soilmec mud pump free sample

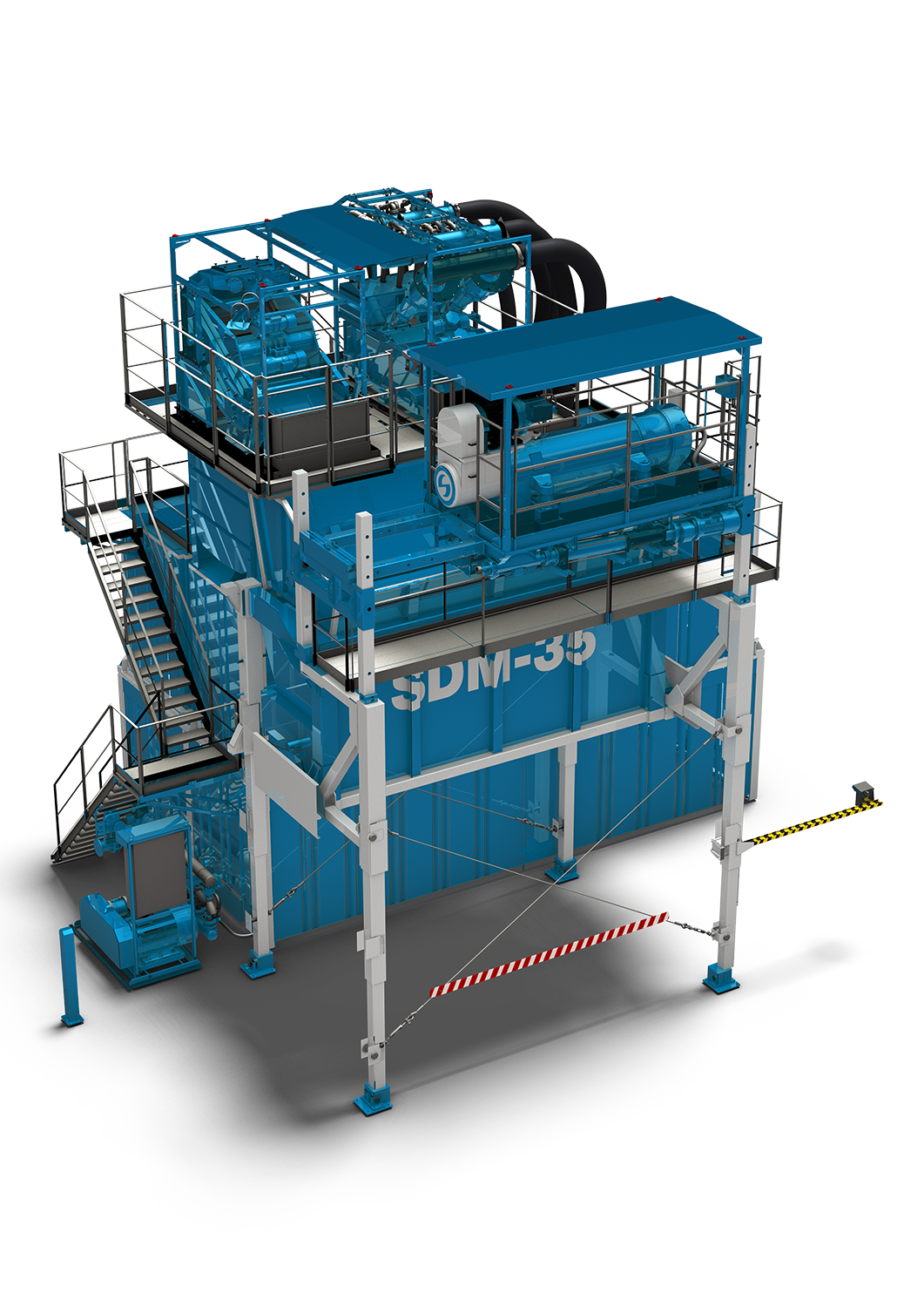

Soilmecoffer a machine, a technology and a solution to meet foundation needs. A comprehensive and technologically advanced jobsite, enriched by IPC technology with highly performing auxiliary equipment and accessories in a Mud product line dedicated to the use of bentonite and slurry.

