remanufactured replace mud pump motor pricelist

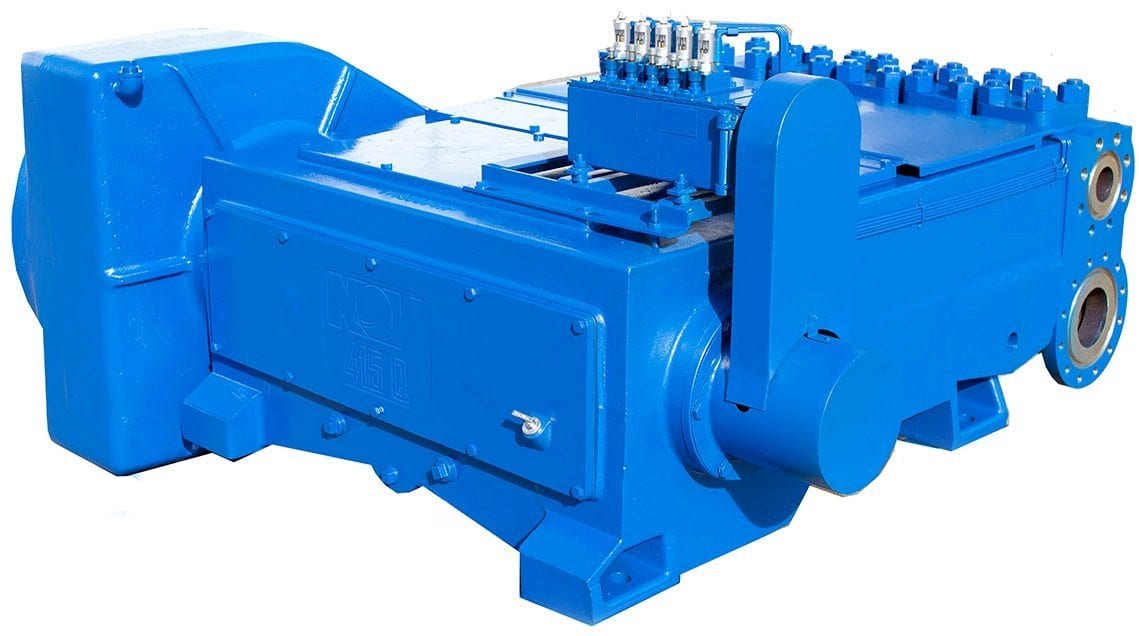

A mud pump is a reciprocating piston/plunger pump designed to circulate drilling fluid under high pressure (up to 7,500 psi (52,000 kPa)) down the drill string and back up the annulus. A duplex mud pump is an important part of the equipment used for oil well drilling.

Duplex mud pumps (two piston/plungers) have generally been replaced by the triplex pump, but are still common in developing countries. Two later developments are the hex pump with six vertical pistons/plungers, and various quintuplex’s with five horizontal piston/plungers. The advantages that Duplex mud pumps have over convention triplex pumps is a lower mud noise which assists with better Measurement while drilling and Logging while drilling decoding.

Use duplex mud pumps to make sure that the circulation of the mud being drilled or the supply of liquid reaches the bottom of the well from the mud cleaning system. Despite being older technology than the triplex mud pump, the duplex mud pumps can use either electricity or diesel, and maintenance is easy due to their binocular floating seals and safety valves.

A mud pump is composed of many parts including mud pump liner, mud pump piston, modules, hydraulic seat pullers, and other parts. Parts of a mud pump:housing itself

Duplex pumps are used to provide a secondary means of fuel transfer in the event of a failure of the primary pump. Each pump in a duplex set is sized to meet the full flow requirements of the system. Pump controllers can be set for any of the following common operating modes:Lead / Lag (Primary / Secondary): The lead (primary) pump is selected by the user and the lag (secondary pump operates when a failure of the primary pump is detected.

Alternating: Operates per Lead / Lag (Primary / Secondary) except that the operating pump and lead / lag status alternate on consecutive starts. A variation is to alternate the pumps based on the operating time (hour meter) of the lead pump.

Ideco is one of the parts of a mud pump that is complete with high quality parts. This is a name that is a leading manufacturer of high quality parts of the fluid end such as the following:Modules

The Ideco pumps allow an addition in the quality trading of the replacements parts of the mud pumps and their parts that also take into account the following varieties such as:Centrifugal pumps

All of the above mentioned ingredients are found in the market and are available for better oil drilling and extraction. There are more than 1000000 varieties of inter changeable mud pump constituents and all the previously mentioned types like centrifugal pumps, parts of a rig and swivel components for the majority of the manufacturers and this includes Ideco. Their components include:Duplex pump spares

Parts of Ideco are provided with a full series of pistons for the triplex as well as duplex mud pumps. This is done for ensuring their popularity among the customers. All the manufacturers of the mud pumps and their parts make sure or try to make sure that their products and constituents are made under the certification of the American Petroleum Institute, the API. Some of them include:Bonded rubber pistons

The Bonded premium urethane piston is a single piece bonded constructed piston that does not have any joints which guarantees the prevention of leaking. The Ideco components like these eliminate the possibility of the abrasive fluids to accumulate between the liner and the piston. The expanded lip of the fluid is not damaged by faster strokes of the pump or high pressure actions. It is a fail proof piston that seals off to increased diameters as the liner keep wearing.

