self running mud pump manufacturer

Distributor of heavy duty submersible mud, sand, sludge & slurry pumps. Specifications of pumps include 5 hp to 30 hp motor, three phase, 208 V to 575 V, 6.8 A to 39 A, 3 in. to 6 in. NPT sizes, 38 ft. to 134 ft. head size & 475 gpm to 1,690 gpm flow rate. Features include impellers, wear plates & agitators made from abrasive resistant 28 percent chrome iron, process hardened ductile iron volutes casted with thick walls, class H motor insulation, double silicon carbide mechanical seals, heavy duty lip seal & stainless steel shaft & shaft sleeve. Sand, sludge & slurry pumps are used in mines, quarries, dredging, coal & ore slurries, sewage treatment plants & steel mills. UL listed. CSA approved. Meets OSHA standards.

Mud Pumps come in both electric and gas / diesel engine drive along with air motors. Most of these pumps for mud, trash and sludge or other high solids content liquid dewatering, honey wagon and pumper trucks. Slurry and mud pumps are often diaphragm type pumps but also include centrifugal trash and submersible non-clog styles.

WARNING: Do not use in explosive atmosphere or for pumping volatile flammable liquids. Do not throttle or restrict the discharge. Recommend short lengths of discharge hose since a diaphragm mud pump is a positive displacement type and they are not built with relief valves.

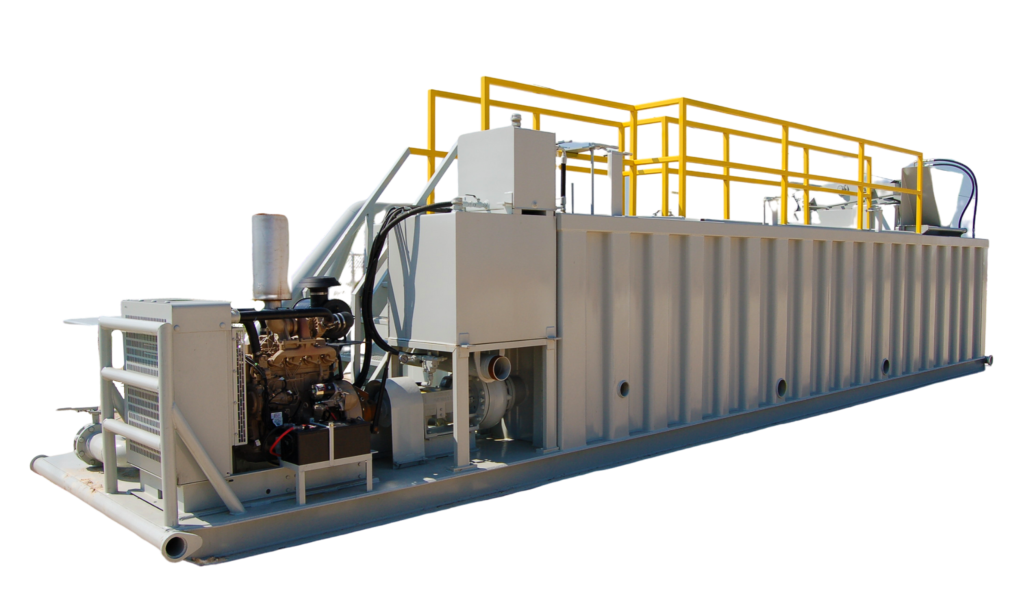

The 2,200-hp mud pump for offshore applications is a single-acting reciprocating triplex mud pump designed for high fluid flow rates, even at low operating speeds, and with a long stroke design. These features reduce the number of load reversals in critical components and increase the life of fluid end parts.

The pump’s critical components are strategically placed to make maintenance and inspection far easier and safer. The two-piece, quick-release piston rod lets you remove the piston without disturbing the liner, minimizing downtime when you’re replacing fluid parts.

Jagdishpump is one of the leading manufacturer and supplier of pumps for industrials purposes. Incepted in 1980, in a short spam of time Jagdishpump made its credibility on the basis of excellence and products, a customer pleasure. Our range include different types of industrials pumps such as dewatering pump, effluent pump, ETP pump, mud pump, muddy water pump, self priming centrifugal pump, sewage pump, trash pump etc. With over 45 years of rich experience in pump industry and 30 years of manufacturing industrial pump, parts, and customize solutions for pumping needs and un-parallel support on after sales service.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

The "VIRAJ" make "VSPM" series is designed in self priming Non-clog Horizontal pump of Mono Block and only pump construction. This series pumps available with semi open type impeller s per customer application. This pump future is quick self priming action, long life due to replaceable wearing parts and for priming no need foot valve and easy maintenance and spare available.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

With the trade name and an outstanding exporter, supplier and manufacturer of Mud Pump, those are the give back needle / piston devices developed to circulate the drilling fluid with high pressure. We are highly flourished and engaged in offering Mud Sewage Pump, Self Priming Mud Pump and many more. These manufactured pumps are an important part of the equipment which is used for oil well drilling. Offered Mud Pumps are hugely used as a part of oil, mining, oil and gushing treatment applications. Besides, conspiracy customers can buy the offered Mud Pump at reasonable costs from us.

