overshot weave factory

Overshot: The earliest coverlets were woven using an overshot weave. There is a ground cloth of plain weave linen or cotton with a supplementary pattern weft, usually of dyed wool, added to create a geometric pattern based on simple combinations of blocks. The weaver creates the pattern by raising and lowering the pattern weft with treadles to create vibrant, reversible geometric patterns. Overshot coverlets could be woven domestically by men or women on simple four-shaft looms, and the craft persists to this day.

Summer-and-Winter: This structure is a type of overshot with strict rules about supplementary pattern weft float distances. The weft yarns float over no more than two warp yarns. This creates a denser fabric with a tighter weave. Summer-and-Winter is so named because one side of the coverlet features more wool than the other, thus giving the coverlet a summer side and a winter side. This structure may be an American invention. Its origins are somewhat mysterious, but it seems to have evolved out of a British weaving tradition.

Twill:Twill along with plain and satin weave is one of the three simple weave structures. Twill is created by repetition of a regular ratio of warp and weft floats, usually 1:2, 1:3, or 2:4. Twill weave is identifiable by the diagonal orientation of the weave structure. This diagonal can be reversed and combined to create herringbone and diamond effects in the weave.

Double Cloth: Usually associated with professional weavers, double cloth is formed from two plain weave fabrics that swap places with one another, interlocking the textile and creating the pattern. Coverlet weavers initially used German, geometric, block-weaving patterns to create decorative coverlets and ingrain carpeting. These coverlets contain twice the yarn and are twice as heavy as other coverlets.

Beiderwand: Weavers in Northern Germany and Southern Denmark first used this structure in the seventeenth century to weave bed curtains and textiles for clothing. Beiderwand is an integrated structure, and the design alternates sections of warp-faced and weft-faced plain weave. Beiderwand coverlets can be either true Beiderwand or the more common tied-Beiderwand. This structure is identifiable by the ribbed appearance of the textile created by the addition of a supplementary binding warp.

