what is reciprocating mud pump made in china

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Emsco、Gardner-Denver, National oilwell, Ideco, Brewster, Drillmec, Wirth, Ellis, Williams, OPI, Mud King, LEWCO, Halliburton, SPM, Schlumberger, Weatherford

BW160/BW200/BW250/BW450/BW600/BW850 mud pumps are mainly used for irrigation agricultural machinery. for water well drilling, borehole drilling, core drilling, anchor drilling, etc projects

The main characteristic is the high pressure, lift much, less energy consumption, easy operation, high quality and durable, easy to move, especially for mountain terraces of irrigation.

But they are also the main equipment of the geological survey, the main role in the process of core drilling boreholes is to supply fluid (mud or water), making it circulate during drilling and carry rock waste back to the ground, in order to achieve and maintain the bottom hole Clean and lubricate drill bits and drilling tools with cooling.

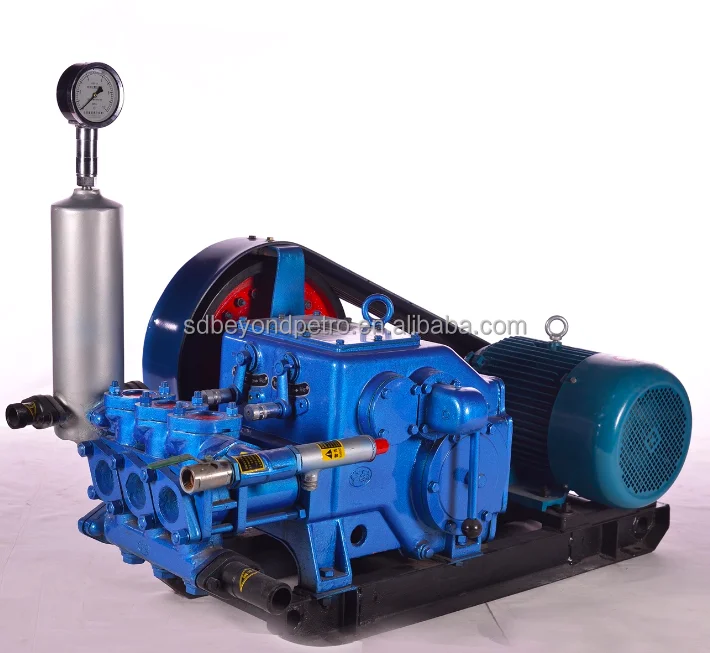

TypeHorizontal single cylinder double-action reciprocating piston pumphorizontal type single-cylinder double-acting pumphorizontal triplex Reciprocating single-acting piston pumpHorizontal three-cylinder reciprocating single-acting piston pumpHorizontal three-cylinder reciprocating single-acting piston pumpHorizontal double cylinder reciprocating double-action piston pump

Mud Pump is also a popular concept of a wide range of pumps. Different regions, habits, and ultimately the pump type will not be the same. The mud pump described in this entry is a pump type in most sense: Applied mud pumps in the field of oil drilling. In fact, some non-clean water pumps and mud pumps, such as sewage pumps and slurry pumps, are also commonly used when they are called.

Mud pump refers to a machine that transports mud or water and other flushing fluid into the borehole during drilling. Mud pumps are an important part of drilling equipment.

In the commonly used positive circulation drilling, it is to send the surface flushing medium—clear water, mud or polymer rinsing liquid to the bottom end of the drill bit through a high-pressure hose, faucet and drill rod center hole under a certain pressure. Cool the drill bit, remove the cut debris and transport it to the surface.

The commonly used mud pump is a piston type or a plunger type, and the crankshaft of the pump is driven by the power machine, and the crankshaft passes the crosshead to drive the piston or the plunger to reciprocate in the pump cylinder. Under the alternating action of the suction and discharge valves, the purpose of pumping and circulating the flushing liquid is achieved.

