plastic see through flow indicator used for water , de-ionized water and dilute chemicals used in waste water treatment. The FlowStream® product uses a different technology to measure the mass flow of clean gasses where fast response and survivability are key.

Putting it all together, Universal and Norco (renamed Rocon) make flowmeters and controls for fluids used in high production. The products are characterized by a simple and robust design backed up by high customer service and dedication to quality.

The MPRx utilizes XXT’s best-in-class decoding algorithms to receive and decode the telemetry pulses received from the standpipe’s pressure transmitter. The decoded mud pulse telemetry is then presented to the DRT for use by the surface equipment. Robust hardware, filtering, and embedded firmware is used to remove mud pump and other undesirable noise, allowing the XXT downhole sensors to transmit data at maximum bit rates.

CROSS-REFERENCE TO RELATED APPLICATIONS This application claims priority to Provisional U.S. Application Ser. No. 61/679,748, titled "Differential Pressure (DP/DT) Mud Pulse Telemetry While Pumping" and filed August 05, 2012 by Victor J. Stolpman, which is hereby incorporated herein by reference.

In most drilling operations, a circulation pump circulates fluid through a drill string and out the drill bit into a borehole. This fluid (often called "mud" in the oilfield industry) may include water and/or oil and additional additives that may be inert or chemically reactive with other molecular compositions present within a borehole during drilling operations. There are a multitude of motivations for pumping mud with one example being simply to remove earth materials from the borehole.

In Mud Pulse Telemetry (MPT), a measurement-while-drilling (MWD) service company (e.g. Halliburton"s Sperry Drilling) may install at least one transducer/sensor within the surface rig"s plumbing system. The surface rig"s plumbing system mechanically connects the circulation pump(s) (also known as "mud pumps") with the drill string, which in turns couples with a drill-bit within the borehole. MPT systems employ downhole "pulser" located near the drill bit to transmit a series of modulated pressure waves through the mud column within a drill string to communicate real-time information to the surface transducers/sensors. However, the surface transducers may be unable to acquire the encoded pulse waveforms due to various forms of attenuation and interference. For example, the circulation pump hinders the operation of the MPT system through the introduction of pump noise. One attempted solution employs pump dampeners (sometimes called "de-surgers") to buffer the fluid itself,

Accordingly, there are disclosed in the drawings and detailed description specific embodiments of methods and systems that provide effective pump noise removal, thereby enabling differential pressure mud pulse telemetry while drilling. In the drawings:

It should be understood, however, that the specific embodiments given in the drawings and detailed description do not limit the disclosure. On the contrary, they provide the foundation for one of ordinary skill to discern the alternative forms, equivalents, and modifications that are encompassed in the scope of the appended claims.

The following description relates to a variety of mud pulse telemetry (MPT) method, apparatus and system embodiments that enable Measurement While Drilling (MWD) services with real-time data transfer from sensors in a bottomhole assembly (BHA) to a surface location. This disclosure does focus on the receiver side configurations, but this does not imply that this disclosure is limited to surface systems. One skilled in the art will recognize that non-surface system embodiments are readily derivable from the ensuing description.

Fig. 1 depicts an illustrative Mud Pulse Telemetry (MPT) apparatus embodiment and system embodiment in use at a typical drilling installation while operating a Measurement While Drilling (MWD) service. As illustrated, the typical drilling installation includes a drilling derrick 102 at the surface of the well. The derrick may be transportable and temporarily erected on location. The drilling derrick 102 supports the drill string 104 and BHA 106 via a hoist 108 and swivel 110. In the Fig.1 example, the BHA 106 includes a pulser 112, a tool sensor 114, and a drill bit 116. The BHA may further include additional MWD tools, stabilizers, and/or drill collars or heavyweight drill pipe (HWDP) to stiffen the BHA and add additional weight to aid with keeping the drill bit "on-bottom".