Parts of the mud pump like the pistons with replacement rubbers are currently running for drilling mud in the highest of pressures. It has a bonded construction as well as build without using leakage and joints. The longer size of the piston helps in guaranteeing the longevity of the equipment. The Ideco component helps the piston to function in higher pressure for ensuring a faster stroke. It is additionally resistant to the mud of the oil base as well as other additives that are put to use.

Pistons with replacement rubbers are actually the premium Ideco pistons or mud pump parts that have been serving the industry for a number of years with excellent and unparalleled performance records to suit extreme drilling conditions. This is a single piece bonded unit that has a number of benefits as it is impermeable to different kinds of chemicals as well as other kinds of oil.

With our experience vast pool of resources and dedication to excellent customer service, we will go to the extra mile to confidently fulfill all of your pumping and equipment needs. One of our most important goals is to set the standard for great customer service. No matter if you need a seal, a gasket, or a complete new pump. We"ll treat you the same, with professional courtesy, throughout the sales process. Here"s a couple of testimonials from our customers.

14 P-220 Mud Pumps 3 available completely overhauled. The pumps have been machine inspected and all data will be provided. These 2200 HP pumps complete with Southwest fluid end modules which have been reworked and pressure tested by Southwest and P-QUIP liner retention systems. The drives can be set up for AC or DC power. All Master Rig equipment meets or exceeds O.E.M. standards and a complete data pack is furnished with purchase. Please call if you have any questions.

READY TO SHIP - Three (3) completely refurbished 1600 HP Continental Emsco 7500 PSI Mud Pump Packages - liner spray system, suction manifold and dampener, discharge strainer cross, reset relief valve, 20 gallon pulsation dampener, 75 HP charge pump, two (2) GE 752 1000 HP rear mounted motors, 10 HP blower, mounted on a 3 runner skid with loading hitches and much more. Units come with complete data books and have been tested. MRI is a API facility and units comply with API standards.

Duplex mud pump package completely refurbished and never operated. Tri-Services Manufacturing TSM-500 pump, CAT engine. Data book provided with complete refurbishment details.

Mud Pumps come in both electric and gas / diesel engine drive along with air motors. Most of these pumps for mud, trash and sludge or other high solids content liquid dewatering, honey wagon and pumper trucks. Slurry and mud pumps are often diaphragm type pumps but also include centrifugal trash and submersible non-clog styles.

WARNING: Do not use in explosive atmosphere or for pumping volatile flammable liquids. Do not throttle or restrict the discharge. Recommend short lengths of discharge hose since a diaphragm mud pump is a positive displacement type and they are not built with relief valves.

Welcome to Pickett Oilfield’s mud pumps web page. Our company has been in the oil & gas drilling equipment industry for over 38 years, supplying new and used mud pumps and mud pump parts to customers in practically every producing region in the world. We are here to serve all your drilling equipment needs – if you don’t see it on this site, just give us a call or email. We can get it, if you need it!

Pickett Oilfield, LLC offers prospective buyers and extensive selection of quality new and used oil & gas drilling equipment, including mud pumps and parts to choose from at competitive prices. Browse our inventory of mud pumps and mud pump parts for sale at competitive rates.For more information or to request a quote, please Contact Us at 936-336-5154 or email to Sales@PickettOilfield.com.

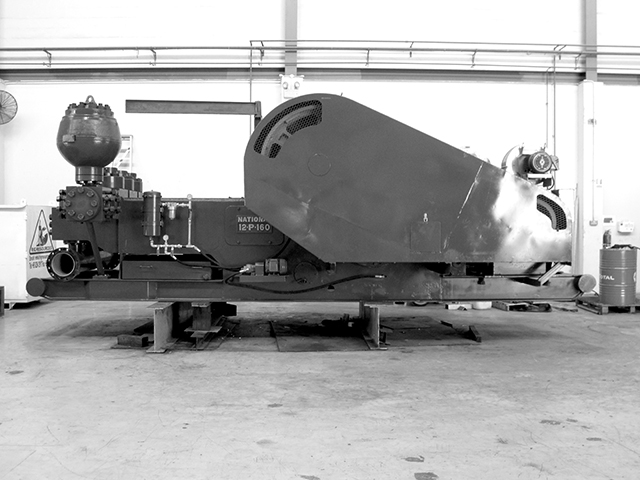

You are viewing three (3) fully reconditioned National Oilwell 12P160 Triplex Mud Pumps for sale by Pickett Oilfield, LLC. These National 12-P-160 Mud Pumps are Rebuilt and Ready to go to work.

