define overshot factory

Overshot: The earliest coverlets were woven using an overshot weave. There is a ground cloth of plain weave linen or cotton with a supplementary pattern weft, usually of dyed wool, added to create a geometric pattern based on simple combinations of blocks. The weaver creates the pattern by raising and lowering the pattern weft with treadles to create vibrant, reversible geometric patterns. Overshot coverlets could be woven domestically by men or women on simple four-shaft looms, and the craft persists to this day.

Summer-and-Winter: This structure is a type of overshot with strict rules about supplementary pattern weft float distances. The weft yarns float over no more than two warp yarns. This creates a denser fabric with a tighter weave. Summer-and-Winter is so named because one side of the coverlet features more wool than the other, thus giving the coverlet a summer side and a winter side. This structure may be an American invention. Its origins are somewhat mysterious, but it seems to have evolved out of a British weaving tradition.

Multi-harness/Star and Diamond: This group of coverlets is characterized not by the structure but by the intricacy of patterning. Usually executed in overshot, Beiderwand, or geometric double cloth, these coverlets were made almost all made in Eastern Pennsylvania by professional weavers on looms with between twelve and twenty-six shafts.

America’s earliest coverlets were woven in New England, usually in overshot patterns and by women working collectively to produce textiles for their own homes and for sale locally. Laurel Thatcher Ulrich’s book, Age of Homespun examines this pre-Revolutionary economy in which women shared labor, raw materials, and textile equipment to supplement family incomes. As the nineteenth century approached and textile mills emerged first in New England, new groups of European immigrant weavers would arrive in New England before moving westward to cheaper available land and spread industrialization to America’s rural interior.

Southern coverlets almost always tended to be woven in overshot patterns. Traditional hand-weaving also survived longest in the South. Southern Appalachian women were still weaving overshot coverlets at the turn of the twentieth century. These women and their coverlets helped in inspire a wave of Settlement Schools and mail-order cottage industries throughout the Southern Appalachian region, inspiring and contributing to Colonial Revival design and the Handicraft Revival. Before the Civil War, enslaved labor was often used in the production of Southern coverlets, both to grow and process the raw materials, and to transform those materials into a finished product.

The most commonly reported type of Ecological Footprint, it is defined as the area used to support a defined population’s consumption. The consumption Footprint (in gha) includes the area needed to produce the materials consumed and the area needed to absorb the carbon dioxide emissions. The consumption Footprint of a nation is calculated in the National Footprint and Biocapacity Accounts as a nation’s primary production Footprint plus the Footprint of imports minus the Footprint of exports, and is thus, strictly speaking, a Footprint of apparent consumption. The national average of per capita Consumption Footprint is equal to a country’s Consumption Footprint divided by its population.

In contrast to the consumption Footprint, a nation’s productive Footprint is the sum of the Footprints for all of the resources harvested and all of the waste generated within the defined geographical region. This includes all the area within a country necessary for supporting the actual harvest of primary products (cropland, pasture land, forestland and fishing grounds), the country’s built-up area (roads, factories, cities), and the area needed to absorb all fossil fuel carbon emissions generated within the country. In other words, the forest Footprint represents the area necessary to regenerate all the timber harvested (hence, depending on harvest rates, this area can be bigger or smaller than the forest area that exists within the country). Or, for example, if a country grows cotton for export, the ecological resources required are not included in that country’s consumption Footprint; rather, they are included in the consumption Footprint of the country that imports the t-shirts. However, these ecological resources are included in the exporting country’s primary production Footprint.

Natural capital can be defined as all of the raw materials and natural cycles on Earth. Footprint analysis considers one key component, life supporting natural capital, or ecological capital for short. This capital is defined as the stock of living ecological assets that yield goods and services on a continuous basis. Main functions include resource production (such as fish, timber or cereals), waste assimilation (such as CO2 absorption or sewage decomposition) and life support services (such as UV protection, biodiversity, water cleansing or climate stability).

