safety release valve mud pump manufacturer

Relief valve mud pump is also called the centrifugal pump, a compressor, and a compressor. It has a series of pistons, this is done in the form of a centrifugal pump, with a compressor. It is usually used by hydraulic maintenance. The rotating pumps have different cuffs and suction cuffs.@@@@@

Relief valve mud pumps are specially designed for the rotation of the vehicle. There are many types of relief valve mud pumps, suitable for a rotating purpose, such as electric relief valve mud pumps. In the case of the different, pumps are suitable for a rotating process. They are suitable for rotating, there are various sizes and varieties of the pumps depending on the rotation pattern, but with a lesser water flow. On the other hand, there are various types of relief valve mud pumps that are specially designed for use in rotating processes. If the pump is suitable for a rotary motion, these pumps are suitable for a rotary process, and can be used on both sides of the vehicle. On Alibaba.com, there are various types of relief valve mud pumps, such as electric relief valve mud.

Thanks for visiting the website of Dezhou Rundong Company. We are an ISO9001 and API 7K certified safety valve manufacturer, located in China. Our location in Dezhou city gives us access to convenient transportation by sea, air, and land. This guarantees lower transportation cost, thus reducing our production costs and saving customers on shipping charges. An extensive line of oil equipment is available at Rundong, such as valve, downhole drilling motor, mud pump parts, and many others. If you require more information, please contact us. The staff at Rundong is happy to assist you with whatever you may need.

Pressure relief valves are installed on mud pumps in order to prevent an overpressure which could result in a serious damage of the pump and serious or fatal injury to personnel.

The discharge pressure is routed to the closer mud tank, via a 3” XXS line clamped strongly on tank side . Mud is flowing into the mud tank until line bled off, bearing in mind that minimum slope is required to avoid mud settling in pipe ( around 1 inch/meter).

Pressure relief valves are set usually to 90% of the maximum working pressure of the liners in use. Read carefully manufacturer chart for pressure setting versus size of liners.

Discharge pressure losses close to the maximum preset pressure.The Pressure relief valves are usually installed on a upper point of the discharge side of the mud pumps.

The pressure relief valve can be reset, if not damaged during the release of pressure. Special care should be taken if no working platform available to access the PRV.

