vertical mud pump suppliers brands

Vertical pumps are constructed from stainless steel, aluminum or cast iron and must be strong enough to withstand internal and external pressures. These pumps are most often used for lifting and transporting water, an application that finds many uses in residential, general purpose, industrial and commercial situations.

Centrifugal pumps are used in wastewater and sewage treatment plants to handle trash and refuse; certain heavy duty models can pump mixtures of solids that are suspended in liquid. As water pumps, vertical pumps are used for deep well pumping and move water from its underground source to buildings for human use or to prevent flooding or drainage issues.

If vertical pumps are made of strong corrosion resistant materials, they are able pump chemicals and acids which is a useful way of transporting hazardous liquids throughout a processing plant.

Vertical centrifugal pumps are simply designed machines. A casing called a volute contains a horizontal impeller mounted perpendicularly on an upright rotating shaft. The electric motor uses its mechanical energy to turn the impeller whose blades impart kinetic energy to the liquid as it begins to rotate up the casing.

Momentum and pressure carry the liquid (most commonly water) through the expanding volute until it exits through a discharge opening, sometimes at high velocities. Vertical pumps are located underground near the source of liquid which they move up to the surface. They are usually electric because a gas tank would be impractical to store and fill. The power cords are kept in a durable protective casing to prevent any leaks or damage.

One example of a vertical pump is an axial flow pump whose impeller is actually a kind of propeller that lifts the liquid in a direction parallel to the pump shaft instead of pushing it in a perpendicular direction like horizontal centrifugal pumps would. Vertical pumps are generally designed in a close-coupled arrangement where the motor and the pump are held in the same slim enclosure that can be lowered into a deep well hole. Another technique is to have the motor at ground level and install the pump underground.

Distributor of engineered fluid handling pumps, packaged pumping systems, repairs, parts, & integrated pump control systems. Mud pumps, chiller/condenser pumps, plumbing pumps, boiler feed systems, in-line circulators, condensate systems, sump & sewage pumps, end suction pumps, submersible sump & sewage, non-clogs & grinders, self primers, packaged lift stations, variable speed pump systems, metering pumps, chemical injection systems, chemical mixing systems, peristaltic pumps for chemical feed, high viscous & shear sensitive fluids, self primers, stainless steel, trash pumps, hot oil pumps, vertical turbine pumps, sanitary pumps, marine pumps, industrial pumps, ANSI end suction, vertical cantilever, double suction, non-clogs, progressive cavity pumps, helical gear pumps, well pumps, lab pumps, hose pumps, control valves, check valves, air release valves, tanks, pressure vessels.

Distributor of vertical turbine pumps. Vertical turbine universal transfer pumps are available in various configurations, surface discharge & drive types including hollow & solid shaft motors, C-face motors & in right angled gear drives suitable for liquid handling applications including rain water, hazardous, abrasive & viscous fluids in various capacities & pressures. Features include T & G discharge heads, ANSI flange base, pressure packing box, mechanical seal, liquid lock bypass construction, lubricated open & enclosed line shafts, flanged columns, rubber & metallic bearings, tapered & bell-mouth suction type flanged bowl assemblies, basket & conical strainers including open construction without strainers. Capabilities include up to 17,000 gpm flow rate, 720 psi pressure & 100 rpm speed. Applications also include steel mills, metal finishing, chemical, paper, municipal, petroleum & agriculture industries.

Continental Emsco Drilling Products, Inc., which consisted of Emsco drilling machinery and Wilson mobile rigs, was purchased by National-Oilwell, Inc on July 7, 1999. To our knowledge, no pumps have been manufactured and sold under the Emsco brand name since National-Oilwell acquired them.

Fairbanks Morse pumps are currently manufactured in Kansas City, Kansas. Fairbanks Morse is a division of Pentair ever since August, 1997 when Pentair purchased the General Signal Pump Group.

Gaso pumps are manufactured by National Oilwell Varco. Gaso was acquired as "Wheatley Gaso" by National-Oilwell in the year 2000. At the time, Wheatley Gaso was owned by Halliburton.

