what is overshot manufacturer

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

A downhole tool used in fishing operations to engage on the outside surface of a tube or tool. A grapple, or similar slip mechanism, on the overshot grips the fish, allowing application of tensile force and jarring action. If the fish cannot be removed, a release system within the overshot allows the overshot to be disengaged and retrieved.

I debated on where to go next, but at the end of the day the most widely used fishing tool has to be an overshot. Some will say why not a spear? Well if you must ask, always go with the strongest fishing tool you can run to catch the fish. And if you run a spear, never plug the I.D. of your fish by breaking it off. Done with that!

The info that follows has been taken from the manuals published on overshots. I realize that paper manuals are a thing of the past, yes, yes at one time fishing tool hands carried massive catalog brief cases full of reference material. Now you have the luxury of your laptop loaded with information. If you have never sat down and read an overshot manual, now might be a good time.

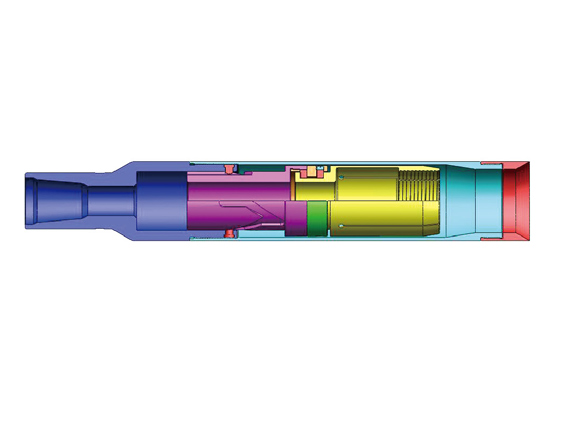

The overshot is highly versatile and efficient tool. There are several different types of overshots, however each overshot is designed to engage a specific size of tubing, pipe, coupling, tool joint, drill collar or smooth OD tool.

The original overshot was developed by Bowen Oil Tools, which is now part of NOV. One thing I will point out is that in the catalogs you will see more than one assembly number for a given OD of Overshot, this came about due to the two locations developing their own variations. I found this information on NOV’s website and thought it was interesting to share.

Bowen dates back more than 105 years, when S.R. Bowen founded his first company in Coalinga, California. Shortly after the United States entered World War I, S.R. sold the Coalinga shop. He formed a second company, the S.R. Bowen Company, in 1920 in Huntington Beach.

In the early 1930s, the consequences of the stock market crash prompted S.R. Bowen to consider starting a company in Houston, where oil exploration and drilling was accelerating. In the early spring of 1934, his son Walter and a friend formed Bowen Company of Texas.

Bowen™ became a leader in innovation with the creation of the first overshot, the Series 150, in 1935. This tool set the standard for fishing equipment, and the quick acceptance of the tool assured the company partners that their business would be successful. The company continued to create new products, building a reputation for their well tool design and construction.

Currently there are several manufacturers of overshots, NOV (Bowen), Rubicon (Logan) and Applied Oil Tools (Gotco). These overshots are designated by a series number as follows:Series 10 - Sucker Rod Overshot

Overshots may be identified by one of the following, known as “type”:Full Strength (FS) - engineered to withstand all pulling, jarring and torsional strain

