vertical mud pump supplier brands

Vertical pumps are constructed from stainless steel, aluminum or cast iron and must be strong enough to withstand internal and external pressures. These pumps are most often used for lifting and transporting water, an application that finds many uses in residential, general purpose, industrial and commercial situations.

Centrifugal pumps are used in wastewater and sewage treatment plants to handle trash and refuse; certain heavy duty models can pump mixtures of solids that are suspended in liquid. As water pumps, vertical pumps are used for deep well pumping and move water from its underground source to buildings for human use or to prevent flooding or drainage issues.

If vertical pumps are made of strong corrosion resistant materials, they are able pump chemicals and acids which is a useful way of transporting hazardous liquids throughout a processing plant.

Vertical centrifugal pumps are simply designed machines. A casing called a volute contains a horizontal impeller mounted perpendicularly on an upright rotating shaft. The electric motor uses its mechanical energy to turn the impeller whose blades impart kinetic energy to the liquid as it begins to rotate up the casing.

Momentum and pressure carry the liquid (most commonly water) through the expanding volute until it exits through a discharge opening, sometimes at high velocities. Vertical pumps are located underground near the source of liquid which they move up to the surface. They are usually electric because a gas tank would be impractical to store and fill. The power cords are kept in a durable protective casing to prevent any leaks or damage.

One example of a vertical pump is an axial flow pump whose impeller is actually a kind of propeller that lifts the liquid in a direction parallel to the pump shaft instead of pushing it in a perpendicular direction like horizontal centrifugal pumps would. Vertical pumps are generally designed in a close-coupled arrangement where the motor and the pump are held in the same slim enclosure that can be lowered into a deep well hole. Another technique is to have the motor at ground level and install the pump underground.

Distributor of engineered fluid handling pumps, packaged pumping systems, repairs, parts, & integrated pump control systems. Mud pumps, chiller/condenser pumps, plumbing pumps, boiler feed systems, in-line circulators, condensate systems, sump & sewage pumps, end suction pumps, submersible sump & sewage, non-clogs & grinders, self primers, packaged lift stations, variable speed pump systems, metering pumps, chemical injection systems, chemical mixing systems, peristaltic pumps for chemical feed, high viscous & shear sensitive fluids, self primers, stainless steel, trash pumps, hot oil pumps, vertical turbine pumps, sanitary pumps, marine pumps, industrial pumps, ANSI end suction, vertical cantilever, double suction, non-clogs, progressive cavity pumps, helical gear pumps, well pumps, lab pumps, hose pumps, control valves, check valves, air release valves, tanks, pressure vessels.

The new generation of FLUX progressive cavity pump VISCOPOWER F 570 for Industry & Hygienic with planetary gear is suitable to pump thin to medium viscous media. The positive displacement pump ...

... new generation FLUX eccentric worm-drive pump VISCOPOWER F 580 for Industry & Hygienic with bearing flange is suitable to pump thin to highly viscous, pasty and still flowing media. The positive displacement ...

The small drum pump JUNIORFLUX F 310 with fixed motor FEM 3070 and mechanical seal is especially suitable for pumping comparatively small quantities out of containers such as canisters ...

The B70V SanitaryPlus food pump is a powerful positive displacement pump for heavy-sensitive, viscous and viscous media up to the limits of flowability. It pumps liquid foodstuffs, ...

The B70V SanitaryPlus food pump is a powerful positive displacement pump for heavy-sensitive, viscous media with and without fiber or solids content up to the limits of flowability. It pumps ...

... reliability, safety and last but not least functionality are important. The submersible centrifugal pump was specially developed as a vertical, wet-installed pump for the rapid emptying ...

The ECP is designed to lubricate bearings and linear guides with oil or fluid grease. The pump works reliably in single-line systems of up to 20 lubrication points and a main line length of approximately 15 meters. It ...

When the application calls for high-volume and/or high head vertical pumps, the practical solution is the use of the Hazleton® vertical, double-suction, Twin-Volute VDM. Designed for ...

When the application calls for high-volume vertical pumps, the practical solution is the use of the Hazleton® vertical, double-suction, Twin-Volute VDS and VND. Designed for slurry handling ...

The VN Family of pumps is designed for the ultimate flexibility in slurry handling applications. The vertical cantilever design eliminates submerged beargings, top suction design eliminates air binding, ...

Vertical single-stage submersible motor pump for wet installation, with cutter (S), stationary or transportable version. Amarex N pumps are floodable, single-stage, single-entry close-coupled ...

Chemical pump with electrical temperature control. The CHEM series is designed to be easy to maintain. Separate pump covers allow a quick inspection of the inner workings from both sides of the pump. ...

