soilmec mud pump manufacturer

Soilmecoffer a machine, a technology and a solution to meet foundation needs. A comprehensive and technologically advanced jobsite, enriched by IPC technology with highly performing auxiliary equipment and accessories in a Mud product line dedicated to the use of bentonite and slurry.

CountryItalyEgyptAfghanistanAlbaniaAlgeriaAmerican SamoaAndorraAngolaAnguillaAntigua and BarbudaArgentinaArmeniaArmeniaArubaAustraliaAustriaAzerbaijanAzerbaijanBahamasBahrainBangladeshBarbadosBelarusBelgiumBelizeBeninBermudaBhutanBoliviaBonaireBosnia and HerzegovinaBotswanaBouvet Island (Bouvetoya)BrazilBritish Indian Ocean Territory (Chagos Archipelago)British Virgin IslandsBrunei DarussalamBulgariaBurkina FasoBurundiCambodiaCameroonCanadaCape VerdeCayman IslandsCentral African RepublicChadChileChinaChristmas IslandCocos (Keeling) IslandsColombiaComorosCongoCongoCook IslandsCosta RicaCote d"IvoireCroatiaCubaCuraçaoCyprusCyprusCzech RepublicDenmarkDjiboutiDominicaDominican RepublicEcuadorEl SalvadorEquatorial GuineaEritreaEstoniaEthiopiaFalkland Islands (Malvinas)Faroe IslandsFijiFinlandFranceFrench GuianaFrench PolynesiaFrench Southern TerritoriesGabonGambiaGeorgiaGermanyGhanaGibraltarGreeceGreenlandGrenadaGuadeloupeGuamGuatemalaGuernseyGuineaGuinea-BissauGuyanaHaitiHeard Island and McDonald IslandsHoly See (Vatican City State)HondurasHong KongHungaryIcelandIndiaIndonesiaIranIraqIrelandIsle of ManIsraelJamaicaJapanJerseyJordanKazakhstanKazakhstanKenyaKiribatiKoreaKoreaKuwaitKyrgyz RepublicLao People"s Democratic RepublicLatviaLebanonLesothoLiberiaLibyan Arab JamahiriyaLiechtensteinLithuaniaLuxembourgMacaoMacedoniaMadagascarMalawiMalaysiaMaldivesMaliMaltaMarshall IslandsMartiniqueMauritaniaMauritiusMayotteMexicoMicronesiaMoldovaMonacoMongoliaMontenegroMontserratMoroccoMozambiqueMyanmarNamibiaNauruNepalNetherlandsNetherlands AntillesNew CaledoniaNew ZealandNicaraguaNigerNigeriaNiueNorfolk IslandNorthern Mariana IslandsNorwayOmanPakistanPalauPalestinian TerritoryPanamaPapua New GuineaParaguayPeruPhilippinesPitcairn IslandsPolandPortugalPuerto RicoQatarReunionRomaniaRussian FederationRwandaSaint BarthelemySaint HelenaSaint Kitts and NevisSaint LuciaSaint MartinSaint Pierre and MiquelonSaint Vincent and the GrenadinesSamoaSan MarinoSao Tome and PrincipeSaudi ArabiaSenegalSerbiaSeychellesSierra LeoneSingaporeSint Maarten (Netherlands)Slovakia (Slovak Republic)SloveniaSolomon IslandsSomaliaSouth AfricaSouth Georgia & S. Sandwich IslandsSpainSri LankaSudanSurinameSvalbard & Jan Mayen IslandsSwazilandSwedenSwitzerlandSyrian Arab RepublicTaiwanTajikistanTanzaniaThailandTimor-LesteTogoTokelauTongaTrinidad and TobagoTunisiaTurkeyTurkeyTurkmenistanTurks and Caicos IslandsTuvaluU.S. Virgin IslandsU.S. Minor Outlying IslandsUgandaUkraineUnited Arab EmiratesUnited KingdomUnited StatesUruguayUzbekistanVanuatuVenezuelaVietnamWallis and FutunaWestern SaharaYemenZambiaZimbabwe

Soilmec is an international, Italian leader as a construction equipment manufacturer, primarily focusing on the production and manufacturing of drilling machinery used in the foundation drilling industry. Additionally, Soilmec has expanded their machine product lines to include those in the crawler cranes and tunnel boring machines categories. Soilmec offers the unique service of analyzing and archiving a machine’s on-site behaviors to be studied by their team of engineers. This enables them to create design solutions for issues directly experienced by Soilmec customers on real job sites. The wide variety of models allows the performance of any pile foundation, micropiles, diaphragm walls, and more. Soilmec makes it a point to include in-field experience as a vital part of their model’s designs and use philosophies, as well as safety and innovation. As end-to-end problem solvers, Soilmec’s machinery proves pivotal on any job site and you could be looking for any of these machines as a Soilmec for sale:

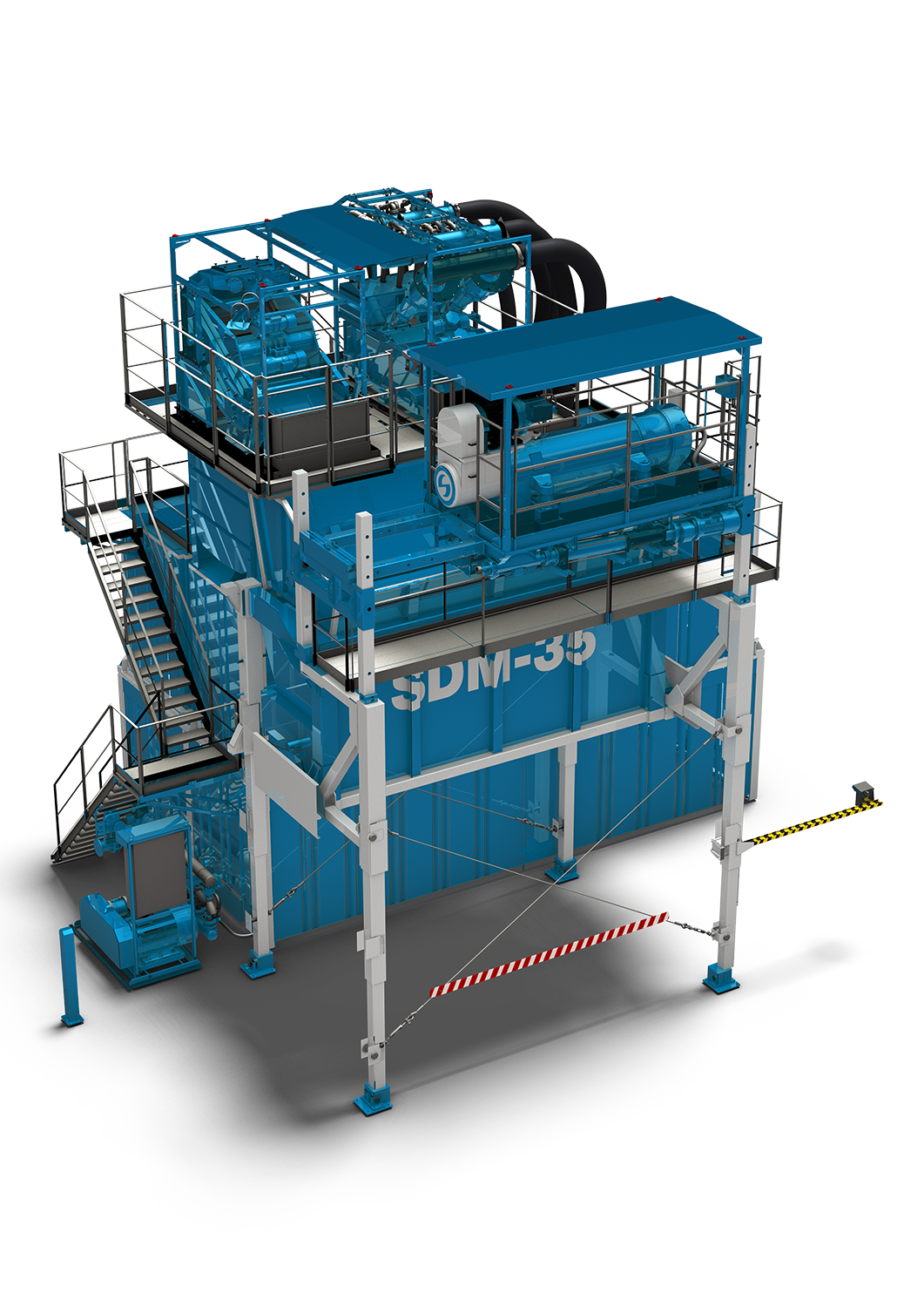

Desanders manufactured by SOILMEC INDIA are particularly designed to treat bentonite mud used in drilling and excavating operations with machines equipped with rotating drills or bucket and with forward of reverse circulation

Roughing is the first treatment carried out on the steel screen in which parts exceeding by 4mm are separated and the mud is stored in the tank and from here it is sucked by the pump and conveyed to the hydrocyclone. Particles with granulometry exceeding 40/50 micron are separated and the treated mud flows to a special circuit where a valve keeps the tank level constant.