A: Normally mud pump products will take about 3-15 days to produce the ordered machines. Most of the time, we can have an immediate delivery of our regular machines in 15 days.

Abstract: An excavation tool for making ground excavations for panels and diaphragms includes at least one rotary excavation drum. At least one frame is adapted to support the excavation drum. At least one pump is adapted for suction of an excavation fluid. A brushless electric motor is adapted to put in rotation the at least one excavation drum. At least one mechanical reducer is operationally connected to the electric motor and the at least one excavation drum. The electric motor is installed in the frame and coaxial to the at least one excavation drum. The at least one mechanical reducer is coaxial to the electric motor and the at least one excavation drum. The at least one mechanical reducer is adapted to transfer rotary motion from the electric motor to the at least one excavation drum.

Abstract: A plant for treating drilling muds, which can be installed in building sites for performing excavations or foundations, includes a main mud storage tank containing clean mud ready to be conveyed to the same excavation, a first grizzly screen, a mud processing hopper, at least one cyclone stage provided with at least an inlet in which entering mud to be treated is introduced and with at least a first outlet from which lightened mud (Fa) exits having a lower density than the entering mud, and with at least a second outlet from which a high density mud (Fd) exits, such high density mud having a higher density than the entering mud, and a dewatering screen. Said devices are connected together through pipes in such a way that a mud filled with detritus coming from the excavation is treated in order to be able to be reused once it is returned to the excavation.

The type of drilling to be adopted is preferably the one with removal of detritus by circulation of mud, in particular what is known as mud flush drilling. In this method, as the holes are made, they are all kept full of drilling mud for balancing the thrusts of the terrain. This drilling mud is sucked up through the rods and draws along with it the detritus excavated by the bit, then unloading it on the surface, usually in a settling tank. The desanded fluid can be re-used for the excavation.

As an alternative to mud flush drilling, the extraction of the detritus can be performed separately with known means, such as submersed pumps or air-lift pumps.

In the preferred, albeit not binding, option, it is envisaged to lower into the hole a pipe 11 made of plastic material sufficiently deformable under the lateral thrusts so as to rest on the walls of the hole and provide a seal. It is to be filled first with concrete as shown in FIG. 2E so as to ensure the conservation of its circular shape. As may be noted, as the hole 10 is filled with concrete, the drilling mud that filled the hole itself flows away or overflows into the adjacent holes according to the casting method used.

As an alternative, the sealing member could be a bag made of suitable material (e.g., woven fabric) to be ballasted and lowered into the excavation provided and then be filled with incoherent materials, sand or gravel. In this case, there is envisaged final saturation of the sand or gravel with a grout-injection pipe, through which to carry out a pressurized pumping of cement grout.

A new mud pump, hydraulic compensators with improved flow rate and new hydraulic fittings for connecting the motors are some of the developments installed on the equipment.

With a small footprint the 2100 Explorer drill has proven technology as a practical drill for those locations where a compact machine is required but more power is needed for deeper drilling, The drill is simple to use and easy to maintain. Designed and built in Australia for tough operating conditions. Depending on the options fitted the machine can be used for Solid and hollow auger Diamond drilling Rotary air blast RAB Mud circulation Reverse circulation RC Vacuum drilling Specifications - Power 33 Hp water cooled Diesel engine std, minimum, depending on the options - Hydraulics G....

2 ATERWELL DRILLING RIGS & ACCESSORIES Drillmec make profit by the experience coming out from the acquisition of five well know rig manufacturers since the beginning of last century, namely: Drillmec presence in the field Comprehensive drilling program Drilling is continuously developing new design in conventional and hydraulic rigs, creating a new frontier for water research drilling. Drillmec S.p.A. is present in more than fifty countries in all the continents with its products. Drillmec S.p.A. presence in the oil industry offers to the customer the up to date solution in the field. Drillmec S.p.A. product line is not limited to drilling; Drillmec S.p.A. can supply everything is needed to drilling contractors, giving a comprehensive drilling program wich portfolio includes: Drawworks and associated products Mud pumps and expendables Power swivels Mast & substructure Rotary & Hammer drilling equipment Rod & casing Structural elements Accessories Every component is designed by Drillmec s experienced engineers to meet the customer needs. The geographic distribution of our equipments grant us a test in every environmental condition from artic through desert to humid tropical environment. After many years of the hardest test imaginable, the real utilization, Drillmec S.p.A. can rely on unparalleled efficiency and safety for the final user. Every components is designed by Drillmec s experienced engineers to meet the drilling industry demand.