Horizontal or vertical seal-less volute casing pump in back pull-out design with fully enclosed canned motor, low noise emission, with radial impeller, single-stage, single-entry, casing connecting dimensions ...

... LSC pump is a submersible single-phase portable residue drainage pump. The specially designed bottom plate enables the pump to drain down to 1mm water level. It has a swing check valve ...

... surface from scratching. Though the pump is a single-phase unit, it has the durability equivalent to three-phase drainage pumps as the wear parts are made of abrasion-resistant materials. The pump ...

The TVM-series is a vertical multistage centrifugal pump designed for handling freshwater. Since it is an in-line type, the pump occupies less installation space. The major wetted parts ...

... Product Line Series 493 and 4193 steel external pumps are available in capacities up to 75 GPM. These pumps can be furnished directly connected to a 50HZ or 60 HZ motor. Series 493 is designed for vertical ...

... plants. The inline housing design allows you to install it in pipeline systems to protect the following equipment, such as your pumps. Despite the pipeline installation, the macerator offers you the proven FSIP® concept ...

ViscoTec dispenser 3VMP18, as a volumetric dispensing pump for larger volumes, ensures smooth and reliable product supplying of abrasive, high-filled or shear sensitive material - with a repeatability of +/- 1 %!

ViscoTec dosing and filling pump type RD-hygienic for food and cosmetics is a volumetric conveying pump based on the endless piston principle. Suitable for discontinuous or continuous pulsation-free metering ...

The DSL pumps are single-stage, double-suction, vertical, centrifugal pumps. The design of the suction side provides for a perfect flow, and the inlet is placed in line with the outlet.

The durable Waukesha Clean-out-of-Place (COP) Positive Displacement "Can-Do Pump". Versatile in application, its reliability has made it the industry ...

The heavy-duty type TPC-M vertical cantilever pump without bottom bearing is designed with run-dry capabilities to pump solids-carrying acids, alkalis and chemically contaminated effluents ...

The heavy-duty type TPC vertical cantilever pump without bottom bearing is designed with run-dry capabilities to pump solids-carrying acids, alkalis and chemically contaminated effluents ...

The ST42 - 22 out of tank vertical pump range benefits from proven design features gained through over 60 years of experience and developments, and has been specially designed to handle the transfer of ...

As an extension to the standard Epsilon range, a vertical pump is available in various materials, including stainless steel or super duplex steels. This competitively priced high pressure pump ...

are plain centrifugal pumps with the impeller fitted on the driving shaft extension. They are mounted on top of the container, the pump extension being immersed in the ...

Immersion Pumps are plain centrifugal pumps with the impeller fitted on the driving shaft extension. They are mounted on top of the container, the pump extension being immersed in the ...

Continental Emsco Drilling Products, Inc., which consisted of Emsco drilling machinery and Wilson mobile rigs, was purchased by National-Oilwell, Inc on July 7, 1999. To our knowledge, no pumps have been manufactured and sold under the Emsco brand name since National-Oilwell acquired them.

Fairbanks Morse pumps are currently manufactured in Kansas City, Kansas. Fairbanks Morse is a division of Pentair ever since August, 1997 when Pentair purchased the General Signal Pump Group.

Gaso pumps are manufactured by National Oilwell Varco. Gaso was acquired as "Wheatley Gaso" by National-Oilwell in the year 2000. At the time, Wheatley Gaso was owned by Halliburton.

Skytop Brewster pumps are no longer available as new pumps. Skytop Brewster(Cnsld Gold), a unit of Hansen PLC"s Consolidated Gold Fields subsidiary, was acquired while in bankruptcy by National-Oilwell, Inc. in November, 1999.

A.R. Wilfley & Sons has manufactured pumps for over 85 years. We provide quality chemical pumps, acid pumps, slurry pumps and centrifugal pumps, all meeting ASME standards. The design of our pumps is meant to meet maximum flexibility and tailored for any application. For over 90 years our pumps have proven efficient and safe, globally. Contact us today for your free application needs assessment.

To be teamed with top-notch manufacturers and our own essential engineers is certainly to your advantage for the offering of self-priming centrifugal pumps, stainless steel centrifugal pumps, multistage centrifugal pumps, sump pumps (vertical) and more that we put forward. We also perform repairs.

Ace Pump’s years of engineering experience with cutting edge development processes make Ace your best choice for custom product development. Ace’s product design employs the latest in 3-D modeling and rapid prototyping tools, which insure design accuracy and efficiency and minimize lead times. Tell Ace your needs and it will design a vertical pump to meet them.

