wholesale mud pump dampener free sample

A wide variety of pulsation dampener mud pump options are available to you, such as 1 year, not available and 2 years.You can also choose from new, pulsation dampener mud pump,As well as from energy & mining, construction works , and machinery repair shops. and whether pulsation dampener mud pump is 1.5 years, 6 months, or unavailable.

If you are supplying pump supplies, you can find the most favorable prices at Alibaba.com. Whether you will be working with piston type or diaphragm type systems, reciprocating or centrifugal, Alibaba.com has everything you need. You can also shop for different sizes mud pump pulsation dampener wholesale for your metering applications. If you operate a construction site, then you could need to find some concrete pump solutions that you can find at affordable rates at Alibaba.com. Visit the platform and browse through the collection of submersible and inline pump system, among other replaceable models.

A mud pump pulsation dampener comes in different makes and sizes, and you buy the tool depending on the application. The pump used by a filling station is not the one you use to fill up your tanks. There are high flow rate low pressure systems used to transfer fluids axially. On the other hand, you can go with radial ones dealing with a low flow rate and high-pressure fluid. The mixed flow pump variety combines radial and axial transfer mechanisms and works with medium flow and pressure fluids. Depending on what it will be pumping, you can then choose the mud pump pulsation dampener of choice from the collection at Alibaba.com.

Alibaba.com has been an excellent wholesale supplier of mud pump pulsation dampener for years. The supply consists of a vast number of brands to choose from, comes in different sizes, operations, and power sources. You can get a pump for residential and large commercial applications from the collection. Whether you want a water pump for your home, or run a repair and maintenance business, and need a supply of mud Pump pulsion days, you can find the product you want from the vast collection at Alibaba.com.ther it is for refrigeration, air conditioning, transfer, or a simple car wash business, anything you want, Alibcom. it has easy to get the pump of your home. Thether of want a supply pump mud residential pulsity daysener is you,ll want the product that want your needs.

The Charge Free Dampening System™ combines the advanced technologies of Sigma’s Charge Free Dampeners™, Sigma’s Charge Free Conversion Kits®, Sigma’s Charge Free Stabilizer™, and Sigma’s Acoustic Assassin® to create the best available pulsation control solution. When it comes to performance and cost, Sigma’s Charge Free Dampening System™ will out perform more expensive dampeners while significantly reducing weight, size, and cost.

The Charge Free Dampener™ was designed to maximize the superior performance of Sigma’s Discharge Charge Free Conversion Kit®. The Charge Free Dampener™ was built from the ground up with performance, safety, and longevity in mind, for every aspect.

The Charge Free Stabilizer™ was designed to be installed directly before the suction manifold port between the mud pump and the charge pump. Maximizing mud pump performance by eliminating cavitation while isolating both the mud and charge pumps.

The Acoustic Assassin® was designed to be installed between the pump loop manifold and the production line. This fixture is a multi-chambered baffling system that will reduce damaging acoustic resonance generated by reciprocating pumps. The Acoustic Assassin® is an ideal addition to any pulsation control system.

The Charge Free Conversion Kit® is a high performance pulsation control kit that utilizes both compression and kinetic exchange for superior performance over traditional pulsation control methods of the past. With a gigantic increase in surface area, compression tuning, and a design to maximize energy exchange, the CFC Kits control pulsations from the pump while cleaning the signal for MWD tools.

We have a professional factory producing durable silicone oil rotary damper with both directions, welcome to wholesale silicone oil rotary damper with both directions made in China and get its free sample with us.

The formula in the webinar is an example and for information only. Other types or manufacturers may have their own formula. In our experience, these formulae are too simple particularly for pumps > 50 HP and variable speed applications.

We have extensive field data validating results from our proprietary software. I do not believe we have field data that tests a single system’s sensitivity to different gas-charged dampener sizes.

We have not done these sensitivity studies for the example used in the webinar. It will likely be done for future presentations. The neck and gas charged bladder essentially form a notch filter or Helmholtz resonator, so the characteristics of the dampener are well understood.

