8 shaft overshot factory

Designed for lightness and portability, our Norah table looms are complete weaver’s tools. They have graded length shaft control keys so fingers can easily identify which keys to lift or return. Warp control pawls and ratchets are outside where the weaver can easily reach them. Changing sheds is an extraordinarily smooth action because cords run over 16 maple wood pulleys, never dragged over rods or around eyelets.

The Nilus II is an updated version of the popular Leclerc Nilus. It features larger heddles for cleaner sheds and a deeper frame to make treadling easier when weaving under high tension. The Nilus II 4-shaft loom is available in two versions- Jack or counterbalance.

The Nilus II loom has been designed with a stabilizer foot, for better stability. The shed is always good with any tie-up combination. The counter-balanced version is built with an integrated shed regulator, so it is possible to weave any kind of material. On the jack-type version, the top can be easily removed, allowing easy access to the shafts for the addition or removal of heddles. Heddles used are 12½" (31.7 cm) long. It is a loom with independent shafts, guided by pegs at each side, preventing friction of the frames which are pushed upwards by an underneath mechanism.

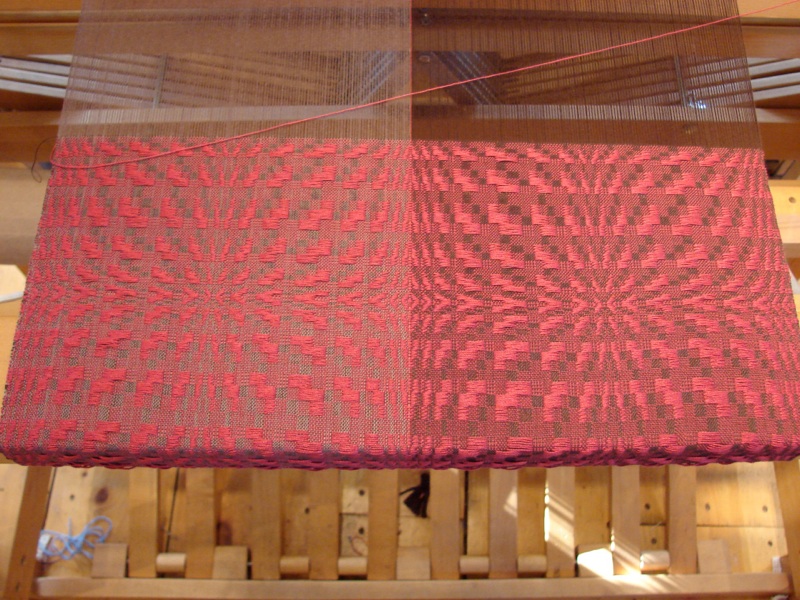

This project was really popular when I posted it on Instagram, so I thought I would share it here also. It is a simple overshot pattern - with a twist. Also a great way to show off some special yarn. The yarn I used for my pattern was a skein of hand spun camel/silk blend. I wove the fabric on my Jack loom but you could also use your four or eight shaft loom.

Overshot is a weave structure where the weft threads jump over several warp threads at once, a supplementary weft creating patterns over a plain weave base. Overshot gained popularity in the turn of the 19th century (although its origins are a few hundred years earlier than that!). Coverlets (bed covers) were woven in Overshot with a cotton (or linen) plain weave base and a wool supplementary weft for the pattern. The plain weave base gave structure and durability and the woollen pattern thread gave warmth and colour/design. Designs were basic geometric designs that were handed down in families and as it was woven on a four shaft loom the Overshot patterns were accessible to many. In theory if you removed all the pattern threads form your Overshot you would have a structurally sound piece of plain weave fabric.

I was first drawn to Overshot many years ago when I saw what looked to me like "fragments" of Overshot in Sharon Aldermans "Mastering Weave Structures".

I wanted to use my handspun - but I only had a 100gms skein, I wanted to maximise the amount of fabric I could get using the 100gms. I thought about all the drafts I could use that would show off the weft and settled on overshot because this showcases the pattern yarn very nicely. I decided to weave it “fragmented” so I could make my handspun yarn go further. I chose a honeysuckle draft.

When doing the treadle tie-up I used 3 and 8 for my plain weave and started weaving from the left, treadle 3 - so you always know which treadle you are up to - shuttle on the left - treadle 3, shuttle on the right treadle 8. I then tied up the pattern on treadles 4,5,6 and 7. You can work in that order by repeating the sequence or you can mix it up and go from 4 to 7 and back to 4 again etc. You will easily see what the pattern is doing.

A 4 shaft floor loom with 6 treadles. My floor loom has a 35" weaving width, but if your loom is smaller I have provided an alternative class project.