Skytop Brewster pumps are no longer available as new pumps. Skytop Brewster(Cnsld Gold), a unit of Hansen PLC"s Consolidated Gold Fields subsidiary, was acquired while in bankruptcy by National-Oilwell, Inc. in November, 1999.

For the successful execution of your projects, it is important to find an appropriate company with a good track record. We help you in connecting with the top mud pump manufacturers and companies and get the best quotation.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

Yes. We help you find the best mud pumps irrespective of your location. We simplify your search by connecting you with top mud pump manufacturers and mud pump companies in your location, according to your budget and business requirement.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

The different parts of a mud pump are Housing itself, Liner with packing, Cover plus packing, Piston and piston rod, Suction valve and discharge valve with their seats, Stuffing box (only in double-acting pumps), Gland (only in double-acting pumps), and Pulsation dampener. A mud pump also includes mud pump liner, mud pump piston, modules, hydraulic seat pullers along with other parts.

The wearing parts of a mud pump should be checked frequently for repairing needs or replacement. The wearing parts include pump casing, bearings, impeller, piston, liner, etc. Advanced anti-wear measures should be taken up to enhance the service life of the wearing parts. This can effectively bring down the project costs and improve production efficiency.

Explore a wide variety of vertical mud pump on Alibaba.com and enjoy exquisite deals. The machines help maintain drilling mud circulation throughout the project. There are many models and brands available, each with outstanding value. These vertical mud pump are efficient, durable, and completely waterproof. They are designed to lift water and mud with efficiency without using much energy or taking a lot of space.

The primary advantage of these vertical mud pump is that they can raise water from greater depths. With the fast-changing technology, purchase machines that come with the best technology for optimum results. They should be well adapted to the overall configuration of the installation to perform various operations. Hence, quality products are needed for more efficiency and enjoyment of the machines" full life expectancy.

Alibaba.com offers a wide selection of products with innovative features. The products are designed for a wide range of flow rates that differ by brand. They provide cost-effective options catering to different consumer needs. When choosing the right vertical mud pump for the drilling project, consider factors such as size, shape, and machine cost. More powerful tools are needed when dealing with large projects such as agriculture or irrigation.

Alibaba.com provides a wide range of vertical mud pump to suit different tastes and budgets. The site has a large assortment of products from major suppliers on the market. The products are made of durable materials to avoid corrosion and premature wear during operations. The range of products and brands on the site assures quality and good value for money.

A part of National Oilwell Varco, the Mission line of centrifugal pumps are equipped with innovative features to match the demanding nature of routine, corrosive and abrasive applications. Because of the need for a low pressure mud system, Mission 1780 Type W centrifugal pumps were introduced in 1950s to replace duplex pumps. The aim was to apply a high quality centrifugal pump with concentric systems that allowed for abrasive fluids to be mixed and transferred thereby lowering the initial and maintenance costs of drilling. As a result, centrifugal pumps with low pressure mud systems such as Mission 1780 Type W became the industry standard.

As well depths increased, so was the need for heavier mud weights and centrifugal pumps that could withstand greater horsepower load. This led to the launch of Mission Magnum- a centrifugal pump.