MCM 250 Mud Master Cantilevered Mud Pump MCM 250 Mud Pump is cantilevered pumps, used for handling strong abrasive and corrosive slurries. It is widely applied in 1.Mining (solids fluid transferring and dewatering) 2.Metallurgy 3.Coal washery 4.Power plant 5.Dredging 6.Building material 7.Waste and sewage treatment 8.Paper and pulp 9.Chemical process industry 10.Cement and blender 11.Water well drilling Materials of Construction The main wear parts of MCM 250 Centrifual Pump are wet parts. Quality Inspection The Quality Control Center is equipped with advanced precise quality testing instruments We have experienced wok team

The owner of this website (china.tradeford.com) has banned the autonomous system number (ASN) your IP address is in (20473) from accessing this website.

Find 3NB series piston reciprocating mud pump from reciprocating piston pump supplier - Saigao gruop in China. The 3NB series reciprocating piston vacuum pump can be widely used...

The diesel engine drilling mud pump has compact structure, light weight, small volume and beautiful appearance, and is driven by hydraulic motor, electricity or diesel engine. It has high stability and high pressure.

The drilling rig three cylinder mud pump is firm and compact in structure, small in size and outstanding in operation performance, and is suitable for the requirements of high pump pressure in oil fields and large displacement technology for drilling.

Small mud pumps can withstand heavy loads and are specially designed for conveying highly abrasive or corrosive slurries and high-density slurries, and are widely used in metallurgy, mining, coal, power stations, seawater river dredging, building materials and other...

High pressure drilling mud pump is a mud pump developed by our company that can be used under high pressure. The high pressure drilling mud pump has a longer stroke and can run at a lower stroke, thereby effectively improving the water supply performance and greatly extending...

Geothermal water well drilling mud pump is a mud pump used for geothermal steam and geothermal water drilling. It is an important equipment required for exploration and exploitation of geothermal fluid. The geothermal water well drilling mud pump is equipped with a gearbox or...

Three cylinder single acting reciprocating mud pump has a long stroke and can run at a lower stroke, which effectively improves the water supply performance and greatly extends the service life of the vulnerable parts of the hydraulic end. Three cylinder single acting...

Industrial horizontal centrifugal mud pump adopts a double-layer metal structure inside and outside, and the pump casing is a vertical open type. It has outstanding features such as high efficiency, energy saving, long service life, light weight, reasonable structure,...

Oilfield hydraulic piston mud pump is a hot-selling mud pump product of our company. All its wearing parts can be interchanged with other spare parts produced according to API standards, so it is easy to repair and maintain. In the common positive circulation drilling, the...

Centrifugal drilling mud pump is a mud pump with centrifugal function. The main features are high pressure, large head, low energy consumption and convenient operation. It is used for geophysical prospecting to provide flushing fluid to the borehole and to provide flushing...

Double piston drilling mud pump is a light grouting machine, which is a horizontal double-cylinder double-acting reciprocating piston pump. It is mainly used to inject flushing fluid into the hole during geological drilling.

The drilling rig compound mud pump adopts an integral hydraulic end, which reduces the systematic high-pressure vibration caused by the bolt connection of the split hydraulic end, enhances the stability of the mud pump operation, and increases the service life of the...

The three cylinder piston mud pump is equipped with three cylinders with multiple levels of flow and pressure, which can well meet the needs of different bore diameters, hole depths or drilling processes.

Triplex and quintuplex piston reciprocating pump are mainly used in: Crude oil transport, Crude oil receiving, circulation mud, slim hole shallow well drilling, Trenchless directional drilling etc.. This series of pump is easy in operation and maintenance and reliable with good absorbing property. It can directly absorb from the ground and pools (like mud pool and pool) below 2 meters with absorbing pipe below 4M under elevation of 1000 meters without poured into, with natural absorption efficiency >95%.