AGI Industries was founded in 1968 as a fluid power service and repair company. Today the company distributes and manufactures high pressure pumps and related components. With locations all over the United States we look forward to serving you. Call us today or visit our website for more information.

Our vision at Albritton Machine is to perform maintenance that significantly reduce cost, increase efficiency, and improve the reliability of your centrifugal pumps. Services include pump repair, on-site delivery, and supervision of final configuration. We are dedicated to bringing you the best quality, so give us a call for more information!

AMT, a subsidiary of The Gorman-Rupp Company, is a manufacturer of centrifugal pumps, including sump pumps, multistage centrifugal pumps and stainless steel centrifugal pumps. Choose from electric and engine driven centrifugal pumps. We have over 70 years of experience with centrifugal pumps.

Armstrong Pumps has been manufacturing centrifugal pumps, stainless steel centrifugal pumps and vertical centrifugal pumps for residential, commercial and industrial markets with experience since 1934. Dedicated to identifying specific market needs and bringing those products to the industry.

Our specialized centrifugal pumps can accommodate your applications. Our robust items require very low maintenance and we ensure our customers they are receiving excellence with every pump. If you already know the specifics of your order then please let us know and we can ship your products right away. Your satisfaction is vital to the growth of our company! Give us a call today!

Here at Blackmer our centrifugal pumps are equipped with secondary features and value-added components which sets our pumps apart from the competition. We are your hassle-free manufacturer of outstanding parts. Just let us know your application and we can handle the rest. Our teams are ready to work with you today! Please give us a call today to learn more!

Founded in 1970, Burt Process Equipment serves many industries as a worldwide leading manufacturer and distributor of high purity and corrosion resistant equipment. Our products include centrifugal pumps, sump pumps, vertical pumps, metering pumps, rotary pumps, ball valves, butterfly valves, diaphragm valves, control valves, plastic solenoid valves, stainless steel tanks and polyethylene tanks.

A world leader in high pressure piston and plunger pumps, CAT PUMPS manufactures industrial positive displacement pumps for industrial high-pressure systems. Our line of submersible pumps and end-suction centrifugal pumps are made from stainless steel, providing durability and high efficiency.

CLYDEUNION Pumps is one of the world"s leading pump companies - a centre of excellence in Pump Technology, Hydraulic Design and Engineering. We are structured to provide a specific focus on each of our customer"s key markets as well as providing full global aftermarket support. CLYDEUNION Pumps incorporates an accumulation of over 300 years of engineering expertise.

The many brands available through Crane® offer a variety of centrifugal pumps, including self-priming centrifugal pumps, sealless pumps, vertical centrifugal pumps and chemical pumps. We have over a century of experience with engineering pumping equipment.

Founded in 1869, Dean Pump has earned a reputation worldwide for high quality industrial centrifugal pumps. Our major product lines include: chemical pumps, heavy duty high temperature process pumps, self-priming pumps and heavy duty industrial pumps all available in a wide range of configurations, materials, sizes, capacities and temperature ranges. Trust Dean Pump to find your pumping solution.

F.H. Pumps has been in business since 1980. We offer both commercial and industrial pump support, and servicing the pump needs of our customers. We provide new pumps, parts for existing pumps, and pump repair services. Our staff has the expertise to make sure your needs are addressed, and we strive to maintain long term relationships with our clients. Contact F.H. Pumps today to learn more!

Flowserve centrifugal pumps are key components in the worldwide oil and gas, hydrocarbon and chemical processing, power generation and water resources industries. Our pumps comply either with ISO, ASME or API standards, and are available in various designs to meet the stringent demands of chemical handling applications. Visit our website today to learn more about our line of products.

Fistam Pumps is driven by innovation. Manufacturing four lines of high quality centrifugal pumps, we consider the interaction of a pump and its system to develop the optimum solution for every client. Stainless steel ensures hygienic use for chemical and water pumps in any application. We invest in research and development so you can expect superior quality and performance in every Fristam pump.

Fybroc Division of Met-Pro offers the most complete line of non-metallic, fiberglass reinforced, thermoset vinyl ester/epoxy pumps for handling corrosive and difficult liquids. Fybroc also provides cantilever, self-priming, vertical and horizontal pumps along with more than 30 years of industry experience, aggressive new product development and continued technical improvement to best serve you.

Since 1978, our radial flow centrifugal pumps have been used for flood irrigation, flood control, liquid waste pumping, & more. Our trailer centrifugal pumps supply water with either 540 or 1000 RPM PTO drive. Our sump pumps “attack” your pumping problem using tractor, diesel or electric power. For more information on our centrifugal pumps give us a call today, we are ready to help!