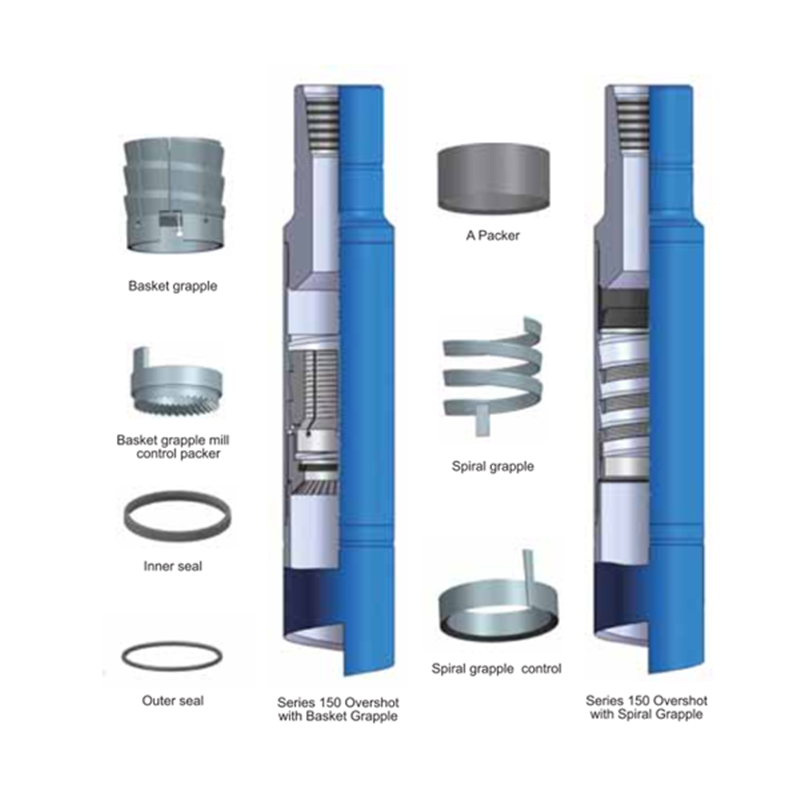

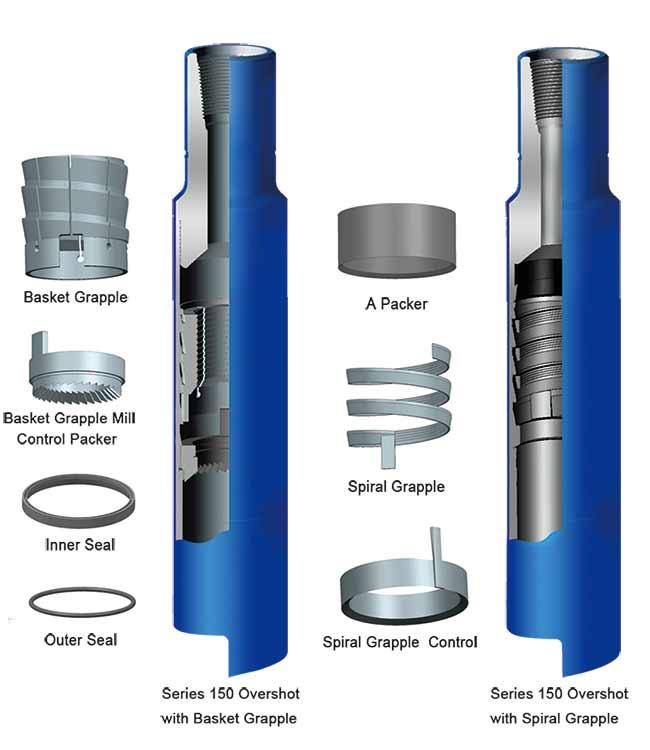

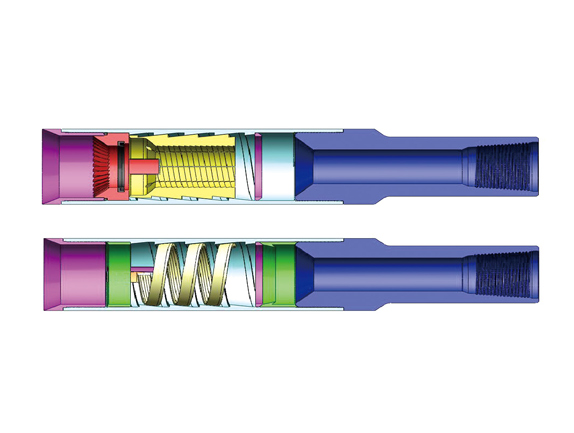

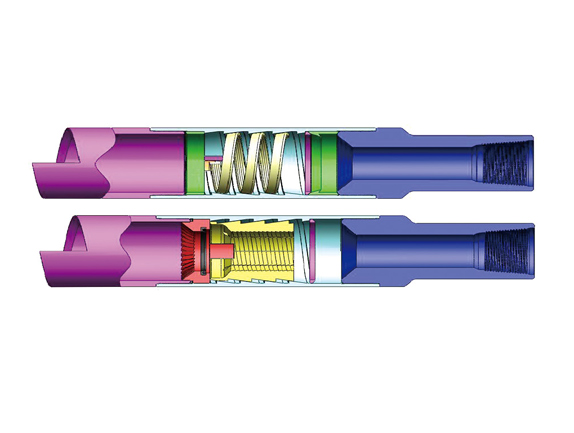

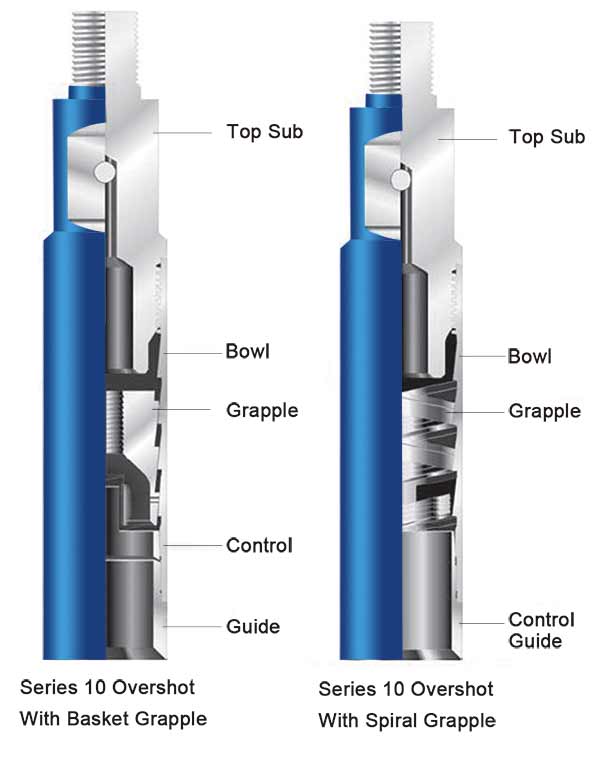

The basic overshot (from top down) consists of a top sub, a bowl, grapple, control, and a guide. In addition to the basic components, some overshots (Series 10 and 150) can be dressed with either a:Spiral grapple used if the fish diameter is near the maximum catch of the overshot, or a

The Series 150 Overshot features the ability to packoff on the fish. When the circulating packoff is not used, the fluid circulates down the drillpipe, aroundthe top outside of the fish, through the slip or grapple assembly, around the guide shoe and up the annulus.

When the circulating packoff is used, the annular space between the top outside of the fish and the inside of the lower part of the overshot is packed off, diverting the fluid flow down into the fish, making it easier to release and recover the fish. Packoffs usually are not high pressure devices but will often withstand sufficient pressure to establish circulation through the fish. Third party high pressure packoffs are available from various sources.

