slurry mud pump parts made in china

Innovation, excellent and reliability are the core values of our company. These principles today much more than ever form the basis of our success as an internationally active mid-size business for China Mud Pump Parts Manufacturers and Suppliers - Factory Pricelist | YAAO, Impeller Pump Spare Parts, Slurry Pump Impeller Price List, Cyclone Rubber Lining,Slurry Pump Wet End Parts. Should you be interested in almost any goods, remember to truly feel totally free to get in touch with us for further facts or be sure to deliver us email right, we will reply you in just 24 hrs as well as the finest quotation are going to be provided. The product will supply to all over the world, such as Europe, America, Australia,British, Macedonia,Atlanta, Seattle.Our continual availability of high grade products in combination with our excellent pre-sale and after-sales service ensures strong competitiveness in an increasingly globalized market. welcome new and old customers from all walks of life to contact us for future business relationships and mutual success!

Sunbo slurry pump manufactures high quality heavy-duty horizontal slurry pumps, vertical slurry pumps, replacement pump parts, and provides pump services to a wide array of markets worldwide.we serve global industries that supply valuable raw materials to the marketplace with trustworthy and reliable pumps, parts, and service. We exist to provide unmatched engineering excellence, ...

Sunbo Pump supports the success of our customers and representatives by delivering quality slurry pumps and parts in a timely and conscientious manner, and maintaining a trustworthy and courteous relationship with each partners.

• 100% interchangeable with AH, AHR, HH, M, L horizontal slurry pumps, SP, SPR vertical slurry pumps, G,GH gravel pumps, AF/AHF froth slurry pumps, MCR mill circuit pumps etc

Shijiazhuang Minerals Equipment Co., Ltd. is a professional Slurry Pump supplier in China. We are engaged in the manufacturing and producing of heavy duty and severe duty slurry pumps and spare parts.

Being manufactured at the highest standards, our pumps can guarantee longer service life, higher performance, easier operation and maintenance. They are widely used in mining, mineral processing, tailings disposal, dredging, construction, metallurgy, power plants, sewage water treatment, as well as chemical and petroleum industry.

With decades of development, we have built a complete system of slurry pump design, selection, application and maintenance. We devote ourselves to offering the solutions of slurry pump application for customers from all over the world. Our team consists of a global pool of highly dedicated people working closely together to ensure our customers"success.

Explore a wide variety of sludge pump parts on Alibaba.com and enjoy exquisite deals. The machines help maintain drilling mud circulation throughout the project. There are many models and brands available, each with outstanding value. These sludge pump parts are efficient, durable, and completely waterproof. They are designed to lift water and mud with efficiency without using much energy or taking a lot of space.

The primary advantage of these sludge pump parts is that they can raise water from greater depths. With the fast-changing technology, purchase machines that come with the best technology for optimum results. They should be well adapted to the overall configuration of the installation to perform various operations. Hence, quality products are needed for more efficiency and enjoyment of the machines" full life expectancy.

Alibaba.com offers a wide selection of products with innovative features. The products are designed for a wide range of flow rates that differ by brand. They provide cost-effective options catering to different consumer needs. When choosing the right sludge pump parts for the drilling project, consider factors such as size, shape, and machine cost. More powerful tools are needed when dealing with large projects such as agriculture or irrigation.

Alibaba.com provides a wide range of sludge pump parts to suit different tastes and budgets. The site has a large assortment of products from major suppliers on the market. The products are made of durable materials to avoid corrosion and premature wear during operations. The range of products and brands on the site assures quality and good value for money.

Centrifugal Slurry pumpsare the most popular slurry pumps on the market due to excellent wear life almost without reducing efficiency during the wear cycle.

Competition for slurry pump spare parts always benefits the end users, you can use slurry components diagrams to determine part numbers for your slurry pumps.

Because we are a slurry pump Original Equipment Manufacturer (OEM) with performance curves and original drawings, we know the exacting tolerances and engineering standards required to build and maintain these slurry pumps, and the replacement parts we supply for centrifugal slurry pumps are identical to the parts we put into our slurry pumps.

Slurry pump partsare described by a part number consisting of three segments. First segment describes the relative pump or frame size of the part, second segment describes the part type, third segment describes the material of part.