The hoist 108 lowers drill string 104 through the rotary table 118 into the casing 120 and beyond into the open borehole 122 until the bit 116 reaches the bottom. The rotary table 118 turns the drill string 104 and bit 116 to extend the borehole through earth formations. If desired, a downhole mud motor can be employed to rotate the bit at a different rate than the drill string.

Circulation pumps 124 take drilling fluid ("mud") from a retention pit 125 and circulate it through a feed pipe 126 to swivel 110 where it flows downward through the drill string interior as indicated by arrow 128. Once the fluid reaches the bit 116, it exits through ports near the cutting elements to entrain and transport rock cuttings upward along the

annulus as indicated by arrow 130. The fluid transports the cuttings into the retention pit 125 via return pipe 132. As the drilling mud circulates through the drill bit, the drilling fluids function additionally as a bit coolant and lubrication extending the lifespan of the bit. Ideally, the weight and hydraulic pressure of the drilling fluid flow balances with the formation pressure to minimize fluid loss to the formation while still preventing an uncontrolled release of formation gases and fluids into the borehole, i.e. a "blowout."

Pumps 124 are normally piston-based, causing a significant degree of pressure variation due to the action of the pistons and valves. A pulsation dampener 134 is positioned along the feed pipe 126 to attenuate the (relatively) high-frequency variation, typically with only a moderate degree of success. Downstream of the pulsation dampener, Fig. 1 shows multiple transducers 136 that respond to pressure variation of fluid in the feed pipe 126. The transducers 136 can be directly coupled to the fluid to physically respond to pressure variations, or coupled to a tubular housing the fluid flow to measure dimensional changes resulting from pressure variation in the flow stream. The transducer provides a measurable reference signal (e.g. voltage, current, phase, position, etc.) sensitive to the temporal derivative of pressure, i.e. dP(t)/dt, with a response that is proportional to within an understood distortion (e.g., scalar gain, constant phase shift, time-shift, finite precision, etc.).

A transducer interface 138 converts the transducer response into an electrical signal suitable for digitization and processing by system 140. System 140 may be dedicated MPT receiver electronics or a general purpose computer with a data acquisition card and suitable software for processing the acquired transducer signal(s). Among other things, system 140 may include circuitry, firmware, or software that implements a pump noise filter that produces a receive signal having a reduced pump noise component.

To communicate with the surface, a downhole "pulser" induces pressure fluctuations in the flow stream 128. The pressure fluctuations propagate upstream as pressure waves 142

until they reach the transducers 136. Information can be encoded into the pressure waves via modulation such as frequency modulation, phase modulation, pulse position modulation, and pulse width modulation. Other suitable modulation schemes also exist. The chosen modulation scheme preferably provides sufficient detection signal-to-noise ratio despite the attenuation, dispersion, and noise effects introduced into the flow stream 128.

As part of the BHA 106, the down-hole pulser 112 may be mechanically and/or electrically coupled with additional down-hole sensors 114 that measure, calculate and/or sense various conditions within or near the bottom of the borehole being drilled. The BHA may have an electrical power source and inter-communicating control buses that facilitate the transfer of data between BHA components. Not limited to the following, the electrical power source may be batteries and/or generator-based deriving power from the flow of fluids via turbine or like mechanism. Likewise, not limited to the following, said control bus lines may be of a metallic, conductive material for use with electrical systems and/or dielectric material when used with optical sources. Fig.1 illustrates a single downhole tool sensor coupled with a pulser, but those skilled in the art understand MWD BHA configurations may have a multitude of tools above and/or below a pulser and may utilize more than one communication media, e.g. mud pulse and electromagnetic telemetry.

A downhole controller may be included in the BHA with electronic circuitry that collects from the various sensors measured formation evaluation values such as density of rock formation, pressure of the drilling fluid, and gamma ray readings, and resistivity of rock formation. Additional measurements may include directional information such as but not limited to inclination, tool-face, azimuthal, and/or surveys. The controller may include an encoding module (e.g., in the form of circuitry or a programmable processor executing software in an associated memory device) that encodes the collected information as a data stream for transmission by the pulser 112.

