run mud pump with one geneator and old scr house manufacturer

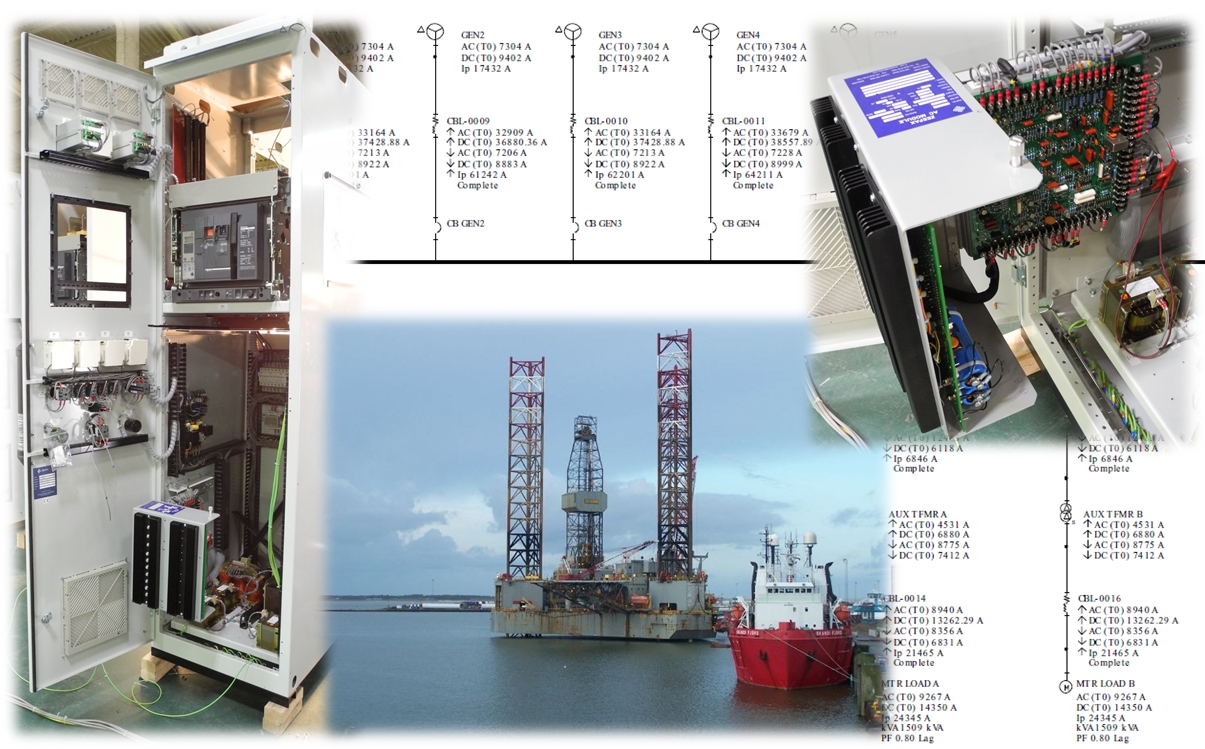

ENSCO 71 is a Jack-Up drilling rig which was originally constructed at the Hitachi Zosen shipyard in 1982. The original GE motor controls comprised five 1163 KVA generators and four 1800 ADC SCR units with associated auxiliary transformer feeders and jacking units. The SCRs were assignable to two 1600 HP twin-motor Mud Pumps, a twin motor 2000 HP Drawworks and a 1000 HP Rotary Table. A separate feeder drives a 1110 HP Top Drive. A fifth SCR was added by Hill Graham Controls in 1985 to power a third 1600 HP Mud Pump, which was cabled to the main busbars.

In early 2012, a decision was made to add a fifth 2500 KVA generator and an additional auxiliary transformer, to close-couple these to the main switchboard via a bus tie circuit breaker, and to include a dedicated feeder for the fifth SCR. A sixth SCR was also included in the switchboard extension to provide an alternative drive source for the third Mud Pump, effectively removing this load from the main switchboard. The switchboard extension, including full integration with the existing GE and Hill Graham equipment, was engineered and built by Zeefax.

As well as providing an extension to the main 600 V switchboard, Zeefax also designed, built and commissioned an accompanying 480 V switchboard comprising of an incoming circuit breaker and a number of small moulded case distribution circuit breakers.

The design and engineering process involved completing a detailed Power Studyto examine the consequences, in terms of fault rating, of adding the new equipment. Various scenarios were considered, and the financial impact was assessed to determine the most cost effective interconnection configuration. As a result of the study the amount of upgrade work required on the existing equipment was minimised.

The Power System Study was completed by gathering data about the existing switchboard arrangement and comparing this to the original, hand written, fault level calculations. The new calculations were performed using software modelling and verified to IEC 61363. The IEC 61363 Short Circuit study represents conditions that may affect typical marine or offshore installations more significantly than land-based systems, including more emphasis on generator and motor decay. This confirmed the original calculations were accurate.

As well as considering the effects of fault currents, Zeefax also completed a complete protective device co-ordination study to confirm and ensure that proper co-ordination was established for all operating scenarios. This included the existing equipment as well as the components in the switchboard extension, and the new 480 V switchboard and transformer.

Finally, the study also included calculating the strength and current-carrying capacity of the busbars under normal and fault conditions to establish the correct busbar sizes and bracing.

Zeefax has developed a program to mitigate against unscheduled stoppages and breakdowns. It is a complete and holistic approach which aims to avoid stoppages but if they do occur, ensure that the resources are on hand to minimise the damage caused. This is the Total Rig Audit (TRA) by Zeefax and is carried out by our very specialised and highly experienced Field Service Engineers.

The Zeefax Total Rig Auditavoids downtime and ensures rig systems remain operational and reliable. Many Drilling Companies will invest in a completeRig Auditin the knowledge that it offers a comprehensive overview of the state of their rig, which can also be submitted for compliance and due diligence purposes.SCR Training Simulator

Every Drilling Rig must have a Power Control Room – sometimes also known as an SCR (standing for Silicon Controlled Rectifier) System – which forms the functional heart of the power control of the drilling operations. Typically, SCR systems comprise a large steel room, inside of which will be a range of Motor Control Centres, Engine & Generator Controls, SCR Control cubicles, and other instruments and systems used for drilling purposes.

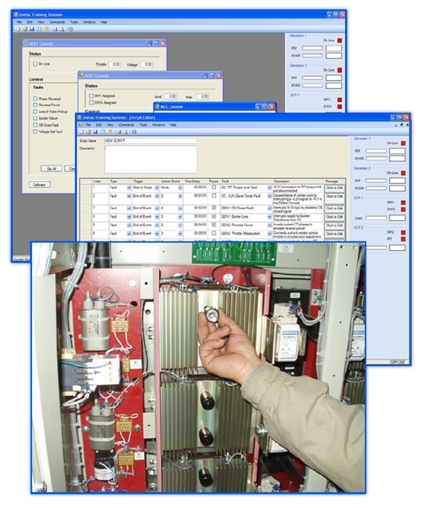

SCR Systems usually operate at 600V, and clearly, these systems can be extremely dangerous if not operated correctly and carefully by suitably trained operators. It is therefore vital that drilling engineers and operators are well trained using a combination of class room tuition and on-the-job training.

