pz 11 mud pump specs brands

The KP-1600 triplex mud pump features a double extended jackshaft carried on heavy duty straight roller bearings and dual roller bearing connecting rods. The main gears bolted to the eccentric are heat treated along with the interchangeable fluid cylinders. The replaceable crosshead slides are bronze and the valve covers are threaded. The KP-1600 includes a complete piston washing system; and a full splash lubrication system with an oil pump, pressure gauge, and replaceable-type oil filter. External electric powered lube pump is optional equipment for secondary lubrication system.

![]()

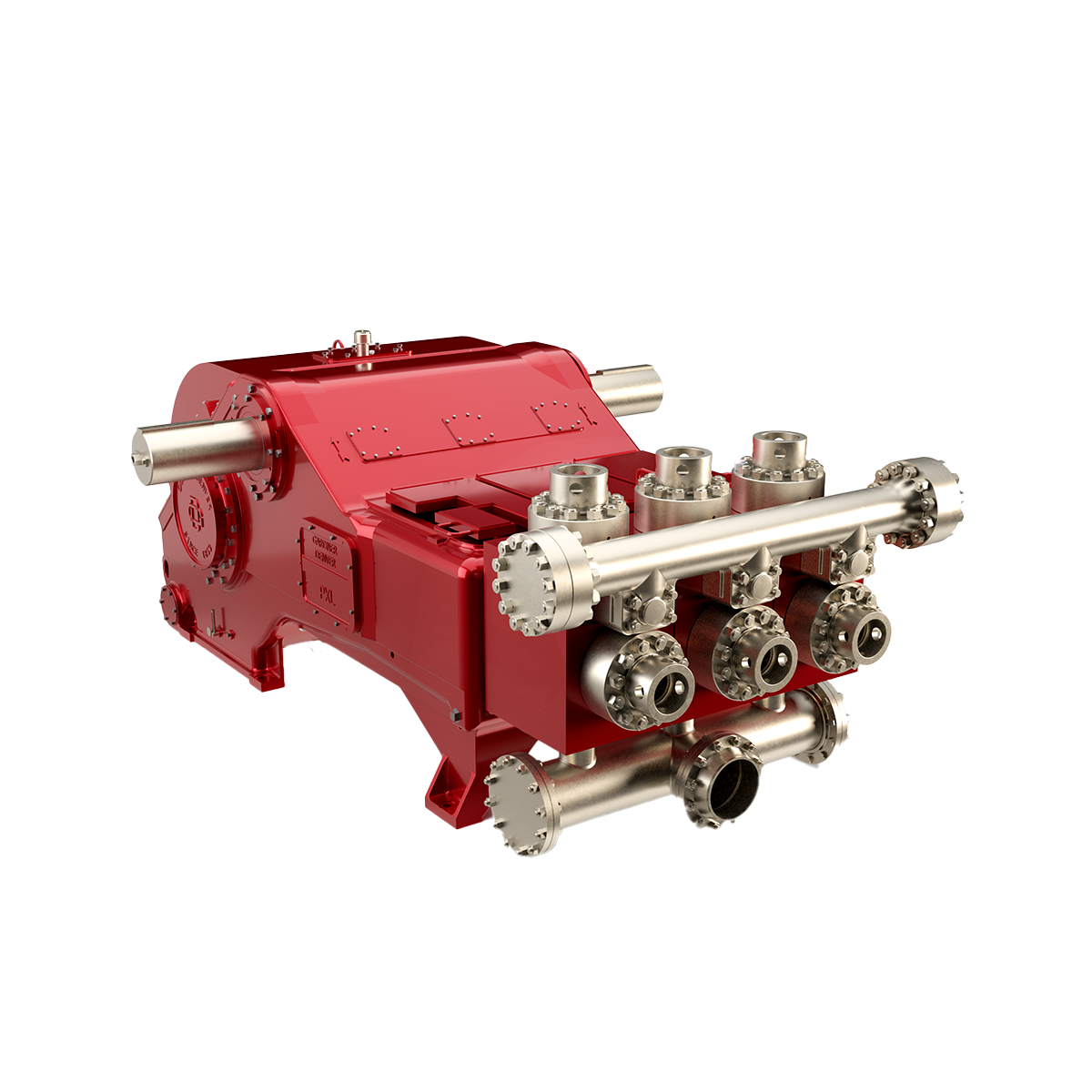

GDEP is the original creator of the drilling pump and continues to set the standard for durable, high-quality drilling pumps that can withstand the world’s toughest drilling environments. Starting with our PZ7 and rounding out with the market"s most popular pump, the PZ1600, our PZ Series of pumps are the perfect choice for today"s high-pressure drilling applications.