Centrifugal slurry pumps are not a necessity for everyone. However, when one is in need of such, they seek us. We manufacture pumps to handle coarse or fine particles, wastewater with solids, highly corrosive slurry, abrasive slurry or basically any water mixture with insoluble matter.

We have a long history of manufacturing a full selection of centrifugal pumps. These items are used in applications such as wastewater pumping, raw water pumping, cooling water, stormwater, flood control, seawater pumping, industrial effluent handling, irrigation, and process water. If you would like more information about our company then please give us a call today!

For over 150 years, we have manufactured centrifugal pumps for industrial global markets. We offer hard metal, rubber lined, vertical cantilever, submersible and self priming pumps. Our solutions lower costs of the pump life cycle for fluid handling problems. ISO 9001 certified company.

Gorman-Rupp is an ISO 9001-certified manufacturer of centrifugal pumps which transfer corrosive & non-corrosive fluids, plus we provide replacement kits. Gorman-Rupp pumps can be custom designed to your specifications. Choose from water pumps, trash pumps, & many more models that meet your requirements. We also offer capabilities in the modification of a current product. See website for details.

As a single manufacturer, Gusher Pumps has one of the largest available selections for centrifugal pumps. Close-coupled pumps, end suction pumps, immersed pumps and self-priming pumps are among the provided models. Gusher Pumps is able to manufacture according to Din and ANSI specifications and also adheres to their ISO 9001:2008 certification. Visit their website to learn more about this company.

With over half a century of excellence in designing and manufacturing internal gear pumps, external gear pumps for the OEM and process market, Haight Pumps prides itself on its outstanding lead time and quality customer service. Our combined expertise means we can offer you a customized response to both your needs and cost requirements. Our centrifugal pumps are sure to meet your needs!

Hydra-Tech can help handle your most difficult jobs and its centrifugal pumps are able to handle high viscosity liquids like refinery waste, molasses, latex & crude oil. Hydra-Tech can make standard pumps as well as custom design them to fit your needs and offers the widest variety of models in a variety of materials. Hydra-Tech is CE Certified and can help find or design the right pump for you.

Hydromatic® produces a variety of pumps and pump products. Some of our pumps include submersible centrifugal grinder pumps, sump pumps, centrifugal sewer ejector pumps, submersible centrifugal high head effluent pumps, centrifugal sewage grinder pumps and many more. Call us today!

Our industrial centrifugal pumps are the Shertech® brand. The cast iron or bronze models transfer a varied range of fluids. Our noryl, polypropylene and stainless steel centrifugal pumps handle corrosive, hard-to-transfer and high-temperature fluids. Used in industrial and other applications.

Our centrifugal pumps are designed from the best software available and all of our products are pre-tested which results in outstanding customer satisfaction. We aim to keep costs low for our customers which is why we have developed systems to improve the customer experience. From the initial contact to after-sales support; we are here to serve all of your needs. Give us a call today to learn more!

March Pumps is the originator of the centrifugal sealless magnetic drive pump. It is the ultimate in reliability, trouble-free performance for chemical, industrial, medical, marine and other applications. It is available in plastic or metallic construction, AC, DC and air motors and can be submersible or non-submersible. To learn about other characteristics and products please visit our website.

For high-flow applications (7.1 gpm), we offer our Series 101 magnetic drive centrifugal pumps. We are the originator of the magnetic drive. Micropump® also manufactures other types of pumps—piston vane centrifugal, external gear, micro annular gear, peristaltic and abrasive fluid pumps.

MTH Pumps manufactures standard and custom-engineered centrifugal and regenerative turbine pumps in iron, bronze, and stainless steel in sealed or sealless designs. Our line of small centrifugal pumps serves applications up to 60PSI or 100GPM, while our regenerative turbines reach 150GPM or 1000PSI.

Myers®, a name that has been around since 1870, is known for sump pumps, centrifugal pumps, pumping systems, waste-handling pumps, submersible well pumps and others for agricultural, commercial, industrial, municipal and residential applications in North America and in foreign countries.

For more than 70 years, Nagle Pumps have been the standard of excellence and reliability in heavy-duty pumps for abrasive, corrosive and high temperature applications. A wide Selection of designs, components, and Materials of construction allows Nagle to custom engineer each pump to meet your specific requirements. Nagle manufactures Vertical Cantilever, Wet and Dry Mounted, Submerged Bearing, Horizontal and Submersible pumps.

