triplex mud pump quotes factory

Manufactured to withstand the toughest drilling and environmental conditions, our K-Series triplex mud pumps are ideal for all drilling applications. This legacy product features a balanced forged-steel crankshaft and Southwest Oilfield Products ‘L” Shaped modules which is essential to minimize wear, noise, and operating vibrations. These attributes are essential when drilling deeper high pressure formations, long laterals and when handling corrosive or abrasive fluids and slurries.

Every American Block triplex mud pump is manufactured and fully load tested before leaving our manufacturing campus, and is available in sizes ranging from 800 HP to 2200 HP. The American Block K1600 HP Mud Pump is also available in a 2000 HP up-grade version, when more HP is needed in the same 1600 HP footprint.

triplex mud pumps and triplex mud pump parts meet the industry standards established by the American Petroleum Institute (API). As a global supplier of quality oilfield equipment to the oil and gas industry, we ship our products around the world.

Besides triplex mud pumps and triplex mud pump parts, we supply drilling rigs, workover rigs, top drives, drilling equipment, blowout preventers, BOP control systems, choke and kill manifolds, well service pumps for well cementing and hydraulic fracturing, wellhead equipment, casing heads, tubing heads, X-mas trees, FC type gate valves, etc. Please visit our company website

We supply unitized mud pump packages driven by DC or AC electric motors or diesel engines for electric and mechanical drilling rigs. The client can select DC or AC motors and diesel engine brands such as Caterpillar, Detroit, Cummins or others. Our unitized mud pump packages including everything on the skid and usually they are ready to work at delivery.