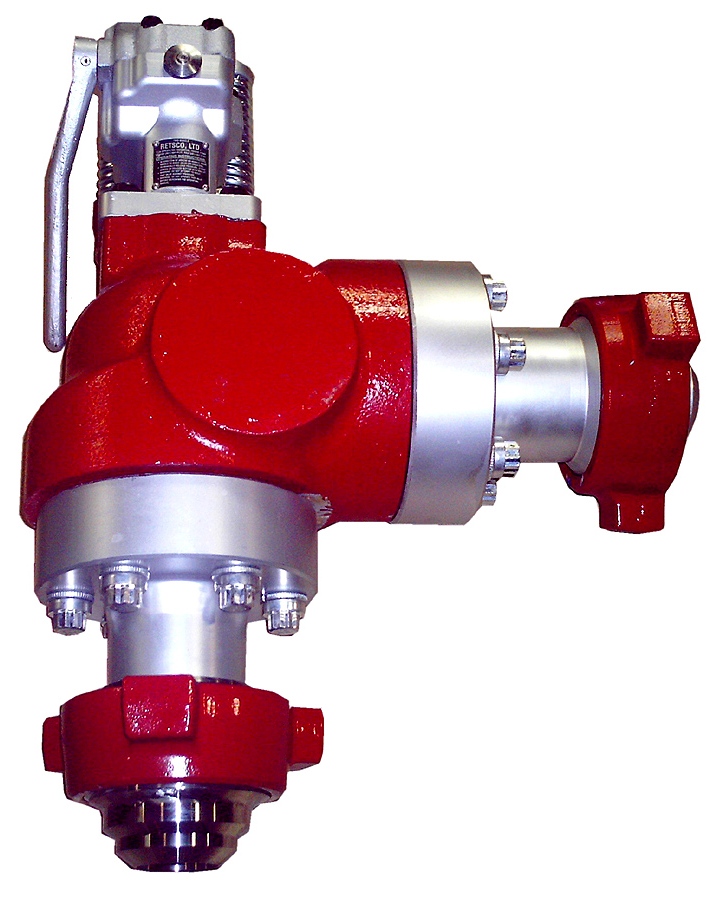

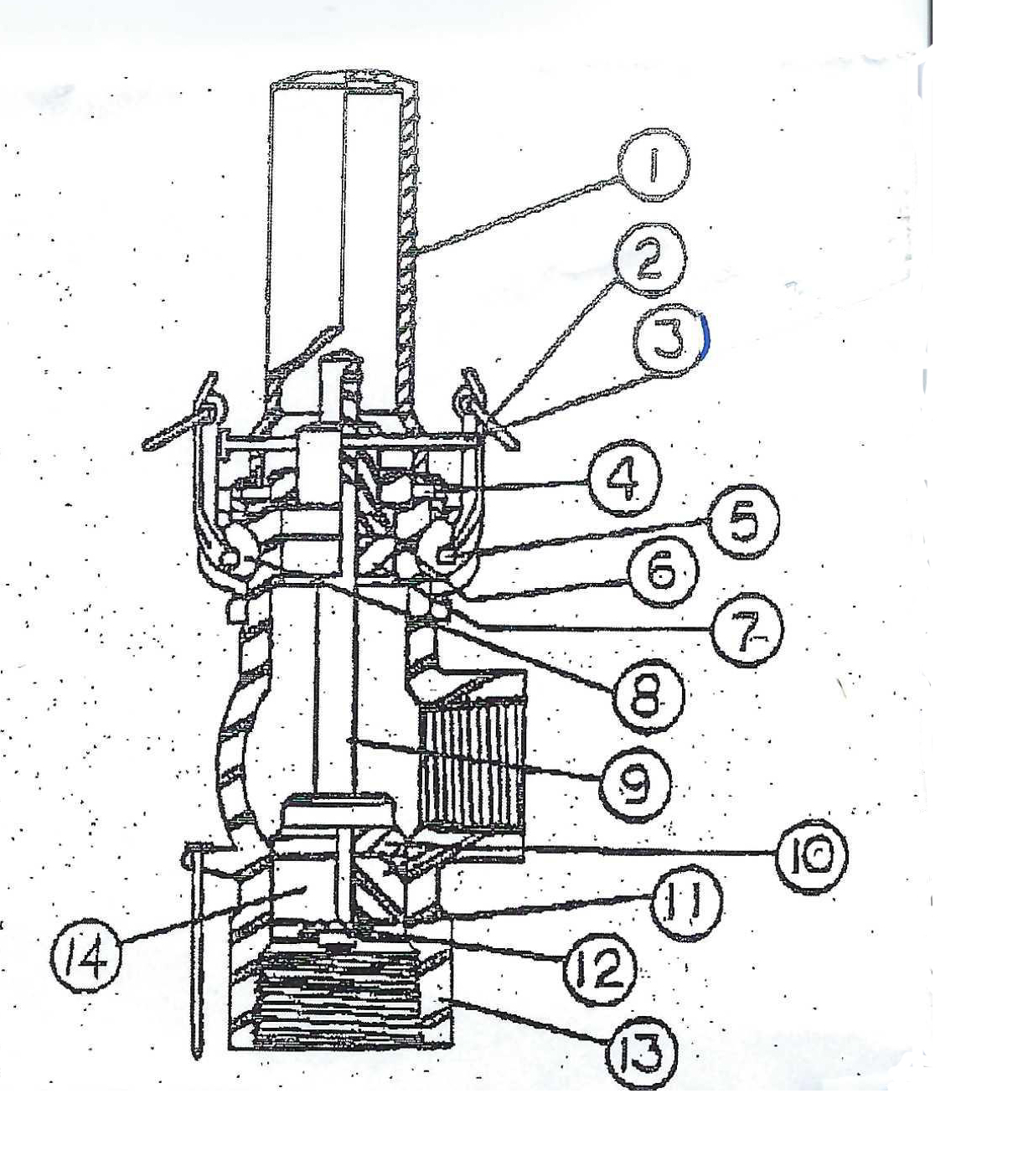

The JA-3 shear relief valve is used for the discharge part of the mud pump. It changes the discharge pressure by changing the position of the shear pin. It is easy to operate, reliable in operation, small in pressure piston area, easy to reset, and versatile. Well, it can be connected to a variety of pumps.

