rod bearing for mud pump in stock

A wide variety of mud pump connecting rod options are available to you, such as 1 year, 2 years.You can also choose from new, mud pump connecting rod,As well as from energy & mining, construction works , and machinery repair shops. and whether mud pump connecting rod is 6 months, unavailable, or 3 months.

ShanDong LongRoll Spare Parts Co., Ltd. is dedicated to supplying industrial bearings and replacement components for countless industry applications, especially for automotive aftermarket, mineral processing industry, petroleum explore industry. More than 90% of our business is export, so we know very well about the exporting and market positioning. That enables any of our users to find the right products from us for their target market.

Furthermore, the company is very focused on its reputation, therefore, the products are all manufactured under rigorous quality control standard and comprehensive testing procedure.

Permian Pump & Power stocks and sources OEM and aftermarket power end parts for most major power pump brands. If we don’t have the parts on the shelf, here in Odessa Texas, we can source them through other vendors in our vast network of suppliers nationwide.

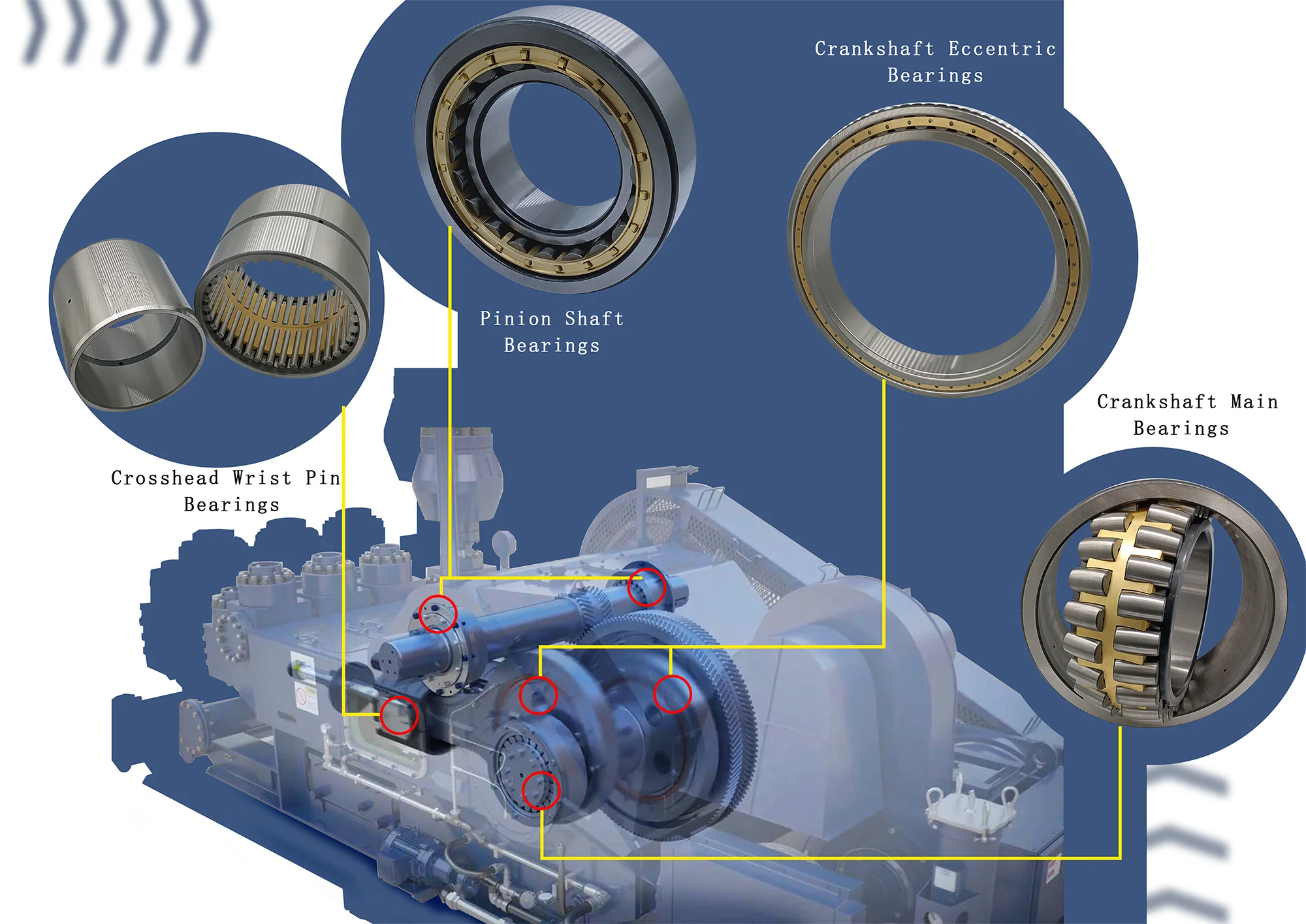

PPP offers most used, rebuilt and new power end pump parts for sale, including main bearings, rod bearings, crankshafts, wrist pins, bushings, connecting rods and seals and gaskets.