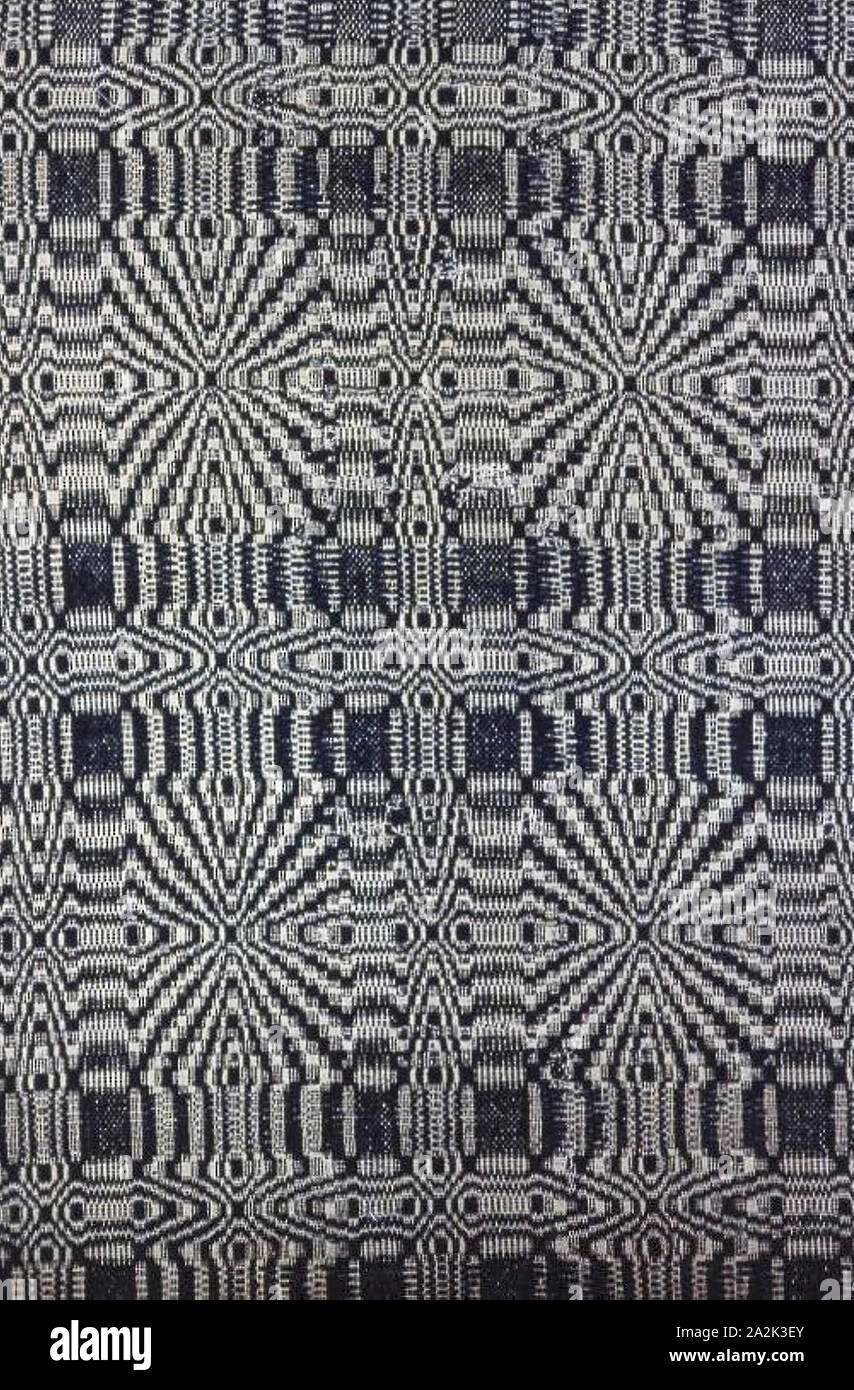

Figured and Fancy: Although not a structure in its own right, Figured and Fancy coverlets can be identified by the appearance of curvilinear designs and woven inscriptions. Weavers could use a variety of technologies and structures to create them including, the cylinder loom, Jacquard mechanism, or weft-loop patterning. Figured and Fancy coverlets were the preferred style throughout much of the nineteenth century. Their manufacture was an important economic and industrial engine in rural America.

Multi-harness/Star and Diamond: This group of coverlets is characterized not by the structure but by the intricacy of patterning. Usually executed in overshot, Beiderwand, or geometric double cloth, these coverlets were made almost all made in Eastern Pennsylvania by professional weavers on looms with between twelve and twenty-six shafts.

America’s earliest coverlets were woven in New England, usually in overshot patterns and by women working collectively to produce textiles for their own homes and for sale locally. Laurel Thatcher Ulrich’s book, Age of Homespun examines this pre-Revolutionary economy in which women shared labor, raw materials, and textile equipment to supplement family incomes. As the nineteenth century approached and textile mills emerged first in New England, new groups of European immigrant weavers would arrive in New England before moving westward to cheaper available land and spread industrialization to America’s rural interior.

The coverlets from New York and New Jersey are among the earliest Figured and Fancy coverlets. NMAH possesses the earliest Figured and Fancy coverlet (dated 1817), made on Long Island by an unknown weaver. These coverlets are associated primarily with Scottish and Scots-Irish immigrant weavers who were recruited from Britain to provide a skilled workforce for America’s earliest woolen textile mills, and then established their own businesses. New York and New Jersey coverlets are primarily blue and white, double cloth and feature refined Neoclassical and Victorian motifs. Long Island and the Finger Lakes region of New York as well as Bergen County, New Jersey were major centers of coverlet production.

German immigrant weavers influenced the coverlets of Pennsylvania, Virginia (including West Virginia) and Maryland. Tied-Beiderwand was the structure preferred by most weavers. Horizontal color-banding, German folk motifs like the Distelfinken (thistle finch), and eight-point star and sunbursts are common. Pennsylvania and Mid-Atlantic coverlets tend to favor the inscribed cornerblock complete with weaver’s name, location, date, and customer. There were many regionalized woolen mills and factories throughout Pennsylvania. Most successful of these were Philip Schum and Sons in Lancaster, Pennsylvania, and Chatham’s Run Factory, owned by John Rich and better known today as Woolrich Woolen Mills.

Coverlet weavers were among some of the earliest European settler in the Northwest Territories. After helping to clear the land and establish agriculture, these weavers focused their attentions on establishing mills and weaving operations with local supplies, for local markets. This economic pattern helped introduce the American interior to an industrial economy. It also allowed the weaver to free himself and his family from traditional, less-favorable urban factory life. New land in Ohio and Indiana enticed weavers from the New York and Mid-Atlantic traditions to settle in the Northwest Territories. As a result, coverlets from this region hybridized, blending the fondness for color found in Pennsylvania coverlets with the refinement of design and Scottish influence of the New York coverlets.

Southern coverlets almost always tended to be woven in overshot patterns. Traditional hand-weaving also survived longest in the South. Southern Appalachian women were still weaving overshot coverlets at the turn of the twentieth century. These women and their coverlets helped in inspire a wave of Settlement Schools and mail-order cottage industries throughout the Southern Appalachian region, inspiring and contributing to Colonial Revival design and the Handicraft Revival. Before the Civil War, enslaved labor was often used in the production of Southern coverlets, both to grow and process the raw materials, and to transform those materials into a finished product.

Because so many coverlets have been passed down as family heirlooms, retaining documentation on their maker or users, they provide a visual catalog of America’s path toward and response to industrialization. Coverlet weavers have sometimes been categorized as artisan weavers fighting to keep a traditional craft alive. New research, however, is showing that many of these weavers were on the forefront of industry in rural America. Many coverlet weavers began their American odyssey as immigrants, recruited from European textile factories—along with their families—to help establish industrial mills in America. Families saved their money, bought cheaper land in America’s rural interior and took their mechanical skills and ideas about industrial organization into the American heartland. Once there, these weavers found options. They could operate as weaver-farmers, own a small workshop, partner with a local carding mill, or open their own small, regional factories. They were quick to embrace new weaving technologies, including power looms, and frequently advertised in local newspapers. Coverlet weavers created small pockets of residentiary industry that relied on a steady flow of European-trained immigrants. These small factories remained successful until after the Civil War when the railroads made mass-produced, industrial goods more readily available nationwide.