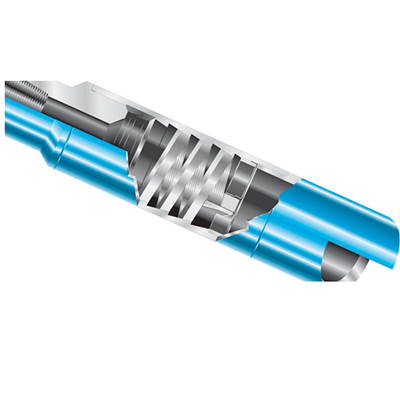

The extension can be installed between the top sub and the bowl of the Series 10, 70, and 150 overshots. It is used to extend the overshot bowl to:Allow the grapple to catch farther down on a fish that may be necked down at the top by having been pulled in two, or latched by an overshot and released several times, or to

A stop ring must be used where a fish OD reduces immediately below the catch area to allow the grapple to bite on full-size pipe.Example - catching a Hydril upset or EUE collar. If the upset of collar should pass completely through the grapple, the overshot may not be releasable.

If a stop ring is needed and the grappledoes not have a built-in stop, a stop ring can be run above the grapple, in the area between the Top Sub pin and the Grapple.

The Series 10 Sucker Rod Overshot is designed to engage and recover sucker rods, couplings, and similar items from inside tubing strings.Basket grapples are recommended for fishing for hardened and ground boxes (Sucker Rod Box).

