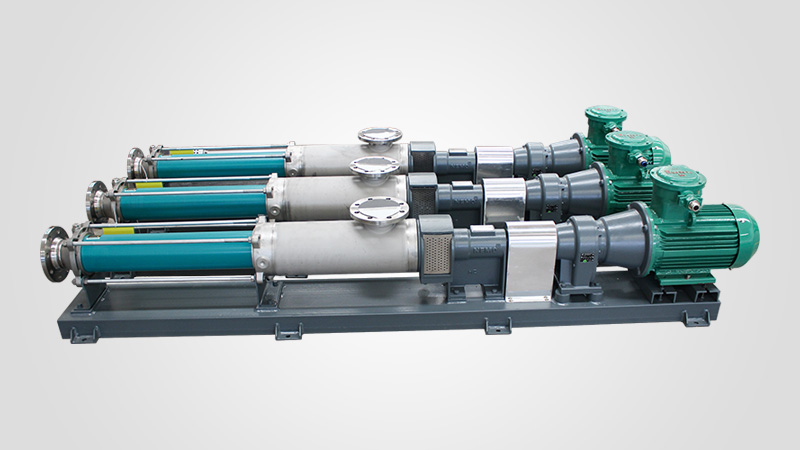

progressive cavity mud pump made in china

The biggest characteristic of progressive cavity pump is that it is especially suitable for conveying sensitive liquids which cannot be sheared, squeezed or stirred, that is, non-Newtonian liquids which will show thixotropic properties when subjected to shearing. It is not only suitable for transporting medium with low viscosity such as water, but also especially suitable for transporting suspension containing solid particles or short fibers and medium with very high viscosity.

When the fluid with high viscosity and poor fluidity is input, we need to pay attention to whether it can flow into the pump fast enough. If it cannot, it will easily cause the dry grinding and volumetric efficiency of the pump to change. So we need to pay attention to the speed of the fluid being conveyed and its viscosity.

In order to ensure the life of the progressive cavity pump, we usually control the speed to a low level so that a large flow will not be generated. If you need to increase the flow, usually add a variable frequency drive (VFD) or stepless speed reducer. Speed and flow are often proportional. But the maximum flow rate of the progressive cavity pump in our factory can reach: 300m³/h;

The progressive cavity pump is a positive displacement pump. It has only one screw rotor, which has slight interference fit with the rubber stator. Screw pumps also need at least two screw rotors to cooperate, and usually there are three or five screw rotors to cooperate. The name is also named after the number of screw rotors. For example, a pump with two screw rotors is called a twin screw pump.

Comparison of the media conveyed by different types of screw pumps:Twin screw pump can transport lubricating, non-lubricating, corrosive and medium containing certain magazines, even used for oil, steam and liquid mixed transportation. Commonly used for conveying various oils, water, emulsion, paste, asphalt and chemical media, etc.

Five-screw pump is suitable for low-pressure and high-flow conditions, conveying lubricating medium, and it is more sensitive to impurities in the medium than three screw pump.

Screw pumps are not made of rubber like progressive cavity pumps, but almost all of them are made of metal. Performance: Screw pump can deliver larger flow and pressure.

Due to the slight interference fit between the stator and the rotor of the progressive cavity pump, it is not allowed to run dry. Once the dry running of the pump is not stopped in time, the stator will burn out immediately. Therefore, it is necessary to fill the pump cavity with the medium, and the medium in the system cannot be interrupted.

Special situation: When installing the pump, if you don’t know whether the motor is in the forward or reverse direction, you can run the pump 1-2 times in dry mode.

It was invented by French engineer MoiNeau, so it is called Mono Pump. It has many nicknames. Sometimes we will call it helical rotor pump, eccentric screw pump, PC Pump or PCM Pump, Crank Rod Pump and Snake Pump. In China, it is also called single screw pump and thick slurry pump. No matter how many nicknames it has, it belongs to positive displacement pump.

In 1930, when aviation pioneer René Moineau was designing compressors for early jet engines, he discovered that this principle could work efficiently for pumping fluids. So he cooperated with Robert Bienaime of Gevelot Group to establish PCM Pompes in 1932 and developed the world’s first known progressive cavity pump.