Power Frame - Power End - Crankcase - Gasket - Seal - Cap Screw - Air Breather - Stud - Nut - Oil Gauge - Drain Plug - Bearing Cup - Bearing Cone - Roller Bearing - Bearing Housing - Shim Kit - Crosshead - Crosshead Bushing - Wiper Box - Connecting Rod - Power End Gasket Kit - Connecting Rod Bearing - Crankcase Cover - Power End Adaptor - Gear Reducer - Integral Gearbox

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

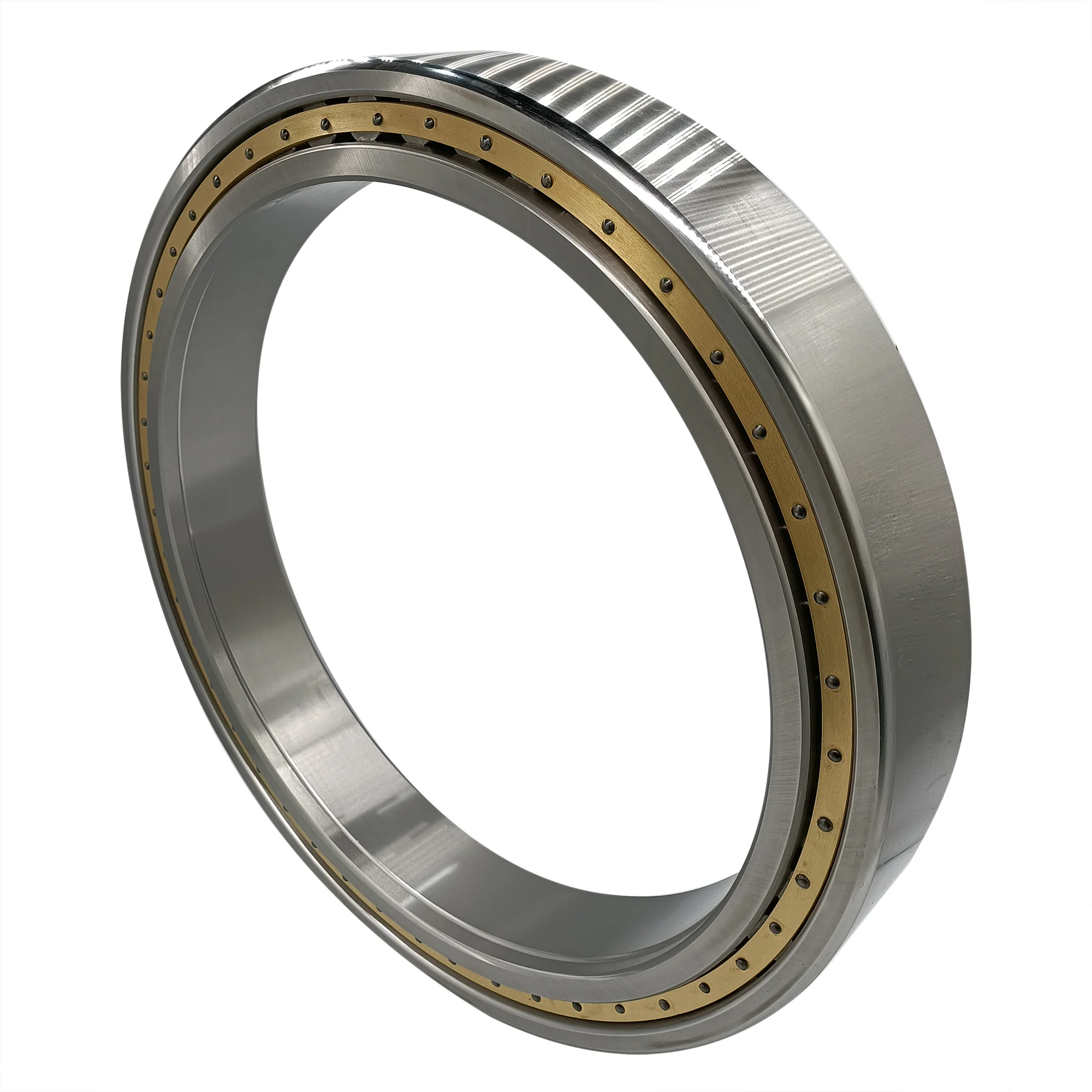

Single row cylindrical roller bearings with cage consists of inner ring ,outer rings ,cylindrical roller and cage . The outer rings have rigid ribs on both sides or no ribs, the inner rings have one or two rigid ribs or are designed without ribs. The cage prevents cylindrical rollers from coming into contact with each other during rolling.