The Series 20 Sucker Rod Overshot is a short catch tool which provides a means for engaging the exposed portion of a fish too short to be engaged with a Series 10 overshot.Uses basket grapples only

Is different from Series 10 in that the grapple control is at the top of the bowl above the basket grapple placing the basket grapple at lowest position in the bowl.

The Series 70 Short Catch Overshot is designed to engage the exposed portion of a fish too short to engage with Series 150 overshots.Uses basket grapple only

The Series 150 Releasing and Circulating Overshot is used to engage, packoff, and retrieve twisted-off lost tubing, drillpipecoupling, tool joint, casing or other similar fish.

Special Grapples:Nitraloy grapples may be available from some vendors. It is available only in the most popular sizes and is not commonly used on standard pipe.

A right hand wicker grapple converts a normal right release overshot to left hand release. This grapple is used where you expect to apply excessive right hand torque to release a packer, safety joint, etc. Note: Overshot will have to be released by left hand rotation.

Grapple Controls:Basket Grapple control packers have built in packoffs. These packoffs will hold various amounts of pressure, depending on the size of the fish and the condition of the packoff after engaging the fish.

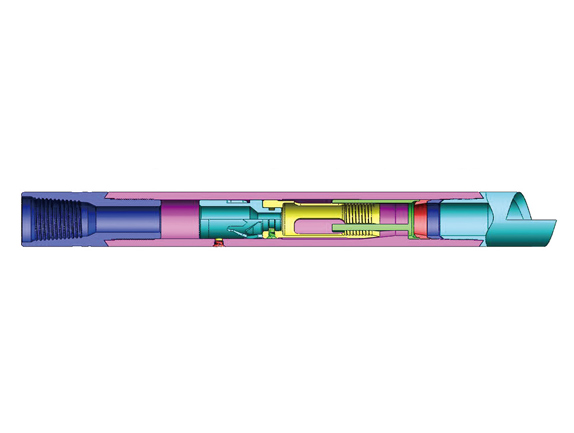

High Pressure Packoff Assemblies:The High Pressure Packoff Assembly is an accessory to the Series 150 Overshots. It is used when high pressure circulation to the fish is required. It consists of a packoff sub with packing and packing rings and is installed between the top sub and bowl of the overshot. By running the packoff sub above the bowl, this design prevents the application of high internal pressures to the overshot bowl. The design of the High Pressure Packoff Assembly allows pressures two to three times the standard overshot packoff to be applied to the fish.

This information comes directly from the NOV manual for the Wide Catch Overshot. This is probably the first and only change to this common tool I know of in my career.

The Wide Catch Overshot provides the strongest tool available to externally engage, pack-off, and pull a fish that has been significantly worn. This tool has similar rugged design features and construction as the industry standard, Bowen Series 150 overshot, with the ability to interchange the Bottom Guide with the full range of existing components used with the standard Bowen Series 150 overshot.

In service, the Wide Catch Overshot (WCOS) takes a positive grip over a large area of fish and is capable of withstanding heavy pulling, torsion, and jarring strains without damage to the tools or the fish.

The WCOS has been designed to significantly increase the catch range of the OD of the fish to be caught, compared to the standard overshot. This enables a greater opportunity for a successful fishing operation in a reduced number of trips, thus reducing overall intervention costs for the operator. In addition to the large catch range, the WCOS has the ability to seal across very large extrusion gaps at both standard and high pressure and provide full circulation through the fish, should it be required.

Connections between the Top Sub/Bowl and Extension Sub have been designed to create a seal. This will prevent the connection from washing out should the overshot be required to be flowed through for a long period of time. In order to lock the Top Sub/Extension Sub to the Bowl from backing off during operation, set screws have become standard and will gall the threads should the connection break free.