SINCE 1997, HNA has been an integrated engineering & manufacturing specialist recognized worldwide for its unique World Leading HIGH PRESSURE Technology and high quality products in the O&G industry, by designing and fabricating HNA Duplex, Triplex and Quintuplex pumps, which are 100% interchangeable to most of the global famous brands: Bomco, Honghua, TSC, Weatherford, Ellis Williams, Gardner Denver, Emsco , National, Oilwell, Ideco, Drillmec & other major types of models, and customized design and production available.

Soilmec with its Solution Provider philosophy has developed a full range of Diaphragm Wall-Hydromill Equipment covering all the various market requests and utilising unique solutions came out from the many job site experiences of more than 20 years. All the technological challenged can be faced with Soilmec fleet, starting from multipurpose DW machine up to the first world record Hydromill for 250 m depth. “Tiger” line “Cougar” line “SMT” line HYDROMILL JOB SITE LAYOUT Mud treatment system Bentonite preparation plant Service cranes Duty cycle cranes with DW grab Hydromill

With the aim of meeting the need for increased diaphragm wall depth in the most challenging soil conditions, Soilmec has designed the “HDD” (Hose Drums Design) hydromill configuration. Hydraulic and mud winders are positioned on a base carrier, allowing high depth drilling performances. 1 UNDERCARRIAGE 2 BASE MACHINE 3 CAB 4 MUD HOSE WINDER 5 HYDRAULIC HOSE WINDER 6 BOOM 7 HYDROMILL MODULE 8 CUTTING MOTORS AND DRUMS

The Hose Wheels Design (HWD) is positioned below the cathead so it can easily follow the hydromill movements with a tensioning and rewinding automatic system. It arises from the need to move simultaneously the hydraulic and bentonite mud circulation hoses to the milling unit. 1 UNDERCARRIAGE 2 BASE MACHINE 3 CAB 4 MUD HOSE WHEEL 5 HYDRAULIC HOSE WHEEL 6 BOOM 7 HYDROMILL MODULE 8 CUTTING MOTORS AND DRUMS

The Soilmec milling unit SH-30, SH-40 & SH-50 are built in sturdy main frame. These units are equipped with swivel system for +/- 90° rotation, Indipendent mobile flaps and Cutting unit with indipendent gearmotors for vertical corrections. Watertight seals on all electrical boxes and DMS system control and visualization system with touch-screen monitor on cab and 3D option for production reports.

FLAT TANKS Configuration CITY TANKS Configuration Single Stage configuration with a level of treatment d50 = 60 µm Second Stage of cyclones increases the level of treatment up to d50 = 20 µm Standard layout of mud tanks (30 ft or 40 ft) with a bentonite storage up to 150 m3 complete with mud agitators and all the prearrangement for the connection to the SMT-500 main unit. Special layout of telescopic mud tanks (30 ft HC) with a bentonite storage of 220 m3 in a smallest footprint; complete with mud agitators and all the prearrangement for the connection to the SMT500 main unit. Perfect for...

SMT-500 mud treatment systems are developed for use with Hydromills or other technologies where it is requested an high level of mud treatment and delivery rates. Through it distinctive design and high-tech solutions is possible to match treatment quality with a compact and modular system guaranteeing unique solutions and easy in logistics. [ft SCALPER [a HYDROCYCLONES & DEWATERING SCREEN MUD STORAGE TANK (“City” Configuration) [4 MUD PUMP ^ DETRITUS MANAGEMENT SYSTEM FOR TRUCK DISCHARGE [ft MUD DECANTER CENTRIFUGE

Nominal flow rate (on water) Max feed density Approx. Solid separation Connection feeding Hydrociclones I stage - Cut point d50 Hydrociclones II stage - Cut point d50 Dewatering potential separation Mud Booster Station max capacity Storage capacity Installed power Discharge flow rate Screw conveyer speed Integrated control system Fully monitored solid production and automatic or manual setting discharge system Structure Bowl inside diameter / length Installed power Max nominal delivery Approx. solid separation

MUD TREATMENT UNIT SMT-500 Single stage SMT-500 Single stage SMT-500 Double stage SMT-500 Double stage Footprint area - - - - Cut Point performance Mud storage Footprint area SMT-500 City Single stage SMT-500 City Single stage SMT-500 City Double stage SMT-500 City Double stage Cut Point performance Mud storage Footprint area

8613371530291

8613371530291