The cylindrical roller bearings with cage have high rigidity, it can withstand high radial load ,and due to the cage, this kind of bearing are more suitable for higher speeds compared to full complement designs. Bearings with the suffix E have a higher load capacity through internal design optimization , and are suitable for higher load carrying capacity working situation.

A: First we discuss order details, production details. Then we issue you an PI for your confirmation. You will be requested to do pr-e paid full payment or deposit before we go into production. After we get the deposit, we start to process the order. We usually need 15-25 days if we don"t have the items in stock. Before production has been finished, we will contact you for shipment details, and the balance payment. After payment has been settled, we start to prepare the shipment for you.

The Liberty Process LL8 Progressive Cavity Pump is ideal for abrasive pumping applications such as drilling fluids with sand and grit common in fracking operations. As a Mud Pump, the LL8 Series is a popular model on many mobile pumping rigs in use today. Replacement mud pump parts are available as well from our stock and work on other popular manufacturers models.

The Liberty LL8 is a standard flanged pump design manufactured with cast iron or 316 stainless steel pump casings designed in 1, 2, and 3 stages for 75, 150 and 225 psi discharge pressures and a flow rate of 18 up to 100 GPM.

The LL8 is a modular design with simple hardened pinned joint drive assembly. LL8 Rotors are typically hardened tool steel or 316 stainless steel with a hard chrome plating for long life in abrasive pumping applications.

All other wetted parts are either carbon steel or 316 stainless steel. Stators are available in many elastomer materials such as Buna Nitrile, Natural Rubber, EPDM and Viton. The standard seal design is a set of gland packing with a lantern ring set and flush connections. Mechanical seal options for this progressive cavity pump are readily available.

The LL8 represents one of the most popular progressive cavity pumps available for the transport of drilling mud with easily replaceable in-stock parts.

A mud pump (sometimes referred to as a mud drilling pump or drilling mud pump), is a reciprocating piston/plunger pump designed to circulate drilling fluid under high pressure (up to 7,500 psi or 52,000 kPa) down the drill string and back up the annulus. A mud pump is an important part of the equipment used for oil well drilling and manufactured according to API specification 7K.

The advantages of the drilling mud pump include the ability to move high-solids-content fluids laden with abrasives, the ability to pump large particles, ease of operation and maintenance, reliability, and the ability to operate over a wide range of pressures and flow rates by changing the diameter of pump liners and pistons.

The fluid end includes cylinders (module), valve assembly, cylinder liners, piston assembly, suction manifold, discharge manifold, piston rod, pulsation dampener assembly, etc.

As an important equipment for oilfield drilling operation, a drilling mud pump delivers circulating high-pressure drilling fluid or drilling mud to the bottom of the oil well, flushes the bottom of the well, breaks the rock, cools, lubricates and clean the drill bit, and carries the cuttings back to the ground.

The drilling mud is also used to suspend and carry out drill cuttings from the drill bits as it is brought in and out of the hole. This ensures that the drill bit does not clog and overheat, and makes the entire drilling operation smooth and safe.

Rotational power is supplied to the mud pump through an external power source like a diesel engine or electric motor. The power end of the mud pump converts the rotational energy through a crankshaft to a reciprocating motion of pistons.

The pistons move back and forth in mud pump liners, exerting a force on the cylinder chamber. During the retraction of the piston, valves open to allow the fluid to be drawn into the cylinder. Once the piston has fully retracted, it is pushed back into the cylinder.

At this time the intake valves are closed and the exhaust valves open, allowing the piston to force the fluid out of the cylinder under pressure. Once the piston reaches its maximum depth into the cylinder, the exhaust valves close and the process repeats.

For Fluid End: piston rod clamp, piston rod, piston assembly, cylinder cover, liner, liner flange, wear plate, cylinder, valve assembly, valve cover, valve guide, flashboard assy., cylinder cover flange, cylinder head, gaskets, studs, nuts, seal rings, pulsation dampener, bladder, discharge manifold, suction manifold, etc.

2022 Vermeer® High-Pressure Mud Pumps SA400The SA400 is a high-pressure mud pump powered by a Tier 4i (EU Stage IIIB) or Tier 3 (EU Stage IIIA) engine.

The SA400 is a high-pressure mud pump powered by a Tier 4i (EU Stage IIIB) or Tier 3 (EU Stage IIIA) engine. It features an engine-mounted lubrication pump to provide constant flow through the system at any pump speed. During drill rod makeup/breakout, a clutch with continuous duty throw-out bearing allows extended clutch disengagement and a suction inlet valve suspends charged flow.

Features may include:Remote pendant controlA remote pendant control allows the operator to place control where it makes sense for them.Light shieldingThe SA400 features light shielding – each panel weighs less than 50 lb (22.8 kg) – making maintenance a one-person task.Liner wash tankA liner wash tank integrated into the machine’s design eliminates the need for extra water containers or electricity when running the pump.

8613371530291

8613371530291