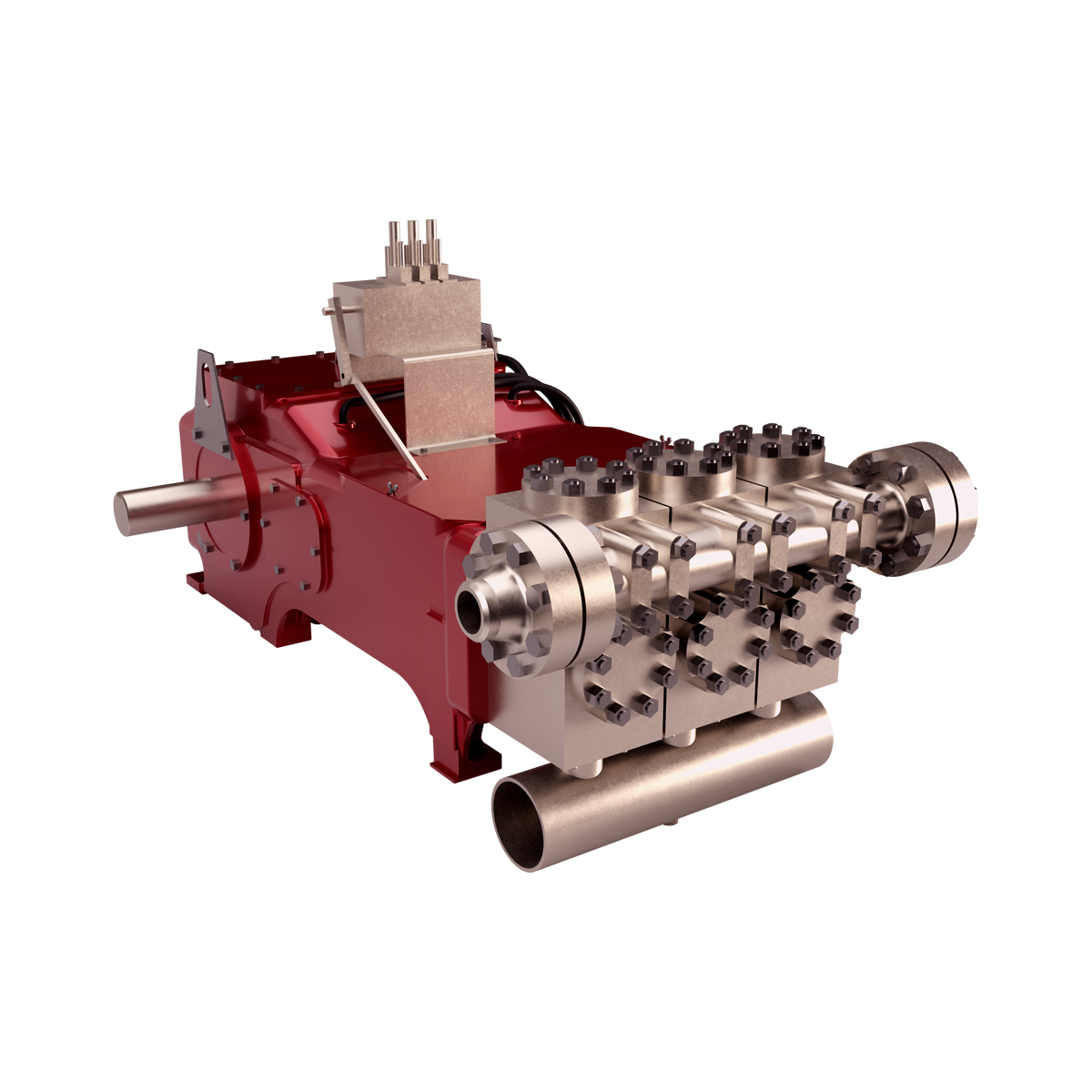

DRILLMEC’s GD Series is the new generation of Gear Driven Triplex Mud Pumps in the ranging from 1600 to 2400 hp for both onshore and offshore drilling operations.

The direct gear driven transmission between the AC motor and the cranshaft together with the top mounted configuration gives to the GD Series Mud Pumps a very compact design despite their high volume and high pressure capabilies.

The NOV FC-1600 Triplex Mud Pump is made of rugged Fabriform construction and designed for optimum performance under extreme drilling conditions. It is compact and occupies less space, yet delivers unequaled performance. The pumps are backed by several decades of design and manufacturing experience, and are considered leaders in the field.

NOV FC-1600 Triplex Mud Pump is conservatively rated at relatively low rpm. This reduces the number of load reversals in heavily stressed components and increases the life of the fluid end parts through conservative speeds and valve operation.

The NOV FC-1600 Triplex Mud Pump design provides an inherently balanced assembly. No additional counterbalancing is required for smooth operation. No inertia forces are transmitted to the pumps’ mountings.

A Triplex Mud Pump sometimes referred to as a drilling mud pump or mud drilling pump. NOV FC-1600 Triplex Mud Pump is a reciprocating piston/plunger pump designed to circulate drilling fluid under high pressure (up to 7,500 psi) down the drill string and back up the annulus. A mud pump is an important part of the equipment used for oil well drilling.

The NOV 12-P-160 Mud Pumps includes (3) Three New National 12-P-160 Triplex Mud Pumps 1600 HP, 7-1/4″ bore x 12″ stroke, single acting. 5000 PSI fluid ends. 1600 HP Bare Mud Pumps are currently configured for Offshore Service. The NOV 12-P-160 Mud Pumps are located in Houston and ready to be unitized for service.

Forged Steel crankshaft, Individual forged steel two piece interchangeable standard modules, 6-1/2” mission fluid king liners, Standard polyurethane valves and seats, Two piece fast change piston rods, Supreme pistons, Metal to metal liner retention, Clamp type liner and piston rod connections, Fast change valve covers standard, Piston liner lubricant spray system, Liner spray pump, Power end lube system with filter. Mounted on Integral two runner skid, Suction Manifold with vertical suction stabilizer, Suction line pressure relief valve, set for 70 PSI

Includes: motor supports, motor frame, tensioning screws, 2 V-belt guards, 2 pump Sheaves, 2 motor sheaves, banded V-belts, Holes to be drilled to accept EDM D79 Or GE-752 Traction Motors

National Oilwell Varco (NOV) is an American multinational corporation based in Houston, Texas. It is a leading worldwide provider of equipment and components used in oil and gas drilling and production operations, oilfield services, and supply chain integration services to the upstream oil and gas industry. The company conducts operations in more than 600 locations across six continents, operating through three reporting segments: Rig Technologies, Wellbore Technologies, and Completion & Production Solutions. National Oilwell’s two main predecessors, Oilwell Supply and National Supply, were founded in 1862 and 1893, respectively. These two companies manufactured and distributed pumps and derricks.

It’s time for piston mud pumps to enter the 21st century. Centerline Mud Pumps utilize common, industry-proven, and easily obtained fluid end parts. Designed to give you better flow capacity, pressure, size and weight advantages, that you won’t find anywhere else. Centerline Mud Pumps are built to exceed the most demanding specifications in the industry. These pumps are built to last.

