preventative maintenance for mud pump factory

Everyone agrees that reactive maintenance is probably the worst pump reliability strategy. Maintaining equipment only after it breaks can mean unexpected downtime, emergencies, rush charges, overtime, and replacement of expensive parts.

The best pump reliability strategy is not either preventive or predictive maintenance, it’s a combination of the two, strategically applied. In this post, we’ll discuss the differences between predictive and preventive maintenance and when it’s best to use them.

Many operators rely heavily on “reactive” maintenance rather than preventing and planning for future repairs. As discussed in our eBook, 36 Ways to Kill Your Pump, “reactive” maintenance accounts for unplanned equipment downtime and increased costs.

Preventive and predictive maintenance programs extend the overall life of the equipment and result in fewer unplanned breakdowns. The choice is not one or the other, it’s a combination of the two.

Preventative maintenance is any variety of scheduled maintenance to a pump or other piece of equipment. Generally, it includes scheduled routine maintenance, such as equipment calibration, greasing, oil change, and analysis.

One of the biggest ways to prevent failures is to make sure your equipment is properly aligned and balanced. Misalignment and pump unbalance are the two most common reliability problems for rotating equipment. Laser alignment also fits within this category since its a service completed upon installation, setting the pump up for success.

These programs are designed to keep your maintenance costs low by preventing costly failures before they happen. If you need a preventative maintenance checklist, you can download one here.

Up to 50% of damage to rotating machinery is directly related to misalignment. Misalignment can cause increased vibration, premature seal and bearing failure, and increased power consumption. An unbalanced pump causes similar issues, such as vibration, which can be easily avoided with the right preventative maintenance measures.

Predictive maintenance services are used to monitor the condition of equipment over time. Vibration analysis, for example, measures the vibration of the equipment while it is still in service. This allows the technician to see the change in vibrations over time to predict when a problem may occur, and why.

Predictive maintenance should be part of routine maintenance for pumps and rotating equipment that absolutely can NOT go down. Operators and maintenance managers get a glimpse into the future life of the pump as it"s running today. This allows them to plan for repairs and avoid unexpected downtime.

Not all pumps are equally important in a manufacturing process, so not all pumps should receive the same maintenance plan. It wouldn’t make sense to spend time and money on vibration analysis for a pump in a non-essential application.

Before creating a maintenance plan, place the pumps into categories. This will help determine how much time and money to invest in each one. Use these categories to get started:

Regularly maintaining pumps will extend the life of your pump. When a pump is properly maintained, the parts that need replacing are usually the less expensive wear parts.

Check shaft alignment – believe it or not, shaft alignment can change! Thermal growth and machine movement due to load shifts can cause pumps to move out of alignment.

Up to 50% of damage to rotating machinery is directly related to misalignment. That’s huge. Machine vibration, bearing damage, premature seal wear, and coupling damage are all examples of issues pumps experience when misaligned.

For the most accurate alignment, we always recommend laser alignment. It’s the most accurate method available (to .0001), and once familiar, an operator can align a pump/motor very quickly. It is the most expensive method to get into if doing alignments in-house and can be difficult to learn at first. But when looking for long-term results, the laser align method is the better choice.

Precision rebuild or precision maintenance is the practice of rebuilding a pump as close to OEM specifications as possible. Attention to detail is required for precision rebuilds.

Precision rebuilds are proven to reduce failures and should be a central piece of a pump reliability strategy. If the team lacks capacity, tools, or expertise to rebuild pumps to OEM standards, look for a capable local shop.

Add taps with isolating ball valves into piping on the suction and discharge sides of the pump. Use these to mount pressure indicators to ensure the pump is performing properly.

Read the pump manual and follow each step in the procedure. The procedures therein give the best possible instruction for long and trouble-free life for the pump.

Upon start-up, record the pump performance baseline data – amps, suction pressure, discharge pressure. This is handy when troubleshooting issues, should they arise.

Vibration monitoring is a very helpful tool for predicting pump failures. Some manufacturing facilities have a vibration technician on staff to take readings on critical pumps. These technicians may read the results themselves or send them to a firm that can interpret the readings and provide a report.

Unfortunately, this is not a skill easily attained by a maintenance team. It requires expensive equipment and a great deal of training to be an effective vibration technician. Unless the facility has a large population of critical equipment, this is a service best hired out.

Arguably the most important piece of a preventative/predictive maintenance plan... The TRAINING! Training isn’t just for the maintenance team, it’s for everyone in contact with pumps, operators especially! Failure prevention is everyone’s responsibility.

The maintenance team is the keeper and protector of equipment in the facility. Train operators on the signs of failure so they can report it quickly. Show them how to properly start-up or shut down a pump and how their actions will affect other parts of the system.

If all these steps were do-able by a maintenance team alone, everyone’s reliability goals would be already met. Some of the steps we’ve laid out require specialized training, tools, or specialized training on tools to make them effective. It’s likely the team doesn’t possess all these as they’re expected to know how to fix every machine in the plant. Hire outside help where it makes sense.

Look to a preventative maintenance program and predictive maintenance measures to save on annual maintenance costs and unscheduled downtime. We recommend working with your local equipment supplier to schedule a preventative or predictive maintenance program for your pumps.

Need more information about our preventative and predictive maintenance services? We are happy to help businesses in Wisconsin and upper Michigan. Got a noisy, underperforming pump? Consider our FREE Bad Actor Pump Assessment!

Pumps are often designed to operate at a single point known as the Best Efficiency Point (BEP). As components begin to wear, a pumps performance begins to decline, with operation away from this point leading to issues such as accelerated bearing or seal wear, vibration, excess temperature rise or cavitation. Quite often declining performance can start gradually, before quickly accelerating until failure if performance issues are not addressed in a timely fashion.

Corrective Maintenance is undertaken when failure has occurred. The unit may be leaking, efficiency reduced, pump stopped or motor tripped, leading to loss of production resulting in an urgent situation where parts must be sourced and fitted quicky.