Tobee® manufactures quality metal slurry pump parts, elastomer slurry pump parts and polyurethane slurry pump parts fully compatible with warman pumps, and provides value to customers through fair pricing and lead times that are some of the lowest in the market. We stock millions of dollars of pumps and parts globally, all of which are interchangeable with warman pump parts. We maintain a global distribution network that stands ready to serve your process needs.

All parts compatible with the warman slurry pumps have been rigorously reverse engineered using FaroArm® technology with 2D and 3D modeling. First article inspection involves comparison to OEM parts followed by fit testing. All impellers have been performance tested to certify them against OEM performance. Tobee pump manufactures replacement parts for other manufacturers as we do our own: with technical expertise, quality, fair pricing, and product availability for the end-user.

The following list provides the basic part number and description for most slurry pump parts, click on one of basic part numbers or descriptions to get more details, or send mail to us directly to find the replacement parts for your slurry pumps.

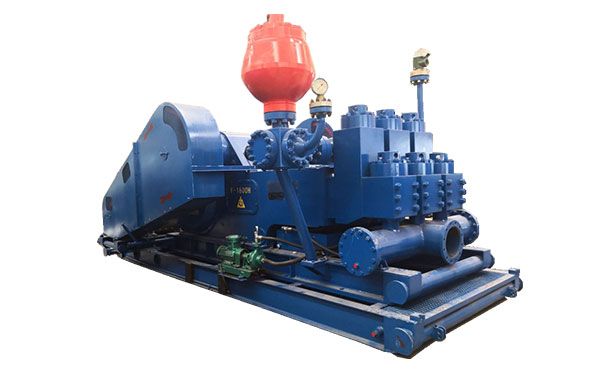

China Slurry Pump Crank Shaft Ang Bull Ring for Mud Pump Power End Tpk1000/Tpk1600/Tpk2000 etc, Find details about China Crankshaft, Shaft from Slurry Pump Crank Shaft Ang Bull Ring for Mud Pump Power End Tpk1000/Tpk1600/Tpk2000 etc - UPET GROUP CO., LTD.

3/2 CAH Shijiazhuang Naipu Slurry Pump. AH metal liners Horizontal Slurry Pump A removable cartridge type grease lubricated Bearing Assembly can be replaced with the pump base in-situ, Horizontal Slurry Pump facilitating easy maintenance. Cr26 Slurry Pump Extra heavy duty and oil lubricated bearing assemblies are available on request. NP-AH Horizontal Slurry Pump .

1. Naipu AH series centrifugal slurry pumps and spare parts can fully interchange with world famous brand.These pumps are of heavy-duty construction, designed for continuous pumping of highly abrasive and corrosive slurries. They feature a wide choice of replaceable abrasion resistant metal liners and Impellers, which are all interchangeable within a common casting assembly.

4x3C-AH Slurry Pump is engineered with the latest hydraulic and wear technologies to cope with the most severe corrosive and abrasive slurry applications, The 4x3C-AH pumps feature patented innovative designs that can significantly reduce the operational costs of slurry pumping, It is widely used in industry of mining, electrical power, metallurgy, coal, environmental protection, etc for ...

China Slurry Pump & Spares catalog of Horizontal Single Stage Centrifugal Mining Slurry Pump (TZJST-350-1000), Horizontal Single Stage Centrifugal Mining Slurry Pump (TZJST-350-800) provided by China manufacturer - Shandong Zhangqiu Blower Co., Ltd., page1.

Slurry Pump Manufacturers in the past have enjoyed a position of captured business when it comes to operating and maintenance expenses for the industries they serve.. This is due to the fact that often, once a slurry pump is installed, expensive bases, piping and most importantly spare parts are solely manufactured by the Original Equipment Manufacturer (OEM).

China Horizontal Centrifugal 80kw Ash Slurry Pump, Find details about China Slurry Pump, Slurry Mud Pump from Horizontal Centrifugal 80kw Ash Slurry Pump - Shanghai Sunpace Machinery Co., Ltd.

SLURRY PUMP PRINCIPLES Section 1 - Slurry Pump Principles Introduction Defi nition of a Slurry A slurry can be a mixture of virtually any liquid combined with some solid particles. The combination of the type, size, shape and quantity of the particles together with the nature of the transporting liquid determines the exact

The Warman® AH® pump is the world"s standard for heavy duties. A wide variety of impellers and shaft seals provide a perfect fit for a wide range of applications. The AH® pump provides excellent wear life while maintaining efficiency during the wear cycle providing the best total operating cost.