In response to this need, Zeefax have created the world’s first full size SCR Training Simulator, which accurately mimics the a real SCR; it looks and feels like the real thing, providing a realistic experience of live field operations – but without the dangerous high voltage. This system was created specifically for Naftogaz – for more details, click here.

A key feature of the simulator is the addition of the on-board computer system, which mimics all of the signals that would normally come into this SCR system from the live engines and generators, including the motors running the mud pumps, the rotary table or the Drawworks, etc. and can also simulate a wide range of known faults, allowing trainees to experience first hand problem solving in the safety of the simulator, before they experience the live system.GE Legacy Drive Systems

Used the same type SCR bridge as the Generation III, but rated at only 1200-1500 amp since the heat sink assembly is of a slightly different design. This system uses the GE generator GEM modules controls.

1980’s, 900amp. SCR bridges using the GE GEM Generator Control. As the bridges are small it requires two SCR bays to run a two-motor Mud Pump or Drawworks.

This module features digital circuitry providing enhanced control accuracy for speed and voltage, and also provides tools for system diagnostics, including “first fault” and multiple fault storage and annunciation. A fully featured internal diagnostic self-test on power up is provided, and available outputs include system KVA and kW limit protection.

The EGR is a direct replacement for the GEM Module and protects the engine through tachometer loss sensing, over speed detection, and reverse power protection with adjust-able time delay.Test and Calibration Engineer – IMP products

If you are interested in applying for this position, then please send us your latest CV and a covering letter toTest and Calibration Engineer – SCR products

Zeefax is the value source for parts and services for your legacy GE Drive and Generator Control Systems. We hold an inventory of critical spare parts and can provide comprehensive service solutions including Repair and Return of Modules and PCBs.

Zeefax operates a comprehensive repair and return service for all legacy GE Drive and Generator Control Systems. which includes cleaning, testing, repairing or replacement of defective components and a full system load test. This service includes a 6-month limited warranty.

Zeefax understands that replacement of a complete SCR Control System is often not viable due to the large cost and loss of production due to system downtime. At Zeefax we can offer a comprehensive service to support your legacy GE Drives and give it a renewed lease of life. That not only includes supply of spare parts and a repair/calibration service; qualified service engineers with years of experience with these Drives are available for regular Health Checks, fault-finding and general support purposes.Careers

Zeefax Limited has been made aware that unauthorised individuals have masqueraded as Zeefax Limited, promising job opportunities in our name and requesting payments to cover processing fees, visas, work permits or other formalities. The job offers are typically supported by forged documents, giving the appearance of an official communication, including the use of the Zeefax Limited logo and links to the Zeefax Limited website.

Zeefax Limited (nor any of the placement firms that recruit on our behalf) will NEVER require potential candidates to make any form of advance payment as part of the hiring process.

These communications are fraudulent (usually from @worker.com or @126.com) and do not originate from Zeefax Limited (@zeefax.com), nor are they associated with the Zeefax Limited recruiting process. The individuals who are sending these communications are doing so in an attempt to solicit money from potential job seekers. Be cautious of any unsolicited offers of employment particularly if you are requested to supply personal banking information or provide any form of advance payment.

If you suspect fraud, we would urge you NOT to respond to these unsolicited offers of employment, and to report such activity to your local law enforcement agency immediately!

Should you have any concerns over the validity of any correspondence received in respect of employment with Zeefax Limited, contact us directly atPLC Programming

We have expertise in many of the commonly used devices, including Siemens, Allen-Bradley, GE Fanuc and Mitsubishi, and we have the operational experience and knowledge to provide completely new applications or modify existing ones. We are also able to help and advise on strategy and implementation, as well as with start-up and commissioning.

Not only can we provide a comprehensive programming resource to help with your programming needs, we also can provide a series of PLC programming training courses. The comprehensive training experience is intended for those who wish to expand their skills and knowledge of PLC programming, fault finding and maintenance, and include modules for both novice and advanced users.

Course materials include information and techniques for a range of manufacturers including Siemens, Allen-Bradley, GE Fanucand Mitsubishi, and the curriculum may be tailored for specific requirements and needs, but will typically focus on the more practical aspects of Programmable Logic Controller applications.

All of Zeefax’s training courses are held in our design and manufacturing facility, located near London, England. To find out more about our training courses, pleaseDigital AutoSync Module

In response to many customer requests, we have designed our own version of the legacy Ross Hill Controls AutoSync AC generator control module; the new module has been completely re-designed and incorporates all new digital circuitry as well as optional expansion capability to future proof the module.

The use of modern digital circuitry and components has resulted in much improved parameter control over the previous legacy module without compromising operational reliability, and the ultra-stable frequency control system ensures safe and accurate control of generation systems.

The new front panel includes the familiar controls, but has been enhanced with the inclusion of an LCD display for module set-up and parameter display purposes; front panel controls include the manual circuit breaker and engine controls, with the addition of digital menu navigation buttons for module set-up and display options.

An important feature of the new modules is that they have exactly the same footprint and connection geometry as the old style legacy modules, making installation and upgrading of the new modules simple and quick.

Wire loom connections and attachment points are identical, meaning that no extra wiring or hardware is required in order to facilitate installation, and the new digital circuitry uses the latest available components and techniques, yielding enhanced reliability and performance over older legacy modules.

Our Research & Development department is currently working on new versions of the traditional AC and DC modules which will be available soon to add to the already released DDC and the Digital AutoSync.

These new modules will provide existing system users with a quick and cost effective upgrade path, maintaining the continuity and availability of well established installations.

Zeefax is an established global supplier of high-quality and reliable electrical and mechanical engineering services. As part of the complete service we provide to the industry, we carry out repair and maintenance of all GE752 Motors, including:

Advancements in technology mean that many of the power semiconductors which were built into SCR systems 30 or more years ago have been superseded by new devices, often with improved specifications.

Our engineers are able to ensure that, when the original component is not available, a suitable replacement can be found. If the replacement is not an exact fit, we can engineer an adaptation to ensure continued serviceability of legacy equipment.Hill Graham Controls (HGC)

Following our acquisition of Hill Graham Controls (HGC), Zeefaxis in a unique position to offer total support for all legacy Hill Graham and Ross Hill Controls (RHC) systems both in the UK and throughout the world.

Zeefax’s unique experience and expertise has allowed the company to design, manufacture, supply, repair and calibrate many of the control modules used within older Hill Graham installations, as well as other manufacturer’s systems, including Ross Hill Controls (RHC) type systems.

In recent times,Zeefax has developed and brought to market a new digital AutoSync module, with an improved contemporary design and operation. This advanced module occupies the exact same footprint and has pin-for-pin connection compatibility with the now obsolete Ross Hill module, thereby providing a simple and cost effective upgrade path for existing users of the AutoSync module.

These services mean that equipment manufactured up to 30 years ago, is still fully supported by Zeefax, and can continue to provide return on investment far beyond the normal life expectancy.Troubleshooting & Maintenance

Zeefax has the experience to assist and provide engineers to troubleshoot issues, help during downtime, and establish a program of scheduled maintenance, targeted and customised for your individual requirements.