Overshot: The earliest coverlets were woven using an overshot weave. There is a ground cloth of plain weave linen or cotton with a supplementary pattern weft, usually of dyed wool, added to create a geometric pattern based on simple combinations of blocks. The weaver creates the pattern by raising and lowering the pattern weft with treadles to create vibrant, reversible geometric patterns. Overshot coverlets could be woven domestically by men or women on simple four-shaft looms, and the craft persists to this day.

Summer-and-Winter: This structure is a type of overshot with strict rules about supplementary pattern weft float distances. The weft yarns float over no more than two warp yarns. This creates a denser fabric with a tighter weave. Summer-and-Winter is so named because one side of the coverlet features more wool than the other, thus giving the coverlet a summer side and a winter side. This structure may be an American invention. Its origins are somewhat mysterious, but it seems to have evolved out of a British weaving tradition.

Multi-harness/Star and Diamond: This group of coverlets is characterized not by the structure but by the intricacy of patterning. Usually executed in overshot, Beiderwand, or geometric double cloth, these coverlets were made almost all made in Eastern Pennsylvania by professional weavers on looms with between twelve and twenty-six shafts.

America’s earliest coverlets were woven in New England, usually in overshot patterns and by women working collectively to produce textiles for their own homes and for sale locally. Laurel Thatcher Ulrich’s book, Age of Homespun examines this pre-Revolutionary economy in which women shared labor, raw materials, and textile equipment to supplement family incomes. As the nineteenth century approached and textile mills emerged first in New England, new groups of European immigrant weavers would arrive in New England before moving westward to cheaper available land and spread industrialization to America’s rural interior.

The coverlets from New York and New Jersey are among the earliest Figured and Fancy coverlets. NMAH possesses the earliest Figured and Fancy coverlet (dated 1817), made on Long Island by an unknown weaver. These coverlets are associated primarily with Scottish and Scots-Irish immigrant weavers who were recruited from Britain to provide a skilled workforce for America’s earliest woolen textile mills, and then established their own businesses. New York and New Jersey coverlets are primarily blue and white, double cloth and feature refined Neoclassical and Victorian motifs. Long Island and the Finger Lakes region of New York as well as Bergen County, New Jersey were major centers of coverlet production.

Southern coverlets almost always tended to be woven in overshot patterns. Traditional hand-weaving also survived longest in the South. Southern Appalachian women were still weaving overshot coverlets at the turn of the twentieth century. These women and their coverlets helped in inspire a wave of Settlement Schools and mail-order cottage industries throughout the Southern Appalachian region, inspiring and contributing to Colonial Revival design and the Handicraft Revival. Before the Civil War, enslaved labor was often used in the production of Southern coverlets, both to grow and process the raw materials, and to transform those materials into a finished product.

So what that means, is I need little looms to easily carry outdoors, and just weave. I have plenty of inkle looms. And many have projects on them. But I have a large collection of 18 little Structo looms, the 8″ wide metal kind, four of them are 8 shafts, and I have a couple of adorable 4 shaft Leclerc 10″ wide looms of about the same vintage. I had visions of setting them all up with different weave structures to explore, and one of the perfect ways to do that is with what’s called a Gamp, which is a sort of sampler with blocks of design across, so whatever you ‘treadle’, affects all the different threadings across. It is like creating a library of little designs.

So over the last few weeks, as my broken shoulder starts to heal, I’ve been really busy just playing in the studio. I’m making progress on the overshot placemats I agreed to do for a friend (this is a really good friend), and I’m actually half way done. I’ve completed three mats and only have three more to go. And I’m really enjoying the scale, working with 20/2 cotton for the ground, and 10/2 for the pattern. I thought I’d hate it, but I can weave half a mat in an hour, and I’m getting really smooth at handling two shuttles. (The pattern is from Handwoven Magazine Nov/Dec 2010 in an article by Mary Berent, pg 38).

And on one of my 8 shaft Structo’s, I found a beautiful Shadow Weave sampler from a draft from Webs Valley Yarns #199, Shadow Weave Sampler Scarf in 8/2 tencel. I wound four spools with the color sequence using yarn I had in colors I already had, and the effect is charming. Can’t wait to sit in the garden and weave on this.

And on one of my 4 shaft Structo’s, I had my guild helper help me wind four spools in 16/2 cotton (I wind the spools using my AVL warping wheel) (this was a couple months ago when my left arm wasn’t strong enough to wind on the AVL, I’m good now). And I threaded a twill gamp I found in Handwoven Magazine, Nov/Dec 2008 in an article by Robyn Spady, pg 40.

I have three more drafts planned out for another group of 8″ Structos, an 8 shaft Quigley from Tom Knisely’s handwoven table linens, a deflected double weave gamp from Marion Stubinetsky’s Double Twist pg 204, and another Robyn Spady gamp, in overshot on 4 shafts from Handwoven Magazine May/June 2014.