The pulser 112 actuates a valve at least in part to encoding the measurement data stream as pressure modulations of the flow stream. Fig. 2A shows a first illustrative pulser implementation having a valve or variable flow restrictor formed from a circular, fan-like stator 201 having multiple fan blades/fins extending radially from a central hub, and a similarly shaped rotor 202 that can oscillate with respect to the (stationary) stator 201. In this implementation, the valve is said to be closed when the relative alignment of the stator and rotor fins maximally restricts fluid flow (by misaligning the openings between blades). It is said to be open when the relative alignment of the stator and rotor fins minimally restricts fluid flow (by aligning the openings between blades).

The valve is coupled serially within the fluid column to restrict (when closed) or ease (when open) the flow of fluid through the valve towards the drill-bit. When the valve is closed, a pressure build up occurs within the fluid on the source side creating a positive pressure change that propagates up to the surface. A subsequent opening of the valve enables the upstream pressure to drop to its previous pressure. Thus as the rotor 202 oscillates, the valve creates a periodic pressure pulsation that is amenable to frequency and phase modulation.

Fig. 2B shows a second illustrative pulser implementation having a spinning rotor 204 in place of an oscillating rotor 202. As before, the alternation between alignment and misalignment of the openings between the blades produces a periodic pressure pulsation that can be frequency and phase modulated. A spinning rotor may offer better frequency stability at the expense of a more limited modulation range.

Fig. 2C shows a third illustrative pulser implementation having a flow orifice 206 and a poppet 208 that moves relative to the orifice to restrict (when closed) and ease (when opened) the flow of fluid through the valve. A closing and re-opening of the valve (also referred to as a momentary closing of the valve) generates an upgoing pressure pulse

Fig. 2D shows a fourth illustrative pulser implementation, which is often termed a "negative pulser". This pulser configuration includes a bypass valve to vent fluid from the drill string bore into the annulus, thereby bypassing the drill bit. This venting of drilling fluid produces a pressure drop (i.e. a negative pressure change) within the drill string"s fluid column. Fig. 2D shows a valve seat and gate 210 configuration. The gate 210 moves relative to the seat to close the valve (i.e., restrict fluid flow into the annulus) and open the valve (permit fluid flow into the annulus). After closing the valve, the fluid pressure immediately rises in the drill-string column towards the steady- state pressure prior to the valve"s opening of the valve. As the name suggests, this opening and closing actuation of the valve creates a negative pulse that propagates throughout the column of drilling fluid.

In the configurations of Figs. 2C and 2D, the valve is controllable to generate individual pressure pulses that propagate to the surface, enabling the use of pulse width modulation and pulse position modulation. The modulation (whether frequency, phase, pulse position, pulse width, or some other form of modulation) is handled by the receiver after the pressure variation signals have been acquired via the transducer(s) 136.

Conventional strain gauge sensors may serve as transducers 136 to provide a measurable reference, e.g. 4-20mA current, proportional to the mechanical fluid pressure present at the coupling point, i.e. P(t), by being directly coupled to the drilling fluid flow. Alternatively, such strain gauges could be employed to measure the strains that the rig"s plumbing undergoes when a mud pulse is present and/or absent. Examples of manufacturers of said sensors include but not limited to Honeywell and Rosemount (Emerson Electric affiliated).

Alternatively, as shown in Fig. 1, transducers 136 may respond to the temporal derivative of the pressure signal at each coupling point, i.e., dP(t)/dt, or the derivative of a

commensurate strain in the plumbing that is proportional to the pressure signal derivative. For the former measurement, direct coupling of the transducer to the fluid flow can be used. For the latter, the transducer can be coupled to the surface of a tubular in the drill rig"s plumbing (e.g., feed pipe 126). In the illustrated embodiment, transducers 136 each include an optical fiber winding on the feed pipe to measure the strains via small changes in the feed pipe dimensions.