As part of our maintenance and service offerings for SCR systems, Zeefax is able to mobilise support and engineers to provide technical assistance during emergency shutdowns and downtime periods.

It is well established that a program of planned maintenance and support can and will ease pressure on people and systems, and can result in increased reliability, uptime and ultimately profitability of the system.

By predicting issues, and by scheduling maintenance, spare parts and manpower can be correctly scheduled, minimising downtime, keeping spare part inventory under control and avoiding unwanted breakdowns.

At Zeefax, we recognise that high-quality and experienced technical resources are required during major works, such as emergency breakdown repairs or un-scheduled downtime.

Given our years of experience and unique position to offer total support for all legacy Hill Graham Controls (HGC), and other manufacturer’s systems including Ross Hill Controls (RHC), IPS, and GE Micro Drill SCR systems, Zeefax can provide a full range of technical services for installation, commissioning, and ongoing operational support.SCR System Health Checks

The time to find out if your system is reliable is when operations are quiet – not during critical well operations – so the Zeefax SCR System Health Check is designed to identify potential weaknesses and either repair or replace immediately, or mitigate against these until a repair or replacement can be effected – usually at a quite time.

Zeefax can help you to perform a comprehensive health check, and propose a detailed scope of work designed to compliment and conform to your operation schedule; this means that any potential disruption is absolutely minimised.

Zeefax understands that each rig or vessel has different circumstances and different requirements. Our engineers are able to tailor a maintenance schedule to suit any installation or operational constraints. Where special equipment is required, such as secondary injection test equipment for testing circuit breakers, Zeefax will arrange to have the equipment on site, and our technician will be competent in its use.

For reliable operation, the contact between the SCR devices and the heatsinks must be as good as possible but over time, and especially in offshore installations, corrosion may attack the interface between the SCR device plating and the aluminium heatsink. If corrosion is present it takes an expert to decide if refurbishment is required because as long as the damage is minimal and the two elements remain undisturbed, the mutual corrosion may still maintain a good contact.

As part of the health check our engineer will do a sample inspection of the heatsinks and recommend a course of action based on experience and knowledge.Repair & Calibration

Since our acquisition of Hill Graham Controls (HGC), our module repair facility and engineers, have been able to test and calibrate modules sent to us for repair within a quick turnaround period. In an important development, Zeefax has designed and built a new AC and DC Module simulator, to provide an improved testing platform for Hill Graham and Ross Hill type AC and DC modules. In particular, the AC module simulator is much improved over the older unit, and provides a greatly enhanced engine control and start-up simulation.

These improvements have been made based on our experience with testing and repairing the modules over many years, and our customers can be confident that any module returned to us for repair will receive the most comprehensive bench test possible.

In addition, we are able to repair and re-calibrate most Hill Graham and Ross Hill type printed circuit boards (PCBs), including Power Limit, Field Supply Regulator, Sprocket Slip, Drillers Console, DC Auxiliary, SCR Auxiliary and Generator Exciter PCBs. Furthermore if following evaluation, repair is not possible, in many cases we can supply new manufactured boards using the original designs, but enhanced by us using modern components and manufacturing techniques. In this way, we can help to ensure that legacy systems remain operational and continue to provide reliable and trouble free service beyond their expected life.Motors & Generators

Even given the relatively controlled working environment of typical SCR pods, the conditions can often cause deterioration to both electrical and mechanical performance, requiring removal of the unit from the system, followed by refurbishment and renovation.

During refurbishment, the pods are disassembled, checked and thoroughly cleaned; resistors and capacitors are replaced, and fuses, actuators and switches are checked and tested for operation, and replaced where necessary, and the pod is fully re-wired.

The heat sinks are inspected and if required, will be re-machined to ensure excellent electrical contact is maintained. Importantly, the SCR Thyristor ‘puck’ is replaced, and very special attention is given to the clamping torque and orientation.

When complete, a full quality inspection and electrical test is performed to ensure that the refurbished cell is in perfect working order prior to dispatch back to the owner.

The severe environment on rigs often leads to a deterioration of both electrical and mechanical performance of Foot Throttles, requiring removal of the unit followed by factory refurbishment and renovation.

Typically, units arrive in poor condition – totally seized and unusable; they are then completely disassembled, thoroughly cleaned and de-scaled, and are fitted with new bearings, bearing blocks, hardware and seals, prior to re-wiring and calibration.

Zeefax is able to provide both factory refurbishment of existing Foot Throttles and in cases where the deterioration is too severe for refurbishment, we can supply a brand new replacement to meet specific requirements.

If you would like to know more about the range of available Driller’s Foot Throttles, please call or email us, and we will be pleased to assist.SCR Blower Assemblies

An important part of every system is the forced air cooling, which is vital to ensure continuity and reliability of operation of the SCR stacks. It is essential that the heat generated during operation is reliably carried away, and Zeefax now produce a series of SCR Blower Assemblies which are compatible with the those used in legacy Hill Graham and Ross Hill type systems.

The Zeefax SCR Blowers are designed to operate with voltages up to 600 V @ 50 or 60 Hz; the operating voltage needs to be specified at the time of purchase (see the details and specification form below) and the blower may be configured with either Single or Duplex impellers and with or without base frames.

In order to aid potential users with the selection of replacement blowers, we have created a simple form which can be used to provide the few technical details we require. In this way, we can ensure that any SCR Blower supplied by us is fully compatible with existing assemblies, and will then install directly into the available location with minimal re-work required. You can download this form from this site; please fill it in and return it to us to receive a quotation.

If you would like to know more about the range of available blowers, please call or email us, and we will be pleased to assist.Printed Circuit Boards (PCBs)

Through our in-house R&D, we are developing improved specification products as replacements for legacy Hill Graham Controls or Ross Hill Controls boards; we can provide original replacements for many of the PCBs used on these systems, and by using modern techniques and components, we can even improve on some of the design features of the original products to enhance reliability and functionality.

This means that equipment manufactured up to 30 years ago is still fully supported by Zeefax, and can continue to provide a return on investment well beyond the normal life expectancy.PLC Training Course Program

During the course, we aim to provide students with an advanced training experience, enhancing the already popular series of PLC training courses provided by Zeefax.

This training course includes modules for both novice and advanced users of PLCs, and includes information and techniques for manufacturers including AB, GE Fanuc, Mitsubishi and Siemens. Courses are intended for both technicians and engineers who wish to expand their skills and knowledge of PLC programming, fault finding and maintenance.

Course programs and content may be tailored for specific requirements and needs, but will typically focus on the more practical aspects of Programmable Logic Controller applications.

At the end of the course, engineers and technicians will be familiar with the program modules and functions, and will be able to fault-find on PLC controlled plants.

Modern drilling techniques require additional equipment not found on older drilling rigs. Existing power systems can be modified by Advanced Control Systems in the field to accommodate the addition of Top Drives, Generators, Mud Pumps, and Independent Rotary Tables.

Obsolete SCR / Engine-Generator Control Systems can be economically retrofitted, refurbished or replaced altogether to increase dependability and decrease downtime.