Since 1980, Oil Trades Supply has been a leader in the well pump industry. Our quality system follows industry Standards and has in place procedures to assure consistency of the product through all aspects of manufacturing and refurbishing. This commitment to quality, combined with our highly experienced and skilled employees make Oil Trades Supply the best place to take your next project. Call us today!

Pacific Design Technologies manufactures centrifugal pumps for aerospace, defense and space applications including fluid cooling and circulation pumps, accumulators, thermal control valves and systems. These pumps use specialized fluids like PEO, EGW, PGW, Freon, Ammonia, Refrigerants, Jet Fuels and more. Pumps are AC or DC powered and come in various voltages. Visit Pacific’s website today.

Durability, high-efficiency and the good NPSH of our products has made us one of the largest centrifugal vertical pump manufacturers in the industry. Some of our other products include sump pumps, horizontal end suction pumps, vertical turbine products, fire pumps and pumping system controllers.

Puffer Sweiven Rotating Equipment offers a wide range of centrifugal pumps from a number of quality manufacturers. We offer these durable products in horizontal, vertical and submersible designs.

Pulsafeeder manufactures stainless steel multistage centrifugal pumps, diaphragm metering, rotary gear, regenerative turbine, magnetically-driven sealless, rotary sliding vane and peristaltic pumps in a wide variety of corrosion-resistant materials. Our products also include pump controllers and systems.

Our centrifugal pump distributing company, Pump Engineering Company, offers fluid handling systems for a diverse market. We are considered the “rotating equipment connection” for many name brand pumps. Types of pumps we provide are standard centrifugal pumps, self-priming centrifugal pumps, submersible pumps, trash pumps, vertical sump pumps, water pumps, & vertical deep submersible well pumps.

Pump Solutions Inc. is a dedicated manufacturer of UL listed packaged pump stations and control panels for Domestic Booster, HVAC, Irrigation, Municipal and Waste water applications. Pumps available include sewage pumps, grinder pumps, storm water and effluents pumps. Our sales engineers & service technicians are eager to assist you in the design of a new system or up-grade of an existing system.

If you are not among the markets which have relied on us in the past, please join those who have. We carry a multitude of industrial-grade pumps from name-brand manufacturers—single and multistage centrifugal pumps, stainless steel centrifugal pumps, centrifugal water pumps and others. Contact us.

Roth Pump Company has been in business since 1932. We"re known for our premium customer service, outstanding products and excellent manufacturing standards. We are a global provider of reliable pumps and pumping systems. Call us today or visit our website for more information on our centrifugal pumps and our other products.

Whatever fluids you must pump, Smart Turner Pumps can help you do it effectively and efficiently. We manufacture enclosed and open impeller centrifugal pumps, multistage pumps, sump pumps and more. The latest technology backed by over 100 years of manufacturing and engineering experience is your assurance of sound design, competent application and quality workmanship with Smart Turner Pumps.

We manufacture Star® Water Systems, one source for sump pumps, centrifugal pumps (single- and 2-stage), centrifugal irrigation pumps, end-suction centrifugal pumps, garden hose centrifugal pumps and jet pumps. We also make water tanks, filters and softeners plus reverse osmosis systems and more.

Dependable pumps at Swaby Manufacturing Company have been around since 1893. Our cast iron and stainless steel centrifugal pumps, submersible pumps (screenless and non-clog), water pumps, vertical sump pumps, explosion proof pumps, and acid handling pumps, have a non-clog ejector when handling waste. Our products are used by commercial, chemical, power and sewage treatment plants.

Generations of professionals have known and trusted Taco to design and build the most reliable products in the industry. Taco Comfort Solutions develops and manufactures centrifugal pumps. Taco is proud to be an ISO 9001 registered company, which means we produce products at internationally recognized quality standards. We focus on delivering fast, responsive service to our loyal customers every time.

Teikoku USA Inc offers a large variety of multi-stage centrifugal pumps for applications requiring high discharge pressures. General pumps, refrigeration pumps, nuclear pumps, high temperature pumps and slurry pumps are also among products offered.

Texas Process Equipment supplies specialty pumps, such as centrifugal pumps and other process equipment. TPE offers products from Chempump, Barnes Pumps, Isochem, Micropump, Price Pump and more. Through a common sense approach to business, communication and information technology, TPE offers the lowest "total cost of ownership" to its customers. Call today to see what TPE can do for you.

Tramco Pump is proud of our inventory and quick delivery of parts, pumps and custom designed systems. Our impressive line includes centrifugal pumps offering flows to 75,000 GPM heads to 2,200ft as well as vertical, sewage and sump, rotary, diaphragm pumps and more to ensure your needs are met. With testing, repair and preventative measures; Tramco delivers the best products with the best service.

