bowen overshot supplier

LT Overshot is one of the fishing tools which is fishing the pipes externally. It can catch drill collar, drill pipe, tubing, subs and other pipes. Because of the seals, the fluid can circulate with the high pump pressure after catching the fish. The top of the fish will be milled by under mill shoe. It can also work with jars to catch the stuck fishes. If the catched fish can"t be release from stucking, we should release the overshot and lifting the drill string.

DLT-T type Releasing and Reversing Overshot, a new type of fishing tool, has many advantages owned by various overshot, box tap and like. It distinguishing features are as follows: to unscrew and recover the stuck fish: to release the fish down hole if necessary: to circulate the washing fluid.

Externally engage, pack off, and pull a fish with our wide range of overshot tools. The first fishing choice when screwing into the fish is not an option, our overshot tools are simply designed but ruggedly built. Choose from options including:

Kelo socket overshots are proven to catch small-diameter workstrings and sucker rods inside casing as well as recover coiled tubing that has parted and remains in hole.

The t-dog, mouse-trap, and flipper-dog (TMF) overshot can be dressed in three different ways for different washover applications. Deploy the t-dog assembly option to washover and recover mud-stuck or sanded-up square-collared pipe in one trip. Use the mouse-trap assembly to catch sucker rods, integral joint tubing, or cables. And with the flipper-dog assembly, you can confidently catch a fish with different ODs.

General Description ................................................ 3Use .......................................................................... 4Construction ............................................................ 4Gripping and Releasing Mechanism ................... 4Pack-off Mechanism ............................................. 5Operation ................................................................ 6Precautions ............................................................. 6Undersize Parts ....................................................... 7Spiral Parts .............................................................. 7Basket Parts ............................................................ 7Overshot Accessories ............................................. 7Subsea Sheared Pipe Retrieval Method ................. 9Specifications and Replacement Parts ......... 12 19Overshot Accessories Tables ........................ 20 22Calculated Strength Tables ........................... 23 24Illustrations .............. 3, 5, 7, 8, 9, 10, 17, 19, 20 22

The Bowen Series 150 Releasingand Circulating Overshot provides thestrongest tool available to externallyengage, pack-off, and pull a fish. Thebasic simplicity and rugged constructionwith which it is designed have madeit the standard of all external catchfishing tools.

The Bowen Series 150 Releasing andCirculating Overshot has gained worldwide acceptance for fishing by meansof external engagement of a fish. EachOvershot is a carefully engineered unit.In service, it takes a positive grip over alarge area of fish and is therefore capable of withstanding extremely heavy pulling, torsional and jarring strains withoutdamage or distortion to either the toolor the fish.

Bowen Overshots are continually developed to new standards of strength andefficiency and are expertly constructedof the highest quality material.Each Bowen Series 150 Releasing andCirculating Overshot is a compact unitdesigned to engage, pack off and pull aspecific size of tubing, pipe, coupling,tool joint, drill collar or smooth O.D. tool.Through the installation of proper undersize parts, they may be adapted toengage and pack off any smaller size.

Bowen course thread Overshots aredesigned for easier assembly andmaintenance. The Bowen CT Overshothas a course ACME thread on the upperend of the Bowl where the Top Sub isattached and at lower end where theGuide is attached. See SupplementalInstruction Manual 1150A for list.The course thread allows much easierfield assembly and will stand moreabuse than the fine series currentlyoffered. The internal parts are completelyinterchangeable with existing BowenOvershots.Cross over bushings can be providedfrom fine thread series to course threadseries, allowing full use of Bowls, TopSubs, and Guides currently in stock.All sizes of Bowen Series 150 Releasingand Circulating Overshot are available inFull Strength or Slim Hole Types. Despitethe extremely small outside diametersof Full Strength Type Overshots, theyare engineered to withstand the pulling,torsional and jarring strains, which mustbe exerted by modern machinery, torelease and retrieve a lost fish.The Slim Hole Type Overshots havereduced outside diameters, as compared to the Full Strength. They are usedto perform pulling jobs in tight holeswhere no other outside catch, releasingfishing tool can be run.Use

A Bowen Series 150 Releasing andCirculating Overshot is used to engage,pack off and retrieve twisted-off or losttubing, drill pipe, coupling, tool joint,casing or other similar fish.