When the viscosity or thickness of the liquid is higher than that of water, which is not suitable for centrifugal pump delivery, use progressive cavity pump.

When the suction conditions of the pumping applications are not ideal and when the suction pressure is lower than 28 inches of mercury (Hg), the progressive cavity pump can pump, but the centrifugal pump cannot.

When transporting sensitive liquids that cannot be sheared, squeezed or agitated, the speed of the centrifugal pump is too high, which will easily damage the fluid structure.

When the liquid contains solid particles, centrifugal pumps or other positive displacement pumps are easy to wear or block. At this time, because the stator and rotor of the progressive cavity pump has a wear resistance design, it will be more suitable for this application.

The main working parts of progressive cavity pump are stator and rotor. Because of the special geometric shape of stator and rotor, when assembled together, several separate sealing cavities will be formed. When the motor drives the rotor to move, the medium in each sealing cavity will be continuously and uniformly transported from the suction end to the extrusion end with constant volume.

Progressive cavity pumps have self-priming performance and good suction performance, and the self-priming height is generally 2-5 meters (taking water as the test); When transporting sludge or medium with high viscosity, self-priming installation is generally not recommended, but natural inflow is recommended.

The customer is required to provide the flow rate, output pressure or head of the fluid to be transported, and to inform the physical and chemical properties of the fluid in as much detail as possible, and then the factory will select and recommend for you based on experience. Because of improper selection of progressive cavity pumps, it is easy to cause many problems in use. The right pump can create more value and reduce costs for you.

Detailed 1.simple structure 2.working safely and reliable 3.convenient to use and repair 4.pressure stability SD-RGB type screw pump Single screw pump is used in all fields widely to feel kinds of medium, running at a constant pressure continuously, without pulse and damage when feeding medium, and change the gauging aim through adjusting rotation speed Features and benefits: 1, Can transport the medium which contain air under a negative pressure. 2, Good self-suction ability 3, Can transport the liquid containing fibers and solid grains; 4, Can do transportation a reversed direction; 5, Small mechanical vibration, no pulsation, stable movement 6, Highly viscous medium permit Technical parameter : Diameter: 32 150mm Flow: ≤45m3/h Head: ≤120m Working temperature: ≤80°C Solid grains: ≤ 60% size of outlet Permitted working pressure: 12 bar Permitted testing pressure: ≤25 bar Type Capacity Pressure Power Inlet Outlet 20-1 0.8m3/h 0.6MPa 0.75KW 25MM 25MM 20-2 0.8m3/h 1.2MPa 1.5KW 25MM 25MM 25-1 2m3/h 0.6MPa 1.5KW 40MM 32MM 25-2 2m3/h 1.2MPa 2.2KW 40MM 32MM 30-1 5m3/h 0.6MPa 2.2KW 50MM 40MM 30-2 5m3/h 1.2MPa 3KW 50MM 40MM 35-1 8m3/h 0.6MPa 3KW 65MM 50MM 35-2 8m3/h 1.2MPa 4KW 65MM 50MM 40-1 12-20m3/h 0.6MPa 4KW 80MM 65MM 40-2 12-20m3/h 1.2MPa 5.5KW 80MM 65MM 50-1 14-20m3/h 0.6MPa 5.5KW 100MM 80MM 50-2 14-20m3/h 1.2MPa 7.5KW 100MM 80MM 60-1 22m3/h 0.6MPa 11KW 125MM 100MM 60-2 22m3/h 1.2MPa 15KW 125MM 100MM 70-1 38m3/h 0.6MPa 11KW 150MM 125MM 70-2 38m3/h 1.2MPa 18.5KW 150MM 125MM 85-1 56m3/h 0.6MPa 15KW 150MM 150MM 85-2 56m3/h 1.2MPa 30KW 150MM 150MM 105-1 100m3/h 0.6MPa 30KW 200MM 200MM 105-2 100m3/h 1.2MPa 55KW 200MM 200MM 135-1 150m3/h 0.6MPa 45KW 250MM 250MM 135-2 150m3/h 1.2MPa 90KW 250MM 250MM

