rod bearing for mud pump quotation

A wide variety of mud pump connecting rod options are available to you, such as 1 year, 2 years.You can also choose from new, mud pump connecting rod,As well as from energy & mining, construction works , and machinery repair shops. and whether mud pump connecting rod is 6 months, unavailable, or 3 months.

Among all the other bearings that people use in various applications in daily lives, rolling element bearings are one of the most common types of bearing that can be found practically anywhere. Rolling element bearings can be found in a great variety of applications, including automobiles, household appliances, industrial applications, and among many types of office equipment. Ball bearings are one of the two main categories of rolling element bearings, and they are widely used in skateboard bearings and various types of bearings for cars. Roller skate bearings, along with bearings used on other household items such as bicycles and washing machines, are among the most popular bearings on the market.

Another type of rolling-element bearing is the roller bearing, which is classified into three main types: spherical roller bearings, cylindrical roller bearings, and tapered roller bearings. Spherical roller bearings can be mostly found among the construction and a variety of paper and maritime industry equipment, whereas cylindrical roller bearings are used in a variety of heavy-duty machinery applications. Tapered roller bearings, on the other hand, are commonly used in vehicle wheels and for a variety of heavy-duty applications. Needle roller bearings, often known as needle bearings, are another type of roller bearing that is widely utilized in automobile components. Because of its small size, it can be used for a variety of small tasks.

p>Now is the time to go through Alibaba.com"s wholesale mud pump bearing listings to see what are the options available! And, of course, don"t forget to check out exceptional deals with large savings among the numerous promotions that various bearing suppliers provide from time to time. Take action now and shop for mud pump bearing right here!

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Jun272016CROSSHEAD BEARING (PART NO - 202-2195) (MAT CODE - 210008820) (SPARES OF WHITE STAR MAKE MUD PUMPS)United StatesNhava Sheva SeaNOS4588,786147,197

F-Series pumps are rated at long stroke length and relatively low strokes per minute, thus they improve the suction performance and increase the service life of the expendable parts on the fluid end.

Our F-Series Mud Pumps feature an advanced and durable design with interchangeable suction and discharge valves, and dual lubrication system.◆Features