Metal Slurry Pump Seals, Rubber Seal, Pump Spare Parts manufacturer / supplier in China, offering 124 Volute Liner Seal and 125 Volute Frame Seal, Naipu Dredge Pump Used in Conjunction with Dredger 300wn 300mm, Naipu Pumps and Accessories .

Ceramic Slurry pumps are applied in the field of mining, metallurgy, electricity, chemical, coal industry, building materials, etc. It can transport abrasive and corrosive seriflux which containing solid particles, such as ash and cola seriflux transportation in power station, mine pulp transportation in metallurgy dressing plant, coal seriflux and other heavy media transportation in coal ...

China Slurry Pump, Slurry Pump China. Mongolian largest gold-copper mine 05-21. Mongolian economic growth in recent years is stabilized at 10%, and China has been its largest trading partner and investor for consecutive 10 years, making a significant contribution to the local economy development.

4 /3 CAH High Chrome Alloy Slurry Pump Price List. Type 4/3 CAH High Chrome Alloy Slurry Pump are cantilevered, horizontal, Centrifugal Slurry Pump. They are designed for the handing high density slurries in the metallurgical, mining, coal, power, building material and other industrial department etc.

Tobee ® TH4x3 Silica Sand Pum p is end-suction, split-case, centrifugal slurry pumps have set the world standard for heavy duty abrasive pumping applications for decades. With large shaft diameters, heavy duty bearing assemblies and robust slurry pumping capacity, Tobee 4x3 pumps provide a cost-effective and ideal alternative to longer lead times and the difficulty associated with working ...

Tobee ® AH Series Slurry Pumps are the most comprehensive range of centrifugal slurry pumps for use in mining, minerals processing, coal preparation, dredging, metallurgy, power plant, chemical and general industry applications. The wetted parts materials designed by High abrasion and corrosion resistance alloy, rubber or polyurethane etc, Expecially for handling high abrasive, high density ...

The Warman ® pump: A trusted name in slurry pumps since 1938. Slurry transportation is at the heart of a mine site, so it"s crucial your pumping equipment is up to the task. Is your existing pump vibrating, cavitating or leaking? Does your pump shaft keep breaking? Maybe you"re .

4/3 CAH Slurry Pump for Mining Tailings. Horizontal Slurry Pump Both metal or rubber liners and impellers, or a combination of both, are interchangeable within the same pump to facilitate use in various applications. AH metal liners Horizontal Slurry Pump Outline dimensions are common to both metal and rubber pumps allowing interchangeability without pipeline or civils rework being necessary.

CSPG Company China Slurry Pump Industry Group is a professional slurry pump manufacturer and is primarily to produce and sale various slurry pumps, sump pumps, sand pumps and others, and meanwhile, all kinds of OEM Warman pumps and Parts are also available from us.

3/2C-AH Slurry Pump is a heavy-duty slurry pump that designed to handle the most abrasive and dense slurries. The 3/2C-AH slurry pump offers users a wide range of seal and liner configurations, allowing the pump to be fully customized to meet any specific application requirements. 3/2C-AH slurry pumps offer unmatched power consumption, long component life, and unmatched reliability.

Slurry Pump, Slurry Pump Parts, OEM Pumps manufacturer / supplier in China, offering Heavy Duty Concentrator Overflow Mineral Processing Slurry Pump, Metal Lined Coal Preparation Plant Horizontal Mining Slurry Pump, 3/2 Cah Slurry Pump Spare Part Expeller C028HS1 A05 and so on.

China Slurry Pump Group,Interchangeable with Warman Slurry . China Slurry Pump Industry Group is a professional slurry pump manufacturer and is primarily to produce and sale various slurry pumps, sump pumps, sand pumps and others, and meanwhile, all kinds of OEM Warman pumps and Parts are also available from us.