We are able to provide you with stable flow, self-priming ability, smooth running mud pump, we have been working on oil equipment for many years, we have overseas markets, such as the United States, Canada, Russia and so on. If you see our website and information, and interested in our products, please contact us, we will be honored very much!

We are a Chinese manufacturer of oil equipment, our mud pump noise is small, smooth operation, vibration is relatively small. Our mud pumps deliver stable flow and low flow rates while maintaining high rejection pressures. Self-priming ability, easy disassembly and maintenance.

Mud pump before starting, please check the inlet pipe, outlet pipe is blocked, before and after the bearing whether to add butter, check the packing is full. Mud pump work should be equipped with high pressure water pump, will be greater than the pressure of the mud pump water leakage leak-proof filler, the filler protection, mud pump work must not turn off the washing pump, otherwise, will make the seal part of the rapid wear and tear. Whether the gap between the impeller and the guard plate is reasonable, a great impact on the life of the mud pump. The gap is unreasonable, the pump running vibration and noise, over flow parts quickly damaged, so the replacement of the impeller, should pay attention to the gap to meet the requirements of the drawings, clearance adjustment, through the rear bearing body to adjust the screw to carry out. The allowable suction of the mud pump is measured when the water is delivered, and the effect of the mud on the suction capacity should be taken into account when sucking the slurry.

Our clients can avail from us Self Priming Mud Pump that comes with self priming action, which ensures easy maintenance. These are durable, cost effective and also provided with non-clogging impeller to handle suspended solids. Designed using latest technology, these pump optimum performance and are used in steel & thermal plants.

A mud pump is a reciprocating piston device designed to circulate drilling fluid under high pressure. RS-240 triplex single-acting piston pump is a horizontal, triplex, single acting reciprocation piston pump which is reliable, agile and simple for operation. It can be driven by diesel engine, electric motor or hydraulic motor. RS-240 triplex single-acting piston pump is characterized by compact structure, smooth running, large-scale variable rates of flow, high output pressure, long service life and so on.

As a well-known global mud pump manufacturer, we provide all kinds of mud pump to meet the needs of different construction demands. RS-240 triplex single-acting piston pump provides 4 different discharge pressure, and it is mainly used to match horizontal directional pipe laying drilling machine. The pump can meet the needs of construction for water well and earth heat, superficial layer oil drilling and mine drainage.

We are a three-decade-old company that manufactures and supplies high quality pumps, for a range of industrial sectors and purposes. Our products are revered for their finesse and integrity which has been honed by our expert engineers. Moreover, as we understand the diverse needs of the dynamic industries we cater to, our products are highly customizable.

The drilling industry has roots dating back to the Han Dynasty in China. Improvements in rig power and equipment design have allowed for many advances in the way crude oil and natural gas are extracted from the ground. Diesel/electric oil drilling rigs can now drill wells more than 4 miles in depth. Drilling fluid, also called drilling mud, is used to help transfer the dirt or drill cuttings from the action of the drilling bit back to the surface for disposal. Drill cuttings can vary in shape and size depending on the formation or design of the drill bit used in the process.

Watch the video below to see how the EDDY Pump outperforms traditional pumps when it comes to high solids and high viscosity materials commonly found on oil rigs.

The fluid is charged into high-pressure mud pumps which pump the drilling mud down the drill string and out through the bit nozzles cleaning the hole and lubricating the drill bit so the bit can cut efficiently through the formation. The bit is cooled by the fluid and moves up the space between the pipe and the hole which is called the annulus. The fluid imparts a thin, tough layer on the inside of the hole to protect against fluid loss which can cause differential sticking.

The fluid rises through the blowout preventers and down the flowline to the shale shakers. Shale shakers are equipped with fine screens that separate drill cutting particles as fine as 50-74 microns. Table salt is around 100 microns, so these are fine cuttings that are deposited into the half-round or cuttings catch tank. The drilling fluid is further cleaned with the hydro-cyclones and centrifuges and is pumped back to the mixing area of the mud tanks where the process repeats.

The drill cuttings contain a layer of drilling fluid on the surface of the cuttings. As the size of the drill cuttings gets smaller the surface area expands exponentially which can cause rheological property problems with the fluid. The fluid will dehydrate and may become too thick or viscous to pump so solids control and dilution are important to the entire drilling process.

One of the most expensive and troubling issues with drilling operations is the handling, processing, and circulation of drilling mud along with disposing of the unwanted drill cuttings. The drilling cuttings deposited in the half round tank and are typically removed with an excavator that must move the contents of the waste bin or roll-off box. The excavators are usually rented for this duty and the equipment charges can range from $200-300/day. Add in the cost for the day and night manpower and the real cost for a single excavator can be as much as $1800/day.

Offshore drilling rigs follow a similar process in which the mud is loaded into empty drums and held on the oil platform. When a certain number of filled drums is met, the drums are then loaded onto barges or vessels which take the drilling mud to the shore to unload and dispose of.