The operation of all overshots is identical. The exception being that the Series 150 carries a packoff which provides circulation through the fish. First, determine that the overshot is properly assembled and dressed with the proper size grapple. Make up the overshot on the fishing string (normally it is run connected to the bottom of the bumper sub) and run it into the well. As the top of the fish is reached make sure circulation has been established to clear overshot ID of any plugging. Lower the overshot onto the top of the fish with no rotation at first. A 5,000 pound set down weight will be sufficient to engage the grapple. While lowering the overshot over the top of the fish watch for pressure build up, shut off pumps if any pressure build up is noticed. Should any back pressure be noticed, release the back pressure to allow the grapple to engage the fish. By elevating the string it can be determined, if the grapple went over and engaged the fish. If unable to work overshot over top of fish without rotation, then slowly rotate the fishing string to the right and gradually lower the overshot over the fish. Combined rotation and lowering over top of the fish are important to keep the grapple in the release position. This provides the maximum clearance between the grapple and fish. While lowering the overshot over the top of the fish, watch for torque build up and an increase in pump pressure. A pump pressure build up indicates the overshot has gone over the top of the fish thereby reducing the flow area. Stop rotation (continued rotation could dull the wickers of the grapple) enabling the grapple to set. Allow the right hand torque to slack out of the string and then pull on the string by elevating the string to set the grapple.

To release from the fish, bump down, then simultaneously rotate to the right and slowly elevate the fishing string. It is best to have a clean fishing top before running the overshot.

As an overpull is applied to the tool, case hardened grapple teeth bite into the fish enabling it to be retrieved. The tool can be released from the fish by flowing through the tool.

The Mills Machine Overshot is a rugged, external catch, fishing tool that is economical and simple to use. Overshots are manufactured like taper taps except they go over the O.D. of the fish. Like taper taps, overshots are stocked in a variety of sizes and standard connections so we are able to get something to you rapidly. To build an overshot from scratch takes four to six days due to the heat treat process necessary to harden the teeth. It is speedier to build a sub to fit a stocked overshot and match your needs than to build the entire product. We can build the overshot with oversize guides to more easily catch the fish or with a wall hook to snag behind a fish leaning against the drill hole wall. Your Mills sales representative will work with you to get the fastest solution to your problem at the lowest cost. The carbonized threads on overshots are extremely hard and brittle. Be extra careful to avoid impact. In use, slowly lower the tool down the hole until the fish is engaged. Then slowly rotate the tool while applying some down pressure. Mark the drill rod to tell how far into the fish you have penetrated. Overshots can be reworked by annealing, re-threading the overshot and then re-heat treating the re-threaded area. We will quote you pricing as necessary.

Overshots are a key component of wireline coring systems. To retrieve the core sample, the overshot is lowered into the hole on a wire cable until it comes in contact with the spearhead point on the head assembly. Positive latching lifting dogs securely attach, and the inner tube assembly is pulled from the hole to retrieve the core. V-lock Overshots Hole Products" V-lock overshots are safe, reliable, fast, and easy to use. The automatic safety feature is designed to reduce the chance of an accidental release. When the inner tube assembly is attached and lifted, the lifting dogs automatically retract into position. No extra manual steps are required to activate the safety feature, thus reducing the potential for human error. Standard Overshots Hole Products" standard overshots feature a manual safety lock pin. Once the core filled inner tube is hoisted above the top of the drill rods the safety lock pin can be inserted through the overshot head and under the spearhead point. This will allow the operator to hoist and remove the core sample from the inner tube.

Tianhe Oil Group Co. Ltd. is a global group. We are specialized in the production of drilling tools, including R&D, production, selling, leasing, maintenance and services. Tianhe has 5 main businesses spread across the globe in more than 50 countries in the world.

Tianhe Oil Group management prioritize its people, technology, continuous improvement and building brand awareness. Our mission is to continuously strive innovation and improvement and expand our business in the oilfield. We increased the investment in technology research and development, always looking to provide our global customers with the best technical products and services.

Tianhe Oil Group strongly believes and promotes Total Quality Management, implements the ISO quality management system, HSE management system and API standards. Our manufacturing facilities are well equipped with four automated induction heat treatment lines and dozens of other types of heat treatment ovens and well furnaces (Box type, well type, carburizing heat treatment furnace) to ensure full coverage of heat treatment required by the different products.