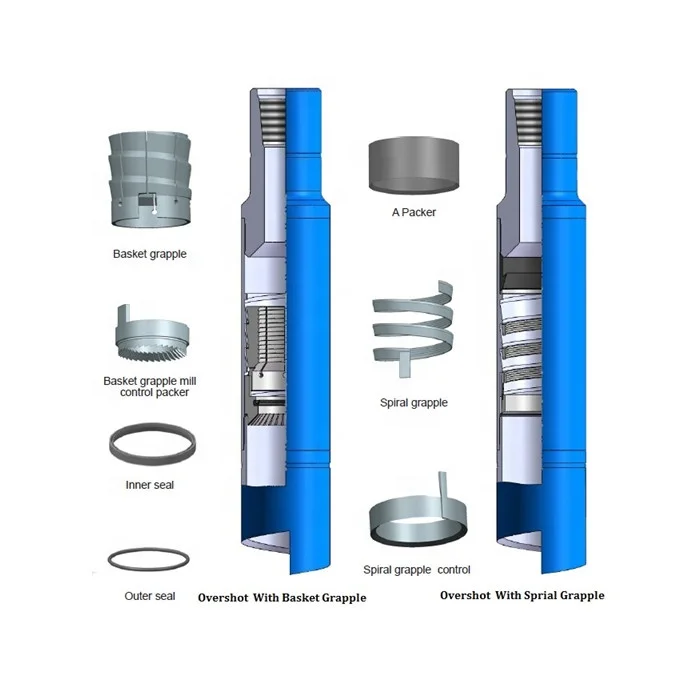

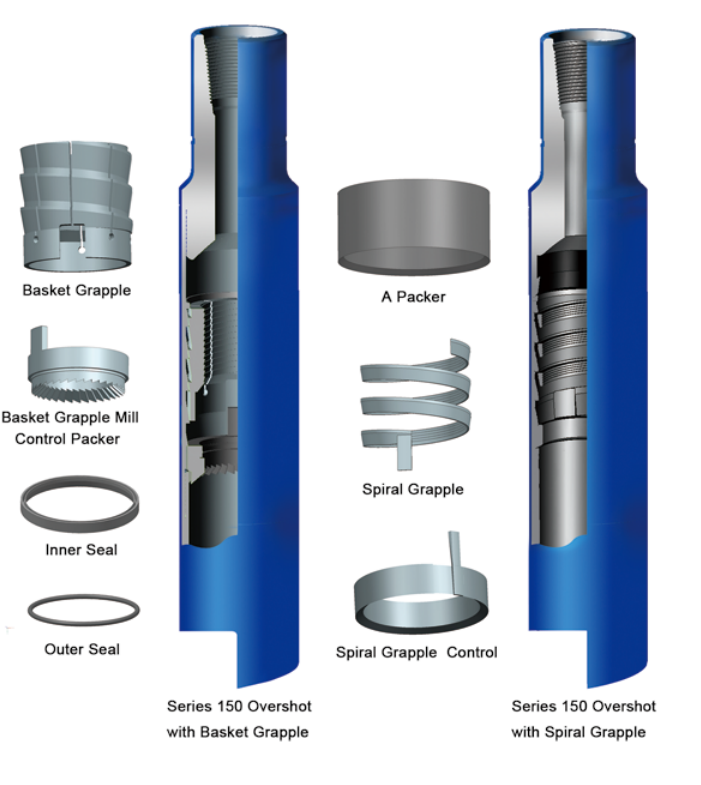

The Bowen Series 150 Releasing andCirculating Overshot is composed ofthree outside parts: the Top Sub, Bowl,and Guide. The Basic Overshot may bedressed with either of two sets of internalparts, depending on whether the fish tobe caught is near maximum catch sizefor the particular overshot.If the fish diameter is near the maximumcatch of the Overshot, a Spiral Grapple,Spiral Grapple Control and Type APacker are used. If the fish is a tubingcollar, a Type D Collar Packoff Assembly will replace the Type A Packer.If the fish diameter is considerably belowmaximum catch size (usually 12"), aBasket Grapple and a Mill Control Packeris used.Gripping andReleasing Mechanism

The Bowl of the Overshot is designedwith helically tapered spiral section in itsinside diameter. The gripping member(Spiral Grapple or Basket Grapple), isfitted into this section. When an upwardpull is exerted against a fish, an expansion strain is spread evenly over a longsection of the fish. No damage or distortion results to either the fish or the Overshot. This design permits a far strongertool with a smaller outside diameter thanis possible with an overshot that employsa single tapered section which supportsslips.A Spiral Grapple is formed as a left-handhelix with a tapered exterior to conformwith the helically tapered section in theBowl. Its interior is wickered for engagement with the fish.A Basket Grapple is an expansible cylinder with a tapered exterior to conform tothe helically tapered section in the Bowl.Its interior is wickered for engagementwith the fish.