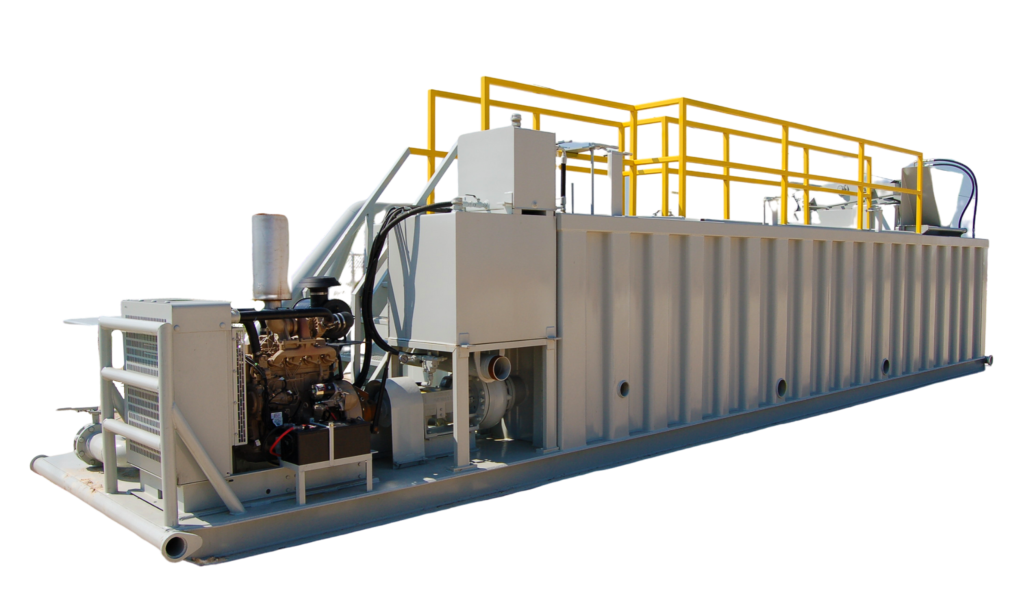

The Magnum has an open impeller design that contains wide-tipped vanes and a more tangential circumference of the suction allowing the pump to create a smoother flow pattern when handling abrasive fluids. The Magnum is available in Magnachrome™, hard iron, stainless steel, and aluminum bronze fluid ends. The pumps can be unitized with electric motors, diesel engines, and hydraulic motors (horizontal, vertical, or close-coupled configuration).

Our pump engineering experts have the industry knowledge to gladly assist you with any questions, concerns, or inquiries you may have regarding the pumps & pump parts we distribute @ 800.560.7867.

The importance of pump manufacturers is rising across the globe. The pump manufacturing industry is one of the largest and fastest-growing industries globally. JEE Pumps was established in 1993. It has a tremendous demand for pumps of all kinds, including centrifugal pumps, reciprocating pumps, rotary vane pumps, screw pumps, magnetic drive pumps, and many others. In addition, manufacturing energy-efficient pumps tailored to engineering requirements are becoming the industry norm.

Several factors have contributed to this rapid growth in the industry. One of these is the increasing global population and its rising living standards. As people’s living standards improve, they tend to consume more resources like water or energy. This has led to a significant increase in demand for the products manufactured by companies in the pump manufacturing industry.

Another important factor driving this growth is rapid technological advancements and innovations that have made various types of pumps much more efficient and cost-effective. Overall, the pump manufacturing industry is expected to continue thriving in the years as some of the best pump manufacturers in the world compete making the market highly lucrative.

Grundfos, a European firm, is one of the largest pump manufacturers with a global reach spanning more than 130 countries. The company offers a wide range of pump solutions for water and wastewater applications and industrial, agricultural, and building services. Grundfos is headquartered in Denmark and has more than 50,000 employees across more than 100 countries. Grundfos has a strong commitment to sustainable development and provides energy-efficient solutions that reduce water consumption and greenhouse gas emissions.

Xylem is another leading player in the global pump market, operating in more than 150 countries. Xylem’s product portfolio includes pumps for water and wastewater applications and HVAC, industrial, and other commercial uses. In addition, the company has built a strong reputation for working on providing return water to major industrial complexes, residential buildings, and commercial estates. With over 16,500 employees serving customers and based out of New York, Xylem does business in three key segments: Water Infrastructure, Environment & Industrial, and Semiconductor.

KSB is a German pump manufacturer with a solid global presence. The company operates in more than 100 countries. It offers a wide range of pumps for water and wastewater applications and oil & gas, power generation, and other industries. KSB has been manufacturing pumps since 1898. Today, KSB Group comprises over 15 000 employees worldwide working to develop innovative solutions for its customers. KSB has a long history of innovation and is constantly developing new products and services to meet the needs of its customers.