Since liquid and gas systems behave differently, dampener sizing criteria are different. The surge volume sizing equation in section 7.9.3.2 is more intended as a starting point for a vessel size as well as provide a consistent size for project proposals. The low-pass filter calculation in Appendix O is similar to the approach described in the webinar. We have a pulsation bottle sizing tool on our website to help determine vessel sizes for reciprocating compressors (API 618).

Yes, the pump type and system layout will affect pulsation results. In general, we find a similar relationship in that the empirical sizing always calculates reductions in pressure pulsations with an increase in dampener volume and the pulsation model does not show significant changes in pulsations with increasing dampener gas volume. We have found that a small amount of volume (gas charged dampener) will attenuate pulsation to a certain level and that additional volume will not attenuate pulsations further.

The geotechnical information and foundation response does not have a significant impact on the focus of this webinar, that being dampeners and the effect of the dampener size on the pressure pulsations, shaking forces and vibration of the piping. In the limit, there is a relationship between the geotechnical information and the support for yard or off-skid piping but it is not discussed in this webinar.

Fluid viscosity does not have a significant impact on pressure pulsations and dampener performance. Fluid density is somewhat related to pressure pulsations. Density is a key term in pressure drop and line losses. Higher pressure drop due to line losses tends to reduce pressure pulsation. Fluid density is also related to the fluid bulk modulus or compressibility of the fluid. The bulk modulus is a key factor that defines the acoustic velocity of the fluid and therefore acoustic resonances. A greater or less dense fluid does not generally mean pulsations are significantly higher or lower, although less dense fluids tend to result in slightly more attenuation of pressure pulsation over a long distance as compared to more dense fluids.

Regarding pressure pulsations and shaking forces, it is our experience that the inlet velocity to a PD pump has little impact on pulsations. Generally, higher velocity flow will result in more pressure drop which means damping or smoothing out of the flow fluctuations caused by the pump.

In our experience, there are no significant effects on pressure pulsations and vibration if a bend is located near the pump outlet. Perhaps there are effects from the flow not being fully developed or distributed across the pipe cross-section a short distance from the pump discharge. This non-distributed flow might lead to a local area of high velocity and perhaps erosion on the bend.

There is generally no influence of the foundation on the pulsation model, that is pressure pulsations and shaking forces generated by the pump. The foundation stiffness and damping properties for pipe supports and the pump package are important to consider. The key goal of the piping structural dynamic design is to achieve piping and pump package mechanical natural frequencies above 1.2x PPF.

Changing the pipe layout to reduce elbows can be thought of as a method of fine-tuning a piping system design to minimize vibration. Changing a pipe layout to reduce elbows will not reduce the underlying pulsation energy that the pump generates as part of its normal operation.

The geotechnical information and foundation response does not have a significant impact on the focus of this webinar, that being dampeners and the effect of the dampener size on the pressure pulsations, shaking forces and vibration of the piping. In the limit, there is a relationship between the geotechnical information and the support for yard or off-skid piping but it is not discussed in this webinar.

I have used in-line pulsation dampeners (process fluid passes thru center of cylindrical bladder, N2 outside of bladder (line a pipe in pipe). This style of pulsation dampener was not included in your presentation. Do you have any thoughts on their advantages/disadvantages?

True, inspection is still required. The same inspection is required for gas charged bladder dampeners. This inspection may be required on a yearly, or longer, time frame. In comparison bladder type devices require frequent checks of the charge pressure and adjustment of the charge pressure if operating pressures changes. Also, the pump system is at risk of fatigue-related failures if the bladder leaks or fails and the bladder failure is not detected in short order.

Regarding getting early involvement of the pulsation specialist - what form of engagement is usual? How would this impact competitive bidding of pump packages - what sort of requirement would be in pump RFQ? Does pump vendor retain responsibility for overall system performance?

The responsibility of the overall project lies with the owner, not the pump vendor or packager. The owner must be properly engaged in the project and understand the issues at risk with an improper dampener design.

There are two approaches that the owner can use to ensure the proper dampener is picked and there is a level playing field for companies bidding on the package:

We have extensive field data validating results from our proprietary software. I do not believe we have field data that tests a single system’s sensitivity to different gas-charged dampener sizes.