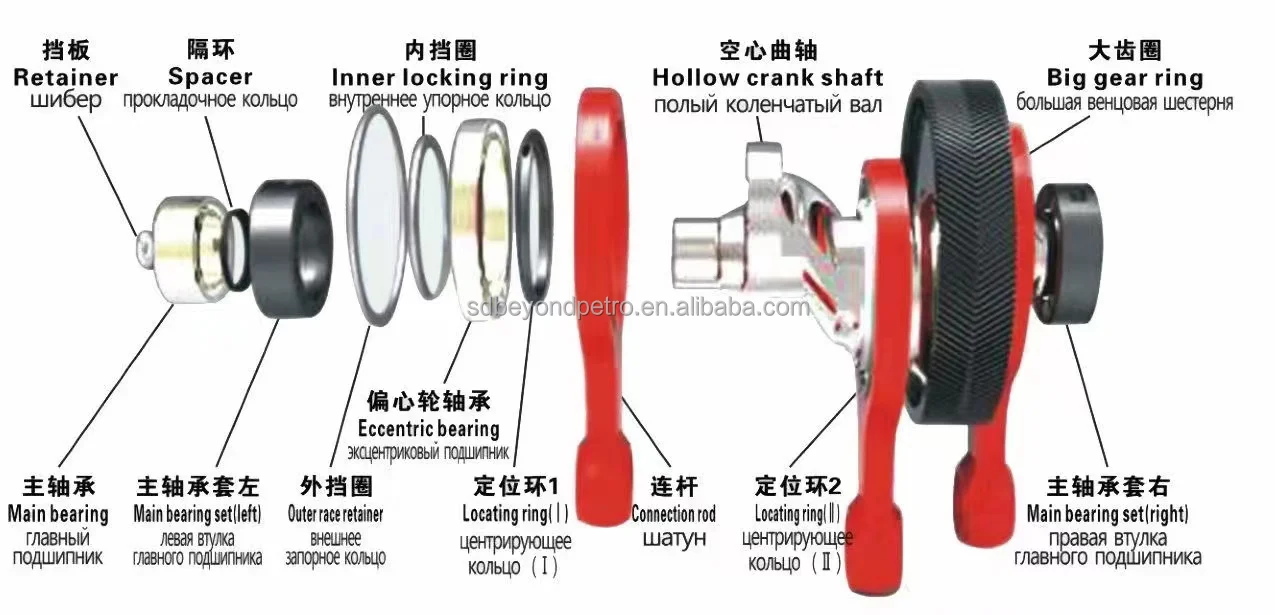

The crankshaft, a casted alloy steel eccentric shaft, is furnished with herringbone ring gear, connection rods and bearings. The ring gear bore and the crankshaft surface is of interference fit and fastened with bolts and lock nuts.The big end of each connection rod is mounted on each eccentric strap of the crankshaft via the single row short cylindrical roller bearing. The small end of each connection rod is mounted on the crosshead pin via the double row long cylindrical roller bearing. Double row radial spherical roller bearings are mounted on either end of the crankshaft.

The crankshaft, a casted alloy steel eccentric shaft, is furnished with herringbone ring gear, connection rods and bearings. The ring gear bore and the crankshaft surface is of interference fit and fastened with bolts and lock nuts.The big end of each connection rod is mounted on each eccentric strap of the crankshaft via the single row short cylindrical roller bearing. The small end of each connection rod is mounted on the crosshead pin via the double row long cylindrical roller bearing. Double row radial spherical roller bearings are mounted on either end of the crankshaft.

Incepted in the year 1996, in Ahmedabad (Gujarat, India), we “Belt And Bearing House” are the distinguished wholesale, trader,exporter, importer, manufacturer of wide assortment of Oil Field Bearings, Industrial Bearings, Industrial Roller Bearing, Bearing Sheaves, Mounted Roller Bearings, Mounted Ball Bearings, etc. We have set business up as a sole proprietorship. Our offered products are precisely engineered using optimum grade metal with the help of cutting-edge techniques in compliance with set industry norms. Moreover, these products are checked for their quality on series of quality parameters before being supplied to our clients assuring their flawlessness at user’s end. The offered products are widely used in different industries such as engineering, manufacturing, automotive, etc. Further, these products are checked for their quality on series of quality parameters before being supplied to our clients assuring their flawlessness at user’s end. Our offered products are widely appreciated by our clients for their enormous features such as rugged construction, precisely engineered, smooth functioning, non-corrosive, hardness, easy to install and durability.

Honghua HHF1600 Mud Pump Valve Rod Guide (Lower), Mud Pump Fluid End GH3161-05.05.00 NB800M.05.28.00 , Valve Rod Guide (Lower) was used in Mud Pump Fluid End.

The mud pump valve rod guide (lower), which is installed in the chamber of the cylinder, acts as a centring and positioning suction valve body assembly. It consists of a guide body and an inner sleeve, which is inserted into the guide body. The material of the guide body is ZG35CrMo, and the inner sleeve is carburized and hardened by 20CrMnTi. Check the inner sleeve of the valve rod guide once a week. Replace it if there is obvious wear (the gap between the valve rod and guide is more than 3mm), so as not to lose the guiding function of the guide and accelerate the wear of the valve.

Upper and lower valve guides are important parts for the fluid end of mud pump in oil drilling. The upper type acts as a connector of valve spring and valve cover inside the hydraulic cylinder. It plays a guiding role in valve operation. The lower one is a connector of valve spring and hydraulic cylinder inside the cylinder. It has the function of fixing and guiding the valve operation.

In most types of reciprocating engines, a valve guide is provided for each poppet valve in the cylinder head. Along with the valve spring, it serves to positively locate the valve so that it may make proper contact with the valve seat. A valve guide is a cylindrical piece of metal, pressed or integrally cast into the cylinder head, with the valve reciprocating inside it. Guides also serve to conduct heat from the combustion process out from the exhaust valve and into the cylinder head where it may be taken up by the cooling system. Bronze is commonly used, as is steel; a balance between stiffness and wear on the valve is essential to achieve a useful service life.

Over time, the inner diameter of the valve guide and the outer diameter of the valve stem may become worn. In the 1980s, many U.S. production engine remanufacturers began reaming valve guides, rather than replacing them, as part of their remanufacturing process. They found that by reaming all the valve guides in a head to one standard size (typically 0.008 in. diametrically oversized), and installing remanufactured engine valves having stems that are also oversized, a typical engine head can be remanufactured in much less time.[1] Since the reaming process leaves the valve guide with a much better surface finish and shape than typical replacement guides, and since the oversize valves often have chrome plated stems, remanufacturers also discovered that valve train warranty issues are virtually eliminated.