Overshot: The earliest coverlets were woven using an overshot weave. There is a ground cloth of plain weave linen or cotton with a supplementary pattern weft, usually of dyed wool, added to create a geometric pattern based on simple combinations of blocks. The weaver creates the pattern by raising and lowering the pattern weft with treadles to create vibrant, reversible geometric patterns. Overshot coverlets could be woven domestically by men or women on simple four-shaft looms, and the craft persists to this day.

Summer-and-Winter: This structure is a type of overshot with strict rules about supplementary pattern weft float distances. The weft yarns float over no more than two warp yarns. This creates a denser fabric with a tighter weave. Summer-and-Winter is so named because one side of the coverlet features more wool than the other, thus giving the coverlet a summer side and a winter side. This structure may be an American invention. Its origins are somewhat mysterious, but it seems to have evolved out of a British weaving tradition.

Twill:Twill along with plain and satin weave is one of the three simple weave structures. Twill is created by repetition of a regular ratio of warp and weft floats, usually 1:2, 1:3, or 2:4. Twill weave is identifiable by the diagonal orientation of the weave structure. This diagonal can be reversed and combined to create herringbone and diamond effects in the weave.

Double Cloth: Usually associated with professional weavers, double cloth is formed from two plain weave fabrics that swap places with one another, interlocking the textile and creating the pattern. Coverlet weavers initially used German, geometric, block-weaving patterns to create decorative coverlets and ingrain carpeting. These coverlets contain twice the yarn and are twice as heavy as other coverlets.

Beiderwand: Weavers in Northern Germany and Southern Denmark first used this structure in the seventeenth century to weave bed curtains and textiles for clothing. Beiderwand is an integrated structure, and the design alternates sections of warp-faced and weft-faced plain weave. Beiderwand coverlets can be either true Beiderwand or the more common tied-Beiderwand. This structure is identifiable by the ribbed appearance of the textile created by the addition of a supplementary binding warp.

Figured and Fancy: Although not a structure in its own right, Figured and Fancy coverlets can be identified by the appearance of curvilinear designs and woven inscriptions. Weavers could use a variety of technologies and structures to create them including, the cylinder loom, Jacquard mechanism, or weft-loop patterning. Figured and Fancy coverlets were the preferred style throughout much of the nineteenth century. Their manufacture was an important economic and industrial engine in rural America.

Multi-harness/Star and Diamond: This group of coverlets is characterized not by the structure but by the intricacy of patterning. Usually executed in overshot, Beiderwand, or geometric double cloth, these coverlets were made almost all made in Eastern Pennsylvania by professional weavers on looms with between twelve and twenty-six shafts.

America’s earliest coverlets were woven in New England, usually in overshot patterns and by women working collectively to produce textiles for their own homes and for sale locally. Laurel Thatcher Ulrich’s book, Age of Homespun examines this pre-Revolutionary economy in which women shared labor, raw materials, and textile equipment to supplement family incomes. As the nineteenth century approached and textile mills emerged first in New England, new groups of European immigrant weavers would arrive in New England before moving westward to cheaper available land and spread industrialization to America’s rural interior.

The coverlets from New York and New Jersey are among the earliest Figured and Fancy coverlets. NMAH possesses the earliest Figured and Fancy coverlet (dated 1817), made on Long Island by an unknown weaver. These coverlets are associated primarily with Scottish and Scots-Irish immigrant weavers who were recruited from Britain to provide a skilled workforce for America’s earliest woolen textile mills, and then established their own businesses. New York and New Jersey coverlets are primarily blue and white, double cloth and feature refined Neoclassical and Victorian motifs. Long Island and the Finger Lakes region of New York as well as Bergen County, New Jersey were major centers of coverlet production.

German immigrant weavers influenced the coverlets of Pennsylvania, Virginia (including West Virginia) and Maryland. Tied-Beiderwand was the structure preferred by most weavers. Horizontal color-banding, German folk motifs like the Distelfinken (thistle finch), and eight-point star and sunbursts are common. Pennsylvania and Mid-Atlantic coverlets tend to favor the inscribed cornerblock complete with weaver’s name, location, date, and customer. There were many regionalized woolen mills and factories throughout Pennsylvania. Most successful of these were Philip Schum and Sons in Lancaster, Pennsylvania, and Chatham’s Run Factory, owned by John Rich and better known today as Woolrich Woolen Mills.

Coverlet weavers were among some of the earliest European settler in the Northwest Territories. After helping to clear the land and establish agriculture, these weavers focused their attentions on establishing mills and weaving operations with local supplies, for local markets. This economic pattern helped introduce the American interior to an industrial economy. It also allowed the weaver to free himself and his family from traditional, less-favorable urban factory life. New land in Ohio and Indiana enticed weavers from the New York and Mid-Atlantic traditions to settle in the Northwest Territories. As a result, coverlets from this region hybridized, blending the fondness for color found in Pennsylvania coverlets with the refinement of design and Scottish influence of the New York coverlets.