For more information about pulsation dampeners, we sat down with Brandon Dalrymple and Nathan Ackeret fromBlacoh Fluid Control(manufacturer of pulsation dampeners, surge suppressors, and inlet stabilizers), and asked them to answer a few of our customers’ most common questions about pulsation dampeners.

Pulsation dampeners absorb the energy from the pulse wave created by a positive displacement pump, much like a shock absorber on a vehicle. Absorbing those pulse waves protects pipe welds and supports, and system components from damage due to pressure or excess movement.

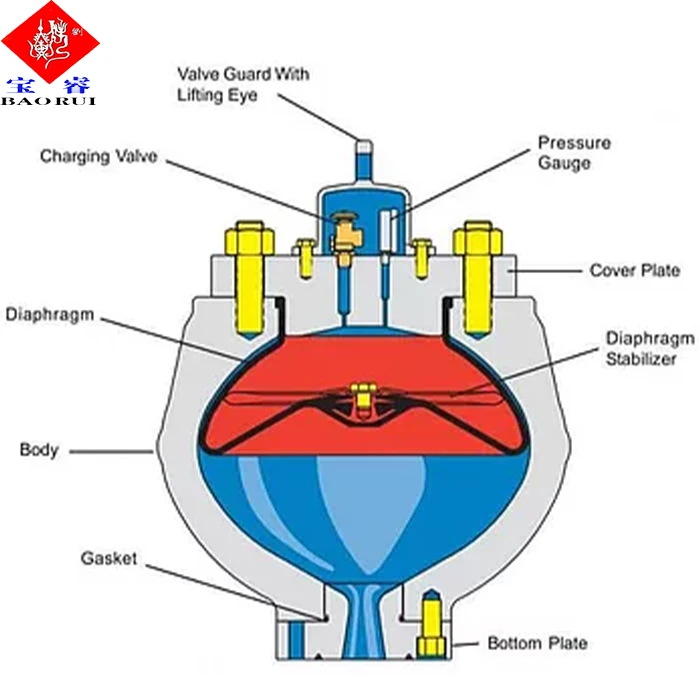

A pulsation dampener creates an area of low pressure in the system with enough volume to absorb the pulsation. The pulsation dampener has a membrane with a "cushion" of compressible gas/air behind it that flexes to absorb the pulse, allowing a laminar flow downstream of the dampener.

Pulsation dampeners are commonly used wherever a positive displacement pump discharges flow in an unsteady manner, and where the pulse is not desired for the piping system. Air operated double diaphragm, metering and hose/peristaltic pumps typically benefit from a pulsation dampener.

The type of pulsation dampener used is typically defined by where they are placed in the system, and what they need to do. For example, "pulsation dampeners" are on the downstream side of the pump, "inlet stabilizers" are on the inlet side of the pump, and an accumulator or "surge suppressor" is used next to a valve or other device that restricts the flow in a system.

This video shows where you would place an inlet stabilizer, and how it is used to reduce the pulsation with an air operated diaphragm pump in suction lift conditions.

TheTruflo PulsePro® PF Series Pulsation Dampeners are designed to provide protection for process instrumentation, eliminate vibration and provide smooth continuous flow. Truflo PulsePro® PF Pulsation dampeners are chargeable and can be adjusted to best suit the process requirements. The PF series can eliminate up to 95% of the pulse caused by positive displacement pumps.

This equipment plays an important role as an accessory to Yamada air-operated double diaphragm pumps. The pulsation dampener serves to reduce pulsation produced in operation and to assure stable discharge flow and pressure.

When pulsations occur with pump operation, it will result in the pressure in Chamber Bbeing greater than that in Chamber A. The diaphragm will act as an air cushion and automatically adjust to this pressure change and absorb the pulsations.

This operation will shift the center rod position upwards and allow more air in Chamber Athrough the air inlet, returning the diaphragm to a neutral position. If liquid pressure decreases, air pressure in Chamber Acauses the diaphragm to move downward, shifting shaft location and changing valve position, releasing excess air pressure in Chamber Awhich returns diaphragm to a neutral position. This action causes a reduction in surges and pulsation caused by a air operated double diaphragm pumps

8613371530291

8613371530291