So far, Tianhe Oil Group has established strong business relationships with over 200 international oil & gas companies in supporting the top 50 oil producing countries. For example, we have partnered with Schlumberger, Halliburton, Baker Hughes, Weatherford, Shell, NOV, etc.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

GAOTON Series 150 Releasing and Circulating Overshot is an external fishing tool for engage, pack off and retrieve tubular fish, especially for fishing drill collar and drill pipe. The grapple of the overshot can be designed for different sizes of fish, so one overshot can be dressed with different size of grapple components for fishing different sizes of fish.

GAOTON Series 150 Overshot consists of three outside parts: Top Sub, Bowl, and Standard Guide. The Basic Overshot may be dressed with either of two sets of internal parts, if the fish diameter is near the maximum catch of the Overshot, a Spiral Grapple, Spiral Grapple Control, and Type “A” Packer are used. If the fish diameter is considerably below maximum catch size (½” or more) a Basket Grapple and a Mill Control Packer are used.

Within those famous China oil and gas overshot manufacturers, GAOTON is a professional such supplier, producer and provider, welcome to wholesale petroleum and oilfield API overshot from our factory.

TIANHE Series 150 Releasing and Circulating Overshot is an external fishing tool for engage, pack off and retrieve tubular fish, especially for fishing drill collar and drill pipe. The grapple of the overshot can be designed for different sizes of fish, so one overshot can be dressed with different size of grapple components for fishing different sizes of fish.

TIANHE Series 150 Overshot consists of three outside parts: Top Sub, Bowl, and Standard Guide. The Basic Overshot may be dressed with either of two sets of internal parts, if the fish diameter is near the maximum catch of the Overshot, a Spiral Grapple, Spiral Grapple Control, and Type “A” Packer are used. If the fish diameter is considerably below maximum catch size (½” or more) a Basket Grapple and a Mill Control Packer are used.

TIANHE Series 150 Releasing and Circulating Overshot can be equipped with a wide range of accessories to meet a variety of complex fishing environmental.

An extension sub is assembled between the top sub and the bowl.It is used when the upper portion of the fish is damaged or cannot be engaged. This accessory will permit the overshot to be lowered far enough over the fish to ensure secure engagement and pack off. They are available in lengths from 24 to 60 inches. When ordering, specify overshot O.D. Unless otherwise specified Extension Subs will be furnished in a standard 36-inch length.

If the fish is positioned in a washed out section of the hole, it may be difficult to engage the top of the fish using a conventional overshot guide. A wall hook guide can be used to capture the neck of the fish, centralize it, and then properly guide the fish into the bowl.

Oversized Guide properly guides the fish into the overshot when the hole size is considerably larger than the diameter of the fish and the overshot may pass alongside the fish without engaging it. Installation of an oversized guide instead of a standard guide will ensure alignment of the fish with the overshot.

Overshot Mill Extension interiors are faced with ltcoloy to a size that will mill away a flared or jagged fish to enable it to pass up into and be engaged by the Grapple in the Bowl. Mill Extensions are installed between the Bowl and the standard, oversize or wall hook guides.

Overshot Mill Guides are designed to remove badly flared or jagged metal from the top of the fish. Mill Guides are used in place of the Standard or Oversized Guide to trim the fish so it can enter the overshot.

Overshot is one of the fishing tools which is fishing the pipes externally. It can catch drill collar, drill pipe, tubing, subs and other pipes. Because of the seals,the fluid can circulate with the high pump pressure after catching the fish. The top of the fish will be milled by under mill shoe. It can also work with jars to catch the stuck fishes. If the catched fish can"t be release from stucking, we should release the overshot and lifting the drill string.

The internal catch mechanisms are of two basic types: a basket grapple and a spiral grapple. According to different uses, it may be equipped with some accessories, such as extension sub, wall hook, enlarged guide, etc.

MFF Oilfield is a worldwide brand providing the best oilfield tools and equipment. Holding stock in multiple locations worldwide including in USA, Singapore, UAE, Indonesia and in multiple other locations worldwide.

David L. Farley ATTORNEY United Statesv Patent O RELEASING OVERSHOT David L. Farley, Duncan, Okla., assigner to Halliburton Company, a corporation of Delaware Filed Mar. 14, 1958, Ser. No. 721,500

1 Claim. (Cl. 294-4102) This invention relates to an oil well device and more particularly to what is known as an overshot for removing objects Ifrom oil wells in a fishing operation.