End-suction cast iron, plastic and stainless steel (corrosion-resistant plus 2-stage high head) centrifugal pumps are manufactured by us. These material types are used for our chemical pumps, sump pumps and self-priming centrifugal pumps. Weber Industries began pump manufacturing in 1963.

Xylem is a leading manufacturer of durable diaphragm pumps, serving the car washing equipment industry. Our factory is ISO 9001 and 14001 certified, thus ensuring the highest level of product quality and dependability. We also offer a wide range of industrial applications.

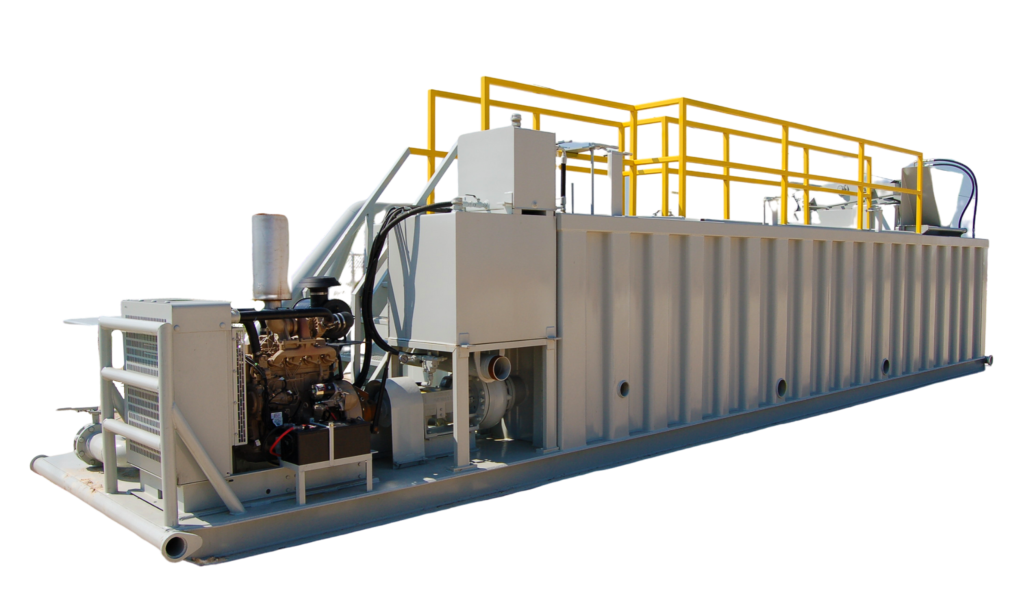

Explore a wide variety of vertical mud pump on Alibaba.com and enjoy exquisite deals. The machines help maintain drilling mud circulation throughout the project. There are many models and brands available, each with outstanding value. These vertical mud pump are efficient, durable, and completely waterproof. They are designed to lift water and mud with efficiency without using much energy or taking a lot of space.

The primary advantage of these vertical mud pump is that they can raise water from greater depths. With the fast-changing technology, purchase machines that come with the best technology for optimum results. They should be well adapted to the overall configuration of the installation to perform various operations. Hence, quality products are needed for more efficiency and enjoyment of the machines" full life expectancy.

Alibaba.com offers a wide selection of products with innovative features. The products are designed for a wide range of flow rates that differ by brand. They provide cost-effective options catering to different consumer needs. When choosing the right vertical mud pump for the drilling project, consider factors such as size, shape, and machine cost. More powerful tools are needed when dealing with large projects such as agriculture or irrigation.

Alibaba.com provides a wide range of vertical mud pump to suit different tastes and budgets. The site has a large assortment of products from major suppliers on the market. The products are made of durable materials to avoid corrosion and premature wear during operations. The range of products and brands on the site assures quality and good value for money.

For the successful execution of your projects, it is important to find an appropriate company with a good track record. We help you in connecting with the top mud pump manufacturers and companies and get the best quotation.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

Yes. We help you find the best mud pumps irrespective of your location. We simplify your search by connecting you with top mud pump manufacturers and mud pump companies in your location, according to your budget and business requirement.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

The different parts of a mud pump are Housing itself, Liner with packing, Cover plus packing, Piston and piston rod, Suction valve and discharge valve with their seats, Stuffing box (only in double-acting pumps), Gland (only in double-acting pumps), and Pulsation dampener. A mud pump also includes mud pump liner, mud pump piston, modules, hydraulic seat pullers along with other parts.

