triplex mud pump displace volume manufacturer

Continental Emsco Drilling Products, Inc., which consisted of Emsco drilling machinery and Wilson mobile rigs, was purchased by National-Oilwell, Inc on July 7, 1999. To our knowledge, no pumps have been manufactured and sold under the Emsco brand name since National-Oilwell acquired them.

Fairbanks Morse pumps are currently manufactured in Kansas City, Kansas. Fairbanks Morse is a division of Pentair ever since August, 1997 when Pentair purchased the General Signal Pump Group.

Gaso pumps are manufactured by National Oilwell Varco. Gaso was acquired as "Wheatley Gaso" by National-Oilwell in the year 2000. At the time, Wheatley Gaso was owned by Halliburton.

Skytop Brewster pumps are no longer available as new pumps. Skytop Brewster(Cnsld Gold), a unit of Hansen PLC"s Consolidated Gold Fields subsidiary, was acquired while in bankruptcy by National-Oilwell, Inc. in November, 1999.

Tulsa Triplex is a Tulsa Rig Iron company. We manufacture pumps from 100 to 600 horsepower for drilling, reverse circulation, hydrostatic testing, water blast, and workover applications. Utilizing roller bearings throughout, our pumps are built to last. They are designed to be easily maintained and are capable of being completely rebuilt. Available as bare pump only, with chainbox, or complete pump packages.Our skids are built tough as an oilfield type with draw bars.

The CLM 7½" x 10" Triplex Hydraulic Mud Pump will pump 75% more rated flow than a 5½" x 10", at almost twice the pressure, is 29.7" shorter, and weighs less than 1/3 as much. It takes four 5½" x 10" pumps (each lined with 4" liners = 24,260 lbs) to match the rated pressure and volume of one CLM 7 ½" x 10" triplex!

Piston pumps can be used for low viscosity and medium-flow media (in the range of 80 m³/h). Additionally, pumping solid particles is impossible with this type of equipment because the pump can ensure proper operation only if the seal between the cylinder and the piston is perfect.

For high-pressure uses, you can opt for a plunger pump, they differ from piston pumps in that the seal does not move with the piston, it is fixed and therefore able to withstand...

... heavy duty frac pump designed to operate at higher pressures for longer periods of time. Its compact design and 11” stroke results in less fatigue cycles and extended consumable life. With a legacy of ...

The HS is a horizontal triplex and quintuplex positive displacement reciprocating pump with very high efficiency and is offered in a wide range of hydraulic, mechanical, and material options.

Flojet Triplex Hi-Flow series pumps are designed for a wide range of applications and are constructed from a selection of materials suitable for handling a broad range of chemicals. ...

... alternative to our diaphragm pump series: The LEWA plunger pump is a high-performance and versatile plunger pump for high-pressure applications in various industries.

Three-es manufactures pumping sets with various flow and pressure characteristics, plug&play and optimised for any washing system. Each pumping unit is assembled using only high quality components.

... plunger pumps for pressure testing, large three, four or five plunger pumps of various designs are available with specific advantages for specific applications.

... plunger pumps for pressure testing, large three, four or five plunger pumps of various designs are available with specific advantages for specific applications.

... plunger pumps for pressure testing, large three, four or five plunger pumps of various designs are available with specific advantages for specific applications.

Triplex pump with connecting rod system. Pistons in ceramic-coated steel. Double gasket sealing system. Pump head in pressed brass. Automatic safety valve with pressure shut-off at pump ...

Drilling pump is also called mud pump, which transport high pressure, high specific gravity, high sand concentration drilling fluid to bottom of hole. Drilling fluid is used to cool bit, wash out bottom ...

Pumps of the WANGEN KL-R Triplex series impress with their consistent dosing option, as an intermittent input is compensated by the buffer volume in the collecting container. No bridge building. The small ...

... consists of 5 pump sizes in triplex execution. The 31.40 model is manufactured also in quintuplex (model 31.40/Q) and septuplex (model 31.40/S) execution, where the same components of the triplex ...

PressureJet pumps are triplex (three plungers), positive displacement, industrial high pressure triplex plunger pumps. We offer both the triplex piston ...

The RDP range of Reciprocating Plunger Pumps by Ruhrpumpen comes in various sizes and in triplex and quintuplex formats. They are designed and manufactured in accordance to the lates edition of API 674 ...

JR500W pump is a horizontal single-acting reciprocating triplex plunger pump. Power end is self-lubricated by oil pump built onto the worm gear. Driven by worm pair, ...

... 1600 mud pump is a single-acting reciprocating triplex mud pump that delivers increased reliability, improved maintainability, and reduced weight and footprint.

Rig pump output, normally in volume per stroke, of mud pumps on the rig is one of important figures that we really need to know because we will use pump out put figures to calculate many parameters such as bottom up strokes, wash out depth, tracking drilling fluid, etc. In this post, you will learn how to calculate pump out put for triplex pump and duplex pump in bothOilfield and Metric Unit.