Oil field drilling operations produce a tremendous volume of drill cuttings that need both removal and management. In most cases, the site managers also need to separate the cuttings from the drilling fluids so they can reuse the fluids. Storing the cuttings provides a free source of stable fill material for finished wells, while other companies choose to send them off to specialty landfills. Regardless of the final destination or use for the cuttings, drilling and dredging operations must have the right high solids slurry pumps to move them for transport, storage, or on-site processing. Exploring the differences in the various drilling fluids, cutting complications, and processing options will reveal why the EDDY Pump is the best fit for the job.

The Eddy Pump is designed to move slurry with solid content as high as 70-80 % depending on the material. This is an ideal application for pumping drill cuttings. Drill cuttings from the primary shakers are typically 50% solids and 50% liquids. The Eddy Pump moves these fluids efficiently and because of the large volute chamber and the design of the geometric rotor, there is very little wear on the pump, ensuring long life and greatly reduced maintenance cost for the lifetime of the pump.

plumbed to sweep the bottom of the collection tank and the pump is recessed into a sump allowing for a relatively clean tank when the solids are removed. The Eddy Pump is sized to load a roll-off box in 10-12 minutes. The benefit is cuttings handling is quicker, easier, safer, and allows for pre-planning loading where the labor of the solids control technician is not monopolized by loading cuttings. Here, in the below image, we’re loading 4 waste roll-off bins which will allow the safe removal of cuttings without fear of the half-round catch tank running over.

Mud cleaning systems such as mud shaker pumps and bentonite slurry pumps move the material over screens and through dryers and centrifuges to retrieve even the finest bits of stone and silt. However, the pump operators must still get the raw slurry to the drill cuttings treatment area with a power main pump. Slurry pumps designed around the power of an Eddy current offer the best performance for transferring cuttings throughout a treatment system.

Options vary depending on whether the company plans to handle drill cuttings treatment on-site or transport the materials to a remote landfill or processing facility. If the plan is to deposit the cuttings in a landfill or a long-term storage container, it’s best to invest in a pump capable of depositing the material directly into transport vehicles. Most dredging operations rely on multiple expensive vacuum trucks, secondary pumps, and extra pieces of equipment.

Using an EDDY Pump will allow a project to eliminate the need for excavators/operators to load drill cuttings, substantially lowering both labor and heavy equipment costs. The EDDY Pump also allows a company to eliminate vacuum trucks once used for cleaning the mud system for displacing fluids. Since the pump transfers muds of all types at constant pressure and velocity throughout a system of practically any size, there’s little need for extra equipment for manual transfer or clean up on the dredge site.

The EDDY Pump can fill up a truck in only 10 minutes (compared to an hour) by using a mechanical means such as an excavator. For this reason, most companies can afford one piece of equipment that can replace half a dozen other units.

This application for the Eddy Pump has the potential to revolutionize the drilling industry. Moving the excavator out of the “back yard” (the area behind the rig from the living quarters) will make cuttings handling a breeze. Trucking can be easier scheduled during daylight hours saving on overtime and incidences of fatigued driving. Rig-site forklifts can move the roll-off boxes out of the staging area and into the pump loading area. The operator can save money on excavators rental, damages, and keep the technician operating the solids control equipment.

The EDDY Pump is ideal for drilling mud pump applications and can be connected directly onto the drilling rigs to pump the drilling mud at distances over a mile for disposal. This eliminates the need for costly vacuum trucks and also the manpower needed to mechanically move the drilling mud. The reasons why the EDDY Pump is capable of moving the drilling mud is due to the hydrodynamic principle that the pump creates, which is similar to the EDDY current of a tornado. This tornado motion allows for the higher viscosity and specific gravity pumping ability. This along with the large tolerance between the volute and the rotor allows for large objects like rock cuttings to pass through the pump without obstruction. The large tolerance of the EDDY Pump also enables the pump to last many times longer than centrifugal pumps without the need for extended downtime or replacement parts. The EDDY Pump is the lowest total life cycle pump on the market.

EDDY Pump enters a new oil and gas contract with National Oilwell Varco (NOV). The EDDY Pump will be moving drilling mud from one of the largest onshore drilling rigs in North America. The operation is located in Alaska and run by NOV.

The EDDY Pump won the contract based on its abilities to move heavy solids and thick drilling mud. The SG ranges from 1.4 to 1.8 and the Centipoise rating is from 50 to 500. This contract is a great win for us and we are looking forward to a strong future in the oil and gas sector.

We would like to take the privilege of introducing ourselves as the trusted manufacturer and supplier of Mud Pump . These pumps are used in various marine, industrial, mine and civil construction applications for lifting slurry & muddy water. Our Mud Pump is made by a team of expert professionals using quality approved materials. We are leading Manufacturer of Mud Pumps, Supplier of Mud Pumps in india, gujarat, baroda, vadodara, ankleshwar, vapi, ahmedabad.

8613371530291

8613371530291