The wearing parts of a mud pump should be checked frequently for repairing needs or replacement. The wearing parts include pump casing, bearings, impeller, piston, liner, etc. Advanced anti-wear measures should be taken up to enhance the service life of the wearing parts. This can effectively bring down the project costs and improve production efficiency.

Fairbanks Nijhuis offers the industry’s most complete set of solutions, products and services to municipal and industrial customers. A wide variety of pumps and controls serve multiple markets to support a range of needs. Fairbanks Nijhuis also delivers professional services including installation, maintenance, repair, and training. Manufacturing operates primarily out of Kansas City, KS, USA and Winterswijk, The Netherlands. The combination of our two world-class engineering and manufacturing groups, with over 200 years of combined expertise, is a win for our customers around the globe.

Bearing type Plain bearing Housing pitch transverse (radial) Frequency of the drive motor 50 Hz /60 Hz Drive type electric motor Voltage of the drive motor Low voltage Fluidity single-flow (single-) design Base plate Coupling type direct Lubrication type Medium lubrication Maximum permissible medium temperature 60 °C max. nominal pressure (discharge side) PN 10 Unit installation wet installed Suction behaviour normal suction Housing design tubular housing Impeller type axial; propeller Connection form flange eClass Allocation 36410000;36410106;36410100 Free passage max. 170 mm maximum head 10.00 m minimum head 0.50 m vertical installation position Shaft seal type packing Main applications Waste water;water Housing material Ni-Resist;chrome-nickel steel;carbon steel maximum drive power 320 kW stationary installation type maximum flow rate 9,000 m³/h minimum flow rate 290 m³/h maximum speed 1,500 1/min

A part of National Oilwell Varco, the Mission line of centrifugal pumps are equipped with innovative features to match the demanding nature of routine, corrosive and abrasive applications. Because of the need for a low pressure mud system, Mission 1780 Type W centrifugal pumps were introduced in 1950s to replace duplex pumps. The aim was to apply a high quality centrifugal pump with concentric systems that allowed for abrasive fluids to be mixed and transferred thereby lowering the initial and maintenance costs of drilling. As a result, centrifugal pumps with low pressure mud systems such as Mission 1780 Type W became the industry standard.

As well depths increased, so was the need for heavier mud weights and centrifugal pumps that could withstand greater horsepower load. This led to the launch of Mission Magnum- a centrifugal pump.

The Magnum has an open impeller design that contains wide-tipped vanes and a more tangential circumference of the suction allowing the pump to create a smoother flow pattern when handling abrasive fluids. The Magnum is available in Magnachrome™, hard iron, stainless steel, and aluminum bronze fluid ends. The pumps can be unitized with electric motors, diesel engines, and hydraulic motors (horizontal, vertical, or close-coupled configuration).

Our pump engineering experts have the industry knowledge to gladly assist you with any questions, concerns, or inquiries you may have regarding the pumps & pump parts we distribute @ 800.560.7867.

The importance of pump manufacturers is rising across the globe. The pump manufacturing industry is one of the largest and fastest-growing industries globally. JEE Pumps was established in 1993. It has a tremendous demand for pumps of all kinds, including centrifugal pumps, reciprocating pumps, rotary vane pumps, screw pumps, magnetic drive pumps, and many others. In addition, manufacturing energy-efficient pumps tailored to engineering requirements are becoming the industry norm.

Several factors have contributed to this rapid growth in the industry. One of these is the increasing global population and its rising living standards. As people’s living standards improve, they tend to consume more resources like water or energy. This has led to a significant increase in demand for the products manufactured by companies in the pump manufacturing industry.

Another important factor driving this growth is rapid technological advancements and innovations that have made various types of pumps much more efficient and cost-effective. Overall, the pump manufacturing industry is expected to continue thriving in the years as some of the best pump manufacturers in the world compete making the market highly lucrative.

Grundfos, a European firm, is one of the largest pump manufacturers with a global reach spanning more than 130 countries. The company offers a wide range of pump solutions for water and wastewater applications and industrial, agricultural, and building services. Grundfos is headquartered in Denmark and has more than 50,000 employees across more than 100 countries. Grundfos has a strong commitment to sustainable development and provides energy-efficient solutions that reduce water consumption and greenhouse gas emissions.

Xylem is another leading player in the global pump market, operating in more than 150 countries. Xylem’s product portfolio includes pumps for water and wastewater applications and HVAC, industrial, and other commercial uses. In addition, the company has built a strong reputation for working on providing return water to major industrial complexes, residential buildings, and commercial estates. With over 16,500 employees serving customers and based out of New York, Xylem does business in three key segments: Water Infrastructure, Environment & Industrial, and Semiconductor.