It.can also apply to other high pressure liquid transportation with self-absorb. Cylinder material: alloy steel, stainless steel, duplex steel or aluminum bronze; cylinder liner material: bi-metal or ceramic; piston material: rubber or polyurethane; suction /discharge valve adopt API standard valve, ball valve, plate valve, cone valve etc.We"re well-known as one of the leading piston pump manufacturers in China for our quality products and customized service. Please feel free to buy quality piston pump made in China here from our factory. For quotation, contact us now.

The mud pump piston assembly is one of the main parts of the hydraulic end system of the mud pump, and it is also one of the vulnerable parts in the drilling work. The discharge pressure of the mud pump is generated by the reciprocating linear movement of the piston assembly in the piston. The piston assembly is composed of piston core, rubber, circlip, pressure plate, etc. The material of the piston core is 42CrMo, and the material of the piston rubber is nitrile rubber or polyurethane rubber.

Nitrile rubber is suitable for ordinary drilling working environment with working pressure below 20Mpa, and the working temperature is not higher than 120 degree . Excellent wear resistance, chemical resistance, long service life in ordinary drilling working environment.

The Made-in-China F series mud pumps have same reliable quality and performance as other USA products. Now, F series mud pumps (from F-500 to F-2200) have been produced in batches and sold to many abroad oilfields. Your order for F series mud pumps is cordially welcome.

Huaxin"s export-orientated mud pump parts, including liners, pistons, piston inserts, valve inserts, oil seals, rod packing, fluid ends etc. All of them meet or exceed DIN and API standards and have been exported to U.K., Germany, USA, Canada, Pakistan, Middle East, and so on.

Mud hog pump is used to circulate oil drilling mud on a drilling rig at high pressure. Drilling fluid or oil drilling mud is circulated down through the drill string, to help cool, lubricate and clean the drill head, and back through the annulus at high pressures. The drilling mud is also used to suspend and carry out drill cuttings from the drill head as it is brought in and out of the hole.

We can provide more types of mud pumps than other oil well drilling equipment suppliers, and the classification methods are different. There are roughly the following types:

According to the number of times a piston reciprocates in a cylinder to inhale or discharge liquid once, it is divided into sing-acting pump and double-acting pump.

According to different driven method, it is divided into diesel mud pump and electric mud pump.It depends on fuel or energy which is available on around area of drilling rigs.

For the successful execution of your projects, it is important to find an appropriate company with a good track record. We help you in connecting with the top mud pump manufacturers and companies and get the best quotation.

We have designed affordable annual subscription plans which would help you get leads for your business. You can have a look at our pricing chart by clicking on this link: https://www.energydais.com/pricing/ . These plans are customized according to the specific needs and requirements of your business.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

Yes. We help you find the best mud pumps irrespective of your location. We simplify your search by connecting you with top mud pump manufacturers and mud pump companies in your location, according to your budget and business requirement.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

The different parts of a mud pump are Housing itself, Liner with packing, Cover plus packing, Piston and piston rod, Suction valve and discharge valve with their seats, Stuffing box (only in double-acting pumps), Gland (only in double-acting pumps), and Pulsation dampener. A mud pump also includes mud pump liner, mud pump piston, modules, hydraulic seat pullers along with other parts.

The wearing parts of a mud pump should be checked frequently for repairing needs or replacement. The wearing parts include pump casing, bearings, impeller, piston, liner, etc. Advanced anti-wear measures should be taken up to enhance the service life of the wearing parts. This can effectively bring down the project costs and improve production efficiency.

Wenzhou Johames Technology Co.,Ltd mainly manufacture and export industrial pumps with good reputation around home and abroad. Product is exported to Europe, North America, South America, Asia, Africa, more than 45 countries and regions.

mission magnum, mission 2500 supreme, mcm250 centrifugal pump, mechanical seal, demco butterfly valve, kemper hammerseal union, varco tong dies, demco mud gate valve and oteco pressure gauge

Kunming Kunshui Industrial Pump Co., Ltd("Kunshui pump" for short) is a professional manufacturer of pump specialized in manufacturing slurry pumps with more than10 years experience in China.