Preventative Maintenance is inspection and repair scheduled at specific intervals (daily, weekly, monthly, yearly) or based on the number of hours run. Visual inspections are made externally and internally by dismantling the unit, replacing seals such as gaskets and mechanical seals, with pump parts checked for wear.

Differential Pressure:Check the operating pressure by calculating the difference between the inlet and outlet pressure of the pump ensuring it is operating on curve.

Mechanical Seal (barrier fluid) – Check for contamination such as changes in general colour or appearance, PH, presence of particles, viscosity, or if fluid is at excess temperature during operation.

The “6 to 1 Rule” discovered by John Day Jr, (Manager of Engineering & Maintenance at Alumax South Carolina stated that the ideal ratio of Proactive Maintenance (PM) to Corrective Maintenance (CM) should be 6 to 1 - 6 PM checks to 1 RM check. If your ratio is below this then according to his theory it is being inspected too infrequently, above and inspections are too frequent.

Although Proactive Maintenance can seem to avoid the urgent costs and downtime associated with reactive maintenance, PM maintenance costs can be high due to the cost of labour in dismantling of complicated designs such as Progressing Cavity, or Triplex Plunger pumps which are often time consuming to maintain with more than one person required to undertake work.

On dismantling units, some seals require replacing regardless of condition, and excess spares can be required in case of gasket entrapment during assembly. Rental of specialist lifting equipment may be required and there can be situations where when inspected, pump parts do not require replacement.

MonitoringThe ideal situation is to ensure components are replaced before failure but not so far in advance that they have experienced little wear with valuable time spent on inspecting components which are otherwise fine.

This can be achieved through a monitoring device, where when the right data is collected, pump failure can be anticipated between 3 and 12 months in advance with an 80-95% accuracy.

With the average lead time on DN100 pumps, and units over 5 years old being 3 months or more, it is essential that spares are either on the shelf or failure is anticipated through advance ordering.

Monitoring devices can vary significantly in capability, and should provide the following to ensure failure can be forecast with sufficient time to plan:

Sample Length – Long sample lengths ensure data is captured for sufficient time to detect issues. A long sample length for fast rotating equipment is 22 Seconds (at 48Khz) or 110 seconds for slowly rotating equipment ensuring a detailed overview is provided.

AI Forecasting –Forecasting data within trends enables machine health forecasting. This allows advance repair decisions to be made, budgets forecast, correct resource allocation and enable stress reduction within supporting teams.

There are hazards during any maintenance activity. Always ensure the correct PPE is worn before attempting repair, that sufficient expertise is on hand and chemical data sheets of any fluid being pumped are checked prior to undertaking work. A full risk assessment should be completed in advance.

Hazardous FluidsIrritation, Chemical burns, ignitionEnsure when pump is opened the unit is cool, not pressurized, ignition sources are not present, and any fluids spilt are contained.

If inspection has been neglected for some time, then additional parts may require replacing than had the unit been inspected earlier, with some pump parts becoming beyond economical repair.

Enables planned work to be undertaken during lower activity levels and at lowest cost & risk.Pump has to be crucial within a process or above a certain size for monitoring to be cost effective

Thread Sealant –The use of semi-permanent thread sealant will ensure vitality important threaded fasteners such as bolts or screws on shafts, couplings or pump casings do not self-loosen due to vibration and become disengaged.

Interchangeable Spares –Our range of pumps are modular in design utilizing interchangeable spares, meaning on site stock holding of parts can be reduced by up to 80% further reducing slow moving stock.

Repair & Replace –Choosing to repair an existing pump within a process of vital importance, as well as replace, is a strategy we recommend for maximizing plant efficiencies and reducing downtime. Should unexpected pump failure occur, your process can be restored quickly.

Checklists & Logs –The use of checklists and logs ensures a fully repeatable process ensuring important maintenance intervals are not missed. Logs can provide valuable insight and reveal a pattern before failure occurs enabling easier troubleshooting.

indicates which areas should be checked, but note that a units maintenance routine is dependent on several factors such as hours of operation, duty, aggressiveness of pump medium, rpm of motor, temperature, inlet conditions and location of equipment.

Many things go into getting the most life out of your mud pump and its components — all important to extend the usage of this vital piece of equipment on an HDD jobsite. Some of the most important key points are covered below.

The most important thing you can do is service your pump, per the manufacturer’s requirements. We get plenty of pumps in the shop for service work that look like they have been abused for years without having basic maintenance, such as regular oil changes. You wouldn’t dream of treating your personal vehicle like that, so why would you treat your pump like that.

Check the oil daily and change the oil regularly. If you find water or drilling mud contamination in the oil, change the oil as soon as possible. Failure to do so will most likely leave you a substantial bill to rebuild the gear end, which could have been avoided if proper maintenance procedures would have been followed. Water in the oil does not allow the oil to perform correctly, which will burn up your gear end. Drilling mud in your gear end will act as a lapping compound and will wear out all of the bearing surfaces in your pump. Either way it will be costly. The main reasons for having water or drilling mud in the gear end of your pump is because your pony rod packing is failing and/or you have let your liners and pistons get severely worn. Indication of this is fluid that should be contained inside the fluid end of your pump is now moving past your piston and spraying into the cradle of the pump, which forces its way past the pony rod packing. Pony rod packing is meant to keep the oil in the gear end and the liner wash fluid out of the gear end. Even with brand new packing, you can have water or drilling fluid enter the gear end if it is sprayed with sufficient force, because a piston or liner is worn out.

There is also usually a valve on the inlet of the spray bar. This valve should be closed enough so that liner wash fluid does not spray all over the top of the pump and other components.