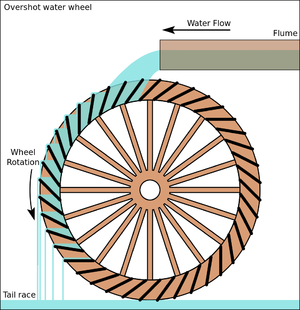

Overshot and backshot water wheels are typically used where the available height difference is more than a couple of meters. Breastshot wheels are more suited to large flows with a moderate head. Undershot and stream wheel use large flows at little or no head.

There is often an associated millpond, a reservoir for storing water and hence energy until it is needed. Larger heads store more gravitational potential energy for the same amount of water so the reservoirs for overshot and backshot wheels tend to be smaller than for breast shot wheels.

Overshot and pitchback water wheels are suitable where there is a small stream with a height difference of more than 2 metres (6.5 ft), often in association with a small reservoir. Breastshot and undershot wheels can be used on rivers or high volume flows with large reservoirs.

Breastshot wheels are less efficient than overshot and backshot wheels but they can handle high flow rates and consequently high power. They are preferred for steady, high-volume flows such as are found on the Fall Line of the North American East Coast. Breastshot wheels are the most common type in the United States of America

A vertically mounted water wheel that is rotated by water entering buckets just past the top of the wheel is said to be overshot. The term is sometimes, erroneously, applied to backshot wheels, where the water goes down behind the wheel.

A typical overshot wheel has the water channeled to the wheel at the top and slightly beyond the axle. The water collects in the buckets on that side of the wheel, making it heavier than the other "empty" side. The weight turns the wheel, and the water flows out into the tail-water when the wheel rotates enough to invert the buckets. The overshot design is very efficient, it can achieve 90%,

Overshot wheels require a large head compared to other types of wheel which usually means significant investment in constructing the headrace. Sometimes the final approach of the water to the wheel is along a flume or penstock, which can be lengthy.

A backshot wheel (also called pitchback) is a variety of overshot wheel where the water is introduced just before the summit of the wheel. In many situations, it has the advantage that the bottom of the wheel is moving in the same direction as the water in the tailrace which makes it more efficient. It also performs better than an overshot wheel in flood conditions when the water level may submerge the bottom of the wheel. It will continue to rotate until the water in the wheel pit rises quite high on the wheel. This makes the technique particularly suitable for streams that experience significant variations in flow and reduces the size, complexity, and hence cost of the tailrace.

The direction of rotation of a backshot wheel is the same as that of a breastshot wheel but in other respects, it is very similar to the overshot wheel. See below.

Some wheels are overshot at the top and backshot at the bottom thereby potentially combining the best features of both types. The photograph shows an example at Finch Foundry in Devon, UK. The head race is the overhead timber structure and a branch to the left supplies water to the wheel. The water exits from under the wheel back into the stream.

A special type of overshot/backshot wheel is the reversible water wheel. This has two sets of blades or buckets running in opposite directions so that it can turn in either direction depending on which side the water is directed. Reversible wheels were used in the mining industry in order to power various means of ore conveyance. By changing the direction of the wheel, barrels or baskets of ore could be lifted up or lowered down a shaft or inclined plane. There was usually a cable drum or a chain basket on the axle of the wheel. It is essential that the wheel have braking equipment to be able to stop the wheel (known as a braking wheel). The oldest known drawing of a reversible water wheel was by Georgius Agricola and dates to 1556.

The Romans used waterwheels extensively in mining projects, with enormous Roman-era waterwheels found in places like modern-day Spain. They were reverse overshot water-wheels designed for dewatering deep underground mines.Vitruvius, including the reverse overshot water-wheel and the Archimedean screw. Many were found during modern mining at the copper mines at Rio Tinto in Spain, one system involving 16 such wheels stacked above one another so as to lift water about 80 feet from the mine sump. Part of such a wheel was found at Dolaucothi, a Roman gold mine in south Wales in the 1930s when the mine was briefly re-opened. It was found about 160 feet below the surface, so must have been part of a similar sequence as that discovered at Rio Tinto. It has recently been carbon dated to about 90 AD, and since the wood from which it was made is much older than the deep mine, it is likely that the deep workings were in operation perhaps 30–50 years after. It is clear from these examples of drainage wheels found in sealed underground galleries in widely separated locations that building water wheels was well within their capabilities, and such verticals water wheels commonly used for industrial purposes.