Overshots are well-known devices for retrieving objects from oil wells. Ordinarily, such overshots are lowered into an oil well on either a wire line or on tubing or drill pipe and surround and latch on to the object or fish to be removed, the grapple having spring fingers of some sort to assist in making the coupling.

The overshot `of the present invention has similar mechanisms, but it is especially designed to release from the fish when desired, as in the case where the fish is stuck and cannot be removed and it is necessary to remove the overshot fro-rn the well without pulling the fish.

The overshot of the present invention is composed basically of a locking spring and a releasing mechanism. The locking spring consists of a cylindrical part split into several sections which act as fingers. When the fingers are spread over the neck of the fish, the inner shoulders of the fingers normally hook below the top of the fishing neck so that when upward force is exerted on the overshot, this force is transferred to the fish. The overshot can be released by jarring downwardly upon the locking spring and the housing which contains it. Within the housing there is la releasing sleeve held in inactive position `during normal operation of the tool, and provided with a snap ring and two shear pins. Downward jarring shears these pinsso that the housing can then slide downwardly and cause the snap ring to secure the releasing sleeve in -a higher position in the housing. Then, when an upward yforce is exerted on the overshot, the releasing sleeve comes in contact with the lower end of the locking spring, thus, spreadingy the fingers and allo-wing the overshot to pull off from the fishing neck.

It will -thus be seen that an object of the invention is to provide a releasing overshot which can be lowered into a .well in such a condition that it will serve as a grapple and impart upward pull or upward jarring action upon a fish but which may be caused to releasefrom the fish upon downward jar being delivered to it.

Figure 2 is a view in vertical quarter cross section of the releasing overshot of Figure l, the view illustrating the position of the parts when the overshot is first brought into grapple posit-ion with a fish; v

Figure 3 is a vertical quarter cross-sectional view similar to that of Figure 2 but illustrating Athe position of the parts where an upward pull is being exerted on the fish or when an upward jar Vblow is being delivered to the fish;

Figure 4 is a view in vertical `cross section of the retrievable overshot similarto that of Figures 2 and 3 but illustrating the position of the parts after a downward ICC jarring blow has been delivered to shear the pins but before the fingers of the locking spring have been disengaged from the leek of the fish; and

Figure 5 is a view of the releasing overshot in vertical quarter cross section similar to Figures 2, 3, and 4 but illustrating the positionvof `the parts after the overshot is released from the neck of the fish.

Referring to the drawing in detail and first to the general assembly of Figure 1it will be seen that a cable 10 is there illustrated as supporting a conventional twoway jar 11 which is, in turn, connected to a releasing overshot 12 connected to a fishing neck L13 of a fish 14.

The novelty of the present invention resides in the general assembly illustrated and more particularly in the details of construction of the releasing overshot which is contained within the housing 12.

Figures 2, 3, 4, and 5 are all similar and illustrate the sequence of operation of the releasing overshot as well as the details of construction of the various parts.

As shown in Figures 2, 3, 4, and 5, the housing 12 is provided with a threaded coupling 16, at its upper end. The housing 12 is a hollow cylinder but is provided with a number of -grooves and lands on its interior. Near its upper end it is provided with a land 15 of circular shape which serves as a guide for the locking spring 23. Some distance below the land 15, there is a second circular land 17 which also serves as a guide, and beneath this land 17 there is a groove y18, the purpose of which will be apparent :from the description hereinafter.

There are two shear pins 19 employed in the overshot, these "being fitted into suitable sockets in the housing 12, as illustrated in Figures 2 and 3, and arranged 180 degrees apart. For purposes of assembly, the sockets for the pins 19 may be provided with externally removable caps, -but these have not been illustrated in the drawing for reasons of clarity.

There is also provided in the overshot assembly a split snap ring 20. This is mounted in a groove on the releasing sleeve 26 and serves to lock the sleeve in its upper position in the housing 12, as described hereinafter, once the pins 19 have sheared. As shown in Figures 2 and 3, this snap ring 20 is held compressed by the lower portion of the housing 12. When it is raised sufiiciently within the housing 12, it snaps outwardly into the groove 18, as illustrated in Figures 4 and 5.