Liner wash fluid can be comprised of different fluids, but we recommend just using clean water. In extremely cold conditions, you can use RV antifreeze. The liner wash or rod wash system is usually a closed loop type of system, consisting of a tank, a small pump and a spray bar. The pump will move fluid from the tank through the spray bar, and onto the inside of the liner to cool the liner, preventing scorching. The fluid will then collect in the bottom of the cradle of the pump and drain back down into the collection tank below the cradle and repeat the cycle. It is important to have clean fluid no matter what fluid you use. If your liners are leaking and the tank is full of drilling fluid, you will not cool the liners properly — which will just make the situation worse. There is also usually a valve on the inlet of the spray bar. This valve should be closed enough so that liner wash fluid does not spray all over the top of the pump and other components. Ensure that the water is spraying inside the liner and that any overspray is not traveling out of the pump onto the ground or onto the pony rod packing where it could be pulled into the gear end. If the fluid is spraying out of the cradle area and falling onto the ground, it won’t be long before your liner wash tank is empty. It only takes a minute without the cooling fluid being sprayed before the liners become scorched. You will then need to replace the pistons and liners, which is an avoidable costly repair. Make a point to check the liner wash fluid level several times a day.

Drilling fluid — whether pumping drilling mud, straight water or some combination of fluid — needs to be clean. Clean meaning free of solids. If you are recycling your fluid, make sure you are using a quality mud recycling system and check the solids content often throughout the day to make sure the system is doing its job. A quality mud system being run correctly should be able to keep your solids content down to one quarter of 1 percent or lower. When filling your mud recycling system, be sure to screen the fluid coming into the tanks. If it is a mud recycling system, simply make sure the fluid is going over the scalping shaker with screens in the shaker. If using some other type of tank, use an inline filter or some other method of filtering. Pumping out of creeks, rivers, lakes and ponds can introduce plenty of solids into your tanks if you are not filtering this fluid. When obtaining water out of a fire hydrant, there can be a lot of sand in the line, so don’t assume it’s clean and ensure it’s filtered before use.

Cavitation is a whole other detailed discussion, but all triplex pumps have a minimum amount of suction pressure that is required to run properly. Make sure this suction pressure is maintained at all times or your pump may cavitate. If you run a pump that is cavitating, it will shorten the life of all fluid end expendables and, in severe cases, can lead to gear end and fluid end destruction. If the pump is experiencing cavitation issues, the problem must be identified and corrected immediately.

The long and the short of it is to use clean drilling fluid and you will extend the life of your pumps expendables and downhole tooling, and keep up with your maintenance on the gear end of your pump. Avoid pump cavitation at all times. Taking a few minutes a day to inspect and maintain your pump can save you downtime and costly repair bills.

www.forconstructionpros.com is using a security service for protection against online attacks. An action has triggered the service and blocked your request.

Please try again in a few minutes. If the issue persist, please contact the site owner for further assistance. Reference ID IP Address Date and Time 0f0306011339f5d05a90afa966ec4a73 63.210.148.230 02/15/2023 08:51 AM UTC

As it is the case with most equipment, pumps require regular maintenance to keep within peak performance benchmarks. The benefits of preventive maintenance in the HVAC industry have proven to improve asset life cycle, boost CRM, cut excessive repair costs and reduce unplanned equipment downtime.

When talking about pump failure the best remedy is having a great schedule and maintenance checklist in place. In a pump’s life cycle, environmental conditions can often be a major factor in its performance. Some other important maintenance tasks and factors to consider include:

All of these issues can be detrimental to a pump’s performance and cause defects if not resolved with regular maintenance. When considering what to include in your regular maintenance checklist a great place to start is the warranty and manufacturer standards as per pump type. Pump manufacturers often set requirements to follow to ensure the best life cycle for your equipment.

Pump efficiency point is the result of hydraulic, mechanical and volumetric parts to ensure performance is within a desired level. The level of efficiency in a pump is drawn from the units of energy that is required for performance.

However in centrifugal pumps, the inner workings of the pump will drive the motor. Essentially this means the mechanical energy is transformed to hydraulic energy and electrical energy is transformed to mechanical energy. This means that for a centrifugal pump you will find your level of efficiency sits at either 75% or higher in larger pumps and around 60% in smaller pumps.

As a part of your work order management for your pump maintenance schedule, you need to do some research behind what factors you need to consider that will be most detrimental to your pump’s health. When you create your ultimate guide to maintenance, your aim is to reduce your unplanned downtime and improve your standard of service by keeping a regular schedule.

When trying to determine the frequency of your maintenance checklist, you need to consider the factors that will impact your pump listed in the beginning of this article. If you have a higher quality pump that is used every day and is largely impacted by elemental factors, you will need to have more regular services in place. The warranty and safety standards will also have an impact here, depending on your pump type and according to the manufacturer’s instructions.

The more thorough your maintenance is, the better service you can provide. While a large maintenance schedule can seem daunting to your maintenance team, the assistance of checklists can ensure no step is missed no matter how big or small. Having a checklist in place will also provide consistency across your team and ensure each pump may receive the correct care it needs.

The main area for concern in centrifugal pumps is the lubrication. As centrifugal pumps rely heavily on correct lubrication to work, maintenance is important to ensure pumps aren’t under or over lubricated, which can cause damage. When you have over lubrication your pump will create too much heat and can result in frothing the oil.

When considering your lubricant level and bearings you also need to consider what oils to use. Try to use non-detergent and non-foaming oilsfor the best performance. In your bearings you want to avoid using different variations and types of oils that can be varying in consistency and can affect performance.

Getting your maintenance plan right means you consider all these above factors and are able to incorporate them into your pump checklist and schedule.

For this checklist, you want to schedule a quick inspection of your pumps to avoid damage and wear. The main reason for having a daily checklist in your schedule is to catch those pesky issues that can turn into defects and pricey repairs if not caught early on.

Generally your quarterly maintenance will be done with the change of the season and can include varying tasks due to elemental factors. The severity of your pump environment will also affect the consistency and schedule of your pump maintenance program. Will your pump be exposed to extreme heat or extreme cold temperatures?

In your annual preventive plan, you will generally go into more detail and evaluate pump performance. Each year you should take a record of your annual operations and benchmarking data that might include:

For your routine maintenance schedule for your centrifugal pumps you need to make sure you have a solid system in place where you can reliably plan and train your team. Having a great software in place will also give you the ability to structure your maintenance program according to the manufacturer’s instructions and adhere to your customer contracts.