JEE Pumps, an India-based company is one of the best pump manufacturers in the world. It manufactures and exports a wide range of pumps in agriculture, domestic, and industrial applications and caters to over 25 countries. Through its state-of-the-art manufacturing units, JEE Pumps manufactures a wide range of pumps such as submersible pumps, centrifugal pumps, jet pumps, etc. The company also offers customized solutions to meet the specific requirements of its clients. JEE Pumps has a team of experienced engineers who design the products as per the latest technology trends. The products offered by JEE Pumps are known for their high efficiency, low noise operation, and long service life.

Flowserve is one of the world’s largest suppliers of pumps and related flow control products and services. The company operates in more than 50 countries. It offers a comprehensive range of pumps for water and wastewater applications and the oil & gas, chemical, and other industries. Apart from pumps, it is also one of the world’s largest suppliers of valves, seals, automation, and services to power, oil, gas, chemical, and other industries.

Weir Group is a UK-based engineering company with a solid global presence. The company’s product portfolio includes a wide range of pumps for water and wastewater applications and mining, oil & gas, and other industries. The company operates in over 70 countries employing approximately 14,000 people focused on mining, oil and gas, and power markets.

Ebara Corporation is a Japanese company that manufactures and markets pumps, compressors, water treatment equipment, and other fluid handling products. The company is headquartered in Tokyo, Japan, and has manufacturing facilities in Japan, China, Italy, Brazil, and the United States. The company was founded in 1912 as Ebara Shokai by Saburosuke Ebara, and its first product was a hand-operated diaphragm pump. Over the years, it has captured a good market share in Southeast Asia with its innovative and reliable products.

Pedrollo SpA is an Italian-based company that manufactures pumps and other water-related products. The company was founded in the early 1900s, and it has since grown to become one of the leading pump manufacturers in the world. Pedrollo produces a wide range of pumps for various applications, including domestic, industrial, agricultural, and municipal. Some of the most popular Pedrollo pumps include submersible pumps, jet pumps, centrifugal pumps, and diaphragm pumps.

ITT Goulds Pumps is one of the oldest and most experienced pump manufacturers globally. The company started in Seneca Falls, New York, in 1848 and today has over 3,000 employees worldwide. Goulds Pumps offers a wide range of pumps for various applications, including industrial, municipal, residential, and agricultural. The company’s products are used in many industries, including mining, oil and gas, power generation, water and wastewater treatment, food and beverage processing, and more.

All the best pump manufacturers in the world rely heavily on providing quality and energy-efficient pump solutions. When choosing the pump manufacturer, you need to consider the location. Importing heavy-duty pumps can attract a lot of logistics costs that you can avoid by choosing a regional pump provider. Cost is another factor you need to consider. US and European suppliers charge a premium amount for products that you can get at a discounted rate from India or other Asian nations. Choosing the proper pump manufacturer can ensure your system’s reliable and cost-effective operations.

We are the original designers and manufacturers of the MudMaster MM420DT and MM435DT mud pumps. For over 35 years, we have built and supported the best pump packages in the industry. With over 1,000 units in service, you are assured of a quality product and after-sales support.

Standard build includes TEFC motor. “Explosion proof” motors are also available. This belt driven unit is easily adjusted and permanently aligned. The triplex piston type pump is simple, rugged and reliable. 50 Hz or 60 Hz motors are available at any common three-phase voltage input. A preset, adjustable pressure relief valve is standard equipment.

Rating is 25 US gpm (95 L) with disc type valves or 20 US gpm (76 L) with ball valves. Disc valves are intended for use with clean fluids and ball valves are suited to drilling mud solutions. The pumps are available with optional materials of construction to suit special applications.

The Rig shall be provided with a Heavy duty 7 1/2 x 10 Mud Pump of High pressure, double acting, duplex, Reciprocating slush pump. Drive by chain, sprocket or V-belt, pulley.

The Pump shall be single cast rugged construction with easy accessibility for change of liners, fluid pistons, valves etc. The Mud Pump shall beread more...

Easy to install:- only the suction hose is immersed in the liquid, The pump can be set up high and dry in the most convenient position for inspection and maintenance.

8613371530291

8613371530291