KSB is a German pump manufacturer with a solid global presence. The company operates in more than 100 countries. It offers a wide range of pumps for water and wastewater applications and oil & gas, power generation, and other industries. KSB has been manufacturing pumps since 1898. Today, KSB Group comprises over 15 000 employees worldwide working to develop innovative solutions for its customers. KSB has a long history of innovation and is constantly developing new products and services to meet the needs of its customers.

JEE Pumps, an India-based company is one of the best pump manufacturers in the world. It manufactures and exports a wide range of pumps in agriculture, domestic, and industrial applications and caters to over 25 countries. Through its state-of-the-art manufacturing units, JEE Pumps manufactures a wide range of pumps such as submersible pumps, centrifugal pumps, jet pumps, etc. The company also offers customized solutions to meet the specific requirements of its clients. JEE Pumps has a team of experienced engineers who design the products as per the latest technology trends. The products offered by JEE Pumps are known for their high efficiency, low noise operation, and long service life.

Flowserve is one of the world’s largest suppliers of pumps and related flow control products and services. The company operates in more than 50 countries. It offers a comprehensive range of pumps for water and wastewater applications and the oil & gas, chemical, and other industries. Apart from pumps, it is also one of the world’s largest suppliers of valves, seals, automation, and services to power, oil, gas, chemical, and other industries.

Weir Group is a UK-based engineering company with a solid global presence. The company’s product portfolio includes a wide range of pumps for water and wastewater applications and mining, oil & gas, and other industries. The company operates in over 70 countries employing approximately 14,000 people focused on mining, oil and gas, and power markets.

Ebara Corporation is a Japanese company that manufactures and markets pumps, compressors, water treatment equipment, and other fluid handling products. The company is headquartered in Tokyo, Japan, and has manufacturing facilities in Japan, China, Italy, Brazil, and the United States. The company was founded in 1912 as Ebara Shokai by Saburosuke Ebara, and its first product was a hand-operated diaphragm pump. Over the years, it has captured a good market share in Southeast Asia with its innovative and reliable products.

Pedrollo SpA is an Italian-based company that manufactures pumps and other water-related products. The company was founded in the early 1900s, and it has since grown to become one of the leading pump manufacturers in the world. Pedrollo produces a wide range of pumps for various applications, including domestic, industrial, agricultural, and municipal. Some of the most popular Pedrollo pumps include submersible pumps, jet pumps, centrifugal pumps, and diaphragm pumps.

ITT Goulds Pumps is one of the oldest and most experienced pump manufacturers globally. The company started in Seneca Falls, New York, in 1848 and today has over 3,000 employees worldwide. Goulds Pumps offers a wide range of pumps for various applications, including industrial, municipal, residential, and agricultural. The company’s products are used in many industries, including mining, oil and gas, power generation, water and wastewater treatment, food and beverage processing, and more.

All the best pump manufacturers in the world rely heavily on providing quality and energy-efficient pump solutions. When choosing the pump manufacturer, you need to consider the location. Importing heavy-duty pumps can attract a lot of logistics costs that you can avoid by choosing a regional pump provider. Cost is another factor you need to consider. US and European suppliers charge a premium amount for products that you can get at a discounted rate from India or other Asian nations. Choosing the proper pump manufacturer can ensure your system’s reliable and cost-effective operations.

Gusher Pumps builds everything from highly specialized single pumps to high quantity custom-engineered pump orders. Our range of industrial pumps represents one of the largest selection of centrifugal pumps available from a single manufacturer.

Models include close-coupled pumps, end suction pumps, immersed pumps, self-priming pumps, vortex pumps, sludge pumps, multi-stage pumps, and full cantilever pumps. Both vertical pumps and horizontal pumps are available to suit installation and application requirements.

Our product range is capable of handling flows from small to large, with our multi-stage pump achieving heads in excess of 800 ft. Numerous models and sizes permit selection of the most hydraulically suitable pump for many capacity/head ranges without having to up or down size operating characteristics.

Over 100 years in the pump business shows in our expertise. Gusher Pumps excels in custom-engineering pumps to meet exacting performance and unique application specifications.

From sales and customer service to engineering, machining, assembly and quality control, our dedicated staff is the driving force behind our reputation for quality, dependable pumps. As one customer put it: Gusher is big enough to have deep engineering expertise, yet small enough to care about each individual order.

Gusher Pumps’ custom-manufactured pumps are suited for a wide range of applications including DIN specification, ANSI specification, machine tool and centralized coolant systems, automatic paint systems, industrial spray washers, filtration systems, phosphate and bonderizing lines, just to name a few.

8613371530291

8613371530291