Job management software like FieldInsight gives you the ability to keep your centrifugal pump maintenance in perfect balance. With FieldInsight, you also gain access to the five primary automations in your business:

To reduce the stress in your scheduling system and improve your maintenance program, book a free demo today and find out what FieldInsight can do for your business.

Book a Demo. You’ll be in touch with an automation expert who has worked in this space for over 5 years, and knows the optimal workflow to address your needs.

Pump maintenance is the process of keeping your pumps in good working condition. A thorough checklist that guides the maintenance engineer for pump maintenance can be very beneficial as pump maintenance is essential to keep your pumps running smoothly and prevent them from breaking down. This includes regularly checking and cleaning your pumps and replacing any parts that are worn out.

Modern pumps are essential equipment in the industrial and manufacturing sectors. These devices allow companies to move liquids and gases from one place to another, which can be crucial to operations. While modern pumps are reliable and rarely need maintenance, they require some attention over time.

The ideal way of classifying pump maintenance is through the method used for drawing out the maintenance plan. Based on this, the following are the four significant types of pump maintenance:

Corrective maintenance is the most reactive type of pump maintenance, and it involves repairing or replacing parts as needed to keep a pump functioning properly. While this approach may be necessary for some situations, it is often not ideal due to its high cost and disruption of operations.

Preventive maintenance is another common approach to pump maintenance that focuses on proactive measures such as regular inspections and adjustments. This can help avoid potential problems and keep pumps operating at peak efficiency. Using a reliable checklist for pump maintenance, engineers conduct a thorough checking and carry out the needful maintenance as and when needed. This approach is widely used in industries.

Predictive maintenance uses advanced sensors and equipment to monitor the condition of pumps and other components in real-time. This enables users to detect potential problems before they become serious issues that require extensive repairs or replacements. However, this type of maintenance is cost-intensive and unsuitable for small-scale pump systems.

This type of pump maintenance is a newer type of pump maintenance that uses data collected from sensors to assess the condition of pumps and other equipment. This information is then used to develop a customized maintenance plan tailored to the equipment’s specific needs. This approach can be more effective than traditional pump preventive maintenance plans and can help to reduce downtime and costs. But setting up a CBM system can prove to be a costly affair.

Whether you are using one of these approaches or a combination of them, it is essential to ensure that your pump maintenance program is adequately designed and implemented to optimize the performance and longevity of your pumps. Pump maintenance plans are also created based on the system they target, including mechanical, electrical, and hydraulic. Mechanical maintenance typically involves replacing parts that have worn out or broken down due to normal wear and tear. Electrical pump maintenance requires checking the wiring for any signs of damage and replacing fuses if necessary. And hydraulic pump maintenance may involve changing fluid levels or upgrading the oil viscosity depending on the level of use.

The strength and effectiveness of your pump preventive maintenance plan depending on how robust your checklist is. While you would want to include all possible checks in the plan, it is impractical and inadvisable for all routine checks. Therefore the checklist is divided based on the frequency of checks making it more sustainable and effective:

Please note that the pump preventive maintenance schedule for each pump would depend on its design and application, and hence you should always consult the pump manufacturer for the same. However, the above checklist is a general checklist that can guide the process of pump preventive maintenance. A well-maintained pump will last longer and perform better than one not correctly cared for.

Check the manufacturer’s recommendation for service interval schedules. Depending on the type of pump, different servicing may be required at different intervals.

Maintain the proper records for all pump maintenance activity. Good data collection will give you the correct information about the pump’s health and operational condition.

Based on the checklist, pump maintenance may seem a simple task that needs to be done regularly. However, this is not true. Understanding the pump behaviour and performing suitable maintenance activities requires years of experience. Therefore, it is always advisable to hire a qualified expert to carry out pump maintenance due to the following reasons:

Safety – Pump maintenance through a qualified expert, ensures that all safety hazards are identified and eliminated. This keeps you, your equipment, and your employees safe from harm.

Efficiency – Qualified experts know how to service and maintain pumps to operate at peak efficiency. This can save you money on your energy bills and help prolong the life of your pump.

Peace of Mind – Pump maintenance can be a complex task. By entrusting it to a qualified expert, you can rest assured that the job will be done correctly and on time.

Avoid Downtime – Downtime is costly, both in terms of lost productivity and repair costs. Pump maintenance through a qualified expert can help minimize the risk of unexpected downtime.

Compliance – Pump maintenance through a qualified expert can help ensure that your pump complies with all relevant safety and environmental regulations. This can save you from costly fines or penalties.

The majority of reliable pump manufacturers offer pump maintenance as a part of their service. Therefore, it is always a good practice to hire them to execute the pump maintenance of your site. They will also be able to create an effective schedule and an exhaustive checklist that your site engineers can follow for pump inspection. Ensuring that pump preventive maintenance is done at the right time in the right way will make your overall system more reliable and efficient.

Please try again in a few minutes. If the issue persist, please contact the site owner for further assistance. Reference ID IP Address Date and Time d94a2288d76f819e65e1cc71545d07c7 63.210.148.230 02/15/2023 08:51 AM UTC

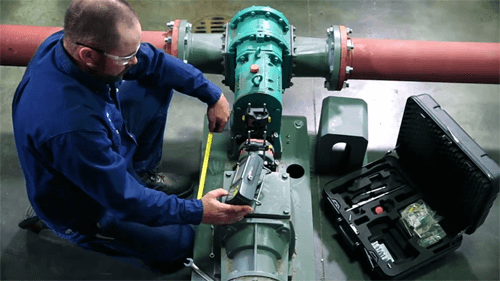

High-pressure stand-alone mud pumps such as the SA400 are constantly tackling tough pipeline drilling projects alongside horizontal directional drills, or HDDs. Tough jobs mean operators should take extra steps when possible to maximize the life of the machine. These steps can vary from visual inspections of the machine to performing preventative maintenance tasks on schedule. Refer to your machines operator’s and maintenance manual for safety messages and further information. Now we will go over some operator best practices that can help extend the life of your mud pump.