By using this site, you are agreeing to security monitoring and auditing. For security purposes, and to ensure that the public service remains available to users, this government computer system employs programs to monitor network traffic to identify unauthorized attempts to upload or change information or to otherwise cause damage, including attempts to deny service to users.

Unauthorized attempts to upload information and/or change information on any portion of this site are strictly prohibited and are subject to prosecution under the Computer Fraud and Abuse Act of 1986 and the National Information Infrastructure Protection Act of 1996 (see Title 18 U.S.C. §§ 1001 and 1030).

If a user or application submits more than 10 requests per second, further requests from the IP address(es) may be limited for a brief period. Once the rate of requests has dropped below the threshold for 10 minutes, the user may resume accessing content on SEC.gov. This SEC practice is designed to limit excessive automated searches on SEC.gov and is not intended or expected to impact individuals browsing the SEC.gov website.

Our DC systems are based on an industry standard design and inherit the dependability, reliability and ease of maintenance of this concept. Our AC systems are built around ABB drive and control technology. Enhanced systems, PLC control and serial links to the Drill Floor are available to reduce rig-uptime for land rigs.

We also have the expertise to source replacements for obsolete spare parts, and re-engineer older systems with new equipment, including adding extra SCR sections for third Mud Pumps or Top Drives, and additional generator sections for additional rig power.

We are able to provide training either on-site using your existing equipment, or from our base in London, England. As well as providing in-depth knowledge and support for SCR and generator control systems.

As to the electric system, we compared the DC drive rigs and AC converterdrive rigs deeply, we recommend AC (AC-VFD-AC)converter drive rigs due to the following advantage of AC Converter drive rigs.

2, It has the limitation function of Torque and rotation speed, strong overload protection could avoid the broken of drill pipes and other main parts.

Being a manufacturer of power generation controls and high power electronic variable speed driveequipment, Joton must maintain qualified personnel to ensure our products are put into service correctly, and effectively. The wide range of specially designed power equipment sold, designed and manufactured by Joton means that our startup and service personnel must be versatile in the full scope of their knowledge.

This can be of great benefit to customers that have not purchased any of our manufactured products. Our technical staff has knowledge in the following areas and can provide technical Oilfield service in these areas if you have equipment that is shut down from an unresolved failure, or just need to ensure the system is operating correctly.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Here"s how electrical equipment is used on rig electrician resumes:Supervised, assisted and trained junior electricians in maintaining electrical equipment.

Here"s how vfd is used on rig electrician resumes:Maintained 1000hp VFD driven mud pump and responsible for the calibration of the fire and gas detection system.

Here"s how motor control is used on rig electrician resumes:Top drives, SCR houses, motor control centers, boilers, lighting, generators, all aspects of rig electrical.

Zippia allows you to choose from different easy-to-use Rig Electrician templates, and provides you with expert advice. Using the templates, you can rest assured that the structure and format of your Rig Electrician resume is top notch. Choose a template with the colors, fonts & text sizes that are appropriate for your industry.

Here"s how electrical repairs is used on rig electrician resumes:Repair Department, Electrical Repair Division Officer (E7): Directed and managed the productive efforts of 80 IC/EM technicians.

Here"s how scr is used on rig electrician resumes:Rig electrical maintenance SCR maintenance & repair Power installation and connection for Top Drive Control Wiring Generator and crane repair Lighting installations

Here"s how preventive maintenance is used on rig electrician resumes:Conduct preventive maintenance on electric motor consisting of greasing bearings and temperature reading to ensure proper operation of motors.

Here"s how electrical systems is used on rig electrician resumes:Installed and repaired electrical systems, machinery, and electrical and electronic components for offshore drilling company.

Connected wires to circuit breakers and transformers Directed electricians on installation, maintenance and repair on electrical wiring and equipment.

Here"s how ac dc is used on rig electrician resumes:Installed electrical equipment, such as AC DC Motors and electrical panels for different sections of the plant.

Here"s how ac is used on rig electrician resumes:Utilize LOTO (Lock-out Tag-out) procedures on all electrical panels, including AC and DC voltage up to 600 volts.

Here"s how dc is used on rig electrician resumes:Experienced with A and DC motors, hydraulic and pneumatic systems, industrial PLC"s and industrial wiring and terminate panels.

MUD SYSTEM: Shakers 2each Derrick, Construction Crimp Wall Tanks Active Mud System 1,500 BBL (Can add 2x 500 BBL Reserve mud tanks available if needed for an additional cost)

AUXILIARY EQUIPMENT: Wireline unit, Two (2) IR floor air hoists, catwalk and pipe racks , elevator bails, Oilwell 500 ton block, BJ 5500 Hook, National P650 Swivel, Two (2) Gardner Denver air compressors & Lister cold start.

• The Power Control Room (SCR House) will be Top Lift Only, and be equipped with roof mounted handrails and an access ladder mounted on the outside (just as the original)

• Includes power and control provisions for an Eddy Brake (Baylor Brake) to include an MCC feed, and internal cables. Our proposal does not include the actual Brake Controller or the transformers.

• The standard electronic engine/generator controller uses a 0-200 mA signal to control the engines direct fuel rack and thus its engine speed. If necessary, a 4-20 mA engine speed signal conversion kit is available for engines that cannot use the 0-200 mA signal.

• All power and control cable terminations are intended to be “hard-wired” through ROX frames. No plug boards will be used. Will include the ROX frames only.

4- Model 1500 I-DRIVE SCR Drive Cubicles each equipped with electronic controllers, primary and secondary assignments, and 600V feeder circuit breaker switches

4 - Generator Control Cubicles each equipped with electronic controllers (metering module, governor module, and voltage regulator module) and 600V feeder circuit breaker

E. One (1) Low Voltage Distribution and Lighting Distribution Panel with 3- pole, 2-pole, and 1-pole breakers as required (will match the existing unit but may be relocated to a new location in the house.

F. One (1) Power Control Room outdoor, weatherproof, insulated, mobile steel building equipped for Top Lifting Provisions. The building will contain the above wired and tested equipment.

* KW/KVA limiting circuitry monitors the available power and compares it against the KW/KVA in use, so that the power consumed by the SCR system does not exceed the available power on the line.

* Control power will be 120 VAC for best contact integrity and line noise immunity. The system will be provided with a control power transformer to provide control for standard contactor logic and alarm function. Each SCR converter section will be assignable to two (2) loads. Assignment switching will provide 100% redundancy in case of converter or load failure.

* All logic functions will be provided according to customer specifications and necessary safety functions. There will be two (2) SPST load interrupting main contactors for each assignment.

5) I-Drive module is a standard unit; interchangeable on any system, on shore/off-shore, single motor, two motor operation and series or shunt motors.

I-Drive Power Limiting protects the diesel engine/generator set(s) from dropping "Off Line" due to an overloading. When maximum KW or KVA capacity has been reached, the system "phases back" the outputs of the SCR drives connected to the AC Buss, and thus prevents the generator sets from dropping off line due to an overload.

The I-Drive SCR Control Module accepts four different current limit settings, which corresponds to the four possible assignments of the SCR drive. The I-Drive SCR DC cardrack test panel has four potentiometers where the Current Limits are set. The current limit settings are a separate module from the D/C module which allows changing the D/C module without resetting current limits.

