what is a triplex mud pump in stock

hex pumps with six plungers. Triplex pumps are the most widely used because the pressure they provide is suitable for most applications and because of their simplicity and efficiency. Triplex pumps are susceptible to high vibration and noise during operation.

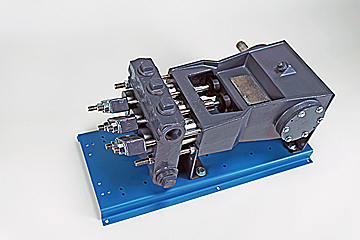

The NOV FC-1600 Triplex Mud Pump is made of rugged Fabriform construction and designed for optimum performance under extreme drilling conditions. It is compact and occupies less space, yet delivers unequaled performance. The pumps are backed by several decades of design and manufacturing experience, and are considered leaders in the field.

NOV FC-1600 Triplex Mud Pump is conservatively rated at relatively low rpm. This reduces the number of load reversals in heavily stressed components and increases the life of the fluid end parts through conservative speeds and valve operation.

The NOV FC-1600 Triplex Mud Pump design provides an inherently balanced assembly. No additional counterbalancing is required for smooth operation. No inertia forces are transmitted to the pumps’ mountings.

A Triplex Mud Pump sometimes referred to as a drilling mud pump or mud drilling pump. NOV FC-1600 Triplex Mud Pump is a reciprocating piston/plunger pump designed to circulate drilling fluid under high pressure (up to 7,500 psi) down the drill string and back up the annulus. A mud pump is an important part of the equipment used for oil well drilling.

Since the NOV A1700-PT Triplex Mud Pump was built approximately 60 years ago, the industry has widely accepted the three cylinder or triplex style pump. Triplex mud pumps are manufactured worldwide, and many companies have emulated the original design and developed an improved form of the triplex pump in the past decade.

NOV A1700-PT Triplex Mud Pumps have many advantages they weight 30% less than a duplex of equal horsepower or kilowatts. The lighter weight parts are easier to handle and therefore easier to maintain. The other advantages include;They cost less to operate

One of the more important advantages of triplex over duplex pumps, is that they can move large volumes of mud at the higher pressure is required for modern deep hole drilling.

NOV A1700-PT Triplex Mud Pump is gradually phasing out duplex units. In a triplex pump, the pistons discharge mud only when they move forward in the liner. Then, when they moved back they draw in mud on the same side of the piston. Because of this, they are also called “single acting.” Single acting triplex pumps, pump mud at a relatively high speeds. NOV A1700-PT Triplex Mud Pump has three pistons each moving in its own liner. It also has three intake valves and three discharge valves. It also has a pulsation dampener in the discharge line.

Explore a wide variety of triplex mud pump on Alibaba.com and enjoy exquisite deals. The machines help maintain drilling mud circulation throughout the project. There are many models and brands available, each with outstanding value. These triplex mud pump are efficient, durable, and completely waterproof. They are designed to lift water and mud with efficiency without using much energy or taking a lot of space.

The primary advantage of these triplex mud pump is that they can raise water from greater depths. With the fast-changing technology, purchase machines that come with the best technology for optimum results. They should be well adapted to the overall configuration of the installation to perform various operations. Hence, quality products are needed for more efficiency and enjoyment of the machines" full life expectancy.

Alibaba.com offers a wide selection of products with innovative features. The products are designed for a wide range of flow rates that differ by brand. They provide cost-effective options catering to different consumer needs. When choosing the right triplex mud pump for the drilling project, consider factors such as size, shape, and machine cost. More powerful tools are needed when dealing with large projects such as agriculture or irrigation.

Alibaba.com provides a wide range of triplex mud pump to suit different tastes and budgets. The site has a large assortment of products from major suppliers on the market. The products are made of durable materials to avoid corrosion and premature wear during operations. The range of products and brands on the site assures quality and good value for money.

Continental Emsco Drilling Products, Inc., which consisted of Emsco drilling machinery and Wilson mobile rigs, was purchased by National-Oilwell, Inc on July 7, 1999. To our knowledge, no pumps have been manufactured and sold under the Emsco brand name since National-Oilwell acquired them.