Three types of Basket Grapples areavailable to meet the need for catchingvarious types of fish:The Plain Basket Grapple is standard,and will always be furnished unlessanother type is specified. It is wickeredfor its entire interior length. It is used tocatch any plain single diameter fish.The Basket Grapple with Long CatchStop has an internal shoulder located atthe upper end, to stop the fish in bestcatch position. It is designed to stop andcatch an upset, or box section of a tooljoint, with sufficient length left below theGrapple to allow the joint or upset to bepacked off with a Basket Mill ControlPacker.The Basket Grapple with Short CatchStop has a double set of wickers, of twodifferent internal diameters. It is used tostop and catch a coupling with aruptured piece of pipe engaged in itsupper end. The upper set of wickers willcatch the ruptured pipe, and act as astop against the coupling, while thelower set of wickers will catch the coupling. The coupling will be stopped in bestposition to be packed off by the MillControl Packer.Grapple Controls are of two types: SpiralGrapple Controls are used with SpiralGrapples; Mill Control Packers are usedwith Basket Grapples.Grapple Controls are used as a specialkey, to allow the Grapple to move up anddown during operation while simultaneously transmitting full torque from theGrapple to the Bowl.Spiral Grapple Controls and BasketGrapple Controls are plain. Mill ControlPackers include a packoff. See Pack-offMechanism for a complete explanation.In operation, the Overshot functions inthe same manner, whether dressed withSpiral Grapple parts or Basket Grappleparts

During the engaging operation, as theOvershot is rotated to the right andlowered, the Grapple will expand whenthe fish is engaged, allowing the fish toenter the Grapple. Thereafter with rotation ceased and upward pull exerted,the Grapple is contracted by the tapersin the Bowl and its deep wickers grip thefish firmly.

During the releasing operation, a sharpdownward bump places the larger portion of the Bowl tapers opposite theGrapple smaller tapered portion, breaking the hold. Thereafter, when the Overshot is rotated to the right, and slowlyelevated, the wickers will screw theGrapple off the fish, effecting release.The fact that Bowen Releasing and Circulating Overshots require right handrotation only, both during engaging andreleasing operation, is extremely important. This feature eliminates the dangersthat are present when it is necessary torotate the string to the left.

The type of Pack-off used depends onhow the Overshot is dressed, and theoperators choice.When the Overshot is dressed with aSpiral Grapple, a Type A Packer is used.The Type A Packer is a sleeve type. Itseats at its O.D. against the inside of theBowl. It has an internal lip which sealsaround the fish. Each type A Packer isdesigned to pack off a specific size. A

Type A Packer should be ordered foreach catch size Spiral Grapple.A Mill Control Packer is used when theOvershot is dressed with a Basket Grapple. The Type R Mill Control Packer isused when a packoff is required. Theunique double lip seal of the Mill ControlPacker provides a positive seal of thefish. The Packer is self energized and isretained within the Mill Control by a lowersecond sealing lip and requires no adhesive for retaining the Packer. The TypeR is most commonly used. It has areplaceable inner seal and a replaceableouter seal. The inner seal and the outerseal may both be replaced in the fieldwhen required. The Type R Mill Control(with mill teeth) is available. Mill ControlPackers are designed to remove smallburrs and rough breaks only. Replacement inner and outer seals are listedon page 20. Also see the special HighPressure Pack-off accessories on page19.All Mill Control Packers are manufacturedto pack off a specific size. One should

Type D Packer assemblies are available to pack off tubing collars in tubingsize Series 150 Overshots. The Type DPacker assembly consists of a Packer,a Spring and an O-Ring. It is assembledin the Bowl above the Grapple. Its upperend is sealed in a counter-bore in theTop Sub, by the O-Ring. In operation,its lower end stops the collar in propercatch position, while the integral moldedseal enters and packs off the collarthreads at the top of the collar. ThesePackers are listed on page 16.The Type D Collar Packer is designedto be used with a Spiral Grapple, in placeof a Type A Packer, where the collarbeing fished is too short to allow effectivecatch and pack off length.