The consumables in the shear relief valve are: shear pin, piston, piston rod and cushion. It is the insurance of the mud pump. Before the mud pump is operated, after the rated pressure is determined according to the specifications of the cylinder liner and the piston, the upper cover of the safety valve is lifted, and the shear pin is inserted into the corresponding pin hole of the shear plate. During operation, when the pressure of the pump head exceeds the rated pressure, the shear pin is sheared and the mud is discharged from the side hole of the safety valve, which plays a corresponding protective role.

The connection method can be divided into two types, one is a threaded connection, and the other is a flange connection, depending on the customer"s needs. The JA-3 shear pin safety valve is currently used in high pressure jet drilling rigs and can also be used in high pressure circulation systems for other media.

4. Regularly apply grease between the Versail body and the upper and lower valve bodies to prevent corrosion and cause safety valve failure and unstable working performance.

6. The safety pin cannot be manufactured at will, so the safety pin carried at random must be installed when using this safety valve, and other similar pins should not be used instead.

We serve you with years of experience in the Slnf-35 Safety Valve/Shear Relief Valve for Drilling Mud Pump 3nb-350/3nb-500/3nb-600/3nb-800/3nb-1000/3nb-1300/3nb-1300c/3nb-1600 etc industry, and sincerely look forward to communicating and cooperating with you in a mutually beneficial and win-win manner. Our company is constantly upgrading equipment to achieve higher standards and longer maintenance cycle. As long as we sincerely pay and treat each other sincerely, the value of our company will be expanded and extended infinitely.

Hot Tags: shear relief valve, China, manufacturers, supplier, factory, company, price, quick delivery, hight quality, oilfield, oil and gas, size, for sale, Grade D sucker rod, Flat TTP strip, OMNI Circulating Valved, 3NB-800 Mud pumps for drilling rigs, Guide Plate, pump parts

Condor Pumps have been appointed exclusive NZ distributors for TTi Trans Tank International - Australia"s safest tanks and trailers - down load your TTi New Zealand catalogue by clicking on the image below

New replacement air compressor pressure safety relief valves. Using the correct one for your application is critical for safety. If you need help picking the right one, please call us for assistance.

A relief valve is a Valve which is installed on a pump or pipework to relieve excessive pressure in a positive displacement pump which could cause damage to a pump or system. Relief valves (also known as bypass valve or safety valve) are known as an Internal Relief Valve if installed on the pump itself, and if installed on the system they are known as an External Relief Valve.

Such valves are used on positive displacement pumps as the pumps are designed to prevent recirculation of fluid back to the inlet, meaning the displacement is always forward. However if a valve is closed on the outlet of the pump, or a blockage occurs the pump will continue to build pressure in the outlet pipework and within itself. This can cause pressures to reach dangerously high levels, and the pressure will vent at the weakest part of the system, causing a leak, damage or pump failure.

Such valves work in different ways depending on where they are installed. If installed on a pump the fluid is recirculated within the pump head, preventing the buildup of pressure, however the fluid begins to heat up, and is something which should only be done temporarily as it can lead to pump failure. External relief valves should be used in conjunction with internal relief valves to relieve any excessive pressure in the pipework either back to a vented tank or to dump contents in an emergency to atmosphere.