Southern coverlets almost always tended to be woven in overshot patterns. Traditional hand-weaving also survived longest in the South. Southern Appalachian women were still weaving overshot coverlets at the turn of the twentieth century. These women and their coverlets helped in inspire a wave of Settlement Schools and mail-order cottage industries throughout the Southern Appalachian region, inspiring and contributing to Colonial Revival design and the Handicraft Revival. Before the Civil War, enslaved labor was often used in the production of Southern coverlets, both to grow and process the raw materials, and to transform those materials into a finished product.

Because so many coverlets have been passed down as family heirlooms, retaining documentation on their maker or users, they provide a visual catalog of America’s path toward and response to industrialization. Coverlet weavers have sometimes been categorized as artisan weavers fighting to keep a traditional craft alive. New research, however, is showing that many of these weavers were on the forefront of industry in rural America. Many coverlet weavers began their American odyssey as immigrants, recruited from European textile factories—along with their families—to help establish industrial mills in America. Families saved their money, bought cheaper land in America’s rural interior and took their mechanical skills and ideas about industrial organization into the American heartland. Once there, these weavers found options. They could operate as weaver-farmers, own a small workshop, partner with a local carding mill, or open their own small, regional factories. They were quick to embrace new weaving technologies, including power looms, and frequently advertised in local newspapers. Coverlet weavers created small pockets of residentiary industry that relied on a steady flow of European-trained immigrants. These small factories remained successful until after the Civil War when the railroads made mass-produced, industrial goods more readily available nationwide.

This post is the third in a series introducing you to common weaving structures. We’ve already looked at plain weave and twill, and this time we’re going to dive into the magic of overshot weaves—a structure that’s very fun to make and creates exciting graphic patterns.

Overshot is a term commonly used to refer to a twill-based type of weaving structure. Perhaps more correctly termed "floatwork" (more on that later), these textiles have a distinctive construction made up of both a plain weave and pattern layer. Requiring two shuttles and at least four shafts, overshot textiles are built using two passes: one weaves a tabby layer and the other weaves a pattern layer, which overshoots or floats, above.

Readers in the United States and Canada may be familiar with overshot textiles through woven coverlets made by early Scottish and English settlers. Using this relatively simple technique, a local professional weaver with a four-shaft loom could easily make a near-infinite variety of equally beautiful and complex patterns. If you’d like to learn more about overshot coverlets and some of the traditions that settlers brought with them, please see my reading list at the bottom of this article!

As it is twill-based, overshot will be very familiar to 4 shaft weavers. It’s made up of a sequence of 2-thread repeats: 1-2, 2-3, 3-4, and 1-4. These sequences can be repeated any number of times to elongate and create lines, curves, and shapes. These 2-thread repeats are often referred to as blocks or threading repeats, IE: 1-2 = block 1/A, 2-3 = block 2/B.