Fairbanks Morse pumps are currently manufactured in Kansas City, Kansas. Fairbanks Morse is a division of Pentair ever since August, 1997 when Pentair purchased the General Signal Pump Group.

Gaso pumps are manufactured by National Oilwell Varco. Gaso was acquired as "Wheatley Gaso" by National-Oilwell in the year 2000. At the time, Wheatley Gaso was owned by Halliburton.

Skytop Brewster pumps are no longer available as new pumps. Skytop Brewster(Cnsld Gold), a unit of Hansen PLC"s Consolidated Gold Fields subsidiary, was acquired while in bankruptcy by National-Oilwell, Inc. in November, 1999.

Buyer acknowledges and agrees that all equipment / parts are sold as is / where is without guarantee or warranty of any kind, either expressed or implied.

Salvex handles surplus, bankruptcy, overruns, obsolete inventory, disposal, insurance claims, online auctions, liquidation sale, foreclosure, lockout, seized, scrap, salvage, new, used, damaged, refurbished, and asset recovery.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

You are viewing three (3) fully reconditioned National Oilwell 12P160 Triplex Mud Pumps for sale by Pickett Oilfield, LLC. These National 12-P-160 Mud Pumps are Rebuilt and Ready to go to work.

Some refurbishments include: Fully reconditioned mud pump assembly. Pinion shaft assembly complete with new SKF bearings and new seals. Pump internals painted with Oil Resistant 2 Part epoxy Jotun Tank guard. MPI inspection of all critical areas of pump frame. MPI of all load path components of Crankshaft and Pinion shaft assemblies, and all new Southwest Premium “L” Shape 6,000 psi Fluid End Modules. A full Data Pack with all dimensional control & MPI reports will be furnished.

Warranty on National 12-P-160 Triplex Mud Pumps: All new parts fitted come with a 12 month warranty or such as offered by the part manufacturer; The refurbished GE-752 traction motors come with an 18 month warranty.

Pickett Oilfield, LLC offers prospective buyers an extensive selection of quality new, used, and refurbished Oilfield Drilling Equipment at competitive prices, including Triplex Mud pumps.

Welcome to Pickett Oilfield’s mud pumps web page. Our company has been in the oil & gas drilling equipment industry for over 38 years, supplying new and used mud pumps and mud pump parts to customers in practically every producing region in the world. We are here to serve all your drilling equipment needs – if you don’t see it on this site, just give us a call or email. We can get it, if you need it!

Pickett Oilfield, LLC offers prospective buyers and extensive selection of quality new and used oil & gas drilling equipment, including mud pumps and parts to choose from at competitive prices. Browse our inventory of mud pumps and mud pump parts for sale at competitive rates.For more information or to request a quote, please Contact Us at 936-336-5154 or email to Sales@PickettOilfield.com.

We noticed you"re using an unsupported browser which may result in limited or no functionality for portions of our website. We recommend using Google Chrome, Mozilla Firefox, Microsoft Edge, or Safari for the best experience.

Triplex Pumps - We carry a wide range of Mud Pumps and Mud Pump packages. We have both duplex and triplex Emsco pumps and packages. We also carry of our line of Goldmark F-Series pump.... More Info

Triplex Pumps - Gardner Denver PAH skid mounted, powered by 8v71 Detroit, skid mounted, PTO driven charge pump, 2 valve discharge manifold and Spicer Manuel 5 speed transmission. More Info

Triplex Pumps - Quantity: 2. Gardner Denver PAH, triplex pump equipped with 5-inch pistons and liners, equipped with 8V9Z diesel engine through a manual transmission More Info

The NOV 12-P-160 Mud Pumps includes (3) Three New National 12-P-160 Triplex Mud Pumps 1600 HP, 7-1/4″ bore x 12″ stroke, single acting. 5000 PSI fluid ends. 1600 HP Bare Mud Pumps are currently configured for Offshore Service. The NOV 12-P-160 Mud Pumps are located in Houston and ready to be unitized for service.