Despite the presence of pulsation dampener 134, the measurements of transducers 136 include a significant pump noise component. Accordingly, system 140 includes a pump filter that targets the cyclostationary noise generated by the pump strokes. Fig. 3 A shows an illustrative pressure variation P(t) that might be present within a feed pipe fluid flow carrying a mud pulse telemetry signal. Fig. 3B shows an illustrative pump noise component of this pressure variation. Notably, this pump noise component is the primary source of pressure variation, but it has a regular cyclostationary character that enables accurate estimation. Fig. 3C shows the difference between the illustrative pressure variation and the illustrative pump noise component. The pressure variation in this illustrative difference is primarily the mud pulse telemetry signal.

Various embodiments of a pump filter may utilize memory storage for holding estimates of "pump signatures". A pump signature estimator may extract such pump signatures from transducer measurements (including transducers responsive to the temporal derivative of pressure, dP(t)/dt ) of the drilling fluid flowing through the tubular at each location where the transducers are coupled with the rig"s plumbing. A pump stroke position monitor (e.g., a whisker switch whose state is coupled to the pump piston"s position) may be included in system 140 and used by the pump signature estimator and the pump filter module to assist with noise removal. The pump signature expectedly includes acoustic distortions of pump noise observable at the transducer locations, including channel effects such as

attenuation, dispersion, and acoustic reflections. In some embodiments, the pump filter module obtains a negated pump signature from the estimator and adds it to the receive signal. The pump signature can be stored in derivative form or regular pressure domain form. The system 140 may employ a processor to identify pump filter parameters and maintain said pump signatures. The system 140 then relies on the pump signatures to filter and remove at least a portion of the cyclostationary pump noise, thereby yielding at the pump filter"s output a filtered version of the transducer measurements.

Fig. 4 shows illustrative signals with an expanded time axis. Curve 402 is an illustrative pressure derivative dP(t)/dt signal which, when integrated over time, yields a pressure P(t) curve 404. For comparison, curve 406 is a pressure curve acquired with a strain gauge sensor. However, this disclosure contemplates measurements of any physical phenomenon that reflects the pressure fluctuations of the surface fluid flow.

Fig. 5 shows an illustrative MPT receiver having an analog integrator. Transducer interface 138 is implemented as an interferometer having a light source 502 which transmits at least one spectral frequency or wavelength to a optical splitter 504. Illustrative light source 502 types include a laser diode, a laser, and a light emitting diode. The optical splitter 504 sends light 506 and 508 in opposite directions around a loop formed from a series of optical waveguides. The illustrated loop includes a fiber optic cable 510, a reference (delay) coil, and a transducer 136 coupled to the feed pipe 126. Additional transducers 136 can be employed for redundancy and/or enhanced signal processing (including directional detection). For example, the embodiment of Fig. 1, has three transducers 136 to obtain spaced apart dP(t)/dt measurements. The transducer locations need not be limited to the feed pipe 126, but rather they can be positioned at any suitable location in the rig"s plumbing including the stand pipe, flex hose, return line, or the casing annulus.

possibly mechanically attached or adhered) around the drilling rig"s plumbing with sufficient contact such that changes in the tubular housing due to fluid pressure will change the tension within the fiber optic dielectric. The loop returns the light 514 and 518 to optical splitter 504, which provides a combined beam to light sensor 520. The overall fiber optic loop has a finite path length, say L, and includes a measurement section (i.e. portion of cable wrapped against the conduit housing) of a length less than L, say X where X< L, and delay section also of finite length, say L-X. In one embodiment, the measurement section may be 2-10 meters in length. In this example, the measurement portion is at least partially wrapped against said conduit containing pressurized fluids and encoded pulses. In some embodiments, the delay section is on the order of 500-3000 meters in length.

Given a constant pressure condition P(ti) within said conduit, the two light beams transverse the same L distance to recombine with a first relative phase φ(ίι) (i.e. a physical measurable phenomenon) at the detector. (Note that the relative phase need not be zero if the optical paths are not identical, for example, perpendicularly polarized beams may have slightly different propagation velocities. Alternatively, unidirectional couplers can be employed to create a slight path difference

8613371530291

8613371530291