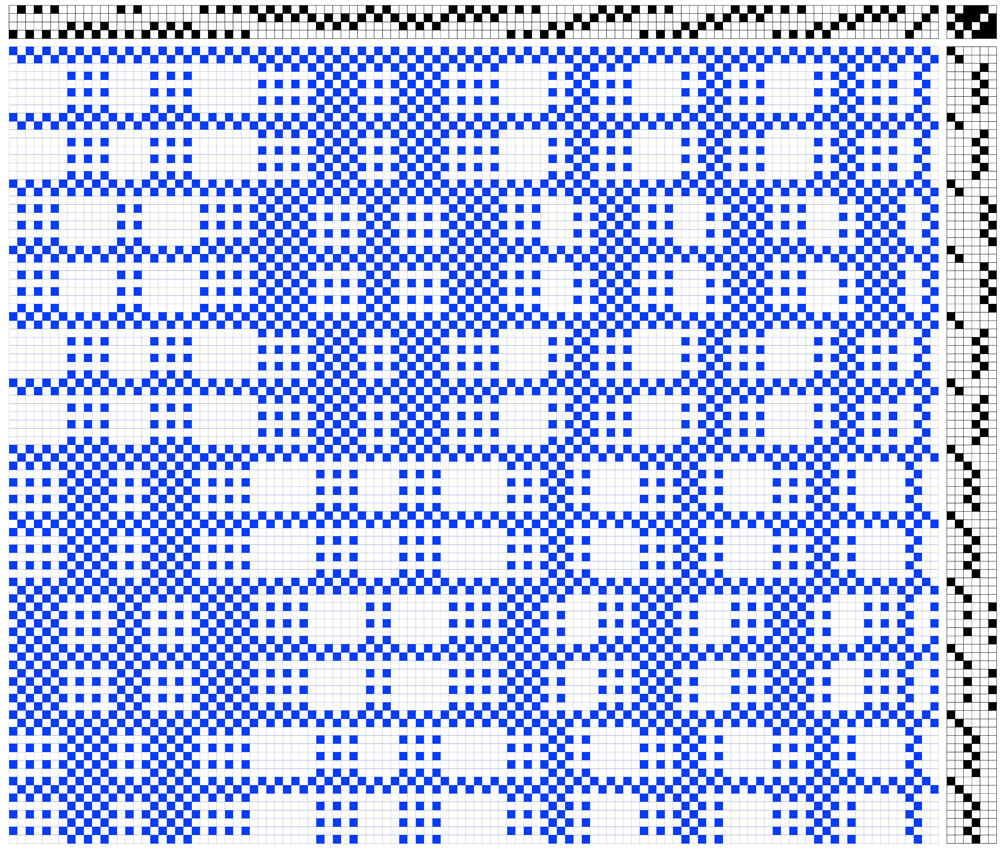

There are three ways weft appears on the face of an overshot cloth: as a solid, half-tone, or blank. In the draft image I’ve shared here, you can see an example of each—the solid is in circled in blue, the half-tone in red, and the blank yellow. Pressing down the first treadle (shafts 1 and 2), for example, creates solid tones everywhere there are threads on shafts 1 and 2, half-tones where there is a 1 or 2 paired with 3 or 4, and nothing on the opposite block, shafts 3 and 4. Of course, there’s not really nothing—the thread is simply traveling on the back of the cloth, creating a reverse of what’s on the face.

Because overshot sequences are always made up of alternating shafts, plain weave can be woven by tying two treadles to lift or lower shafts 1-3 and 2-4. When I weave two-shuttle weaves like overshot, I generally put my tabby treadles to the right and treadle my pattern picks with my left foot and my tabby with my right. In the draft image I’ve shared above, I’ve omitted the tabby picks to make the overarching pattern clearer and easier to read. Below is a draft image that includes the tabby picks to show the structure of the fabric.

Traditional overshot coverlets used cotton or linen for warp and plain weave wefts, and wool pattern wefts—but there’s no rule saying you have to stick to that! In the two overshot patterns I’ve written for Gist, I used both Mallo and Beam as my pattern wefts.

In the Tidal Towels, a very simple overshot threading creates an undulating wave motif across the project. It’s easy and repetitive to thread, and since the overshot section is relatively short, it’s an easy way to get a feel for the technique.

The Bloom Table Squares are designed to introduce you to a slightly more complex threading—but in a short, easy-to-read motif. When I was a new weaver, one of the most challenging things was reading and keeping track of overshot threading and treadling—but I’ve tried to make it easy to practice through this narrow and quick project.

Overshot works best with a pattern weft that 2-4 times larger than your plain weave ground, but I haven’t always followed that rule, and I encourage you to sample and test your own wefts to see how they look! In the samples I wove for this article, I used 8/2 Un-Mercerized Cotton weaving yarn in Beige for my plain weave, and Duet in Rust, Mallo in Brick, and Beam in Blush for my pattern wefts.

The Bloom Table Squares are an excellent example of what weavers usually mean when they talk about traditional overshot or colonial overshot, but I prefer to use the term "floatwork" when talking about overshot. I learned this from the fantastic weaver and textile historian Deborah Livingston-Lowe of Upper Canada Weaving. Having researched the technique thoroughly for her MA thesis, Deborah found that the term "overshot" originated sometime in the 1930s and that historical records variably called these weaves "single coverlets’ or ‘shotover designs.’ Deborah settled on the term "floatwork" to speak about these textiles since it provides a more accurate description of what’s happening in the cloth, and it’s one that I’ve since adopted.

Long out of print, this fabulous book covers the Burnham’s extensive collection of early settler textiles from across Canada, including basic threading drafts and valuable information about professional weavers, tools, and history.

Amanda Ratajis an artist and weaver living and working in Hamilton, Ontario. She studied at the Ontario College of Art and Design University and has developed her contemporary craft practice through research-based projects, artist residencies, professional exhibitions, and lectures. Subscribe to herstudio newsletteror follow her onInstagramto learn about new weaving patterns, exhibitions, projects, and more.

This project was really popular when I posted it on Instagram, so I thought I would share it here also. It is a simple overshot pattern - with a twist. Also a great way to show off some special yarn. The yarn I used for my pattern was a skein of hand spun camel/silk blend. I wove the fabric on my Jack loom but you could also use your four or eight shaft loom.

Overshot is a weave structure where the weft threads jump over several warp threads at once, a supplementary weft creating patterns over a plain weave base. Overshot gained popularity in the turn of the 19th century (although its origins are a few hundred years earlier than that!). Coverlets (bed covers) were woven in Overshot with a cotton (or linen) plain weave base and a wool supplementary weft for the pattern. The plain weave base gave structure and durability and the woollen pattern thread gave warmth and colour/design. Designs were basic geometric designs that were handed down in families and as it was woven on a four shaft loom the Overshot patterns were accessible to many. In theory if you removed all the pattern threads form your Overshot you would have a structurally sound piece of plain weave fabric.

I was first drawn to Overshot many years ago when I saw what looked to me like "fragments" of Overshot in Sharon Aldermans "Mastering Weave Structures".