For normal operation in making connection with the head 21, there is a locking spring consisting of a cylinder of spring steel having a ring portion 23 and depending fingers 24 terminating at the lower end in catches 25. Thus, when the overshot "is lowered into the well, the

fingers 24 move outwardly radially and then inwardly to" clasp the fish beneath the head 21. l" The locking spring is so mounted as to have a certain amount of play within the cylinder 12 in that it can slide upward-ly and downwardly between the top of the housing 1-2 and the upper land 15. This locking spring is more or less of conventional design and need not be described furtherl here.

The important -feature of the invention resides in the provision of mechanism for spreading the fingers 24 outwardly and holding them in an outwardly or expanded position should it be desired to release the overshot from the fish. To this end a releasing sleeve 26 is mounted in the lower portion of the housing 12 and held in place therein by the shear pins 19. So long as the pins 19 are not sheared, the releasing sleeve is held stationary with respect to the sleeve 12 and occupies the inactive posit-ionv shown in Figures 2 and3 with respect thereto. When the "pins 19 are sheared,.the sleeve 26 can then move upwardly with respect to the housing 12 and occupy thepositions of Figures 4 and 5, the split ring 2t) serving to limit the amount of travel of the sleeve 26 with respect to the housing 12 as the ring 20 enters the groove 1S.

The upper surface of the sleeve 26 is provided with a tapered cam surface 27. The purpose of this surface 27 is to engage the lower edges of the catches 25 and force them outwardly when pulling upwardly on `the cable and housing 12.

With the above mechanism, it will be clear that the overshot mechanism, consisting of the housing 12 and the parts mounted in it, may be lowered into a well until the locking spring engages and grapples a suitable shing neck, such as illustrated in Figure 2. In normal operation an upward pull may then be taken on housing 12, and the upward pull may be transmitted by the land 15 to the locking ring and iish. Any number of upward jar blows can then be delivered by the jar 11 to the fish through the spring lingers 24 and catches 25.

Assume, however, that the fish cannot be moved or that for any other reason it is desired to release the overshot from the fish, the upward pull is discontinued and a downward jar blow is delivered b v the jar 11 to the housing 12. Such downward blow will cause the parts to take the position shown in Figure 4. 1n this position, the sleeve 26 is resting upon the sh and the downward stress of the jar blows has been taken by the jar pins 19 so that they have sheared. As soon as the pins 19 shear, there can be relative movement between the housing 12 and the sleeve 26 so that the ring 2G snaps into the groove 18 and holds the sleeve 26 in its upper position in the housing 12. After this has happened, upward pull upon the overshot will cause the cam surface 27 to engage the catches and spread the spring iingers 25a outwardly so that the catches 25 can be moved upwardly past the head 21 and the overshot removed from the ,well without engagement with the tish 13.

While only one embodiment of the invention has been shown and described herein, it is obvious that various changes may be made in the arrangementand construction of the parts yWithout departing from the spirit of the invention or the scope of the annexed claim.

A releasing overshot for use in removing a fish from a well or the like, comprising a cylindrical housing, a locking spring within said housing and having a sh engaging catch depending therefrom, a releasing sleeve Within said housing beneath said catch, said catch and said releasing sleeve having opposed surfaces eifective to positively cam said catch to a fish releasing position upon movement of said releasing sleeve relatively toward said catch, releasable retaining means for holding said releasing sleeve in a lower inoperative position in said housing and out ot" engagement with said catch, said retaining means being releasable upon forcible downward movement of said housing relative to said releasing sleeve to position said releasing sleeve in an upper operative position in said housing, and a latch between said releasing sleeve and said housing for holding said releasing sleeve in said upper position in said housing after said forcible upward movement therein, said opposed surfaces engaging in said upper position of said releasing sleeve to positively cam said catch to a sh releasing position whereby the overshot maybe removed from the well without the tish.

References Cited in the tile of this patent UNITED STATES PATENTS 2,281,389 Shaffer Apr. 28, 1942 2,605,131 Marshall et al July 29, 1952 2,745,693 McGill May 15, 1956 2,872,238 Dailin Feb. 3, 1959

8613371530291

8613371530291