Twin screw pump, screw pump price, progressive cavity pump (Alibaba trade assurance and TOP supplier) Twin screw pump, also called f ood grade screw mud pump , mono screw pump are widely applied in the beverage, food, dairy, pharmaceutical, chemical and process industries , to transport thick liquid material . Product Features: 1) Material: SUS304/ SUS 316L 2) Flow rate: 0.5-60m3/h 3) Max Pressure: 18 bar 4) Speed: 720-1400rpm 5) Power: 0.37kw-15kw 6) Voltage: 220V/380V/415V/440V, can be customized 7) Temperature range: -20~+180 degree 8) Inlet & Outlet size: can be customized 9) Can add hopper Factory Scale: 1) Located in: Wenzhou, Zhejiang 2) Factory Area: 5000SQ. M 3) Employees: 37 4) Production Ability: 100 Pieces/M jacketed tank Advantages: 1) Certificates: CE ,ISO, 3A 2) Warranty: 12 months 3) OEM/ODM: can design, exploitation and manufacture by CAD software and drawing.

Wenzhou Johames Technology Co.,Ltd mainly manufacture and export industrial pumps with good reputation around home and abroad. Product is exported to Europe, North America, South America, Asia, Africa, more than 45 countries and regions.

mission magnum, mission 2500 supreme, mcm250 centrifugal pump, mechanical seal, demco butterfly valve, kemper hammerseal union, varco tong dies, demco mud gate valve and oteco pressure gauge

Kunming Kunshui Industrial Pump Co., Ltd("Kunshui pump" for short) is a professional manufacturer of pump specialized in manufacturing slurry pumps with more than10 years experience in China.

GREENTECH was founded in 2000, The company is professional blower and vacuum pump manufacturer specializing in producing and supplying full range of 2BV and 2BE series liquid ring vacuum pump, vacuum compressor etc.

air operated diaphragm pump,including metal and non-metal series, widely applied in chemical, paints & coatings, food processing, pharmaceutical, construction, mining, utilities, pulp & paper, metal finishing

BLDC PUMP produces excellent small electric DC water pumps for cooling, circulation system in the various device, for fish tank aquarium, small fountains and other applications. We are a magnetic DC water pump manufacturer located in Shenzhen of China.

Shanghai Shenbao Industrial Pump Co., Ltd. is located in Minhang Development Zone in Shanghai, occupying an area of over 45,000sq.m .Shenbao has become a multi-industry enterprise and specialist in research and manufacture pump...

Slurry pumps, Vertical slurry pumps, slurry pumps, Gravel sand pumps, Dredging pumps, Paper pulp pumps, Molten Salt Pumps, End suction pumps, Double suction pumps, Multistage pumps, Boiler feed water pumps...

Wuhan EvenWall Machinery Co., Ltd. specialized in even wall thickness stator and hollow rotor for progressive cavity pump, even wall thickness stator for mineral oil transportation(artificial lift), multi lobe power section for downhole drilling motor(mud motor).

Shijiazhuang Jiurun Pump Co., Ltd is a pump engineering, manufacturing and distribution company for industrial, municipal and dewatering applications. With over 60 years’ expertise, we have developed great reputation by serving the mining, power, metallurgy, dredging, petroleum

we are a professional pump manufacturer in China with many years experience. We mainly produce slurry pump, spare parts and OEM wear resistance casting.

APK, A Pump that Keeps water moving, is the brand name of Zhengzhou Shenlong Pump Industry Co., Ltd. APK Submersible pumps is short as APK Pump. We are a large scale submersible pump manufacturer officially registered on Apr 25, 1996. Our factory is in Henan Province

Weifang Subtor Rotating Precision Machinery Co. was founded in China as an expansion project by Subtor Germany, a professional enterprise with a focus on the research and development and manufacturing of pumps based on the principle of the Mono. We also produce related pump components to round off our catalog.

Progressive cavity pumps, downhole progressive cavity pumps, directional drilling mud motor power sections, progressive cavity pump grinder macerators, progressive cavity pump connecting rods, and other related spare parts. The pump bodies of our progressive cavity pumps are all custom designed to meet the various application needs of customers in different industries.

