pz 10 mud pump free sample

A wide variety of gardner denver pz 10 mud pump options are available to you, such as 1 year, not available.You can also choose from new, gardner denver pz 10 mud pump,As well as from energy & mining, construction works gardner denver pz 10 mud pump.And whether gardner denver pz 10 mud pump is unavailable, {2}, or {3}.

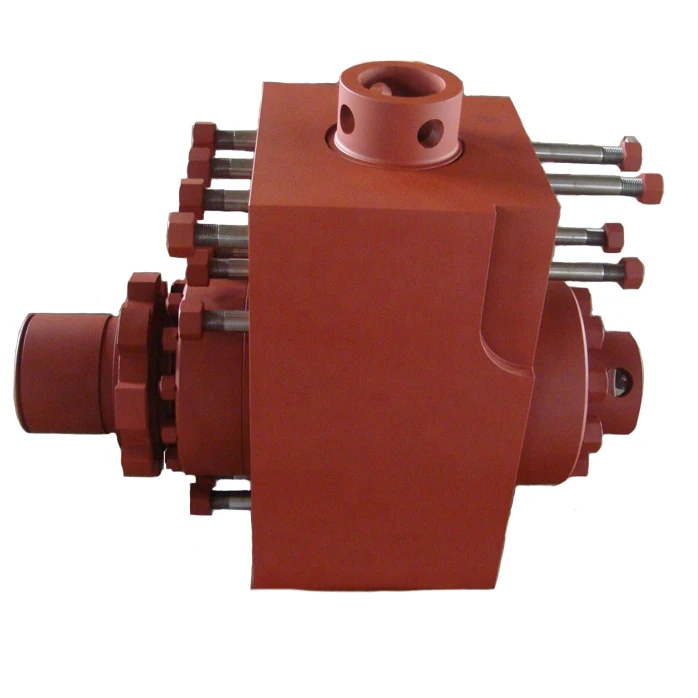

GDEP is the original creator of the drilling pump and continues to set the standard for durable, high-quality drilling pumps that can withstand the world’s toughest drilling environments. Starting with our PZ7 and rounding out with the market"s most popular pump, the PZ1600, our PZ Series of pumps are the perfect choice for today"s high-pressure drilling applications.

Super Bolt Liner Retention SystemInstall a new CDI pressure energized (spring supported) wear plate gasket (GD part # 314PZL316). Install the wear plate Install a new CDI pressure energized liner gasket (GD part # 316PZL316) into the Southwest 1377B liner groove. The Southwest 1377B liner has an effective bore length of 14.625. Insert the liner into the pilot bore, and slide it toward the module until it makes contact with the wear plate. Slide the new LRS liner clamp plate over the liner and onto the studs.

Super Bolt Liner Retention SystemApply a grease-based, molybdenum disulfide, anti-galling compound (Fel-Pro 670, Sweeney 503, or Loctite 51048) to the exposed length of the four corner studs, as well as the load face of the jackbolts and the hardened washer. Install the hardened washer and Superbolt multi-jackbolt tensioner onto each of the two upper studs, outboard corners.

Super Bolt Liner Retention SystemInstall a hardened washer and multi-jackbolt tensioner onto each of the two stud extenders, to hold the compression sleeves in place. Starting with the tensioner at the 10:00 position, back the entire tensioner off 1/4 turn. At the 10:00 position tighten the 3 jackbolts to 55 ft.lbs each, using a torque wrench and a 6-point 5/8 socket.10:00 position (1st)

Super Bolt Liner Retention SystemReturn to the tensioner at the 10:00 position, and tighten the jackbolts to 110 ft.lbs each, using a torque wrench and a 6point 5/8 socket. Repeat at the 5:00 position, then the 7:00 position, and last the 2:00 position. The sequence and cross pattern is important to help ensure that the gaskets are squarely loaded. Check all jackbolts to ensure that they are torqued to at least 110 ft.lbs (do not exceed 125 ft.lbs).

Mud Line ConnectionNote the extremely large nut and extended neck This is a 1003 mis-aligning union. It makes a more Stable connection when pipe is not lined up perfectly

We export-orientated mud pump parts, including liners, pistons, piston inserts, valve inserts, oil seals, rod packing, fluid ends etc.. All of them meet or exceed DIN and API standards and have been exported to U.K., Germany, USA, Canada, Pakistan, Middle East, and so on.

Oilfield bearings include mud pump bearings, turntable bearings, rotary table bearing, tap bearings, crown block bearings, petroleum vehicle bearing, oil refining machinery bearing, industrial pump bearings, etc.

8613371530291

8613371530291