3 Rig systems Service and repair center Customer care service Commissioning Training: Drilling Academy On site repair service Customize solutions Rig systems are as imporrtant as the rig itself in the field. Drillmec S.p.A. furnishes complete mud systems, with fully personalized layouts, at request in the exclusive fast moving configuration, and capacity adequate for all the necessity of the field. Drillmec S.p.A. manufactures a wide range of duplex & triplex mud pumps up to 1600 HP, and all the manifold system to connect the mud pumps and the drilling rig. Drillmec S.p.A. can supply Air systems and air vessels, generator packs, yard equipment, camp hospital, warehouses and workshops, on a turn key approach. In the Drillmec facility there is a big workshop dedicated to the reconditioning and repair of customer rigs, mud pumps and accessories. Well experienced technicians work to replace consumables and renew equipment after many years of work. Drillmec provides a wide variety of services from overhauling equipment to upgrading of existing equipment for new customer specification. Drillmec can provide comprehensive engineering services directly on site. When a customer buy a rig, a mud pump or a full package from Drillmec S.p.A. he buy also its 360 degree customer care service. Drillmec S.p.A. rigs are fully tested in one of our test yards before shipment, but our technicians follow the rig to assist client personnel in the first days or weeks on site of the equipment. It is possible, following customer s requests, furnish highly qualified personnel also to drill one or more complete wells with the purchased rig. The training of the personnel, is a key point for reach the high performances Drillmec S.p.A. rig are famous for. Drillmec S.p.A. staff organizes real full immersion training courses, aimed to teach to operators how to work with the various equipment, and to the engineers all the technical features to enable them to make repairs by themselves. We have several ready-to-go technical teams that can reach in the fastest way field with the right spare parts to solve any problem in the minimum time possible. Drillmec S.p.A. has also spare parts warehouse in many countries in the world, with local well trained technicians that can intervene much faster than our engineers from Italy. Drillmec S.p.A. is committed to provide solutions to meet the need for economical and ecological performance of its customer. Drillmec S.p.A. is able to reach this result by means of an A-Z program beginning with the accurate analysis of the customer needs, the individuation of the solutions he needs to begin the design: the customer can work along with our engineers at the definition of the project to get exactly the product he need with all the specific features for his job in a manner that is both reliable and cost effective. In the frozing Siberian plains or in the baking Sahara Desert, for any request Drillmec S.p.A. has a solution or is willing to find one. Our R&D department utilize the latest available software to analyze data, guaranteeing accurate results and providing clients with the necessary calculations and certifications according to API requirements. Since its inception, Drillmec has been dedicated to putting forward innovative proposal that add real value to projects by reducing the cost of drilling operations in the gas & oil field. Figures 1 - Mud pump during refurbishing 2 - Supply chain integration 3 - Training of the personnel "A good partner for customer satisfaction"