I have not included details of number of warp ends, sett and yarn requirements for my project - you can do your calculations based on the sett required for plain weave in the yarn you wish to use.

I wanted to use my handspun - but I only had a 100gms skein, I wanted to maximise the amount of fabric I could get using the 100gms. I thought about all the drafts I could use that would show off the weft and settled on overshot because this showcases the pattern yarn very nicely. I decided to weave it “fragmented” so I could make my handspun yarn go further. I chose a honeysuckle draft.

Warp the full width as per the threading below. You will weave plain weave every other row, the warp yarn and the plain weave base weft yarn should be the same weight. Your pattern yarn should be twice as thick as you base yarn.

When doing the treadle tie-up I used 3 and 8 for my plain weave and started weaving from the left, treadle 3 - so you always know which treadle you are up to - shuttle on the left - treadle 3, shuttle on the right treadle 8. I then tied up the pattern on treadles 4,5,6 and 7. You can work in that order by repeating the sequence or you can mix it up and go from 4 to 7 and back to 4 again etc. You will easily see what the pattern is doing.

Wind two shuttles. One with your plain weave base weft and the other with your pattern yarn. You will weave plain weave between each pattern row. The plain weave always goes across the full width. To weave the pattern rows (green on draft below) take the shuttle through the shed and bring it out through the top of the warp, sit it on the warp and then after the next plain weave row take it back into the warp where it came out and back through the shed.

Weaving rag rugs is an immensely satisfying process that enables you to use cast-off remnants of fabric - and a favorite old shirt or two - to make something beautiful and functional for your home. In this book, you"ll explore the fascinating history of rag weaving, learn how to weave a basic rag rug, master some of the most popular traditional designs, and experiment with contemporary techniques for weaving and embellishing rugs. Filled with scores of colour photographs of rugs by more than 40 artists from around the world, this book is a delight for weavers and non-weavers alike.

The basics of rag rug weaving have remained the same over the years, but the materials, designs, weave patterns, and color combinations have changed significantly. Today"s weavers have access to an abundant array of warp and weft materials, with a wide variety of fiber content, color, and pattern. There are few-if any-limitations on what you might incorporate into your design: plastic shopping bags, bread wrappers, nylon stockings, and industrial castoffs have all been included.

In this book, you"ll find the old and the new, traditional designs and contemporary approaches. Starting with a basic, plain-weave rug, it describes the materials and tools you"ll need, how to prepare your warp and weft, how to dress the loom, and how to weave with a rag weft. Then you"ll learn how to make more complex designs: stripes and plaids, block patterns, reversible designs, inlay motifs, tufted weaves, and many other variations. Applications of surface design techniques, such as immersion dyeing, screen printing, and painting with textile inks, are also explored. In the chapter on design, you"ll be guided through the process of choosing colors and deciding upon compositions for your rugs. You"ll also find several options for finishing your rug, from traditional braided fringe to a crisp, clean Damascus edge.

Is it old Colonial blankets, usually white background with blue, black or red wool pattern and large, large designs? A corner box with the weaver"s initials and a date.They bring to mind an image of early residents of colonial America and also the British Colonies, later to be called Upper and Lower Canada.

It is thought that overshot was brought over from Europe with the early arrivals to the New Land. Settlers brought many ideas and tools with them and adapted them to the new life here. With a colder climate and long winters, overshot blankets meant you had a thick stable cloth, woven on four shafts, that kept the sleeper warm and also served as a decorative bed covering.

I have seen some stunning coverlets quietly doing their job in movies: "The Patriot" with Mel Gibson and Heath Ledger. I had to watch it again and freeze frame the movie to get a good look! It was a natural setting for a colonial coverlet. The coverlet that was wrapped around Dakota Fanning in "War of the Worlds", featuring Tom Cruise was a pleasant surprise! Are you one of those weavers who"s eye scans movie scenes for textiles and gets excited when you spot something handwoven ?

Lets get back to our weaving with overshot and some of the basics with the four shaft variety. I need to point out here that these are simple guidelines and by no means complete. Just a small primer to pique your interest. I will post reading / study material list at the end. These notes are based on an overshot study I undertook some years ago.

Most new weavers are introduced to overshot at an early newbie weaver stage and usually start with a draft from Marguerite Davison"s classic: A Handweaver"s Pattern Book.Itsstill available to purchase after all these years. The drafts in this book are for sinking shaft looms such as counterbalance looms. You can flip the tie up for jack looms. If you don"t, it means you will be weaving the pattern upside down, which isn"t a problem but it would be nice to see the front as you weave. This little detail would make it confusing for new weavers starting on overshot for the first time, in addition to handling two shuttles!