Tobee® TH3x2C Mining Slurry Pump, 3x2 Mine Slurry Pump, Warman 3x2C-AH Slurry Pump, Wet Crushers Slurry Pump, China 3x2 Slurry Pump, SAG mill Discharge Pump, Ball Mill Discharge Pump, Rod Mill Discharge, Ni Acid Slurry Pump, Coarse Sand Pump. [email protected] +86 .

we are able to supply high-quality merchandise, competitive selling price and finest customer support. Our destination is “You come here with difficulty and we supply you with a smile to take away” for China OEM China Manufacturer /Mud Pump Connecting Rod, We imagine we’ll become a leader in building and producing high quality products in equally Chinese and international markets. We hope to cooperate with a lot more friends for mutual added benefits.

we are able to supply high-quality merchandise, competitive selling price and finest customer support. Our destination is “You come here with difficulty and we supply you with a smile to take away” for China Mud Pump, Connecting Rod, We have been committed to meet all your needs and solve any technical problems you may encounter with your industrial components. Our exceptional solutions and vast knowledge of technology makes us the preferred choice for our customers.

WX(R) & WXA(R) hard metal/rubber heavy duty slurry pumps are designed for the most difficult pumping applications for highly abrasive , high density or corrosive slurries. Extra thick sections at the critical wear points and superior Impeller structure ensures improved performance with extended wear and minimised maintenance, thus improving cost of ownership.

Rubber lined pumps expand applications to chemical products handling, several different rubber options are available to meet different application requirements.Best fitted in aggressive applications, like mill discharge and tailing transfer

WXA( R ) pumps are improved version of WX(R) pumps, in that it has an adjustable wear plate seated in at the Throatbush. This can be adjusted while the pump is running.

Usage of versatile wear-resistant and corrosion-resistant materials allows WX(R)/ WXA( R ) series slurry pumps to service in various industries, such as mining mill discharge, delivery of tailings, ash removal in power plant, FGD and coal washing in coal plant, etc.,resulting in low operating cost, as well as minimized maintenance and down time.

Wet Ends - Impellers, liners, volutes are made of high-chrome alloy or rubber or polyurethane, to resist wear, corrosion or impact, parts made of metal or rubber are interchangeable.

Wenzhou Johames Technology Co.,Ltd mainly manufacture and export industrial pumps with good reputation around home and abroad. Product is exported to Europe, North America, South America, Asia, Africa, more than 45 countries and regions.

mission magnum, mission 2500 supreme, mcm250 centrifugal pump, mechanical seal, demco butterfly valve, kemper hammerseal union, varco tong dies, demco mud gate valve and oteco pressure gauge

Kunming Kunshui Industrial Pump Co., Ltd("Kunshui pump" for short) is a professional manufacturer of pump specialized in manufacturing slurry pumps with more than10 years experience in China.

GREENTECH was founded in 2000, The company is professional blower and vacuum pump manufacturer specializing in producing and supplying full range of 2BV and 2BE series liquid ring vacuum pump, vacuum compressor etc.

air operated diaphragm pump,including metal and non-metal series, widely applied in chemical, paints & coatings, food processing, pharmaceutical, construction, mining, utilities, pulp & paper, metal finishing

BLDC PUMP produces excellent small electric DC water pumps for cooling, circulation system in the various device, for fish tank aquarium, small fountains and other applications. We are a magnetic DC water pump manufacturer located in Shenzhen of China.

Shanghai Shenbao Industrial Pump Co., Ltd. is located in Minhang Development Zone in Shanghai, occupying an area of over 45,000sq.m .Shenbao has become a multi-industry enterprise and specialist in research and manufacture pump...

Slurry pumps, Vertical slurry pumps, slurry pumps, Gravel sand pumps, Dredging pumps, Paper pulp pumps, Molten Salt Pumps, End suction pumps, Double suction pumps, Multistage pumps, Boiler feed water pumps...

Wuhan EvenWall Machinery Co., Ltd. specialized in even wall thickness stator and hollow rotor for progressive cavity pump, even wall thickness stator for mineral oil transportation(artificial lift), multi lobe power section for downhole drilling motor(mud motor).

Shijiazhuang Jiurun Pump Co., Ltd is a pump engineering, manufacturing and distribution company for industrial, municipal and dewatering applications. With over 60 years’ expertise, we have developed great reputation by serving the mining, power, metallurgy, dredging, petroleum

we are a professional pump manufacturer in China with many years experience. We mainly produce slurry pump, spare parts and OEM wear resistance casting.