We would suggest you to visit our website for further references. And please feel free to inform us of your interested items for quotation or the detail information you need.

GREENTECH was founded in 2000, The company is professional blower and vacuum pump manufacturer specializing in producing and supplying full range of 2BV and 2BE series liquid ring vacuum pump, vacuum compressor etc.

air operated diaphragm pump,including metal and non-metal series, widely applied in chemical, paints & coatings, food processing, pharmaceutical, construction, mining, utilities, pulp & paper, metal finishing

BLDC PUMP produces excellent small electric DC water pumps for cooling, circulation system in the various device, for fish tank aquarium, small fountains and other applications. We are a magnetic DC water pump manufacturer located in Shenzhen of China.

MINDONG ELECTRIC was established in 1958. Over the past 50 years, we adhere to the business principles of “Lived with quality, Developed with varieties, Benefited with management”

Shanghai Shenbao Industrial Pump Co., Ltd. is located in Minhang Development Zone in Shanghai, occupying an area of over 45,000sq.m .Shenbao has become a multi-industry enterprise and specialist in research and manufacture pump...

Slurry pumps, Vertical slurry pumps, slurry pumps, Gravel sand pumps, Dredging pumps, Paper pulp pumps, Molten Salt Pumps, End suction pumps, Double suction pumps, Multistage pumps, Boiler feed water pumps...

Wuhan EvenWall Machinery Co., Ltd. specialized in even wall thickness stator and hollow rotor for progressive cavity pump, even wall thickness stator for mineral oil transportation(artificial lift), multi lobe power section for downhole drilling motor(mud motor).

Shijiazhuang Jiurun Pump Co., Ltd is a pump engineering, manufacturing and distribution company for industrial, municipal and dewatering applications. With over 60 years’ expertise, we have developed great reputation by serving the mining, power, metallurgy, dredging, petroleum

we are a professional pump manufacturer in China with many years experience. We mainly produce slurry pump, spare parts and OEM wear resistance casting.

APK, A Pump that Keeps water moving, is the brand name of Zhengzhou Shenlong Pump Industry Co., Ltd. APK Submersible pumps is short as APK Pump. We are a large scale submersible pump manufacturer officially registered on Apr 25, 1996. Our factory is in Henan Province

We intention at becoming one among your most trusted partners and earning your fulfillment for Bomco mud pump rod clamp, Hydraulic rotary table drilling, Mud pump fluid end modules. Due to our strict pursues in quality, and after-sale service, our product gets more and more popular around the world. Our products and solutions are sold to many countries and regions, and are favorably appraised by clients. We will continue to standardize operations, innovate marketing, strengthen communication and cooperation with friends, and meet the various needs of customers. We will definitely cooperate with friends from all over the world with our dedicated service to create a better tomorrow!

32PL spray pump is made up of cooling water tank, spray pipe, etc, aiming at conducting necessary cooling and washing on the cylinder liner and piston to lengthen their service life.

32PL spray pump adopts single-stage single-suction horizontal cantilever centrifugal-type pump, mainly used for spraying, cooling and lubrication of cylinder liner and piston as well as for transporting clear water or sewage containing a little sediment with the temperature below 80℃.

32PL spray pump adopts belt drive when it is used together with oil drilling pump and it can also be directly connected with explosion-proof motor in other places.

We hope to open up a wider range of 2500HP Reciprocating Quintuplex Frac Pumps, Mud Pumps Made in China application fields, and to make it widely used, durable in quality, and low in price. We pursue the corporate spirit of integrity, responsibility and excellence, and provide users with the highest quality products and services through a complete after-sales service system. We have rich operating experience and cases.

Lake Petro provides high quality Mud Pump Parts including Mud Pump Liners, Mud Pump Fluid End Module, piston, Valve and Seat etc. With more than 10 years of experience in the oil and gas industry, we are dedicated to help and support our loyal clients with the most cost-effective and quality Liners and Pistons. We also provide mud pump price and mud pump for sale.