Centerline Manufacturing is pleased to introduce their line of hydraulic drive mud pumps. Since 1983, Centerline Manufacturing has been involved in the design, manufacture, and production of drilling equipment, support equipment, and tooling for the water well industry. Our line of mud pumps include several new milestone technologies not found anywhere else in the industry.

Provides 150-180* GPM (Gallon Per Minute) of standard mud flow at 350 psi continuous. The 180 GPM is a provisional condition that requires the mud pressure to be below 275 psi and the hydraulic oil temperature below 165 degrees F.

Provides 300-360* GPM (Gallon Per Minute) of standard mud flow at 350 psi Continuous. The 360 GPM is a provisional condition that requires the mud pressure to be below 275 psi and the hydraulic oil temperature below 165 degrees F.

Provides 450-540* GPM (Gallon per Minute) of standard mud flow ar 350 psi Continuous. The 540 GPM is a provisional condition that requires the mud pressure to be below 275 psi and the hydraulic oil temperature below 165 degrees F.

GDEP is the original creator of the drilling pump and continues to set the standard for durable, high-quality drilling pumps that can withstand the world’s toughest drilling environments. Starting with our PZ7 and rounding out with the market"s most popular pump, the PZ1600, our PZ Series of pumps are the perfect choice for today"s high-pressure drilling applications.

Triplex pumps are positive-displacement reciprocating pumps that are configured with three plungers. They are the most common configuration of pump used in both drilling and well service operations. Triplex pumps used in well service activities generally are capable of handling a wide range of fluid types, including:

Triplex pumps are used in applications that require continuous pumping. For example, a triplex pump is a common component in large-capacity commercial car wash equipment. The plunger pump design of a triplex pump offers a reinforced seal and uses ceramic plungers for tight alignment and long life in high-pressure applications, such as oil well stimulation, surface preparation or rust removal, and gas turbine misting. Triplex pumps used in low-pressure applications also include a submersible liquid pump and an end-suction centrifugal pump. A submersible pump is typically constructed of stainless steel for corrosion resistance and can typically handle wastewater with suspended particles as large as 2 inches in diameter.

Triplex pumps are also suited to pump liquids other than fresh water or wastewater. They can be used to pump salt water in desalination applications, chemicals, and high vapor liquids like carbon dioxide. They can also be configured to pump mud in land-based or offshore oil drilling applications. A mud pump is a heavy-duty, high-pressure pump designed to provide a smooth discharge of mud and debris from oil wells. A triplex well pump can also be used as a well stimulation or servicing pump in oil fields and other industrial applications, such as cementing.

Industrial triplex pumps are used in public places that require a consistent water pressure with variable flow rates, such as hotels and office buildings, schools, hospitals, and in general industrial processes such as boosting the water supply for rural areas or municipalities or for irrigation. Because they are able to handle a wide range of fluid types, a triplex pump may also serve as a sump pump or in conjunction with other pumps to drain sump pits and wastewater storage lagoons.

reciprocating triplex plunger pump. It consists of three parts: power side, slow down boxes, hydraulic components side. It is the biggest brake horsepower to 400BHP of the pump with small size, power, and high...

You can find our high-performance mud pumps at some of the largest oil and natural gas drilling operations on the planet. Now, we’re ready to supply one of our mud pumps to you.

Looking for a mud pump for sale? Bridges Equipment has the biggest inventory of rebuilt duplex and triplex mud pumps and pump packages ready to ship. Unlike some suppliers, we completely rebuild our mud pumps to OEM standards and guarantee our work from 90 days up to six months against major failure.

Our fabrication facility customizes mud pumps, equipment, and pump packages to meet the needs of operations large and small, across the nation and around the world. Whether you need a custom-fabricated mud pit or a unitized pump package, we have the expertise to get it done.

Nothing wastes time and money like waiting on parts. With two supply stores stocked with the fluid ends and other mud pump parts you need to keep your operation running, and the field mechanics to install them, we can help keep your operation up and running.

Customizability. Functionality. Quality. Reliability. You’ll find these attributes and more in every mud pump, mud pump part or mud pump package we have available for sale or rental.