APK, A Pump that Keeps water moving, is the brand name of Zhengzhou Shenlong Pump Industry Co., Ltd. APK Submersible pumps is short as APK Pump. We are a large scale submersible pump manufacturer officially registered on Apr 25, 1996. Our factory is in Henan Province

FEATURES .An agitator is provided to assist smooth suction of the pumping fluid .The side -flow, top- discharge keeps the motor cooling even the pump runs continuously .High chrome iron Semi -open impeller enables the pump to maintain its original performance OPERATING CONDITIONS .Liquid...

INSTALLATIONS AND USE .For pumping slurry, sewage, waste water (non-aggressive) in industrial and residential installations and drainage applications .For applications with big size solids up to 100mm .For water supply and drainage in farming, construction sites, etc. PERFORMANCE RANGE .Flow...

INSTALLATIONS AND USE .For pumping slurry, sewage, waste water (non-aggressive) in industrial and residential installations and drainage applications .For applications with big size solids up to 100mm .For water supply and drainage in farming, construction sites, etc. PERFORMANCE RANGE .Flow...

INSTALLATIONS AND USE .For pumping slurry, sewage, waste water (non-aggressive) in industrial and residential installations and drainage applications .For applications with big size solids up to 100mm .For water supply and drainage in farming, construction sites, etc. PERFORMANCE RANGE .Flow...

INSTALLATIONS AND USE .For pumping slurry, sewage, waste water(non-aggressive) with solids and filamentous parts in industrial and residential installations and drainage applications .For water supply and drainage in farming, construction sites, etc. .Available with an agitator to assist smooth...

INSTALLATIONS AND USE .For pumping slurry, sewage, waste water(non-aggressive) with solids and filamentous parts in industrial and residential installations and drainage applications .For water supply and drainage in farming, construction sites, etc. .Available with an agitator to assist smooth...

INSTALLATIONS AND USE .For pumping slurry, sewage, waste water(non-aggressive) with solids and filamentous parts in industrial and residential installations and drainage applications .For water supply and drainage in farming, construction sites, etc. .Available with an agitator to assist smooth...

INSTALLATIONS AND USE .For pumping slurry, sewage, waste water(non-aggressive) with solids and filamentous parts in industrial and residential installations and drainage applications .For water supply and drainage in farming, construction sites, etc. .Available with an agitator to assist smooth...

INSTALLATIONS AND USE .For pumping slurry, sewage, waste water(non-aggressive) with solids and filamentous parts in industrial and residential installations and drainage applications .For water supply and drainage in farming, construction sites, etc. .Available with an agitator to assist smooth...

INSTALLATIONS AND USE .For pumping slurry, sewage, waste water(non-aggressive) with solids and filamentous parts in industrial and residential installations and drainage applications .For water supply and drainage in farming, construction sites, etc. .Available with an agitator to assist smooth...

INSTALLATIONS AND USE .For pumping slurry, sewage, waste water(non-aggressive) with solids and filamentous parts in industrial and residential installations and drainage applications .For water supply and drainage in farming, construction sites, etc. .Available with an agitator to assist smooth...

INSTALLATIONS AND USE .For pumping slurry, sewage, waste water(non-aggressive) with solids and filamentous parts in industrial and residential installations and drainage applications .For water supply and drainage in farming, construction sites, etc. .Available with an agitator to assist smooth...

Many of you are purchasing warman slurry pump from China because China is now biggest OEM pumps country, but at the same time, there are many problems followed.

Most of time, your pump supplier in China will say “yes” when you try to describe your needs and ask them if they can make it out. Slurry pump competition is very strong here in China, getting orders are first issue by them. Especially when you and your supplier have never cooperated before.So always find and cooperate with suppliers who will ask you question about centrifugal slurry pumps , such as:pump flow rate,head,wet parts materials(A05,A49,A33,S31,S42,R55,Natural Rubber?),bare shaft pump or complete pump,with or without motor,motor power,pump driven type(CV,ZVz,DC,CR,CL?),shaft seal type(packing seal,expeller seal,mechanical seal ?)

Sometimes the problem just happened, like the slurry pump material is wrong, it should be A05 metal liner but your slurry pump suppliermade a mistake and now the material is rubber liner,which is much cheaper.