With the jobsites that these mud pumps encounter, it is no surprise that some parts of the machine can experience considerable wear. High sand content and mud weight on a jobsite will affect the life span of fluid-end components on your pump. Parts on the mud pump that may experience heavy wear include, but are not limited to:

Another area of the mud pump operators should diligently monitor are the intermediate rod seals. If a leakage occurs, these seals will need to be adjusted periodically by following the steps outlined in your machines operator’s manual.

Performing preventative maintenance is a game-changer when it comes to helping extend the life of your mud pump. It is recommended to check lubrication levels daily and inspect the transmission, gear reducer and drive motor. After a job is complete, flush the pump so that it is ready to head to the next jobsite. If the pump will not be used for an extended period of time between jobs, it is recommended to lubricate liners, pistons and valve seats. Doing this will help prevent the liners and seats from becoming pitted due to condensation.

When temps begin to drop, operators will want to remove all drilling fluids from the pump, hoses and any exposed drill string. After that is complete, fill the end of the mud pump with antifreeze, which will offer protection from freezing temperatures beyond what is anticipated. Planning and performing this maintenance before temperatures drop is key to optimizing machine performance.

These pumps are typically used on large-diameter projects, which means going at a slower rpm can maximize machine longevity and productivity. While the pump is processing heavy material, if it is run too quickly, it could affect machine performance. Keeping an eye on the rpm and adjusting when needed can help avoid plugging the pump with heavy material.

When setting up at the jobsite, remember to set the mud pump onto a level area of ground. Inside the pump many internal components only receive splash lubrication and if the pump is working on uneven ground, it is more difficult for those components to receive the adequate amount of lubrication.

Developing a consistent routine to check fluid levels and the condition of highly wearable parts will go a long way when it comes to maximizing the life of your mud pump. It is essential that operators take the time to inspect the pump between jobs and utilize the operator’s and maintenance manual for further instructions and safety messages.

Prior to performing service or maintenance on Vermeer equipment, always refer to the product’s operator’s and/or maintenance manual for safety messages and further instructions. Vermeer Corporation reserves the right to make changes in product engineering, design and specifications; add improvements; or discontinue manufacturing or distribution at any time without notice or obligation. Equipment shown is for illustrative purposes only and may display optional accessories or components specific to their global region. Please contact your local Vermeer dealer for more information on machine specifications.

If the slurry pump is driven by a belt, please check the tension of the rope at least once a quarter. Too tight belts will cause damage to the motor bearing and once the bearing is broken the bearings will start to fail inside the pump. Belt that is operated when it is too loose will cause poor performance and cause slip damage to the belt.

If your dredge pump is using lubricant for cooling, please check it periodically to make sure there is no water or other impurities in the oil. If the pump seal remains stable, changing the oil periodically will increase the life of any pump.

Best performance is achieved by occasionally checking the out-of-wing clearance. Refer to instructions to check gaps appropriately. When checking the clearance, it is also necessary to check the impeller wear and other parts of the dredge pump.

For this problem, the best solution is to install pressure gauges and flowmeters on the discharge lines of the pumps. You can take the display pressure and multiply it by 2.31 to get the relative TDH (total dynamic head). You can then take that TDH along with the measured flow and see if your pump runs near the BEP (best efficiency point) on the pump’s baseline. If not, please contact your provider.

Temperature sensors are provided with our submersible pumps for engine protection. Each guide provided with the pump will outline how to connect and monitor the temperature sensors for the maximum life cycle.

If the engine is overheated, the sensors will automatically shut off and the pump will stop working until the engine cools down. If there is no sensor, or the sensor is not connected to the pump, there is a risk of engine fire.

Horizontal and vertical pump cantilever need to check the temperature of the bearing weekly while the pump is in operation. Use a temperature gun to check the bearing housing temperature closest to the bearing.

While most pump bearings run in the range of 140 to 170 degrees Fahrenheit, it is recommended that users never allow temperatures in excess of 200 degrees Fahrenheit (about 94 degrees Celsius). High bearing temperatures may be a sign of excessive lubrication or a problem with the bearing.

Proper vibration monitoring will provide the operating team with useful information that can increase MTBF (mean time between failures) and improve pump performance. Refer to the Hydraulic Institute’s vibration monitoring guide (American Hydraulic Institute) for vertical, horizontal and submersible pumps for appropriate limits.

Currently Thai Khuong Pump is representing the pump brand Schuro Slurry in Vietnam specializes in providing products with large capacity US brand mud pump (you can refer to the productshere).

If you have not yet selected a suitable mud pump product, or have any questions need advice or provide technical information, product prices. Let’s contact right with us.

The maintenance checklist, implemented a few months ago, covers equipment to monitor on a daily, weekly, and monthly basis. An area is devoted to tracking service truck miles, rig miles and hours, as well as welder hours to know when an oil change is needed. The goal is to not let any maintenance task fall by the wayside.

“It’s kind of brought about them (drilling crews) thinking of other things, recognizing other things, and having a mindset towards maintaining their equipment,” says Baker, owner of Apex Drilling LLC in Burley, Idaho, “and that’s the most important thing—having that mindset towards maintenance.”

Baker, president of the Idaho Ground Water Association, worked as a maintenance mechanic for nearly nine years at a potato processing plant before entering the water well industry. He worked at the plant under the supervision of a 20-year Air Force veteran who previously was a maintenance manager of intercontinental ballistic missile sites in the Midwest. Baker credits those years for helping him get keyed in on being proactive with equipment maintenance.

“I learned a lot about preventative maintenance and things you start looking for,” Baker says. “If you know about some of these small things before they become big things, then you don’t have downtime on the jobsites.”

Months into implementing the maintenance checklist, Baker is seeing his drill crews take ownership by noticing minor issues on their four drill rigs and making note of them. The crews then look at the list and fix the issues during half a day in the shop while they’re in between jobs, or at a jobsite when time allows for it.