Overshot is a twill derivative using two threads to create a unit block. This means you can have four blocks on four shafts. One thread in each block, is shared by the next block. This one thread in common creates half units in between blocks of either all pattern or all tabby. (This can be expanded through to eight shafts but we"ll stick with four shafts for this post) See what I mean by this in the picture below:

Overshot is actually two pieces of cloth, being woven simultaneously; one is a tabby or plain weave cloth, the second is the pattern that "over-shoots" the plain weave. You throw one shuttle for the plain weave and a second shuttle for the pattern weft, beating *very* firmly between each shot. If you were to take away the pattern weft, you would find a perfectly balanced 50/50 plain weave cloth. The pattern weft should compact well but be "lofty" to cover and produce blocks of solid colour with no plain weave peeking through. Normally the pattern weft is twice the size of the tabby yarn. Traditionally, cotton for tabby and with wool for pattern.

I keep the "odd" tabbies of treadles one and three to enter from the left hand side, and the "even" tabbies of treadles two and four from the right hand side. Also I work with both shuttles, tabby and weft, on one side of the warp. If you end up with divided shuttles then you have a treadling error to find!. The shuttles can be awkward to coordinate at first but you soon develop a rhythm. Be aware that many overshot drafts may say "use tabby" but don"t show it in the treadling. Then there are some that don"t mention the tabby at all. They are assuming you know to insert it.

The majority of overshot is woven "as drawn in" which means you repeat the exact threading as your treadling. Old drafts say "tromp as writ" which is the same thing.

Twill fashion is where you treadle a block over again to produce exact squares. This may be more repeats than is in the threading. You can also follow twill treadlings such as: rosepath ( 1, 2, 3, 4, 1, 4, 3, 2, 1), point twill (1, 2, 3, 4, 3, 2, 1) , or broken twill (1, 2, 4, 3). Its then called overshot treadled as rosepath, or treadled as summer and winter. There are many other ways to vary the treadling and these all make very pretty borders! The following examples are from my first level of the Guild of Canadian Weavers Test. I took portions of the treadling and created these border patterns. They had to have a purpose for being woven. Click to enlarge...

When designing overshot patterns you can place many identical units together and then continue through to other blocks but the turning point block in your design will have an uneven number of threads. When treadling, the turning blocks are treadled one extra repeat.

So besides bed coverlets, what else can you make with overshot? I have seen beautiful modern looking table runners, scarves, overshot style borders on placemats and towels. I saw a beautiful (apparently) plain weave table cloth that had inlaid overshot motifs scattered like stars! They looked like snowflakes on the royal blue cloth.

I always thought it would be a neat challenge to weave overshot and have it look totally modern and comfortable in today"s home. ( Its on my "to-do" list..)

So if you have followed me through to this point and are now thinking it might be nice to try some overshot study yourself. Perhaps try inventing some borders for towels? Here are a few books on overshot that are on my library shelf:

Weavers are fortunate to have an extensive literature of books on weaving techniques and woven cloth. “How-to” having books and illustrated exhibition catalogs that feature woven textiles are well-known month weavers. Less well known are the numerous readable and informative books on history, anthropology, and psychology that address the “what, why, and how” of both textiles in particular and craft in general. This talk will feature a discussion of three books that look at textiles and craft, and that ask questions such as “What is this object? Why was it made? Who made it? How was it used?

Scott Norrisis a weaver who specializes in tablecloths, bath towels, and other utilitarian household items, woven in hand-dyed linen. He is also a writer, with essays and reviews published in magazines and journals such as American Craft, Ceramic Monthly, Ceramics Art and Perception,andUnder the Sun. Visit his website at www.elamswidow.com.

Color and weave effect describes an infinite number of patterns, which can be created by repeating a small pattern of light and dark colors in the wrap and wefts using a basic weave structure. The visual patterns formed do not resemble the weave structure and cannot be predicted without a color draft. The program will explore the general characteristics of color-and-weave effect by looking at samplers and drafts and reviewing color drafting. A 50-plus page-learning packet will be available to each student containing notes, drafts and project ideas. Please bring pencil, eraser, ruler and colored pencils. A small fee will be charged for the handout TBD.

Beth Cederberg Guertinof Waltham, Massachusetts has been teaching both rigid heddle and multi shaft weaving for more than thirty-five years to children and adults. She enjoys designing projects to use up small amounts of yarns. She is a member of the Weavers’ Guild of Boston and is their treasurer. Beth was recognized by the WGB with the Helen Barrett Award in 2013 and the Celebration of Weaving Life Award in 2017. Beth owns and teaches weaving at her studio, A Place to Weave,in Waltham. Her website is www.aplacetoweave.com

Collapse weave is simple and complex at the same time. Collapse weave creates a cloth which draws-in in controlled ways, displaying a 3-dimensional effect. It often involves the sue of very simple structures. It is the materials used and the method of use, which is unusual. We will discuss a variety of methods for producing collapse, and my practice with these methods. Many examples of samples, finished products, and materials will be on display.

Deborah Kaplanbranched into weaving 20 years ago from a background of handspinning and knitting. Her knowledge of materials informs her work. For a number foyers she has worked with collars weave and unusual materials such as copper, steel, under gummed silk, and horsehair to obtain open, gauzy, surprisingly effects. Most recently, she has been working with differential shrinkage for collapse. Thinking outside the box is a passion. Debbie’s work has been featured in SpinOff, Handwovenand the CW Journal,and has won awards at NEWS and Complex Weavers.