The I-Drive Firing Circuit Regulator works in conjunction with the AC Buss Phase Sensing and the Six Gating Pulse circuits. The SCR firing pulses are referenced to the Three AC Lines, and timed to trigger the respective SCR"s at the correct instant.

There are six firing pulses (each spaced 60 degrees from the previous) in each cycle and all are adjusted simultaneously by the firing enable circuit to get the correct SCR firing angle.

This feature allows the I-Drive SCR drive to deliver more current for a short period of time than what is preset with the current limit Calibration as set on the DC cardrack test panel. This feature can be used in situations where high current is needed for short periods of time, I.E. for a drawworks motor. The amount of overcurrent allowed is set at the Timed-Overcurrent Module, from 110% to 130% of the present current limit for approximately 60 seconds. After the 60 seconds period, the current will revert to the normal current limit as set at on the I-Drive DC cardrack test panel so as not to damage or overheat the SCR bridge.

1. Over-temperature: When the SCR Blower is lost or the SCR house internal ambient temperature rises to an unacceptable level so that proper cooling of the SCR’s is not possible, a set of thermo-switches, mounted on the SCR bridge heatsinks detect when the temperature goes above 70 degrees C and signals an alarm condition

2. Blown Fuse: The SCR bridge has a set of semi¬conductor fuses for the protection of the SCR"s. If any of the fuses open, the FFAS (fuse failure alarm signal) is activated (isolated contact closure) and the firing pulses to the SCR bridge are automatically inhibited

All the controls ARE interlocked. If the bay is re-assigned during power on, the bays shut down and will not restart until their respective throttles have been returned to the ZERO (off) position. This includes the foot throttle.

The I-Drive SCR drive is of modular design, compact, NEMA type 1 A construction WITH DRIPSHIELDS, front access only. The D.C. control module contains the circuitry necessary to control the SCR Bridge’s output. The module is interchangeable between all I-Drive SCR systems. The module is furnished with no adjustments necessary. The module is easily disconnected for replacement should the need arise. This makes for a minimum of “down-time” should a failure occur.

The I-Drive SCR Bay cooling is assisted by a squirrel cage blower forcing air in the direction from bottom to top of the cabinet. Air is drawn in through a filter in the lower section of the front door. It then proceeds over the contactors, DC buss, and into the blower intake. The blower’s output airflow goes directly into the plenum below the SCR bridge, into the bridge heatsinks (the point of the most air flow resistance), out the top of the bridge, upward past the circuit breaker and AC buss, and out the top of the cabinet.

The I-Drive SCR Bridge is composed of three (3) identical and interchangeable modules (Phase Cells). Each Phase Cell has an AC input flag, a minus DC output flag, and a plus DC output flag. In the Phase Cells the discrete SCR devices have heatsinks on both sides. Thermodynamics proves that this allows the SCR devices to operate at a lower temperature than single sided “bricks” for the same device current. The lower the operating temperature, the more reliable the SCR device is. The system is designed for low maintenance and to operate in ambient air temperature up to 50 degrees C without air conditioning.

The I-Drive drawworks dynamic brake will slow the drawworks motors from full speed within eight to ten seconds after the foot throttle is released. The power of the free wheeling motor is fed back into a resistor bank. During normal operation the dynamic brake system is non-operative, and the drawworks is either OFF or operating at the desired cathead speed. If however, at any time the motor speed is higher than the DW throttle speed setting, and the foot throttle is OFF, the dynamic brake system is actuated, reducing the motor speed to the DW throttle setting.

The I-Drive foot throttle is constructed of rugged stainless steel throughout; built to withstand the environment normally encountered on the rig floor.

The I-Drive Drillers Console will be NEMA type 4X construction of #316 stainless steel1 outdoor weather proof and provided with air purge/pressurization fittings to allow use in a Class 1, Division 2 hazardous area. All assignment switches, hand throttles and controls will be front mounted on the door. All meters, instruments and annunciators will be mounted behind the front door with a safety glass view window provided to view the meters and instruments, etc. The door will be attached with stainless steel hinges and positive latching stainless steel latches.

One set of I-Drive generator control cubicles consisting of three (3) each I- DRIVE model 1200 engine/generator control modules, breakers and related equipment for the control of three (3) each engine/generator sets and a synchronizing and ground detection cubicle.

I-Drive AC Electronic Control Section contains the AC cardrack. Three modules plug into the AC cardrack. They are the Engine Electronic Governor module, Generator Electronic Voltage Regulator module and the Metering control module. All external connections to the AC cardrack are by barrier strip (screw type).

Dynamic KW load sharing - each regulator is independent and automatically shares when placed “on line” KW sharing can be set to track within 2% of rated KW of generator.

Dynamic KVAR sharing - each regulator is independent and automatically shares when placed “on line” KVAR sharing can be set to track within 2% of rated KVAR of generator.

The HOCC System will supply power for the engine starting circuit and the pulse pick-up circuit in each generator control module. The system/operation will consist of the following.

1 – Set of Hands off cranking batteries consisting of gell cell batteries and electronically regulated battery chargers to provide cold start power for engine controls.

1 –Engine control power supply (each generator control section) to provide engine control power to each engine. Upon initial start up (cold) the batteries will supply cold power to the engine controls to allow engine starting. After the generators are online, the engine control power supply will provide control power for continuous operation. After the engine control power supply is activated, the batteries will drop out and revert to stand-by power in case of primary power supply failure.

2 Each - 800AF/800AT circuit breakers, DRAWOUT MONTED each to feed power to one (1) 1000 KVA 600/480V power transformer and interlocked so that only one can be closed at one time

Motor Control Center will be NEMA Type lA Construction, front access only with horizontal and vertical solid copper bus. Motor starters to be motor starter/circuit breaker combination type full voltage, non-reversing with 3 pole overload blocks, overload heaters, control power transformer, fuses, operating handle, and start/stop push button (or H-O-A Control) in the door.

The horizontal buss will be copper and suitably rated. The vertical buss will be will be copper and rated for 300 amps. A copper round buss will run the full length of the MCC Line-up.

The columns and ceiling framing will be constructed from structural steel. The outside steel sheeting will be fabricated from sheet steel, min. 12 ga.

The walls and roof sheeting sections will be welded together. The floor will be fabricated from three sixteenth inch thick smooth steel plate. The inside surface of the walls will be finished with a sandwich style insulating board, three eights inch thick with white pebble coating in the interior. The ceiling will be formed from inverted Tee-Bar and lay-in insulated ceiling board.

Two (2) industrial steel doors are provided on the sides with "Anti-Panic" handles for quick, easy opening. Doors open outward. Doors can be locked from the outside but can be opened from the inside even when locked.

Standard 48-inch fluorescent lights, a battery operated emergency light activated by loss of power on generator main bus, and convenience outlets for customer use will be provided.

Two (2) 7.5-Ton Self-contained air conditioning units that will maintain the inside temperatures within the design limits of the installed electrical equipment are included. The air conditioning will be supplied by a total of two units. Either unit will maintain operating temperature limits with one for a back-up. These air conditioning units will be fed from the A/C MCC. AC units will be installed on the roof.