First determine that the Overshot isproperly assembled, is dressed with theproper size Grapple and that all its partsare in good working condition. Refer toSpecifications beginning on page 11.

Bump down; then simultaneously rotateto the right and slowly elevate the fishingstring until the Overshot is clear of thefish; combined rotating and elevating isimportant.

If the hole size is so much greater thanthe fish size that it is possible for theOvershot to pass alongside the fish,install either a Wallhook Guide or anOversize Guide in place of the StandardGuide. (see page 18)If the top of the fish is a heavily burredtool joint, replace the Standard Guidewith the proper Milling Guide, Type A orC. (see page 19)If the fish has an unengageable upperend, install an Extension between theTop Sub and the Bowl (see illustration onpage 7).Using the Top Sub, connect the Overshotto the fishing string and run it in the hole.To Engage and Pull the Fish

As the top of the fish is reached, slowlyrotate the fishing string to the right andgradually lower the Overshot over thefish; combined rotating and lowering isimportant.Allow the right-hand twist to slack out ofthe fishing string and then pull on the fishby elevating the fishing string.If the fish does not come, turn on thecirculating pumps and maintain anupward strain while circulation is forcedthrough the fish.

Unless an upward strain is maintained,never rotate the fishing string to the leftwhile the Overshot is engaged with thefish.Always bump the full weight of the fishingstring before starting releasing operations.Always shut off the circulating pumpsbefore lowering the Overshot over thefish.Function of the Overshotin Engaging the Fish

After the Overshot has reached the topof the fish, combined rotation andlowering results in the following:1. The guide will direct the fish into theOvershot.2. The Grapple will expand and the fishwill pass through it.3. The fish will pass through the Packoff Rubber and will be halted when itcontacts the pin end of the Top Sub.In the case where an external upsetsection is being engaged by a Basket Grapple, the fish will be haltedby the solid steel stop in the upperend of the Basket Grapple.

5. Likewise, once the fish is in thisposition, the circulation will sealthe Packoff Rubber around the fishand prevent fluid passage downthe outside. Thus, by building uppressure with the pumps, the fluidcan be forced down through the fish.Function of the Overshotwhen Releasing

The sharp downward bump places thelargest portion of the Bowl tapers opposite the Grapple and breaks the hold.Right-hand rotation expands the Grappleand by maintaining right-hand rotation,the Overshot may be withdrawn from thefish.Function of the Grapple

The mechanical conditions which causedthe Grapple to expand and contract are:1. The Grapple is a left-hand helix.2. The lower end of the Grapple isanchored in the Overshot Bowl.3. The inside diameter of the Grappleis smaller than the outside diameterof the fish.As the Overshot is rotated to the rightand lowered over the fish, the drag ofthe fish against the grapple causes theGrapple to unwind and expand sufficiently to allow the fish to enter.As the Overshot is rotated to the rightand withdrawn from the fish, the dragof the fish against the Grapple causesthe Grapple to unwind and expandsufficiently to allow the Overshot to bewithdrawn.

4. The fish is now properly located inthe Overshot and thereafter whenupward pull is exerted, the Grappleis contracted by the tapers in theBowl and the hold will be secure.

Undersize Spiral parts: Spiral Grappleand Type A Packer are used to catchsizes from Maximum Catch SpiralGrapple, down to Maximum CatchBasket Grapple, as specified in thespecifications tables on pages 11 thru15 inclusive.These Spiral Grapples and Type APacker should be changed for eachdifferent size fish. They will effectivelycatch and pack off worn fish as much as332" maximum undersize. The over-rangeof each grapple is approximately 132".There are exceptions, particularly in theSlim Hole type Overshots. Some of thesewill effectively catch undersize oroversize fish by no more than 116"maximum.Basket Parts

Bowen Lock Rings provide a positiveand releasable means for lockingstraight-threaded shouldered joints sothey will not back off.Type SS Top Sub(Short with Shoulder)

