well service mud pump factory

For more than 40 years, American Block has continued to provide high quality oil and gas equipment to the Upstream Energy Sector. With a legacy of manufacturing the most reliable and toughest drilling and well service equipment in the market. American Block has expanded into designing and manufacturing Well Service Pumps, in both configurations 600HP and 1000HP. Featuring a forged alloy steel fluid end and an integral heavy duty single helical gearbox with 4.61:1 gear ratio. Our pumps are engineered for endurance, performance and reliability.

Centerline Manufacturing is committed to the highest level of customer service quality. Every Centerline pump is comprehensively and repeatedly tested at diverse pressure levels to assure that it goes to our customer in perfect operational order. Centerline technicians work to ensure that our customers fully understand the operation of the model being delivered. If a customer"s pump is down, we understand the importance of timely response and parts availability. Centerline technicians will assess the problem and make repairs to bring the pump back into new specification. The Centerline mud pump technicians are well versed and qualified to operate and repair any product that is provided to the customer.

Continental Emsco Drilling Products, Inc., which consisted of Emsco drilling machinery and Wilson mobile rigs, was purchased by National-Oilwell, Inc on July 7, 1999. To our knowledge, no pumps have been manufactured and sold under the Emsco brand name since National-Oilwell acquired them.

Fairbanks Morse pumps are currently manufactured in Kansas City, Kansas. Fairbanks Morse is a division of Pentair ever since August, 1997 when Pentair purchased the General Signal Pump Group.

Gaso pumps are manufactured by National Oilwell Varco. Gaso was acquired as "Wheatley Gaso" by National-Oilwell in the year 2000. At the time, Wheatley Gaso was owned by Halliburton.

Skytop Brewster pumps are no longer available as new pumps. Skytop Brewster(Cnsld Gold), a unit of Hansen PLC"s Consolidated Gold Fields subsidiary, was acquired while in bankruptcy by National-Oilwell, Inc. in November, 1999.

We also served as the acting shop and field repair representative for the Western Gear Company and as a manufacturing facility for Wilson Manufacturing Company based in Wichita Falls, Texas. Wilson was a manufacturer of well service rigs and mud pumps. SMC Inc. has served and currently serves as a manufacturing and repair center for Oil Well Supply, Cabot-Franks, National, Halliburton, The Western Company, B.J. Hughes, Gardner Denver and many others. We manufacture a triplex pump of 165 H.P. with parts interchangeable to the Gardner Denver model TEE and are currently developing a 500 H.P. pump with parts interchangeable to Oilwell"s SA-644-5 pump. SMC has a large warehouse full of quality replacement parts for various types of equipment such as Triplex Plunger Pumps, Mud Pumps, Swivels, Drawworks and Rotaries.

We manufacture positive displacement pumps and replacement parts vital to the oil industry worldwide. We have customers that include both domestic and foreign oil companies. We also manufacture and repair a variety of products used in routine maintenance by customers with rock crushers, aggregate and commercial cement manufacturing plants.

Black gold is truly the best description to sum up the value of oil. One of the most important contributors to change and industrialization, it drives the wheels of progress. ShalePumps is headquartered in Houston, the global oil capital. Headed by experts, it has a vision to support the industry with superior completion equipment. Frac operators, drilling contractors and well service companies source rely on ShalePumps for superior quality.

The key personnel of ShalePumps have a combined experience of more than a hundred years. This experience is reflected in the quality of our equipment. The fracking pumps, components and all services are much sought after for reliability and long life. This is because of the processes we follow. The design, materials, precision engineering and expertise contribute to an advanced assembly line.

After many years of thought and conscientious engineering, the team at ShalePumps is proud to add the Q5K™ 5000 HP Frac Pump to their list of many product offerings. Perfectly capable and suited for the next generation of hydraulic fracking market demands and technology. The Q5K is the only frac pump that has been designed and developed from the ground up to be capable of accepting true 5000 HP in a continuous duty frac application.

ShalePumps has consistently delivered high quality completion equipment to all stakeholders. The mission is to develop faster, rugged and efficient equipment to help the Oil and Exploration Industry. The vision is to continue leading the race with the best quality in completion equipment.

For the successful execution of your projects, it is important to find an appropriate company with a good track record. We help you in connecting with the top mud pump manufacturers and companies and get the best quotation.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

Yes. We help you find the best mud pumps irrespective of your location. We simplify your search by connecting you with top mud pump manufacturers and mud pump companies in your location, according to your budget and business requirement.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

The different parts of a mud pump are Housing itself, Liner with packing, Cover plus packing, Piston and piston rod, Suction valve and discharge valve with their seats, Stuffing box (only in double-acting pumps), Gland (only in double-acting pumps), and Pulsation dampener. A mud pump also includes mud pump liner, mud pump piston, modules, hydraulic seat pullers along with other parts.