Factoring into the maintenance of his equipment is the fact that Baker is using a higher-grade oil and additives package rather than what the manufacturer recommends. Also, every 200 to 300 hours of use, he has equipment oil samples (engine, hydraulic, and compressor oils) sent and analyzed by a lab in Salt Lake City, Utah. The lab runs an International Organization for Standardization (ISO) cleanliness analysis and designates a code to how clean the oil is and the results dictate when Baker needs to change the oil in his equipment.

The lab analysis, Baker says, provides a clear indication as to whether filtration is working properly, and if therefore, the oil is clean. Conversely, it indicates when a change might be necessary.

“Hydraulics, pumps, and motors have an ISO cleanliness code on the oil,” Baker explains. “If you run that hydraulic system within that cleanliness code at 70 degrees in a controlled environment, you’re going to get 10,000 hours out of your pumps.

“When putting the pumps on mobile equipment, it cuts it in half, so you get 5000 hours on pumps because they’re working in the extreme heat, cold, and dirt. As long as you maintain that cleanliness code in your oil, you can expect 5000 hours, but as soon as you go one code dirtier in your oil, you cut that in half. If you can operate one code cleanlier you can double it, and so we’re trying to operate in a manner that is not necessarily normal in an effort to try and get our equipment to last longer. Ultimately, it reduces our cost of maintenance.”

“When you put new bearings in and you’re running it, you’re going to see zinc in your oil, just a little bit all along and then you’ll see copper,” he says. “When you see copper, you know you’ve worn through the zinc. Then you watch it, and when it wears through the copper and starts showing up with brass in the oil, you know you’re ready for an engine overhaul.”

“The biggest thing—yes, it pushes out the engine overhaul timewise,” Baker says, “but it’s that it gives you a heads-up that it needs an overhaul before you’re on a well and you’ve got tooling 300, 400 feet down in the ground and all sudden you have an engine breakdown. If I know my engine needs rebuilt and is still running, after this job, we’re going to bring it in and do an engine overhaul. It’s on scheduled downtime and the other rigs are filling in the gaps.”

Beinhower Bros. Drilling Co. in Johnstown, Ohio, began using an oil sampling system when it purchased its 2018 GEFCO 40K. The company initially conducted oil sampling for warranty purposes, but it has continued to sample and monitor its equipment fluids.

“Typically before, the service interval would be based on hourly usage,” explains Nic Sprowls of Beinhower Bros. Drilling, “whereas with sampling, I have a better idea on how to gauge when to perform service. I feel it maximizes the life you get out of each fluid and doesn’t allow you to change too early or wait too long.

“Where I would’ve normally gone by footage drilled before doing this simple task, I’ve since changed to every use,” Sprowls says. “That simple change because of sampling saved a costly repair down the road. Every rig is different to where the sampling will give you an idea of what your rig needs.”

Sprowls, president of the Ohio Water Well Association, also shared how hydraulic oil in the GEFCO 40K came back with elevated metal content. He says nothing indicated that the hydraulics were acting up, but the oil sample prompted further investigation which revealed a hydraulic pump failed prematurely.

“I’ve heard most of them will do oil sampling,” he says. “If their rig manufacturer or rig mechanic knows of a place to get this done, it works well for us to have results go to them also. If they get this far with it, definitely consult the operator on their thoughts. It’s only as effective as the person taking the sample.

Sprowls stresses that maintenance needs to be intentional where time is made for it. He makes a point that being proactive is less stressful than reacting to an engine replacement in a customer’s front yard. After all, it’s much easier to work on the machines in a climate-controlled shop or gravel lot with no mud.

“What I’ve done for routine items is put a value on them that is relevant to our industry,” he shares. “Most drilling is accounted for by the foot, so I will analyze what kind of drilling I’m doing and put a footage on it. For example, I grease the rig every so many feet of overall drilling. If I’m mud drilling, the mud pump and swivel get greased very well, no matter the footage. Air drilling may be more frequent on the swivel due to the temperatures.

“Some items I track are hydraulic pressures, oil changes, and even if the design of a pipe wrench gets changed,” he says, because “the more you write down the better. Time gets away from us so fast, you’d be surprised at what gets written down and forgotten about.”

“The main reason Layne is dedicated to a robust equipment inspection/maintenance program is the safety of our employees,” Snelten says. “If we can keep our equipment safe to operate, it reduces the hazards to our employees and helps prevent injuries. They go home to their families at the end of the day in the same condition they came to work.

“We’ve made incredible strides in our safety performance over the past four years, and we see equipment maintenance as a required component to our continued safety evolution to not just maintain industry leading safety performance, but achieve true world-class safety.”

Beyond improved safety, Layne sees additional benefits of an aggressive maintenance and repair program achieving increased employee engagement, client appreciation and recognition, decreased maintenance costs, decreased downtime, increased productivity and profitability, and differentiation from the competition.

Layne rolled out a new maintenance program in 2021 for its several thousand pieces of equipment—drill rigs, pump rigs, trucks, trailers, and support equipment—and for the roughly 350 field staff who operate them.

“We’re showing our crews that we care about their safety by caring for our equipment. We’re showing our clients that we care about our equipment and our people and making sure that their projects are completed in a safe and efficient manner,” says Snelten, chair of the NGWA Government Affairs

The program consists of daily, monthly, and annual inspections of the drill rigs, pump rigs, and service trucks. Inspection items include fluid levels, wire ropes, sheaves, frame welds, controls, emergency stops, etc. A copy of the inspection goes to the field superintendent and mechanic and repairs

The program also presents Layne with information to determine action steps for a piece of equipment. If a piece of equipment continues to have persistent maintenance issues, and its records show maintenance costs are excessive, the question becomes: Is it better to perform a mid-life rebuild where another seven to 10 years can be gained, or is it better to replace it?