![]()

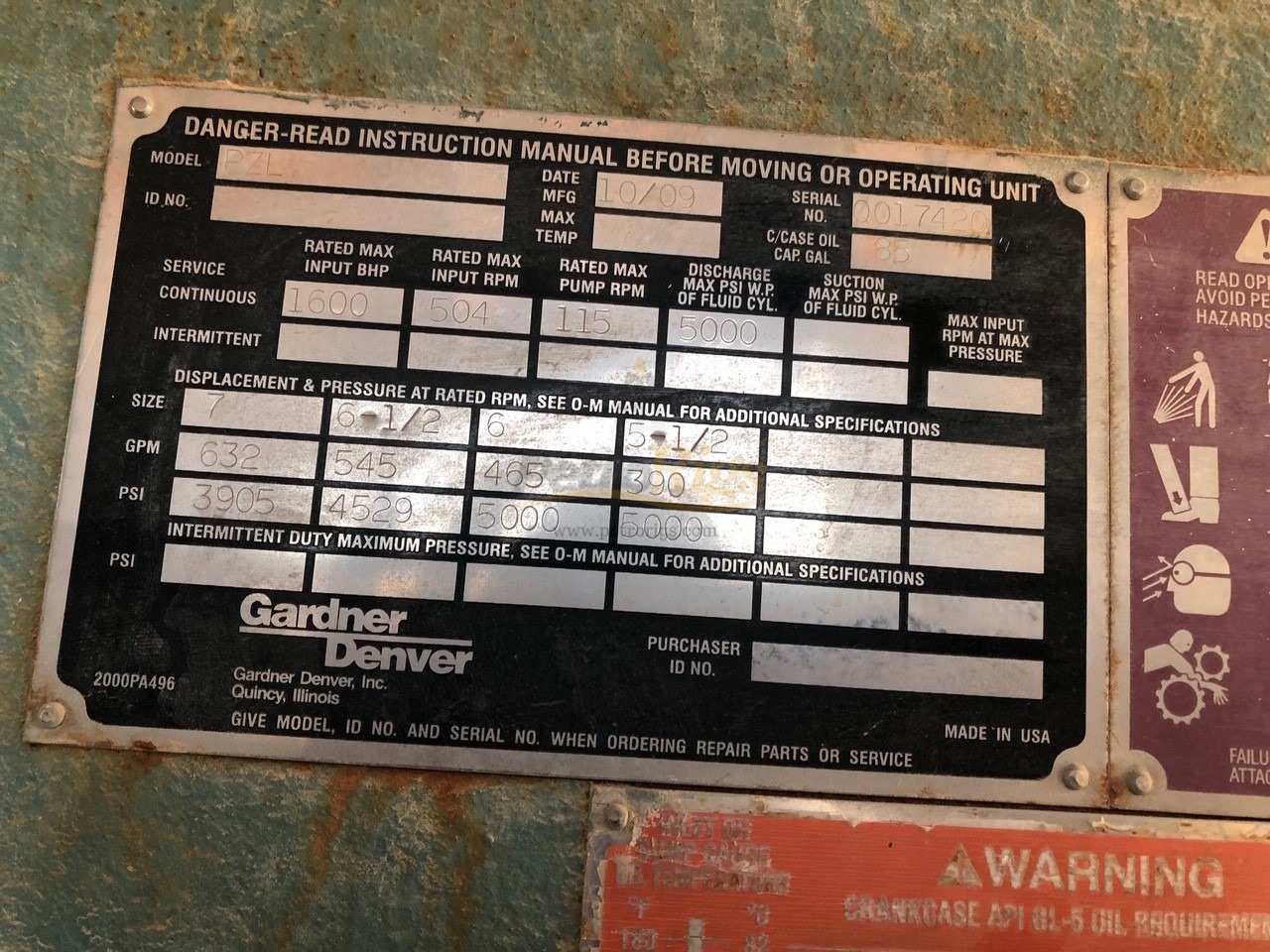

Gardner Denver is a leading manufacturer of petroleum drilling pumps. The quality and performance of their products have contributed in setting the standard for low cost of ownership, reliability, and uptime. One of their most popular products is the Gardner Denver PZ 11, a reciprocating triplex mud pump that is considered a reliable workhorse. The equipment is noted for its robust construction attributed to its cast frame, valve-over-valve fluid ends, and double helix AGMA gears. Despite its power and ruggedness, the PZ 11 is lightweight with a small footprint that makes it appealing to drilling contractors who want to improve their productivity without compromise on long-term value.