Subtor was established in November 2013, our Chinese factory covers an area of more than 6000 square meters and is staffed by 85 dedicated employees, including 15 developers. We also have 3 experts from the China Screw Pump Association on our payroll as technical advisors. In addition, we collaborate with Lanzhou University of Technology for the development of new products.

GNG series Progressive cavity pump is also called single screw pump. The Progressive cavity pump consists of helical rotor turning inside a helical stator. When the rotor turns inside the stator, the honeycomb progresses spirally along the axis of the pump without changing either shape or volume. This action transfers the material from the pump intake to the pump discharge without degrading the product. So the GNG series Progressive cavity pump is an ideal pump for feeding decanter centrifuges.

The GNG series pump Progressive cavity pump body and transmission parts are designed according to the maximum load of 6 bar pressure. The pump has many features include: stronger strength, durable, safe and reliable. The flow and head of the pump fully meet the requirements of sludge transportation and dosing. Moreover it fully meet the stable and unmanned long-term operation.

The pump stator rubber of the GNG series Progressive cavity pump is firmly combined with the outer casing. There are no seams, pores or cracks in the working face. The stator is made of SBBPF or other required material. The design normal working life is not less than 10,000 hours under the specified working conditions. The stator feed end is funnel-shaped, which is conducive for full flow of material.

Depends on different material and application, the pump rotor can be stainless steel or hard alloy material with special treatment to make it anti abrasion as well as corrosion resistant.

The gear reducer selected for GNG series pump is compact and integrated with the motor. The motor is suitable for 380V/460V or any customized power supply. It is completely suitable for 10-60Hz range regulation.

Lake Petro provides high quality Mud Pump Parts including Mud Pump Liners, Mud Pump Fluid End Module, piston, Valve and Seat etc. With more than 10 years of experience in the oil and gas industry, we are dedicated to help and support our loyal clients with the most cost-effective and quality Liners and Pistons. We also provide mud pump price and mud pump for sale.

We offer Liners with Ceramic (Zirconia and Aluminium oxide) and Steel (Metal and Bi-metal) materials for all common brands of the mud pump and triplex mud pump.

All Lake Petro liner products are interchangeable with O.E.M. products. Meanwhile, we provide customized Liners according to drawings. Our liners, also with our other mud pump spares, are supplied for use in Honghua, F-Series, Bomco, Emsco and National lines of triplex drilling pumps. Let Lake Petro be your one-stop shop for your whole fleet of pumps. Please refer to “Suitable Pump Models” Lable for more details.

Recently, efforts have been made to develop pumps capable of handling multiphase fluids. However, results indicate that most types of pumps are restricted by their inability to automatically adjust to rapidly fluctuating gas-to-liquid ratios. They can’t handle sand or other solids in suspension or efficiently pump fluids with varying API gravities. Many have a tendency to emulsify the fluid making separation much more difficult.

Prompted by a market need for a more efficient multiphase fluid transfer solution, Moyno, Inc. developed the breakthrough Moyno Tri-Phaze® System. Its patented progressing cavity design effectively pumps oil, gas and water from the wellsite or satellite through a single pipeline to a remote processing station without degradation or emulsification of the fluids. It effectively transfers multiphase flows up to 80,000 BPD and differential pressures up to 1,350 psi.

The progressing cavity design consists of a single-threaded, external helix (rotor) turning within a double-threaded internal helix (stator). As the rotor turns within the stator, cavities are formed that progress from the suction to the discharge end of the pump. The fluid flows in a spiral path through the pump not far removed from a straight line. The resulting low shear pumping action will not emulsify the oil and water phases, therefore making separation easier at the processing station.

Subtor GmbH, Germany is a private owned company withproduction facilities in Germany, Austria and China. With over 20 years of experience, we design, manufacture & market progressing cavity pumps, using our own rubber formulations, and producing the rotor geometries with our own manufacturing know how. With reliable quality and material, our products are able to constantly meet the utmost technical and qualitative customer demands.

Committed by our Sales & Marketing team in various regions, we strike for excellent service, technical expertise, out-standing quality and satisfied customers with global present. Our comprehensive range offers wide flow capacity, low- to-high pressure, various material combinations of metal and elastomer, providing pumping solutions on each of your applications.

8613371530291

8613371530291