Top Subs are available for BowenOvershots in two types: SS, Short Subwith shoulder; and LS, Elevator Sub withshoulder. Type SS Top Subs are furnished as part of the assembly, unlessotherwise specified.Lock Rings

Bowen Lock Rings are available asoptional equipment to prevent the TopSub and Bowl of Bowen Series 150Releasing and Circulating Overshotsfrom unthreading during backing-offoperations. Use of Bowen Lock Ringseliminates the weakening practice ofdrilling and tapping the Bowl to installa set screw for securing the Bowl to the

If a twist-off has left a fishwhose upper end is unengageable, an ExtensionSub should be installedbetween the Top Sub andthe Bowl of the Overshot.This will permit lowering ofthe Overshot over the fishfar enough to insure engagement and a perfectpack off in the fishingoperation. Extension Subsare listed on page 21.Extension Sub

Basket Grapples will effectively catch fishworn as much as 332" maximum undersize. The over range of each grapple isapproximately 132".There are exceptions, particularly in theSlim Hole type Overshots. Some of thesewill effectively catch undersize fish bymore than 132" maximum.

Bowen Lock Rings are used in pairsconsisting of two identical rings. Therings have cam-teeth on one face, knurlson the other, and two breakout grooveson the edges. They are precision madefrom alloy steel, stress relieved, and heattreated.Assembly

When the Overshot is dressed with aspiral grapple and type A Packer, aSpacer is required between the Packerand Top Sub. Please refer to Lock RingTable on page 21. The purpose of theSpacer is to fill the space produced bythe extra standoff of the Top Sub whenused with the Lock Rings. No Spacer isrequired when A Packer is not used.

Itcoloy Mill Extensions are used to millaway flared or jagged metal from the topof the fish so that the fish will pass easilyinto the Overshot Bowl. For ordinarywork, they are installed between the Bowland the standard, oversize or wall hookguides.The Itcoloy Mill Extension is also usedin the Bowen Subsea Sheared PipeRetrieval Method (see page 9). In thiscase it is installed between the OvershotBowl and the special guides. They maybe ordered by giving the Overshotnumber and specifying Itcoloy MillExtension Type and fish size. Pricesavailable on request.

When unthreading is desired, a specialBowen Lock Ring Breakout Clamp isrequired. Slight right-hand torque mayhave to be applied for lining-up the Ringbreakout grooves to receive the Clamp.Lower Key Seat

Itcoloy Mill Guides are used to millaway jagged metal form the top of thefish so that the fish will pass easily intothe Overshot Bowl.They may be ordered, using the standard Guide number, and specifying,Itcoloy Mill Guide Type C and fish size.Subsea ShearedPipe Retrieval

The BOP being used must have at leasttwo sets of rams: lower pipe rams andshear rams above them. Before shearing, it is necessary to land the nearesttool joint on the pipe rams and closethem to suspend and pack off the string.The shearing then produces flattenedflare-ends with protruding ears.When the rig returns, the string must beretrieved, the end brought to the surfaceand the sheared piece removed. In thepast, sheared pipe retrieval has been difficult, costly and time-consuming. Oftenlarge parts of the BOP stack must bebrought to the surface to effect retrieval.The Bowen method of sheared piperetrieval can be achieved in a simple,time-saving and economical manner.It requires only two easy steps usingthe Series 150 Circulating and ReleasingOvershot equipped with a few specialaccessories

If the hole size is so much greater thanthe fish size that it is possible for theOvershot to pass alongside the fish, anOversize Guide or a Wallhook Guidemust be installed in place of the Standard Guide to insure alignment of thefish with the Overshot. These are listedon page 18.

Twist-offs in tool joints are not alwaysimmediately revealed at the surface andas a result drilling is not halted at once.In such cases the top of the fish is usually a badly burred tool joint, or drill pipe,and a Type A Mill Guide must be installedon the Overshot to trim the burr off thefish so that it can enter the Overshot.Itcoloy Mill Guides perform the sameservice on undersize tool joints and arealso used when the top of the fish is anunusually jagged section of pipe. Moreinformation on these is shown on page19.