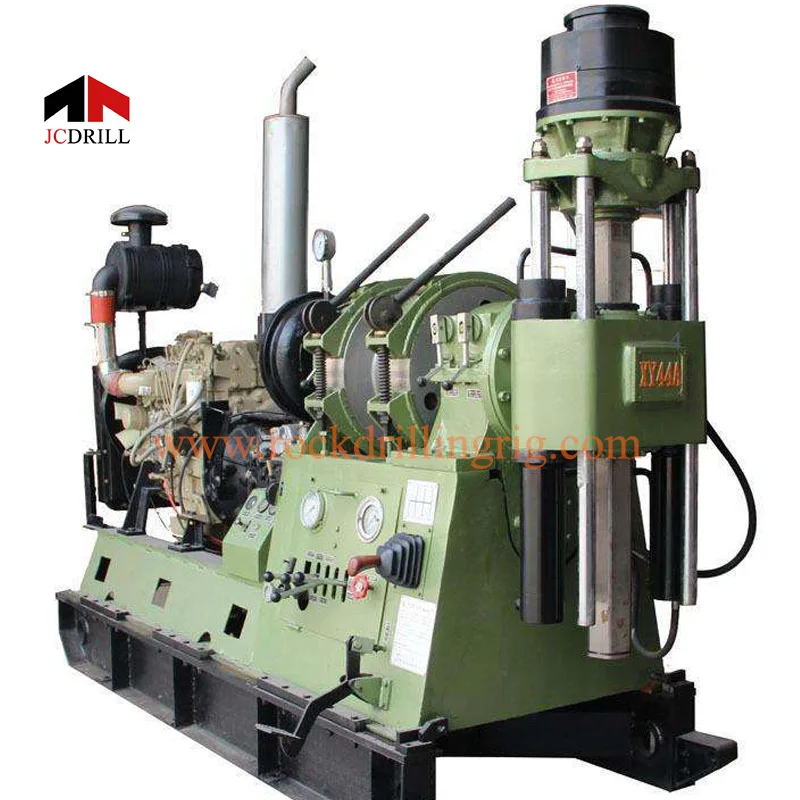

9 Duplex pumps for water well drilling DUPLEX MUD PUMPS 6DC3C 8D1S 6DS 10D2C 8DS liner size (In) min max / / /2 stroke in max pressure psi bar max delivery GPM. l/min rated input HP kw approx. mass lbs kg max SPM Based on 100% volumetric and 90% mechanical efficiency Triplex pumps for drilling-cementing-fracturing TRIPLEX MUD PUMPS 7TS600 9T800 9T T T1600 liner size (In) min max /2 stroke in max pressure psi bar max delivery GPM. l/min rated input HP kw approx. mass lbs kg max SPM SPECIAL TRIPLEX MUD PUMPS liner size (In) min max stroke In max pressure psi bar max delivery GPM l/min rated input HP kw approx. mass lbs kg max SPM 8T300M 8T600M 4 7 1/ / Based on 100% volumetric and 90% mechanical efficiency Figures 11-12T Duplex Pump 13-7TS

10 Drillmec can supply any kind of drilling accessories Rotary drilling equipment - Bits - Drill string components Rods and casing - Mud testing kit - Mud testing apparatus - Chemicals (polymers, bentonite, foam...) Stabilizer and rollerbit Hammer drilling equipment - Down the hole hammers - DTM bits - Hammer drilling accessories Accessories 1 Bit 2 Drill pipes 3 Hole opener 4 Stabilizers 5 Drill pipes

11 Integrated Services Drillmec can supply the full chain of water village supply. Including: Drilling water wells Water distribution pipe line Water treatment (potabilisation) Agricultural distribution Optionals 1 - Outriggers with mechanical locking 2 - Reverse circulation kit 3 - Reverse circulation kit 4 - Side shifted top drive (20 ) to clear the hole axis 5 - Hydraulic power tong. 1 - Opening: Centrifugal pump 7 - Drillmec mud pump mod. 8DS 8 - Crown block and travelling 9 - block with triple hook 9 - Soilmec mud pump mod. 8DS 10 - Crown block and travelling block with triple hook Mast extension 12/13 - Air compressor 14 - Control board

12 Drillmec continuously improves its products, therefore technical specifications are nominal and subject to change commercial network SOILMEC S.p.A. - Beijing Repr. Office SOILMEC JAPAN CO. LTD. SOILMEC MISR. S.A.E. CO. SOILMEC (H.K.) LIMITED SOILMEC EMIRATES L.L.C. SOILMEC FAR EAST PTE. LTD. SOILMEC GULF FZCO SOILMEC LTD. SOILMEC BRANHAM INC. 04/ N-Cils-Il Digitale certified quality system Drillmec quality management system is certified by API (American Petroleum Institute) and DNV (Det Norske Veritas) and GOST-R (Russian approval) for special products a company 12, via 1 Maggio Gariga di Podenzano PIACENZA (Italy) Tel Fax / web site: info@drillmec.com

8613371530291

8613371530291