And on a personal note. Today would have been my 44 wedding anniversary. I miss my husband, I would just love to have 10 minutes with him to hear what he has to say about the mess in the world right now. I’d probably need more than 10 minutes. We were married in the spring of 1978 in a little chapel in southern NJ. The Kwanzan Cherry tree outside the chapel was in full bloom.

When we bought the home where I’m currently living, in the early 80’s, the first thing we did was plant a Kwanzan Cherry in the front yard. It has bloomed every year for our anniversary. Never fails. Recently I had to call in a tree expert to save the tree from some fungal infection, which really brought the tree back to life, so much so that the top became too heavy and it was in danger of splitting right down the middle of the trunk. So the tree experts came back, and for a considerable sum of money, I had them bolt through the trunk, and top the tree, by about half. And sure enough, on my anniversary today, this beloved tree hasn’t let me down. What we do for love…

Elsa Krogh, Danish weaver, spinner and author, has brought together her favourite weaving patterns using four, six and eight shafts. Elsa has woven beautiful and exciting shawls, scarves, cushions, towels, table runners, placemats and fabric material, She uses a variety of techniques from twill to summer and winter and modern backed weaves and there are projects for all levels of weaving experience. Many of the patterns are sourced from archival material from local museums. Elsa brings a wonderful sense of continuity to her craft as well as elegant Scandinavian style. 92 pages

As a young child visiting my great aunt in the nursing home, I would love to sneak to the lower floor and watch as residents wove blankets on large floor looms. I dreamt of weaving my own blanket. When I married and moved to Charlottesville, Virginia, over 30 years ago, I walked by a shop selling Schacht looms and offering classes. I went home with a table loom that day—a far cry from those big looms in the nursing home, but just as exciting. Money was tight, so I got an old spinning wheel and ordered raw fleeces to make my own yarn. When we moved to a small colony farm in Palmer, Alaska, in 1989, I knew right away I would get the perfect sheep to grow the best wool for my projects. Many more looms and sheep followed. Superfine merino sheep originally from Morehouse Farm in New York entered the picture in 1990 and our flock continued to grow and produce amazing wool. I was unable to keep up with the spinning and started sending our wool to Blackberry Ridge Woolen Mill, who do a great job spinning yarn. I use this yarn to make woolen goods for purchase, including blankets, shawls, scarves, and felted yardage.

We purchased the 60″ 8-shaft Cranbrook with 12 treadles, the sliding threading bench, the sectional warping beam, tension box, and spool rack. The instructions were amazing, and it was easy to set up. The tension box was essential during the beaming process. We only had one Schacht spool rack which only controlled 20 of our 40 cotton bobbins. We improvised “racks” for the remaining 20 bobbins, which we do not recommend. The threading bench is another accessory that helped us to complete the warping of this large project (getting a friend to sit there is also recommended). With the ease of the tension box, it made sense to warp a 30-yard warp. In this way, the warped loom would be available for commissions and studio hours for those weavers who wish to weave their own coverlet.

One thing I did not realize when I bought the Cranbrook was that the treadles can lock into place to keep the shed open. This is especially helpful when weaving a wide project, as you don’t need to keep your foot on the treadle when you “catch” the shuttle at the other side. (If I had known this, I would have bought the 72″). I tied my tabby threads to treadles 3 and 4, skipped two treadles, and tied my pattern threads to treadles 7, 8, 9, and 10. It was easy to get in a great rhythm and “dance” through the pattern. Good music kept up my beat. The weighted hanging beater option made it relaxing and gave me a dense consistent beat with minimal effort.

Thread following Lee’s Surrender draft in A Handweaver’s Pattern Book, page 184. Repeat center block 30 times. Tie up according to draft. Note: the drafts in this book are written for a sinking shed loom. For a rising shed loom, tie up the blank boxes, not the boxes marked with X.

My name is Tal Saarony and I have been weaving for many years. I belong to the tribe of masochistic weavers who enjoy, while cursing like a sailor, battling with very fine yarn and, on occasion, inlaying patterns with several complicated treadling sequences, e.g., different overshots, into each row of weft. Not for me the simple life. These days I’m more of a plain weave kind of person, a balanced-weave tapestrier (in contrast with the weft-faced kind), but it still takes me hours to weave a full inch of cloth.

The skewer method works with manual winders too, but it makes an unholy racket; they’re, annoyingly, noisy enough already. I found that wrapping some masking tape (you will later have to scrub off the sticky residue, so there’s that to consider) around the shaft works better.

The photo shows the end of a skewer peeping out. Note that the spool is pushed almost all the way to the wooden base and pushed a little bit onto the thicker part of the shaft. In the background is the manual winder with masking tape that was shredded when I struggled to pull the spool off.

8613371530291

8613371530291