Gardner Denver PZ 11 is versatile and can be used with the manufacturer’s latest 6,000 psi drilling module. Its maximum pressure is 5,000 psi, and the maximum flow is at 632 gpm. There are many advantages to its design. For instance, the cast frame reduces stress and extends the lifespan of the frame. The full roller bearing build ensures dependable service, and high-quality gears ensure conformance to AGMA standards. The PZ 11’s power end lube pump is integrated into the build, and the valve-over-valve fluid ends are a single piece, which helps simplify maintenance while providing a more robust and reliable construction.

While you have the option to purchase a brand-new Gardner Denver PZ 11, consider exploring re-manufactured and new units, too. As long as they are sold by established and reputable suppliers, they are likely reliable and in good working condition. Look for a US-based supplier or re-manufactured and new drilling rigs and equipment and make sure it is trusted by both international and domestic drilling contractors. That way, you can be sure that you are buying high-quality equipment from a dependable source that takes time to inspect and service the products they carry before adding them to their inventory.

You can possibly save some money by choosing a remanufactured or used Gardner Denver PZ 11, but be sure to inspect the specifications and verify where and how it was used. Compare prices to see if you can get the best value for your money with used equipment. Remanufactured mud pumps can be delivered straight to your work site and they will be ready to use.

A mud pump (sometimes referred to as a mud drilling pump or drilling mud pump), is a reciprocating piston/plunger pump designed to circulate drilling fluid under high pressure (up to 7,500 psi or 52,000 kPa) down the drill string and back up the annulus. A mud pump is an important part of the equipment used for oil well drilling and manufactured according to API specification 7K.

The advantages of the drilling mud pump include the ability to move high-solids-content fluids laden with abrasives, the ability to pump large particles, ease of operation and maintenance, reliability, and the ability to operate over a wide range of pressures and flow rates by changing the diameter of pump liners and pistons.

As an important equipment for oilfield drilling operation, a drilling mud pump delivers circulating high-pressure drilling fluid or drilling mud to the bottom of the oil well, flushes the bottom of the well, breaks the rock, cools, lubricates and clean the drill bit, and carries the cuttings back to the ground.

The drilling mud is also used to suspend and carry out drill cuttings from the drill bits as it is brought in and out of the hole. This ensures that the drill bit does not clog and overheat, and makes the entire drilling operation smooth and safe.

Rotational power is supplied to the mud pump through an external power source like a diesel engine or electric motor. The power end of the mud pump converts the rotational energy through a crankshaft to a reciprocating motion of pistons.

The pistons move back and forth in mud pump liners, exerting a force on the cylinder chamber. During the retraction of the piston, valves open to allow the fluid to be drawn into the cylinder. Once the piston has fully retracted, it is pushed back into the cylinder.

TR provides high quality Mud Pump replacement parts including Mud Pump Liners, Mud Pump Fluid End Module, piston, Valve & Seat etc. We are dedicated to assisting worldwide clients with most cost-effective and quality guaranteed mud pump liners, pistons and other mud pump replacement parts. Reducing the mud pump production cost is our priority so that significant saving can be achieved for our valuable clients and end users.

TR liners offer both ceramic mud pump liners and high-chrome mud pump liners (bimetal liner) with excellent resistance to abrasion, erosion and corrosion for most mud pumps in worldwide. Advanced anti-wear measures are adopted and highest-grade materials are selected in our mud pump liners production to increase their service life, which can reduce our clients’ investment cost of the project, and improve their production efficiency.Replacement Mud Pump Liners for Gardner Denver PZ 6/7/8/9/10/11

TR provides a wide series mud pump liners for all major brand mud pumps. We also offer custom design-built service per our clients’ drawings and specifications

TR also offers high quality replacement parts for all major brand mud pumps including valve module, piston/extension rods, pistons, valves and seats etc.

8613371530291

8613371530291