We supply mud pump spare parts like mud pump liner including zirconia ceramic liner and high chrome bimetallic liner, Mono-metal Liner, fluid end module, valve and seats, piston, piston rod, pony rod etc. parts for mud pump, we can also customize and machine as your drawing.

The bimetal liner offers long service life of about 800 hours, which is 2 to 3 times the lifetime of common ones in severe environment.Dezhou Changhong is a professional Chinese bimetal liner manufacturer, with more than 20 years manufacturing experience. Through our consistent effort, we are able to manufacture high quality mud pump parts, valve, drill rig, and other products. Due to reliable performance and long lifetime, our products are well accepted byglobal customers. If you require more information about our oil equipment, please feel free to contact us.

Dezhou Changhong Machinery Manufacture Co.,Ltd produces monometal liner of which is processed by carbonizing and high frequency.The product’s hardness reaches 58-60HRC.Liners have such characteristics as best surface finish,high wear proof resistance,high corrosion resistance,long service time.It suited to be used in mildly corrosive mud.

Piston assembly is the expendable parts at the drilling pump hydraulic system,and its one of the biggest wearing parts of drilling work.The piston core is made of 42CrMo.Our company can produce F series,3NB series,9-P-100/13-P-130/12-P-160 series,PZ7/8/9 series of drilling pump piston assembly metric(inch) with various sizes.

The piston rubber is also called the piston cup,its the expendable parts at the drilling pump hydraulic system,and its one of the biggest wearing parts of drilling work.The piston rubber is made of rubber vulcanization.The material of ordinary piston rubber is NBR. But if you use the PU can enlarge the work temperature range.

Our company has studied and developed the new model piston rubber with good properties of high anti-friction,long period of validity and enhances the working efficiency of the mud pump.

Bonded Piston without plate and snap ring, is integrated to the piston rubber (CTBN) or polyurethane sulfide on the piston made of core directly. It is suitable for all kinds of mud, especially high pressure jet drilling and ceramic liners. Also can be used with the piston interchangeably .

Module belongs to hydraulic end, which is important component of mud pump. It is a kind of anti-pressure valve and mainly responsible for sucking and discharging mud in hydraulic end. We selected anti-corrosion and high strength superior forging big alloy pieces as material, it possess high tensile and anti-wearing after quenching and tempering. We have applied drilling milling & tapping craft by XH768 CNC Machining Equipment which improves machining precision & safety factor. It makes the module can bear 31MPa working pressure and possess anti-high pressure, anti-corrosion & long life time, which is more suitable for strict requirement of oil drilling. Our module are completely meets API SPECT 7K Standard. It is widely used in oil drilling industry. It is not only widely used in domestic oil well, but also exported to USA, Middle East marktet. Besides, we also can machining other modules as per customer’s drawings.

The material of module is forged 35CrMo or 40CrMnMo pieces. Three modules of each pump are interchangeable. The through way F type pump namely valve coupling with valve structure, have lessen the volume of module and improved cubage. For improving anti-corrosion, We can nickelizing on module surface as per customer’s requirement.

Thanks for visiting website of Dezhou Changhong Company. We are a professional piston rod manufacturer, located in China. Our company has received the ISO9001 and API 7K certifications due to our production and operation in conformity with international standards. In addition to mud pump parts, manifold, valve, drilling rod, cementing tool, and other products are also available at Dezhou Changhong. We also provide customized equipment and accessories to accommodate different needs of global customers. In order to better serve our customers, we offer excellent service. If you have any interest in our products, please contact me for more detailed information.

Function: For certain mud pump, the nominal pressure ruled by manufacturer as per different liner size in the pump. The nominal pressure of large size liner pump is lower, small size liner pu is higher. For unloading hydraulic end pressure, shear pin relief safety valve will cut off shear pin and relief pressure when the pressure of pump exceeds nominal pressure.

AQFA—II Safety valve is a new type of specialized high pressure equipment which is used on drilling machine. It mainly used in the voltage limited security system on 3NB—900,3NB—1000,SL3NB—1300,SL3NB—1600 pump etc., to protect pump, high pressure pipe, rotary hose, drilling equipment and working people.

High pressure fluid liquid flowed from pump effect on piston, the occurred pressure is spread to security arm by valve. The shear pin is cutted off when the liquid pressure exceeds safety pressure. The liquid is discharged by connection pipe, then high pressure is relieved, The safety of people and equipment is assured.

8613371530291

8613371530291