We offer Liners with Ceramic (Zirconia and Aluminium oxide) and Steel (Metal and Bi-metal) materials for all common brands of the mud pump and triplex mud pump.

Bi-metal liners (double metal liners) are made of forged steel shell and wear-resistant sleeve of high chromium iron. In the production process, the size accuracy should be strictly controlled, which can ensure that they can be easily and stably installed. The inner sleeve with high finish and hardness is wear-resistant, corrosion-resistant and has a long service life. The bi-metal liners are suitable for a lot of bad working conditions. Its service life is more than 800 hours.

Ceramic Liners are made of a ceramic inner sleeve and a forged steel outer shell. The service life of ceramic liners is about 4000 to 10000 hours, the minimum time is at least 2000 hours, which is a lot more than bi-metal liners. Because of the phase transformation toughen technology, the ceramic liners have the features of wear-resistance, erosion-resistance, high-pressure-resistance, high hardness and strength. Zirconia type and Alumina type are common type of ceramic sleeve. Compared with Alumina type, Zirconia type liners have better toughness properties and a much longer service life. Piston wear and water consumption for lubrication can be reduced as well.

Seal Rings for Liner packing are also important. Liner Seal Rings is designed and made with hard corner which is an integral part of seal rings and soft nitrile element rubber center. We could provide reliable liner Seal Rings for our customers could order them at the same time.

All Lake Petro liner products are interchangeable with O.E.M. products. Meanwhile, we provide customized Liners according to drawings. Our liners, also with our other mud pump spares, are supplied for use in Honghua, F-Series, Bomco, Emsco and National lines of triplex drilling pumps. Let Lake Petro be your one-stop shop for your whole fleet of pumps. Please refer to “Suitable Pump Models” Lable for more details.

We offer triplex reciprocating mud pump. Nbb-3006~12 mud pump product usage this kind of pump is mainly used for supplying flushing fluid to the borehole in core, coalfield geology, metallurgical geology, hydrogeology engineering drilling process. The fluid can be divided into mud, water, etc. It also can be used as transfer pump of the above mentioned medium. Structure features 1.horizontal triplex single-acting piston pump 2.crank connecting rod structure 3.lip-shaped, self-sealing piston, which made of rubber or ptfe and nylon pads 4. Adopting auto gearbox which makes it have five kinds of flow rate 5. Compact structure, high efficiency, durable and long life, safe and reliable, easy maintenance, low maintenance costs. Main technical parameters piston stroke (mm) 100 id of cylinder liner (m) 90 reciprocating times 187 121 76 43 25 nominal flow rate (lmin) 300 193 121 68 39 nominal pressure (mpa) 6 10 max working pressure (mpa) 7 11 12

alumina ceramic insulating liner 1. High temperature 2. Good insulation 3. High strength 4. Precision ProcessFeatures:1) A variety of specifications available. 2) Satisfy various technical request3)

Hydraulic cylinder is also called the valve box or module, it is a major part to the fluid end parst. Blank forged by high-strength alloy steel. After heat treated, with multi-channel processes. The three cylinders of each pump is interchangeable.

Ceramic Liners are made from zirconium and oxygen, which is stabilized in the cubic crystal structure and avoids cracking and mechanical weakening during heating/cooling for long life.

Piston Assembly is main parts of mud pump fluid end, piston Assembly is reciprocating linear motion within cylinder liner, thereby creating a mud pump discharge pressure.

Cylinder head flange is the main parts of drilling mud pump in the system ,we can produce all kinds of the cylinder head flange.They are exchangeable with all major pump models.

Shaanxi Rongle Petroleum Machinery Co.,Ltd is one of the best China mud pump parts manufacturers and suppliers, and also a professional company and factory, welcome to import quality mud pump parts products from us.

8613371530291

8613371530291