Framing allows a textile to stand on its own and gives it value. This power point presentation focuses on the many options we have to “frame” our work, from simple stripes to using pattern blocks and woven edges to isolate a woven piece from its background. We will look at twills, overshot and summer and winter weave structures, among others, as ways to provide well-designed boundaries. Proportion, color value and simplicity are also factors to consider.

Tapestry weaver Archie Brennan feels that wall pieces of fiber art still search for a proper presentation; his comments will be considered. An unusual approach is to allow the image to break through the border. Photos of textiles through the ages will show many solutions for textiles both functional and decorative.

Norma Smayda, master weaver, teacher and author, established the Saunderstown Weaving School in 1974. She learned to weave in Norway. Scandinavian design, colors and weave structures continue to be an important focus of her work. She also specializes in the contributions of William Henry Harrison Rose and Bertha Gray Hayes. She is the co-author of Weaving Designs by Bertha Gray Hayes.More recently, she has immersed herself in weaving with fan reeds and has written Ondulé Textiles: Weaving Contours with a Fan Reed.She received the Weavers Guild of Boston Distinguished Achievement Award and the New England Weavers Seminar Weaver of Distinction. She is a Past President of the Handweavers Guild of America and an Honorary Member of the Weavers Guild of Rhode Island.

Janet Austinlearned to weave at Massachusetts College of Art, in 1972. After weaving and selling functional items for 8 years, she felt a yearning to express herself in images, and earned an MFA in Painting at the University of NC, Greensboro. Almost accidentally the weaving and painting came together, and she has been weaving tapestries inspired by her paintings since 1983.

Jan served on the board of the American Tapestry Alliance, and as coordinator of Tapestry Weavers in New England. She exhibits regionally, nationally and internationally. She has been teaching tapestry for more than 30 years, speaks to guilds and art groups and demonstrates tapestry weaving whenever she can.

As a member of the WGRI when the meetings were held in Slater Mill, I first met Antonia Kormos as she shared in the mostly meetings, bringing her extraordinary textiles to share with the group. I was lucky to meet with her as we curated the pieces for her solo exhibition at The American Textile History Museum in 2014, for that HGA Convergence year. It was Tony who inspired me to take the plunge to attempt the Handweavers Guild of America, Certificate of Excellence Level I. This is a PowerPoint program with the woven samples for inspection.

Laurie Carlson Steger grew up in central Massachusetts. She learned to weave and sew as a child. She earned a BFA in Textile Design and and MFA in Artisanry/Fibers from The University of Massachusetts-Dartmouth. She was recently awarded the Handweavers Guild of America, Certificate of Excellence Level I. Ms. Steger works and contemplates from her home studio in South Dartmouth, MA. For more information, visit her website: www.liteweave.com.

Mayan Hands is a fair trade nonprofit organization dedicated to empowering Mayan women weavers in their quest to bring their families out of extreme poverty as they continue to live within the culture they cherish. Founder, Brenda Rosenbaum, and artist, Anastasia Azure, will share their current project “Crafting Change” that involves teaching Mayan women to create woven metal jewelry.

Anastasia Azurehand-weaves dimensional art exploring the grace of geometry. She shares her connection with our harmonious universe by creating contemplative wall sculptures and innovative jewelry. Her art emits radiant symmetry, providing centering as well as expansive energy. Combining metalsmithing with an ancient, Peruvian textile technique, she weaves wire and hand-dyed nylon on a traditional floor loom. Her designs create sophisticated serenity, beauty and wonder.

Fabrics that appear to change colors as the light and orientation change seem almost magical! Despite the restrictive “rules” you might have heard, these fabrics are easy to weave, and it doesn’t take gossamer silk or just plain weave to do it! Learn the many factors that influence the results: hue, value, luster, weave structure, and more. You’ll weave a plain-weave color sampler with a limited range of warp colors and up to 24 weft colors in pearl cotton. You’ll then analyze the sampler and choose two effective weft colors to make a second sampler on the same warp, experimenting with a variety of weave structures and color variations. Dozens of fabric swatches, both handwoven and factory-produced, will be available for your study. Multicolor iridescence and iridescence in black and white are some of the amazing possibilities!

Weave a Pin Loom Scarf Part 1, Introduction to Pin Loom Weaving - Instructor: Margaret Stump Date:Friday 9:00 a.m. to 12:00 p.m. Max: 12 Min Age: 10-13 Class Fee:$45 Materials fee payable to instructor: $3

This is a 3 hour class that will introduce the process of pin loom weaving and weaving overshot patterns on the pin loom in order to begin to make a 4" x 80" scarf. Participants will learn how to weave on the pin loom and how to weave patterns on the pin loom.No previous experience is necessary but participants will probably have more fun if they have practiced weaving a few squares on their pin loom before class.

Students should bring:A 4" pin loom with the traditional 3 pin grouping. Examples of these looms include vintage Weave-Its, Schacht Zoom Loom, the Hazel Rose Multi-loom and other pin looms available on Etsy. Blue Butterfly looms will not work because they are a different sett.

8613371530291

8613371530291