The wearing parts of a mud pump should be checked frequently for repairing needs or replacement. The wearing parts include pump casing, bearings, impeller, piston, liner, etc. Advanced anti-wear measures should be taken up to enhance the service life of the wearing parts. This can effectively bring down the project costs and improve production efficiency.

American Mfg Company’s roots lie in the fertile soil of America’s water-well Industry. When American Mfg Company opened it’s doors in 1986 it was a company 100% dedicated to manufacturing the highest quality spare parts for the water-well drilling industry.

While we may have grown a bit since the mid 80’s, and added several new divisions to our product line, our passion of manufacturing 100% identical and interchangeable parts for the water-well drilling pumps hasn’t wavered in the slightest. In fact, over the past 5 years we’ve added 3 complete duplex pumps which are OEM equipment for the most reputable water-well drilling rig manufacturers in the industry.

The government push towards geothermal heat has lead to an explosion in the geothermal drilling industry. A fairly new industry for American Mfg Company, we dove head in with our revolutionary 5” X 5” duplex mud pump which delivers the mud volume of a 5” X 6 pump, with the footprint of a 4.5” X 5”.

It’s time for piston mud pumps to enter the 21st century. Centerline Mud Pumps utilize common, industry-proven, and easily obtained fluid end parts. Designed to give you better flow capacity, pressure, size and weight advantages, that you won’t find anywhere else. Centerline Mud Pumps are built to exceed the most demanding specifications in the industry. These pumps are built to last.

Centerline Manufacturing is pleased to introduce their line of hydraulic drive mud pumps. Since 1983, Centerline Manufacturing has been involved in the design, manufacture, and production of drilling equipment, support equipment, and tooling for the water well industry. Our line of mud pumps include several new milestone technologies not found anywhere else in the industry.

Provides 150-180* GPM (Gallon Per Minute) of standard mud flow at 350 psi continuous. The 180 GPM is a provisional condition that requires the mud pressure to be below 275 psi and the hydraulic oil temperature below 165 degrees F.

Provides 300-360* GPM (Gallon Per Minute) of standard mud flow at 350 psi Continuous. The 360 GPM is a provisional condition that requires the mud pressure to be below 275 psi and the hydraulic oil temperature below 165 degrees F.

Provides 450-540* GPM (Gallon per Minute) of standard mud flow ar 350 psi Continuous. The 540 GPM is a provisional condition that requires the mud pressure to be below 275 psi and the hydraulic oil temperature below 165 degrees F.

Weir provides the oil and gas industry with the best in full open valve and seat technology and manufactures a wide variety of valves and seats for workover pumps, high pressure well service fracturing pumps, cementing pumps and mud pumps through its Novatech™ pressure pumping equipment line.

Novatech leads the industry in full open valve and seat technology and manufactures valves and seats for workover pumps, high pressure well service fracturing pumps, cementing pumps and mud pumps. Novatech also manufactures caged assemblies for almost all well service pumps and applications, including workover, cementing, acidizing and fracking. Novatech developed the first valve and seat in the industry rated for continuous service at 7,500 psi. Products are 100% made in U.S.A.

Reasontek carry Weir/Novatech products for oilfield applications including valves, seats, inserts replacement of pump maintenance. Please check the catalogue below and let us know your request.

The 2,200-hp mud pump for offshore applications is a single-acting reciprocating triplex mud pump designed for high fluid flow rates, even at low operating speeds, and with a long stroke design. These features reduce the number of load reversals in critical components and increase the life of fluid end parts.

The pump’s critical components are strategically placed to make maintenance and inspection far easier and safer. The two-piece, quick-release piston rod lets you remove the piston without disturbing the liner, minimizing downtime when you’re replacing fluid parts.

After drilling many dry wells, George Strake Sr. struck oil on December 13, 1931 in Conroe, Texas, just 30 miles north of SWOP’s headquarters. By the end of 1932, his 8,500 acre oilfield was producing more than 65,000 barrels of oil a day.

Southwest Oilfield Products is a premier oil and gas equipment manufacturer that provides our global customer base with best-in-class mud and well servicing pump solutions. We manufacture rugged and reliable equipment for your specific needs including Mud Pump Fluid Ends, Frac Pump Fluid Ends, Liners, Pistons, and other consumable items.