Bourgoyne, A.J.T., Chenevert , M.E. & Millheim, K.K., 1986. SPE Textbook Series, Volume 2: Applied Drilling Engineering, Society of Petroleum Engineers.

Mud pumps are the heart of a drilling operation. TSM designs and manufactures extremely reliable and easy-to-maintain mud pumps, eliminating unnecessary maintenance and downtime.

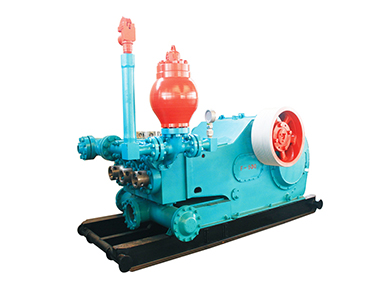

The structural features and properties of F series mud pumps are more advanced. Wearing parts of fluid end can be universally used with those of API standards.

F series mud pumps are firm and compact in structure and small in size, with good functional performances, which can adapt to drilling technological requirements such as oilfield high pump pressure and large displacement etc. The F series mud pumps can be maintained at lower stroke rate for their long stroke, which effectively improves the feeding water performance of mud pumps and prolongs the service life of the fluid end. The suction stabilizer, with advanced structure and reliable service, can achieve the best buffering effect. Power ends of the F series mud pumps adopt the reliable combination of forced lubrication and splash lubrication to increase the service life of power ends.

This series of pumps is manufactured strictly in accordance with API Spec 7K Drilling and Workover Equipment Specifications and carried out delivery test in accordance with the standard.

Since the NOV A1700-PT Triplex Mud Pump was built approximately 60 years ago, the industry has widely accepted the three cylinder or triplex style pump. Triplex mud pumps are manufactured worldwide, and many companies have emulated the original design and developed an improved form of the triplex pump in the past decade.

NOV A1700-PT Triplex Mud Pumps have many advantages they weight 30% less than a duplex of equal horsepower or kilowatts. The lighter weight parts are easier to handle and therefore easier to maintain. The other advantages include;They cost less to operate

One of the more important advantages of triplex over duplex pumps, is that they can move large volumes of mud at the higher pressure is required for modern deep hole drilling.

NOV A1700-PT Triplex Mud Pump is gradually phasing out duplex units. In a triplex pump, the pistons discharge mud only when they move forward in the liner. Then, when they moved back they draw in mud on the same side of the piston. Because of this, they are also called “single acting.” Single acting triplex pumps, pump mud at a relatively high speeds. NOV A1700-PT Triplex Mud Pump has three pistons each moving in its own liner. It also has three intake valves and three discharge valves. It also has a pulsation dampener in the discharge line.

Rig pump output, normally in volume per stroke, of mud pumps on the rig is one of important figures that we really need to know because we will use pump out put figures to calculate many parameters such as bottom up strokes, wash out depth, tracking drilling fluid, etc. In this post, you will learn how to calculate pump out put for triplex pump and duplex pump in bothOilfield and Metric Unit.

Bourgoyne, A.J.T., Chenevert , M.E. & Millheim, K.K., 1986. SPE Textbook Series, Volume 2: Applied Drilling Engineering, Society of Petroleum Engineers.

A mud pump is a reciprocating piston device designed to circulate drilling fluid under high pressure. RS-240 triplex single-acting piston pump is a horizontal, triplex, single acting reciprocation piston pump which is reliable, agile and simple for operation. It can be driven by diesel engine, electric motor or hydraulic motor. RS-240 triplex single-acting piston pump is characterized by compact structure, smooth running, large-scale variable rates of flow, high output pressure, long service life and so on.

As a well-known global mud pump manufacturer, we provide all kinds of mud pump to meet the needs of different construction demands. RS-240 triplex single-acting piston pump provides 4 different discharge pressure, and it is mainly used to match horizontal directional pipe laying drilling machine. The pump can meet the needs of construction for water well and earth heat, superficial layer oil drilling and mine drainage.

Manufactured to withstand the toughest drilling and environmental conditions, our K-Series triplex mud pumps are ideal for all drilling applications. This legacy product features a balanced forged-steel crankshaft and Southwest Oilfield Products ‘L” Shaped modules which is essential to minimize wear, noise, and operating vibrations. These attributes are essential when drilling deeper high pressure formations, long laterals and when handling corrosive or abrasive fluids and slurries.

Every American Block triplex mud pump is manufactured and fully load tested before leaving our manufacturing campus, and is available in sizes ranging from 800 HP to 2200 HP. The American Block K1600 HP Mud Pump is also available in a 2000 HP up-grade version, when more HP is needed in the same 1600 HP footprint.

BW-160/10 mud pump is a horizontal, triplex, single acting reciprocation piston pump. It"s function is to supply the drilling hole with flushing liquor in order to cool bit. It is used matching drill rigs. It is applied to geological and engineering prospecting such as the railway, the water conservancy, the met-al lurgy, the build and the geology etc industry whose hole deep is within 1000m. Also it can be used to deliver water to high mountains or in the execution domain of middle and low pressure grouting and non excavating matching.

8613371530291

8613371530291