The exterior of the building will be cleaned with a sweep blast of sand to remove scale and oxidation. The exterior coating will consist of a sub-coat of zinc rich primer, and covered with a coat of polyurethane, color white. The interior floor of the building will be covered with black colored epoxy enamel. The skid base will be primed and painted black.

NOTE - Includes one Caterpillar 12-cylinder, direct-injected, turbocharged, aftercooled diesel oilfield engine; 4 cycle, 170 mm bore x 191 mm stroke (6.7 in bore x 7.5 in stroke) with separate-circuit after- cooler and optimized for low emissions. Engine rotation is standard (counter-clockwise as viewed from flywheel end).

COOLING SYSTEM - In order to ensure compliance in use, optional or customer-supplied radiators must be capable of rejecting enough heat to allow proper operation at worst case site conditions, and also must supply 122 deg F (50 deg C) SCAC cooling water to the aftercooler inlet, with an SCAC flow rate of at least 100 GPM (379 l/m) with an ambient temperature of 86 deg F (30 deg C) and at-site conditions (including altitude considerations). Maximum allowable SCAC flow rate is 115 GPM (435 l/m). RADIATOR COOLED LAND BASED: Outlet controlled thermostat and housing. Jacket water pump, gear driven. Dual outlets: 88.9 mm O.D. (3.5 in) elbow hose connections. Aftercooler fresh water cooling pump (SCAC), gear driven centrifugal SCAC pump circuit contains a thermostat to keep the aftercooler coolant from falling below 30 deg C (85 F).

EXHAUST SYSTEM - Exhaust outlet: 292 mm I.D. (11.5 in). 12-10.5 mm dia holes EQ SP, 376 mm bolt hole dia. Shipped loose: Exhaust flexible fitting: 318 I.D. mm (12.5 in) 12-14 mm dia. holes EQ SP, 375 mm bolt hole dia. 306.6 mm tall with compressed gasket. Exhaust adapter: 297 mm I.D. to 340 mm I.D. (11.7 in to 13.4 in). 12-10.5 mm dia. holes EQ SP, 376 mm bolt hole dia. 12-13.8 mm dia. holes EQ SP, 430 mm bolt hole dia. 158.5 mm tall with compressed gasket. Weldable flange: 360 mm I.D. (14.2 in). 12-13.8 mm dia. holes EQ SP, 430 mm bolt hole dia. 17.4 mm wide with compressed gasket. Exhaust manifolds, dry. Dual turbochargers with w/c bearings.

INSTRUMENTATION - Electronic instrument panel, LH. Analog gauges with digital display data for: Engine oil pressure gauge. Engine water temperature gauge. Fuel pressure gauge. System DC voltage gauge. Air inlet restriction gauge. Exhaust temperature (prior to turbochargers) gauge. Fuel filter differential pressure gauge. Oil filter differential pressure gauge. Service meter (digital display only). Tachometer (digital display only). Instantaneous fuel consumption (digital display only). Total fuel consumed (digital display only). Engine start-stop (off, auto start, manual start, cooldown timer).

PROTECTION SYSTEM - ADEM A3 ECM monitoring system provides engine de-ration, or shutdown strategies to protect against adverse operating conditions. Selected parameters are customer-programmable. Status available on engine- mounted instrument panel and can be broadcast through the optional customer communications module or programmable relay control module(s). Initially set as follows: Safety shutoff protection, electrical: Oil pressure, water temperature, overspeed, crankcase pressure, aftercooler temperature. Includes air inlet shutoff, activated on overspeed or emergency stop. Alarms, electrical: ECM voltage, oil pressure, water temperature (low and high), overspeed, crankcase pressure, aftercooler temperature, low water level (sensor is optional attachment), air inlet restriction, exhaust stack temperature, filter differential pressure (oil and fuel). Derate, electrical: High water temperature, crankcase pressure, aftercooler temperature, air inlet restriction, altitude, exhaust temperature. Emergency stop push button, located on instrument panel. Alarm switches (oil pressure and water temperature), for connection to customer-supplied alarm panel. Unwired.

REVISION HISTORYRev. A B C D E F G H J K Description Initial Release Added Revision History page and drawing number in footer. Revised figures 1-10, 113, and 1-14. Formatting corrections. Corrected text and figure item callouts items in figures 1-4, 1-5, and 1-6. Make formatting correction. Remove references to ARH and Ansaldo Ross Hill on pages 1-1, 1-2, and 1-25. Update figures. Update (2) photos (Figure 1-5, Figure 1-9); add photo numbers; update figure number style. Revise Figure 1-1 to reduce printing time and printer memory problems. Convert to Word 97 format. Add Table of Contents codes. Correct Level 5 and Level 6 styles and errors. ERO/ECN # 041251 C23375 C24068 C24394 C24670 C25368 C25939 C26330 C28670 C29222

SCR DRIVE SYSTEMSYSTEM INFORMATIONDESCRIPTIONThe SCR Drive System provides electrical power conversion and control for the DC motors on a drilling rig. The system regulates AC power from engine-generator sets and delivers continuously variable DC power to traction motors which are coupled to functions such as Drawworks, Rotary Table, Top Drive, Cement Pumps and Mud Pumps (see Figure 1-1). A typical drive system consists of the following units: Generator Units for control of enginegenerator sets. SCR Units for AC to DC rectification for traction motor power and control. Transformer Feeder Unit - AC feeder breakers to feed step-down transformers that deliver low voltage power for AC auxiliaries such as motor blowers, water pumping, lighting and living accommodations. DW Dynamic Brake - electrical resistance or regenerative brake for Drawworks motors. Field Supply Unit for DC field supply to shunt wound, separately excited DC traction motors. Driller"s Console for control of all drilling functions from the drill floor. Mud Pump/Cement Pump Console for local control of the pumps during maintenance. Motor Control Center containing starters for AC auxiliary motors and feeder breakers for lighting panels and smaller distribution transformers.

SPECIFICATIONSThe drive system conforms to IEEE-45 standards for electrical switchgear. For offshore systems, certification can be obtained from American Bureau of Shipping (ABS), United States Coast Guard (USCG), and Det Norske Veritas. See Table 1-1 for system specifications. Table 1-1. System Specifications ELECTRICALAC Input Prime Power Engine Governor Three phase, 60 Hz, 600 VAC Usable KW depends horsepower of prime mover. on

Generator Voltage Regulator 3% regulation one second response time with 10% load unbalance of rated KVAR"s DC Output Zero to 750 VDC at zero through maximum current

MECHANICALTemperature Range Cubicle Construction -22F to 105F (-30C to 40C) Fabricated from 12 gauge cold-rolled steel with welded construction and expanded metal ventilation openings. The cubicle bus is solid copper with a 0.0005 Inch (0.0013 cM) electroplating of silver. Fabricated from 12-gauge #304 stainless steel plate with welded construction.

FUNCTIONAL DESCRIPTIONFigure 1-2 shows a typical one-line diagram. Observe that power from the engine-generator sets is collected on a common AC bus. AC to DC rectification occurs in SCR bridges. The output of the SCR bridge is applied to the DC traction motors via contactors. Contactor logic is set at the Control Console being used. Note that circuit breakers isolate each generator set and SCR Unit from the Main AC Bus.