“Find what works for your business and your equipment and keep working at it. Will it take money? You bet it will. But at the end of the day, it’s the right thing to do for employees to provide them with safely operating equipment. Your customers will thank you also when you don’t leave an oil bloom on their driveway or yard.”

We kicked off a two-part series on a water well and pump maintenance program and how to set one up in July’s Water Well Journal. This month, we will conclude this series with how to prepare and use the forms.

To fully evaluate the feasibility and cost of a preventive maintenance program, it is important to first establish the program’s parameters and limits. This means you first need to decide how much advance system information you should provide to the technician.

I found the technician should be given the information needed to perform the required maintenance and to determine if the system was running just right or too far outside the design boundaries. At the same time, I also believed too much or too little information could be just as harmful—leading to unnecessary, unproductive, and unbillable time spent developing and expressing to the client theories not plausible or not in the technician’s job description.

As shown in July’s WWJcolumn, we finally settled on the use of Master Form 1 (republished again as Figure 1) for wells and well pumps; Master Form 2 (Figure 2) for booster pump stations with one up to four units; and Master Form 3 (Figure 3) to describe the various drivers used for the units outlined in Forms 1 or 2. Master Form 3 was specifically developed to match the well or booster pump data on Forms 1 or 2 for a single well and pump up to four booster units at a single site.

Deciding what to include or exclude on the master forms is largely a matter of personal preference. Although I would suggest even though you may wish to include the design COS (Conditions of Service) for each pump, other specific design criteria—such as capacity and head calculations—should not be included on the master forms. This not only takes up space on the forms better used for data, but also creates the real possibility of field personnel making ill-informed opinions to the client that you may have to retract later.

Generally, the information contained on the master forms remained and were updated in the office after each inspection from data filled in on the Field Data Form (Figure 4) but were often distributed to field personnel as background information on an as-needed basis. Each of these four forms can be developed and include the information required by your individual firm and region.

Developing the Field Data Form, however, requires you to decide how much onsite field work should be performed each visit, determine the average amount of time required for each task, and then add a factor for data collection, documentation, and travel (usually invoiced for a two-way trip).

Other tasks—especially those requiring substantial time to generate and reach stabilized operating parameters, as with pumping water levels, or sufficient time to generate maximum operational (running) temperatures, particularly a motor, motor starter, load terminals, or circuit breaker/fuses—may require a much longer and non-uniform period to reach individual operating temperatures.

The key is to first identify those specific parameters you feel should be examined during each or every other inspection and those not as important. Although the information shown in Figure 4 can provide a basic guide, it is also just one person’s idea as to what is important.

Since I would never presume to tell another water system firm what to include or exclude in their market area, I will also not make any specific recommendations as to what to examine in your preventive maintenance (PM) program. However, whatever you select, I recommend you invest the first month or two in a trial program to verify the scope and validity of the selected parameters and to determine the total billable time required for the typical unit.

To determine the total cost for each PM visit, you should include or consider separate time or cost elements for a proportional cost factor for equipment rental, use, depreciation, retrieval, and setup.

depreciation) and fuel; hand tools; water level measuring device (probe, air compressor for airline, transmitter, etc.); calibrated pressure gauges; flow measuring device (if not already present); and electrical test meters.

Labor and incidental costs can include lockout/tagout procedures and system shutdown (if already running); initial or static inspection along with the static maintenance procedures; consumables (packing, oil and/or grease for bearings); operating inspection (including adding time for operating temperatures to rise and pumping levels to stabilize); conduct readings and record data; system restoration and reactivation; retrieve and collect equipment and tools and return to service vehicle; cleanup, travel, and the always dreaded paperwork. Not every PM visit will require invoicing for every separate time or cost factor listed above.

Another simple way to ensure covering the technician’s time, plus an adequate return on investment without overcharging a client, is to develop a cost rate for the “Base Inspection,” along with billing extra per-hour rates that include individual charges for tasks or items not required for each inspection, such as flow or water level measurements or use and setup of other devices (where none are present), calibrated gauges, or consumables such as packing, oil, or grease.

For what it’s worth, after a three-month initial trial period we eventually arrived at a typical average total time for our PM program around 1.88 hours for a single well or pump installation to an average of 1.66 hours per unit for multiple pumps at one site. This generally resulted in a billing time averaging about 2 to 3 hours for a single

An effective PM program is built on developing a database of past performance and operating conditions along with a trigger to identify any errant operational conditions to provide advance notice to the client of impending failure or those issues requiring immediate attention.

Our program was established and functioned with these goals in mind as the primary objective, along with a specific set of criteria to provide a reasonable uniformity of cost expectations to clients. For those who wish to receive some general guidelines as to what parameters to look for when establishing a PM program, I offer the following.

Introduction and Header: The header includes the typical information you would expect on a form of this type such as client name, facility location and address, technician’s name, date along with time work started and stopped, and other information specific to the tasks.

a—Initial Pre-Inspection: The area for the pre-inspection includes the work normally conducted while the unit is disabled. This is more important than may be apparent since performing the pre-inspection and system examination is generally conducted immediately upon arrival and up to one to two days following advance notification to the client of an impending visit.

This usually provides enough notice to permit operational transfer to other facilities, followed by an orderly shutdown of the well/pump station and recovery of a well to static conditions and cooling of motors and other electrical equipment.

b—Locked Out/Tagged Out:As far as safety is concerned, this step may be the most important. By listing this step as an individual procedure, the technician is expected not only to verify the unit is off, but implement the appropriate “lockout/tagout” procedures before beginning any work potentially harmful to the technician.

c—Operational Inspection: After all elements of the pre-inspection have been completed, the operational inspection is conducted. Once again, this not only permits a progressive and orderly examination of the plant in a safe environment, but ensures the prior lockout/tagout procedures have been removed and the unit has been restored to a functional status, which tends to remove any likelihood of forgetting to reactivate the unit.

d—Operating/Pumping Data: Obtaining the data in this category is generally a matter of obtaining readings once the unit is operating and all well or pump operating conditions have stabilized. This is critical for obtaining measurements such as pumping water levels and operating temperatures of motors and related electrical components.