Most of the slurry pump suppliers will try to send it to you anyway, maybe you won’t notice or when you receive it, everything is settled now.So if you ever met a pump supplier who will take his responsibility to rework on e-plating work, cheers!! you are lucky enough to work with them.

●The parts immersed in the liquid of china sump slurry slurry pump are equipped with rubber outer lining, which is suitable for conveying abrasive slurry without edges and corners.

●With various speeds and variations, the pump can operate under the best conditions, with long service life, high operating efficiency, and meet many kinds of harsh transportation conditions.

The sump slurry pump is mainly used to transport corrosive, coarse particles and high concentration slag slurry. Widely used in metallurgy, mining, coal,power, building materials, environmental protection and other departments.

ZJQ submersible sludge pump is hydraulic machinery, the motor and the pump of which are coaxially submerged in medium to work. The overflowing parts of the pump are made from high alloy wear-resistant material, so the pump has good wear resistance and large flowing passage. It is applicable for conveying media such as sludge, ore slurry, coal slurry, sandstones containing big solid particles. The product is designed and manufactured by domestic and over sea advanced technologies. Besides the main impeller, the bottom of the pump is additionally provided with a set of agitation impeller which can spray the deposited sludge into turbulent flow, and therefore the pump realizes high-concentration conveying under the condition of no auxiliary device. The unique seal device can effectively balance the pressure inside and outside the oil chamber, so as to project the reliability of the mechanical seal to the maximum extent. The motor adopts various protective such as overheat protection, water inlet detecting projection, and can operate safely for a long term in harsh working conditions. The pump is applicable for pumping sand for building, silty sand, silt, tailing slurry, ore, iron sand ore, sediment in sewage treatment works, etc.

The whole machine is dry submersible pump, and the motor adopts oil chamber seal mode and is provided with mechanical seal inside, so that high pressure water and impurities and are effectively prevented from entering inner cavity of the motor.

Besides the main impeller, there is the agitation impeller which can agitate the sludge deposited on the water bottom into turbulent flow and pump the sludge

The trans-flux parts such as the impeller and the agitation impeller are made from high-hardness high chromium cast steel, have wear resistance, corrosion resistance and strong drainage capacity, and allow big solid particles to

This product is a cantilever centrifugal pump. It adopts a pump casing structure with double axial and vertical opening with an inner lining of cemented carbide or rubber with good wear resistance, corrosion resistance and high reliability.

The flow components, the impeller, the front protection plate and the rear protection plate of the WN dredge pump are made of an abrasion-resistant abrasion-resistant steel alloy that is resistant to abrasion.

The desulphurisation pumps of the MTL (R) series are single-stage horizontal stage centrifugal pumps and are mainly used in circulation pumps of absorption towers in humid flue gas desulphurisation plants.

This product is a cantilever centrifugal pump. The single-pump housing structure with box connection has good wear resistance, corrosion resistance and high reliability.

The product adopts an axial and vertical double-open pump housing structure with hard-alloy or rubber inner lining, which has good wear resistance, corrosion resistance and high reliability.

This product is a cantilever centrifugal pump. Adopting the structure of the pump housing with double axial and vertical opening, the inner lining is made of carbide, which is resistant to wear, corrosion resistant and highly reliable.

This series of foam pumps are designed based on normal mizztech MAH pumps, which are used in the foam handling application. The special design of the foam impeller allows the pump to handle viscous muds.

Hydroman 300TJQ Submersible Slurry Pump is a heavy duty slurry pumping and dredging solutions. Th 300TJQ slurry pumps can easily handle any liquid - from dirty water to the most difficult slurries with high concentration of solids. Hydroman pumps are the best choice for mining and dredging jobs.

▪ Advanced mixing and excavating movement is created by High chrome steel agitator cutter blades. The agitator lifts and sucks settled sediments of solids, creating a continuous flow of concentrated slurry into the pump. Additional hydraulic excavators can be connected directly to the pump for extra digging support in hard-packed sand and clay.

▪ Low operating costs. Lower speed (rotations) ensures lower wear and long life of components. Hydroman pump works at amazingly low operating speed of only 650 rev/min.

▪ Abrasion resistance, long service life and reliability guaranteed by the rugged and heavy construction. Extra strong wear parts produced in the chrome steel alloys are resistant to highly abrasive particles and provide longer life between spare parts replacements.

8613371530291

8613371530291