The standard guide, grapple and packerhave been removed from a BowenOvershot and it is then dressed with aMill Extension and special flat-bottomLong Guide, and installed on the drillstring. The Mill Extension has taperedmilling ribs of Bowen Itcoloy (sinteredtungsten carbide) facing on its I.D. TheOvershot is lowered into the BOP andover the end of the drill pipe, and thenrotation takes place to mill down theflared ears of the sheared pipe. The endof the Long Guide is faced with softmetal so that if inadvertently it contactsthe BOP pipe rams, it does not damagethem. The Guide is also of a lengthwhich prevents the Mill Extension fromcontacting and damaging the tool joint inthe BOP. This is important because thisjoint O.D. is where engagement of thestring will take place.

After the milling step is completed, theBowen Overshot is brought back to thesurface, dressed with a special flatbottom Short Guide, Extension Sub anda Basket Grapple and Mill Control Packersized to engage the joint. (The ShortGuide also has a soft metal end toprevent ram damage.) The Overshot islowered again and as it enters the BOP,the milled-down flare-end passesthrough the Grapple and Mill ControlPacker, and is housed in the ExtensionSub while the Grapple engages andpacks off the tool joint. A pull is exertedon the Overshot to make certain ofengagement and then the BOP piperams are retracted, and the string israised to the rig floor where the severedjoint is removed and replaced, allowingnormal operations to resume.

The lists of assemblies and accessoriesin this Instruction manual have beenreduced to the most popular Overshotsand parts worldwide. This has been doneto make it easier for the customer toquickly find the information they requireand also for the ease of transmitting theelectronic version of the file.The Bowen Series 150 Overshot productline consists of many different sizes andtypes of assemblies and items. A listof over 225 of these is in SupplementalInstruction Manual 1150A. If a locallypopular assembly is not listed in Manual1150 it will most probably be listed inManual 1150A. However, this is still nota complete list. There are additionalassemblies not listed.The standard Series 150 Overshot is aright-hand operation tool with right-handthreads. But there are many specialsoffered. Some of the other tools madeare right-hand tools with left-handthreads, left-hand tools with left-handthreads, left-hand tools with right-handthreads, tools for H2S service, toolsfor CO2 service, tools for H2S and CO2service, very high strength tools, verythin wall tools, and with sizes rangingfrom 25/16" OD to above 32" OD.Even with all the possible combinations,National Oilwell continues to design newassemblies to add to aproduct line thatwas started almost 60 years ago!

If the hole size is so much greater than the fish size that it is possible for the Overshot to pass alongside the fish,an Oversize Guide or a Wallhook Guide must be installed to insure alignment of the fish with the Overshot.

In cases where the top of the fish is a badly burred tool joint or drill pipe, a Type A MillingGuide should be installedon the Overshot to trim the burr of the fish so that it can enter theOvershot. Type C Milling Guides perform the same service on undersize tool joints; theyare also used when the top of the fish is an unusually jagged section of pipe. Type C Guidesare available as carbonized, fluted guides or Itcoloy Guides.

The High Pressure Pack-off Assembly is a special assembly for use in areas of extreme pressure. It consistsof a Bushing and four packing elements. It is normally installed between the Bowl and the Guide of the Overshot.

ADHESIVE: Bowen has developed an adhesive which is particularlysuited to bonding Type R Inner Seals to Mill Control Packers. It is composed of two compounds, an epoxy resin with strengtheningmaterial and a catalyst, which are mixed prior to using. Bowen Adhesive Compound No. 1 (Resin) Part No. 41241-1 and Bowen Adhesive Compound No. 2 (Catalyst) Part No. 41241-2. One-pint cans.NOTE: Use the Same Outer Seal for Type R and Type E Mill Control Packer

If a twist-off has left a fish whose upper end is unengageable, an Extension Sub is installedbetween Top Sub and the Bowl of the Overshot. This will permit lowering of the Overshot overthe fish far enough to insure a secure engagement and a perfect packoff.Extension Sub SpecificationsSizes

Lock Rings prevent the Top Sub and Bowl of a Bowen Overshot from unthreading when reverserotation, such as backing-off, occurs. They provide a positive means of locking straight-threaded,shouldered joints without excessive torque or pins. Knurled surfaces on the rings dig into theshoulder when the joint is made-up. Cam teeth between the rings have pitches greater than thethread pitch and these cams produce the locking action.Lock Ring SpecificationsBowl No.

NOV Downhole is the manufacturer of Bowen® Fishing Tools, the world’s most respected and reliable fishing tool products in the oil and gas industry for over 85 years.

8613371530291

8613371530291