Some refurbishments include: Fully reconditioned mud pump assembly. Pinion shaft assembly complete with new SKF bearings and new seals. Pump internals painted with Oil Resistant 2 Part epoxy Jotun Tank guard. MPI inspection of all critical areas of pump frame. MPI of all load path components of Crankshaft and Pinion shaft assemblies, and all new Southwest Premium “L” Shape 6,000 psi Fluid End Modules. A full Data Pack with all dimensional control & MPI reports will be furnished.

Warranty on National 12-P-160 Triplex Mud Pumps: All new parts fitted come with a 12 month warranty or such as offered by the part manufacturer; The refurbished GE-752 traction motors come with an 18 month warranty.

Pickett Oilfield, LLC offers prospective buyers an extensive selection of quality new, used, and refurbished Oilfield Drilling Equipment at competitive prices, including Triplex Mud pumps.

Do you have a pump that is starting to vibrate and lose efficiency, but cannot be taken offline because production must continue and the pump does not have an installed spare? PumpWorks may have a custom solution. In this situation, we may have a duplicate pump that can be remanufactured from our inventory. Once complete there is minimum downtime while the pumps are exchanged. Your pump can then be remanufactured as a warehouse spare or added to PumpWorks’ inventory for credit. This may also be a great time to perform a hydraulic rerate to dial your pump into the exact performance your process now requires.

You have a new project upcoming and several decommissioned/surplus pumps. Perhaps PumpWorks can remanufacture and rerate your existing pumps for the new project. If the pumps cannot be rerated to fit the new project, PumpWorks may be interested in purchasing them for our inventory. In this scenario, a credit equal to the surplus-value of your pumps may be applied towards the purchase of a remanufactured pump from our inventory.

PumpWorks will custom engineer the skid footprint and nozzle heights of a newly remanufactured pump to fit your current foundations and piping centerline heights. Truly a custom solution.

Does the project require changing one or several pumps at a station or at multiple stations on a line? PumpWorks may have an identical pump in inventory that can be remanufactured and rerated to match the new requirement. This pump can be exchanged for one of the existing pumps which could then be overhauled and rerated. This process can then be repeated down the line. At the end of the process, there will be an extra pump that can be rerated as warehouse spare or can be returned to PumpWorks inventory for credit. This will help eliminate downtime during project execution.

Do you have an obsolete pump with no spares? PumpWorks can overhaul that pump and collect all the critical data to produce a full set of spares, drawings, and parts. Your pump can be returned to service on an expedited turnaround and PumpWorks can then manufacture anything you need including a complete spare rotating element.

Everyone has a bad actor. That pump that does not perform to the curve, runs hot, vibrates, or continues to fail prematurely. Is it the pump? The operational parameters? The installation? Let PumpWorks test that pump with our motor on our fully automated and instrumented test stand as an unbiased third party. We can help you identify the source of the problem. If the problem is the pump, we can propose a repair, upgrade, or rerate while the pump is in our facility. If the problem is the installation, our field service team can provide a variety of solutions including field machining of your existing skid.

A mud pump is a reciprocating piston or plunger device designed to pump drilling fluid under high pressures and volumes down the drill string of a drilling rig. The main functions of drilling fluid are to provide hydrostatic pressure to prevent formation fluids from entering and to stabilize the bore, to keep the drill bit cool and clean, to carry drill cuttings back out to the surface, and to suspend the drill cuttings while drilling is paused or during the pullback process.

Mud pumps consist of two main sub-assemblies- the fluid end and the power end. The fluid end performs the pumping process with valves, pistons, and liners, or plungers and stuffing boxes- depending upon the type used. These components are considered expendables, and are designed to be easily replaced in the field. The power end contains the eccentric or crankshaft, along with the connecting rods, and cross heads/slides.

Tulsa Triplex is a Tulsa Rig Iron company. We manufacture pumps from 100 to 600 horsepower that are designed to be easily maintained and are capable of being completely rebuilt. Our pumps feature a smaller footprint and lighter weight than competing models, making them completely legal load size and weight in most instances. They are available as a bare pump, with chainbox, or a complete skidded package.

Take a look at our newly rebuilt RS-F1600 Triplex Mud Pump powered by dual 1,000-HP Joliet traction motors. This unit is mounted on an oilfield type three runner skid and unitized with the following equipment:

triplex mud pumps and triplex mud pump parts meet the industry standards established by the American Petroleum Institute (API). As a global supplier of quality oilfield equipment to the oil and gas industry, we ship our products around the world.

Besides triplex mud pumps and triplex mud pump parts, we supply drilling rigs, workover rigs, top drives, drilling equipment, blowout preventers, BOP control systems, choke and kill manifolds, well service pumps for well cementing and hydraulic fracturing, wellhead equipment, casing heads, tubing heads, X-mas trees, FC type gate valves, etc. Please visit our company website

We supply unitized mud pump packages driven by DC or AC electric motors or diesel engines for electric and mechanical drilling rigs. The client can select DC or AC motors and diesel engine brands such as Caterpillar, Detroit, Cummins or others. Our unitized mud pump packages including everything on the skid and usually they are ready to work at delivery.

8613371530291

8613371530291