American Block was founded in 1979 in the heart of the oil patch – Houston, TX by an entrepreneurial mechanical engineer, Mr. Rajani Shah. Originally set up to be a general machine shop serving the local oilfield community,, the business has now expanded into an internationally recognized UEM manufacturing company providing a wide array of oilfield drilling and marine products. Over the years, and since our inception, the company has used its engineering skills and world-class manufacturing techniques to improve on focused drilling products like Sheaves, Traveling Equipment, Triplex Mud Pumps, and Drawworks.

In addition to these legacy products, the company has also developed, and now distributes, a line of Flow Iron and Hammer Union products. New to our product line this year is well service pumping solutions in the form of 600 Triplex and 1000 and 2500HP quintuplex pumps.

Today, we stand alert and ready to tackle any challenge our clients’ face with the most experienced and knowledgeable team in the industry. With our hands-on management team, expert engineers, and highly-skilled machinists, welders, and service men and women, we are equipped to handle any project large, small, or unique on a global scale. We are proud of our in-house team, a team with decades of experience in design and manufacturing of highly engineered products.

Our number one priority is our customers, and we believe customer satisfaction is at the core of our business. As a company, we strive to continue to increase efficiency, improve quality, and reduce project(change) overhead (total cost of ownership). By cultivating long-term relationships both internally and externally, we base our performance on service and customer experience. As a company, we will continue to innovate the market, improve design and manufacturing processes, and reduce costs to better serve our customers and the industries that we serve.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

triplex mud pumps and triplex mud pump parts meet the industry standards established by the American Petroleum Institute (API). As a global supplier of quality oilfield equipment to the oil and gas industry, we ship our products around the world.

Besides triplex mud pumps and triplex mud pump parts, we supply drilling rigs, workover rigs, top drives, drilling equipment, blowout preventers, BOP control systems, choke and kill manifolds, well service pumps for well cementing and hydraulic fracturing, wellhead equipment, casing heads, tubing heads, X-mas trees, FC type gate valves, etc. Please visit our company website

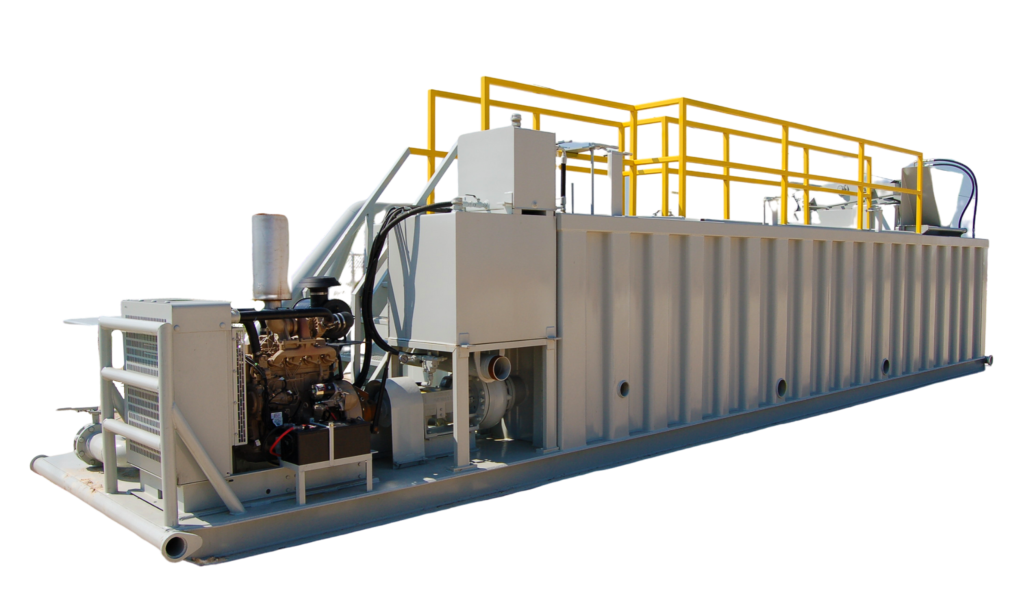

We supply unitized mud pump packages driven by DC or AC electric motors or diesel engines for electric and mechanical drilling rigs. The client can select DC or AC motors and diesel engine brands such as Caterpillar, Detroit, Cummins or others. Our unitized mud pump packages including everything on the skid and usually they are ready to work at delivery.

8613371530291

8613371530291