Adjust the VOLTAGE ADJUST control knob so the VOLTS meter indicates 600 Volts. Charge the circuit breaker (if necessary), by pushing the CHARGE pushbutton for electrically charged circuit breakers, or by cranking the circuit breaker handle for manually charged breakers. Close the circuit breaker by pushing the illuminated PUSH TO CLOSE pushbutton on the appropriate generator cubicle door. Turn the SYNC switch to the OFF position.

SYNCHRONIZING GENERATORSTO BRING AN ADDITIONAL GENERATOR ON LINE 1. (Models 1200, 1201, 1500) Turn the SYNCHRONIZING switch (Item 9 on Figure 1-3, Item 11 on Figure 1-4) to SYNC. (Model 1400) Turn the SYNCRONIZING switch (Item 15 on Figure 1-5) to the number of generator about to be brought on line. (Model 1600) turn the SYNCHRONIZING SWITCH (Item 20 on Figure 1-6) to AUTO. Position the VOLTS ADJUST knob (Item 13 on Figure 1-3 and 1-4, Item 10 on Figure 1-5, Item 17 on Figure 1-6) so the AC VOLTMETER (Item 5 on Figures 1-3 and 1-4, Item 18 on Figure 1-5, Item 7 on Figure 1-6) indicates 600 Volts.

STARTING AN ENGINE1. 2. 3. Place the ENGINE CONTROL switch to IDLE. Start the engine and run it at idle speed until it is warmed up. Place the ENGINE CONTROL switch to RUN. OR 1.

Figure 1-2. Typical One Line Diagram 3. Adjust the SPEED ADJUST knob (Item 12 on Figures 1-3 and 1-4, Item 9 on Figure 1-5, Item 18 on Figure 1-6) until the SYNCROSCOPE needle (Item 20 on Figures 1-3 and 1-4, Item 17 on Figure 1-5, Item 22 on Figure 1-6) moves clockwise (the engine/generator speed is faster than desired) and the two SYNCHRONIZING LIGHTS (Items 21 on Figure 1-3, Items 19 on Figures 1-4 and 1-5, Items 23 on Figure 1-6) brighten/dim.SCR DRIVE SYSTEM TECHNICAL MANUAL

Description GEN Circuit Breaker AC Kilowatts Meter AC Kilovars Meter AC Ammeter AC Voltmeter Generator Run Light Generator On Line Light Engine Control Switch Synchronizing Switch Ammeter Select Switch Voltmeter Select Switch Speed Adjust Knob Volts Adjust Knob % AC Ground Ammeter % DC Ground Ammeter Ground Fault Indicator Lamps Ground Detector Test Button Power Limit Light Hertz (Frequency) Meter Synchroscope Synchronizing Lights

Description GEN Circuit Breaker AC Kilowatts Meter AC Ammeter AC Kilovars Meter AC Voltmeter Generator Run Light Generator On Line Light Ammeter Select Switch Voltmeter Select Switch Engine Control Switch Synchronizing Switch Speed Adjust Knob Volts Adjust Knob % AC Ground Ammeter % DC Ground Ammeter Ground Fault Indicator Lights Ground Detector Test Push Button Power Limit Light Synchronizing Lights Synchroscope Hertz (Frequency) Meter

Description GEN Circuit Breaker AC Kilowatts Meter Kilovars Meter AC Ammeter Engine Control Run/Off/Idle Switch GEN Run Light GEN On Line Light Push to Close Lighted Pushbutton Speed Adjust Knob Volts Adjust Knob % AC Ground Fault % DC Ground Fault Ground Fault Indicator Lights Ground Detector Test Push Button Generator Synchronization Select Switch Frequency (Hertz) Meter Synchroscope AC Voltmeter Synchronizing Lights Power Limit Light Hour Meter

Description AC Kilowatt Meter Temperature Meter Kilovars Meter AC Ammeter % DC Ground Meter % AC Ground Meter AC Voltmeter Generator Run Light Circuit Breaker Push to Charge Push Button Ground Fault Indicator Lights Ground Detector Test Push Button Circuit Breaker Indicator Lights

Description Ammeter Select Switch Engine Governor Switch Circuit Breaker Switch Voltmeter Select Switch Volts Adjust Knob Speed Adjust Knob Temperature Select Switch Synchronizing Switch Frequency (Hertz) Meter Synchroscope Synchronizing Lights GEN Circuit Breaker

1-9 4. Crank the handle of the GEN CIRCUIT BREAKER (Item 1 on Figures 1-3, 1-4, and 1-5, Item 24 on Figure 1-6) once to charge the GEN CIRCUIT BREAKER. Close the GEN CIRCUIT BREAKER when the needle of the SYNCROSCOPE points straight up, the SYNCHRONIZING LIGHTS go out, and the PUSH TO CLOSE pushbutton on the GEN CIRCUIT BREAKER is illuminated. Position the VOLTAGE ADJUST knob so the KVAR meter gives the same reading as the other generator(s) on line. Turn the SYNCHRONIZING SWITCH to the OFF position. 2. Charge the circuit breaker (if necessary), by pushing the CHARGE pushbutton (for electrically-charged circuit breakers) (refer to Figures 1-3 through 1-6) or by cranking the circuit breaker handle (for manually-charged circuit breakers). Some systems have molded-case circuit breakers. These do not require charging. Close the SCR circuit breaker by pushing the PUSH TO CLOSE pushbutton (this may be mounted remotely or directly on the circuit breaker). Crank the circuit breaker handle once to close molded-case circuit breakers.

REMOVE GENERATOR FROM LINE AND STOP ENGINE1. 2. 3. Open the circuit breaker by pushing the circuit breaker OFF pushbutton. Place the ENGINE CONTROL switch in the IDLE position. If the GOVERNOR CONTROL switch has an OFF position, go to the OFF position only after engine has cooled down. If system equipped with a GOVERNOR CONTROL pushbutton switch, the engine must be shut down at the engine.

SWITCH ON AUXILIARIES1. Close the feeder circuit breaker to feed AC supply to the distribution transformers and the MCC. Close the circuit breakers corresponding to each of the blowers and auxiliaries. Set the HAND/OFF/AUTO switch to AUTO (if applicable). If the motors are shunt wound, switch on the appropriate field power supplies. Each motor"s field current should be 50 Amps (or per the motor nameplate rating).