Typically, adding the observed pumping water level lift (in feet) with the operating head for wells or the net difference between the suction (inlet) and discharge head for booster pumps (again, in feet) provides a close approximation of the total dynamic head.

Lastly, space has been provided at the bottom of the pumping data to indicate whether a water sample has been taken or not. This is critical for a water well since the position and time pumped shown in this question is both intentional and critical for the indicated time must be adequate to provide sufficient “purging” of the well to occur or at least two full raw volume exchanges of water within the wellbore.

Generally for most wells, this required an operational period of only 5 to 15 minutes. Coincidentally, this is also the minimum amount of time needed for most electrical components to elevate to desired operating temperatures. This is believed important to ensure a water quality sample extracted from the well represents an actual sample of fresh and unadulterated water from the aquifer and is not a sample that has spent excessive residence time within the wellbore.

Due to factors surrounding possible oxygenation, sedimentation, and precipitation, the results obtained from a water sample that has been exposed to significant time and the accompanying environmental factors occurring in a typical wellbore may easily distort or negate test results. This becomes particularly important when obtaining water samples to evaluate possible causes of well issues or the optimum well rehabilitation chemicals and procedures to use for a given well and was always an established element of the protocol whenever obtaining raw water samples from pumping wells.

e—Electrical Data: The data obtained for electrical readings is a function related to the type of system and whether power readings can be obtained from onsite watthour, clamp/clip-on types of power meters, or derived from the known horsepower relationship that exists between power factor, voltage, and amperage. In either case, determining the associated water and input horsepower, and thus the plant efficiency, is simply a matter of conducting accurate observations of various operating parameters and employing a few fundamental equations.

Whether these calculations are performed in the field or later in the office, following this type of test procedure on every visit ensures a uniform set of criteria is used for each inspection. This goes a long way toward ensuring accurate and meaningful data is collected for each unit and for each site visit. This provides the ability to determine and track unit and system performance and efficiency over a long span of time.

Finally, the bottom of Master Form 1, Master Form 2, and the Field Data Form provides space for comments and red flags. Red flags are emphasized to indicate situations representing an immediate or short-term condition that may present a risk to equipment or personnel.

The intent is all red flags will be documented by the field technician and transferred and recorded to the appropriate master form for notification to the client to determine any desired further action.

A second Field Data Form (Figure 5) has been added as a guide for those also charged with routine service and maintenance of diesel or gasoline engines used as primary, backup, or emergency sources of power. Again, the information and data important to your firm can be customized on the form.

If a PM program is properly developed and conducted, with emphasis on a sufficient but not excessive interval of inspection, the capability of using a program to help gauge the need for a well or pump rehabilitation is significant.

By testing and recording various static and operational well parameters—such as static and pumping water levels and flow rates—potentially important well conditions like loss of specific capacity or yield can be determined and tracked.

This data, when tracked carefully over time and during a uniform time of year, can assist in determining critical well operational factors, including drawdown and recovery rates which may indicate a trend or potential need for an immediate or scheduled well rehabilitation or service.

If conducted properly and at appropriate intervals, performing routine preventive maintenance on a water well pumping plant can identify potential or minor well problems before they develop into a major headache.

In addition to the PM elements themselves, an effective program on a well installation will also track water quality issues and the potential for well plugging, especially for biological or mineral incrusting material. Obtaining a water sample during the test procedure and having it analyzed for the water quality parameters common to biological and mineral growth can assist in scheduling needed well maintenance as well as pump repair.

To help meet your professional needs, this column covers skills and competencies found in DACUM charts for drillers, pump installers, and geothermal contractors. PI refers to the pumps chart. The letter and number immediately following is the skill on the chart covered by the column. This column covers: PIE-18, 22: PIF-2, 3, 4, 5, 6, 7: PIG-3, 8, 10 More information on DACUM and the charts are available at www.NGWA.org/Certification and click on “Exam Information.”

The use of pumping plant performance, whether in a well or booster application, can also be used for tracking loss of pump performance, increased load vs. theoretical horsepower (decreased overall efficiency), and other conditions which may lead to a catastrophic and sudden failure.

In many cases—often due to simple ignorance, personnel overload, or time constraints—operating personnel may not be familiar with or recognize the need to conduct routine maintenance on pumping equipment.

This not only creates a situation where the equipment is neglected and doesn’t receive regular or scheduled maintenance, but also a condition where an early warning or advanced indication of impending failure may be offset and prevented by a few simple repairs.

This is particularly true for hidden types of deep well pumps, such as vertical turbine or submersible pumps. These factors are in addition to the real benefits gained from implementing a PM program with the basic goal to provide an enhanced and scheduledmaintenance and check on the condition of the well, pump, or driver.

In addition to the data forms, other firms may wish to set up forms for evaluating and servicing other equipment and components used in water systems, such as control valves, filtration systems, and control systems.

This concludes the short series on establishing a preventive maintenance program. I hope you can use some of the information I have provided as a guide or outline for your own program.

Pumps are vital to industries including water treatment and wastewater facilities, power generation, oil and gas, food processing and more. In the oil and gas industry, the uptime of industrial pumps is especially critical. The total world consumption of global petroleum and other liquid fuels averaged 92.30 million barrels per day in 2020, according to the U.S. Energy Information Administration. That total has risen by approximately 5 million in 2021 and will continue to grow in 2022. Any unplanned downtime can impact the ability to meet this growth.

There are three basic types of pumps, and they are classified by how they transport fluid: positive-displacement, centrifugal and axial-flow. Pumps can experience several different types of failures, including cavitation, bearing failures and seal failures, among others. In oil and gas, conditions in which pumps operate are often challenging, dirty and hazardous, resulting in wear and tear. Failure of these pumps not only results in unexpected operation delays and increased costs, but it can lead to dangerous oil and gas leaks, impacting labor safety and the environment. To avoid these unexpected failures, many companies increase preventative maintenance and create aggressive inspection schedules. These practices,

8613371530291

8613371530291