Forged Steel crankshaft, Individual forged steel two piece interchangeable standard modules, 6-1/2” mission fluid king liners, Standard polyurethane valves and seats, Two piece fast change piston rods, Supreme pistons, Metal to metal liner retention, Clamp type liner and piston rod connections, Fast change valve covers standard, Piston liner lubricant spray system, Liner spray pump, Power end lube system with filter. Mounted on Integral two runner skid, Suction Manifold with vertical suction stabilizer, Suction line pressure relief valve, set for 70 PSI

Includes: motor supports, motor frame, tensioning screws, 2 V-belt guards, 2 pump Sheaves, 2 motor sheaves, banded V-belts, Holes to be drilled to accept EDM D79 Or GE-752 Traction Motors

Flange-reducing weld neck, National, #5912404, 5-1/8 x 2” XXH 5000#, MOD, 6B, RTJ, R-44, to match 2” XXH pipe 1.500”ID, API 45K material, PSL-1, TC-U, M/C-DD

Flange-reducing weld neck, National, #5912402, 5-1/8 x 3”, XXH, 5000#, MOD, 6B, RTJ, R-44, to match 3” XXH pipe, 2.300”ID, API 45K material, PSL-1, TC-U, M/C-DD.

Flange-blind, National, #5912392, for Strainer cleanout, 5-1/8”, 5000PSI, API 6BX blind flange, BX-169, API 60K Material, 4130 steel, PSL-1, T/C-U, M/C-DD

National Oilwell Varco (NOV) is an American multinational corporation based in Houston, Texas. It is a leading worldwide provider of equipment and components used in oil and gas drilling and production operations, oilfield services, and supply chain integration services to the upstream oil and gas industry. The company conducts operations in more than 600 locations across six continents, operating through three reporting segments: Rig Technologies, Wellbore Technologies, and Completion & Production Solutions. National Oilwell’s two main predecessors, Oilwell Supply and National Supply, were founded in 1862 and 1893, respectively. These two companies manufactured and distributed pumps and derricks.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

The 12-P-160 is rated @ 1,600 input horsepower (1,193 kW) at 120 strokes per minute with a 12 inch (304 mm) stroke. Multiple liner sizes allow pressure and volume to handle circulation in deep drilling applications.

Triplex pumps are positive-displacement reciprocating pumps that are configured with three plungers. They are the most common configuration of pump used in both drilling and well service operations. Triplex pumps used in well service activities generally are capable of handling a wide range of fluid types, including:

Triplex pumps are used in applications that require continuous pumping. For example, a triplex pump is a common component in large-capacity commercial car wash equipment. The plunger pump design of a triplex pump offers a reinforced seal and uses ceramic plungers for tight alignment and long life in high-pressure applications, such as oil well stimulation, surface preparation or rust removal, and gas turbine misting. Triplex pumps used in low-pressure applications also include a submersible liquid pump and an end-suction centrifugal pump. A submersible pump is typically constructed of stainless steel for corrosion resistance and can typically handle wastewater with suspended particles as large as 2 inches in diameter.

Triplex pumps are also suited to pump liquids other than fresh water or wastewater. They can be used to pump salt water in desalination applications, chemicals, and high vapor liquids like carbon dioxide. They can also be configured to pump mud in land-based or offshore oil drilling applications. A mud pump is a heavy-duty, high-pressure pump designed to provide a smooth discharge of mud and debris from oil wells. A triplex well pump can also be used as a well stimulation or servicing pump in oil fields and other industrial applications, such as cementing.

Industrial triplex pumps are used in public places that require a consistent water pressure with variable flow rates, such as hotels and office buildings, schools, hospitals, and in general industrial processes such as boosting the water supply for rural areas or municipalities or for irrigation. Because they are able to handle a wide range of fluid types, a triplex pump may also serve as a sump pump or in conjunction with other pumps to drain sump pits and wastewater storage lagoons.

The 2,200-hp mud pump for offshore applications is a single-acting reciprocating triplex mud pump designed for high fluid flow rates, even at low operating speeds, and with a long stroke design. These features reduce the number of load reversals in critical components and increase the life of fluid end parts.

The pump’s critical components are strategically placed to make maintenance and inspection far easier and safer. The two-piece, quick-release piston rod lets you remove the piston without disturbing the liner, minimizing downtime when you’re replacing fluid parts.

8613371530291

8613371530291