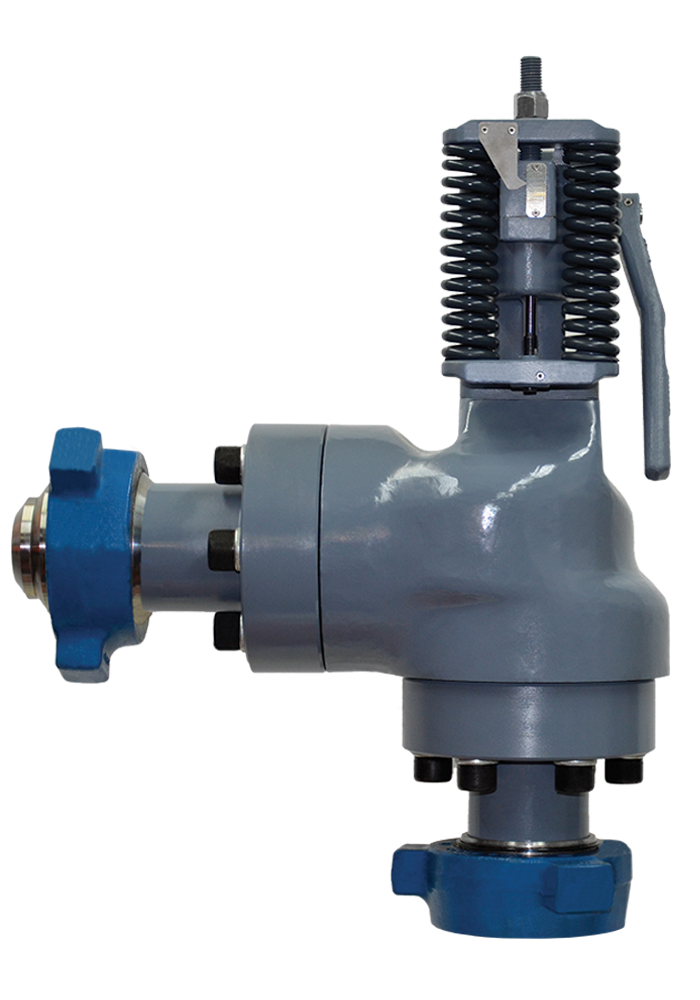

A relief valve design consists of a housing with inlet and outlet connections, a spring within a chamber which keeps a plate in place sealing the discharge. When the valve reaches the set relief pressure, the pressure plate causes the spring to compress revealing the discharge, causing the pressurised contents to vent through the discharge. A set screw or nut is used to set the relief pressure, at the top of the housing and when screwed clockwise, compresses the spring increasing the amount of pressure required to compress the spring and open the valve.

Internal relief valve set pressure is usually set at 10% above the operating pressure of the pump, and external relief valves should be set at 10% higher than the relief valve on the pump to prevent nuisance tripping. Valves are typically calibrated during manufacture and can be set on site with the use of pressure gauges during commissioning. Valves are rated in ranges such as from 0-10 bar, or 10-15 bar so should a valve pressure rating require recalibrating, checks should be made to ensure the setting is inline with the rating of the valve. Equipment should be checked at regular intervals to ensure succesful operation during an emergency.

Relief valves are not always required if the pressure capability of the pump is low, but also if used in conjunction with a product which can solidify when cooled if it enters the relief valve such as Chocolate or Bitumen. If fluid sets within a relief valve this will prevent it from operating as normal as any material which hardens will form a plug and can also cause contamination as it can be very difficult to clean thoroughly.

On some pumps a pressure relief valve is used in conjunction with a pressure regulator which regulates the pump to deliver the required pressure for the system. An analogy often used to describe a pressure regulator is akin to brakes in a car, with and the relief valve being the seat belt. A relief valve should only be relied on for use in emergencies to prevent damage to the pump or system and not as frequent protection for the system.

To ensure safety, the drilling pump is equipped with a safety valve in the outlet, which is able to control the ultimate pressure of the pump within the admitted scope.

The high-pressure safety valve is forged by high-quality structural alloy steel. As a kind of protection device and human safety device, it is generally installed on cementing devices, fracturing pumps, high-pressure operation piping, pressure vessel and devices under high pressure and high flow capacity. It controls the elastic force of the valve seat by adjusting the nut on the top. Once the pumping pressure or piping pressure exceeds the pre-established pressure value, the safety valve opens automatically to release the pressure. When the pressure value reaches the normal value, the valve rod will recover the position by spring and close the valve.

8613371530291

8613371530291