1-10 KW SHARING (CONCLUDED) The master generator is the lowestnumbered unit connected to the Main AC Bus. The remaining generators are slaved to the master. For example, if Generator 1, 2, and 4 are connected to the Main AC Bus, Generator 1 is the master. In systems using Auto Share (Auto Sync) AC Control Modules, master/slave floats. No AC Control Module can be the dedicated master in an Auto Share system. The magnetic coupling that exists between paralleled generators insures that all engine generator sets connected to the Main AC Bus at the same time will run at the same speed. The SPEED ADJUST knob on the master generator has total control of the Main AC Bus frequency. The slave units SPEED ADJUST controls are disabled. The combination of KW (Real Power) and KVAR (Reactive Power) sharing between engine generator sets should cause all generator AMMETERS to read about the same value. Any imbalance in the readings of the various KVAR meters can be adjusted by using the VOLTAGE ADJUST knob of the generator that has the lowest KVAR meter reading. POWER DISTRIBUTION Distribution of the total power is governed by the following equation: DCPower Demand = Power Used (Total - AC) Bring additional generators on line to increase the total power available. To increase the total DC power available, increase the total power by putting more generators on line. AC power is usually a small fraction of the DC power. To increase power for a specific DC function, it also helps to reduce the power consumed by the other DC functions.SCR DRIVE SYSTEM20605-45 Rev K

Due to the Main AC Bus feature and the Power Limit circuit, it is possible to connect as few generators to the Main AC Bus as are necessary to do the work. For economy and efficiency, match the total available power to the total load.

CRISIS OPERATIONUNIT MALFUNCTION The GEN ON LINE and SCR ON lights will illuminate when the respective units are connected to the Main AC Bus. The lights go out when that unit is tripped off-line (disconnected from the Main AC Bus). If a generator\SCR unit becomes inoperative, continue the system operation on other units. SYNC MALFUNCTION If the SYNCHROSCOPE is inoperative, use the SYNC lights to parallel the generators. If both the SYNCHROSCOPE and the SYNC lights fail, use a Multimeter. Switch the Multimeter to a 600 VAC scale. Connect it across the generator circuit breaker from the top to the bottom of any one phase. The voltage will swing from minimum to 600 VAC just as the SYNC lights should change from dim to bright. Adjust the SPEED ADJUST knob for the oncoming generator until the swing slows. Close the circuit breaker when the Multimeter voltage reading is minimum. TRANSIENT AC SURGE The green SURGE SUPPRESSION light will extinguish if a problem blows the Surge Suppression Circuit incoming line fuses.

1-11 SPROCKET SLIP The SPROCKET SLIP light illuminates when Mud Pump assignment contactors trip. This is caused by a sprocket slip, chain failure, or belt slippage on a dual motor mud pump. After the chain drive is repaired, push the SPROCKET SLIP RESET button to extinguish the SPROCKET SLIP light and to allow the contactors to close. GROUND FAULT The three GROUND DETECTOR lights and the % AC GROUND and % DC GROUND meters indicate ground faults. These are only indicators and the fault must be located and corrected. AC ground faults can occur anywhere along the AC power network (generator to AC bus cables, feeder distribution to the AC motors, and the generator control bus in the cubicle itself). The GROUND DETECTOR lights will isolate the fault to one of the phases, and the % AC GROUND meter will indicate the degree of the fault. DC ground faults may occur anywhere along the DC network from the DC (+) and DC (-) buses in the SCR cubicles to the motor cables. Isolate the fault to one motor by observing the % DC GROUND meter. The % DC GROUND meter needle will fluctuate as the faulty motor speed is changed.

SHUT DOWN INSTRUCTIONS1. Turn off the SCR unit by tripping the SCR circuit breaker. The SCR ON light will extinguish. Disconnect the generator from the Main AC Bus by tripping the Generator circuit breaker. The GEN ON LINE light will extinguish. Push the engine IDLE pushbutton. Cool the engine per the engine manufacturer. After the engine cool-down period is over, turn the Generator Control cubicle OFF/IDLE/RUN switch to OFF to stop the engine. Shut down the fuel rack if there is no OFF button.

CAPABILITIESFigure 1-7 shows an SCR bridge Current versus Voltage response curve. Figure 1-8 shows DC series and shunt motors Speed versus Torque curves. These are for a specific brand and model motor. Other brands and models will be different.

MAINTENANCEThis chapter contains information to assure proper operation of the system through periodic functional tests and preventive maintenance. If the system fails to perform as indicated in the functional test instructions, consult the troubleshooting guidelines listed in this manual.

If the house is not ordered, the equipment should be handled with care to prevent excessive mechanical shock, and protected from possible damage due to moisture and dirt during rig-up. See Figures 1-11 and 1-12 for cubicle lifting procedure.

RECEIVING & HANDLINGSCR switchgear is normally installed in a truckload-sized house (see Figure 1-9), a self-contained, structural steel building mounted on skids. Cabling to external devices such as generators, motors and control consoles is terminated at weatherproof plug panels (see Figure 1-10).

If an SCR house was not ordered, refer to the following instructions for installation of the SCR Cubicles. Figure 1-14 shows a typical SCR Drive Cubicle lineup.

CUBICLESPRELIMINARY CONSIDERATIONS Door Clearance The SCR room must be large enough to allow the doors to be opened 90 degrees. The doors cover the full height of the cubicles. The height of the room must have clearance for the cable tray, piping, and ducting. Ventilation and Ducting The room air must be changed twice per minute when the cubicles are enclosed in a room. Ducting in the front and rear of the room should force the air to flow the full length of room. Heat Loss Heat loss for a SCR system housed in a room fully insulated on walls, floor and ceiling, and containing no distribution transformers, is approximately 2.5 tons for each 1,000 HP of DC load. Vibration Pads If the cubicles are mounted in a high vibration area, such as the region close to the engine skid, the cubicles should be mounted on vibration insulating pads. The vibration frequency should be within 30 Hz, and the amplitude should not exceed 0.02 cM. Korfund spring-type vibration isolators are recommended. Location Lift the cubicle with a crane into the general installation area. Use four lifting points per cubicle. Refer to Figures 1-11 and 1-12 for the lifting procedure.

Use hydraulic hand trolleys (Rol-A-Lift or equivalent) to move the cubicles into the exact location. Two trolleys may be required for wide cubicles such as the Motor Control Center. Cover the vertical rest beams of the trolleys with carpeting to protect the finish of the cubicle panels. Slide the trolley horizontal forks all the way underneath the cubicle. Jack up the cubicle approximately 6" (15 cm) above the floor. Push the cubicle carefully into the location, jack down, and remove the trolley horizontal forks. Mounting Butt the sides of the cubicles tightly together. Bolt the cubicles together at the top and bottom using 3/8" bolts. Install the AC bus splices to connect the bus together from cubicle to cubicle. Cable Installation Refer to the cabling diagrams in the SCR job book. Cables between the cubicles are furnished by the customer unless the SCR drive system is installed in a Power Control Building. All power terminations are made through the cubicle top unless otherwise designed. If the SCR system is supplied inside a Power Control Building, power and control cable terminations are at one end of the building. The terminations are copper stubs with an one inch diameter bolt hole. The customer should furnish plated-copper, crimp-type lugs. Avoid screw-type pressure connectors.SCR DRIVE SYSTEM TECHNICAL MANUAL

1-19 If multiple single conductor cables are used to feed the system, transposing of the cables must be considered to ensure current sharing between conductors. Control Consoles The Driller"s Console is typically mounted on top of the Drawworks pneumatic control console. The Mud Pump and Cement Pump consoles are provided with tabs. Each tab has a bolt hole for wall installation. Refer to the respective console drawings for detailed installation instructions. Control cable terminations are made from the bottom with plug-in-type Pyle National connectors or screw-type terminal blocks fed through stuffing tubes. Team Work Maintenance work should preferably be

8613371530291

8613371530291