The clearance between the inner diameter of the valve guide and the outer diameter of the poppet valve stem is critical for the proper performance of an engine. If there is too little clearance, the valve may stick as oil contaminants and thermal expansion become factors. If there is too much clearance, the valve may not seat properly and excessive oil consumption can occur.

A: First we discuss order details, production details. Then we issue you an PI for your confirmation. You will be requested to do pr-e paid full payment or deposit before we go into production. After we get the deposit, we start to process the order. We usually need 15-25 days if we don"t have the items in stock. Before production has been finished, we will contact you for shipment details, and the balance payment. After payment has been settled, we start to prepare the shipment for you.

ERUI has an independent third-party inspection team, which strictly controls the quality of products, guarantees genuine products and eliminates fakes.

ERUI has been deeply engaged in the field of oil and gas energy for many years, integrating a large number of high-quality supply channels. Our products are comprehensive and the price advantage is obvious.

The time depends on the MOQ of the order. The delivery time for parts is generally 1-3 days, and equipment is 7-30 days. In addition, contact us to get the full time of the order.

NOV A1700PT Bearing meet the most stringent tolerances ensuring equipment runs at maximum load for peak output. Bearings specially designed and manufactured to operate in extreme temperatures and specifically designed for NOV Mud Pump.

NOV A1700PT Bearing enhance smooth performance and efficiency of Triplex Mud Pump. These Anti-friction bearings permit free motion between moving and fixed parts. These NOV A1700PT Bearing is very essential to mechanized equipment as they hold or guide moving machine parts and minimize friction and wear. American Roller Bearing Company is a leading manufacturer of quality Anti-Friction Bearings in the industrial markets.

The connection rod for mud pump, is used for connecting power end of mud pump to fluid end of mud pump. The big end of the connection rod is installed to the craneshaft assembly of the mud pump, and the small end of the connecting rod will be installed to the crosshead of the mud pump.Crank adopt 35CrMo material casting/forging.

The big end bearing of the eccentric rod connected to the crankshaft, the small end is connected to the crosshead. The rotation of the crankshaft connecting rod into reciprocating linear motion by the crosshead. The main technical requirements rod big end and small end hole parallel, to ensure smooth motion.

Mud pump connecting rod and crosshead connection structure, crosshead and connecting rod through crosshead pin connection, crosshead installed in the sliding sleeve, connecting rod and crosshead shaft is provided with a radial joint bearing. The connecting rod has simple structure and reliable positioning. The centripetal joint bearing plays a role in adjusting coaxiality, which can effectively reduce the eccentric wear of the connecting rod to the crosshead pin shaft and reduce the eccentric wear of the crosshead to the sliding sleeve.

Drilling rig equipment and the related spares for the oil and natural gas industries. Like Rig Components, Drawworks Spare parts and Mud Pump Spare parts, Hydraulic Disc Brake,Solids Control Equipment, Drilling and Fishing Tools,Wellhead Control Equipment,Drilling Accessories, Cementing Equipment and Tools etc.

A: Generally by T/T, 30% advance payment, the balance 70% payment should be paid before delivery. We support EXW, FOB, FCA, CFR, CIF, CIP, DAP, DDU and DDP INCO Terms.

14 P-220 Mud Pumps 3 available completely overhauled. The pumps have been machine inspected and all data will be provided. These 2200 HP pumps complete with Southwest fluid end modules which have been reworked and pressure tested by Southwest and P-QUIP liner retention systems. The drives can be set up for AC or DC power. All Master Rig equipment meets or exceeds O.E.M. standards and a complete data pack is furnished with purchase. Please call if you have any questions.

READY TO SHIP - Three (3) completely refurbished 1600 HP Continental Emsco 7500 PSI Mud Pump Packages - liner spray system, suction manifold and dampener, discharge strainer cross, reset relief valve, 20 gallon pulsation dampener, 75 HP charge pump, two (2) GE 752 1000 HP rear mounted motors, 10 HP blower, mounted on a 3 runner skid with loading hitches and much more. Units come with complete data books and have been tested. MRI is a API facility and units comply with API standards.

Duplex mud pump package completely refurbished and never operated. Tri-Services Manufacturing TSM-500 pump, CAT engine. Data book provided with complete refurbishment details.

8613371530291

8613371530291