About the same time, the overshot wheel appears for the first time in a poem by Antipater of Thessalonica, which praises it as a labour-saving device (IX, 418.4–6).Lucretius (ca. 99–55 BC) who likens the rotation of the waterwheel to the motion of the stars on the firmament (V 516).central Gaul.Barbegal watermill complex a series of sixteen overshot wheels was fed by an artificial aqueduct, a proto-industrial grain factory which has been referred to as "the greatest known concentration of mechanical power in the ancient world".

The type of water wheel selected was dependent upon the location. Generally if only small volumes of water and high waterfalls were available a millwright would choose to use an overshot wheel. The decision was influenced by the fact that the buckets could catch and use even a small volume of water.

Overshot (and particularly backshot) wheels are the most efficient type; a backshot steel wheel can be more efficient (about 60%) than all but the most advanced and well-constructed turbines. In some situations an overshot wheel is preferable to a turbine.

The power is how fast that energy is delivered which is determined by the flow rate. It has been estimated that the ancient donkey or slave-powered quern of Rome made about one-half of a horsepower, the horizontal waterwheel creating slightly more than one-half of a horsepower, the undershot vertical waterwheel produced about three horsepower, and the medieval overshot waterwheel produced up to forty to sixty horsepower.

One major way to classify watermills is by wheel orientation (vertical or horizontal), one powered by a vertical waterwheel through a gear mechanism, and the other equipped with a horizontal waterwheel without such a mechanism. The former type can be further divided, depending on where the water hits the wheel paddles, into undershot, overshot, breastshot and pitchback (backshot or reverse shot) waterwheel mills. Another way to classify water mills is by an essential trait about their location: tide mills use the movement of the tide; ship mills are water mills onboard (and constituting) a ship.

There are two basic types of watermills, one powered by a vertical-waterwheel via a gear mechanism, and the other equipped with a horizontal-waterwheel without such a mechanism. The former type can be further divided, depending on where the water hits the wheel paddles, into undershot, overshot, breastshot and reverse shot waterwheel mills.

The Greeks invented the two main components of watermills, the waterwheel and toothed gearing, and used, along with the Romans, undershot, overshot and breastshot waterwheel mills.

Most watermills in Britain and the United States of America had a vertical waterwheel, one of four kinds: undershot, breast-shot, overshot and pitchback wheels. This vertical produced rotary motion around a horizontal axis, which could be used (with cams) to lift hammers in a forge, fulling stocks in a fulling mill and so on.

An inherent problem in the overshot mill is that it reverses the rotation of the wheel. If a miller wishes to convert a breastshot mill to an overshot wheel all the machinery in the mill has to be rebuilt to take account of the change in rotation. An alternative solution was the pitchback or backshot wheel. A launder was placed at the end of the flume on the headrace, this turned the direction of the water without much loss of energy, and the direction of rotation was maintained. Daniels Mill near Bewdley, Worcestershire is an example of a flour mill that originally used a breastshot wheel, but was converted to use a pitchback wheel. Today it operates as a breastshot mill.

Larger water wheels (usually overshot steel wheels) transmit the power from a toothed annular ring that is mounted near the outer edge of the wheel. This drives the machinery using a spur gear mounted on a shaft rather than taking power from the central axle. However, the basic mode of operation remains the same; gravity drives machinery through the motion of flowing water.

A different type of watermill is the tide mill. This mill might be of any kind, undershot, overshot or horizontal but it does not employ a river for its power source. Instead a mole or causeway is built across the mouth of a small bay. At low tide, gates in the mole are opened allowing the bay to fill with the incoming tide. At high tide the gates are closed, trapping the water inside. At a certain point a sluice gate in the mole can be opened allowing the draining water to drive a mill wheel or wheels. This is particularly effective in places where the tidal differential is very great, such as the Bay of Fundy in Canada where the tides can rise fifty feet, or the now derelict village of Tide Mills, East Sussex.Eling, Hampshire and at Woodbridge, Suffolk.

The origin of the technique itself may have started in Persia and spread to other parts of the world, according to the author, Hans E. Wulff, of The Traditional Crafts of Persia. However, it is all relatively obscured by history. In The Key to Weavingby Mary E. Black, she mentioned that one weaver, who was unable to find a legitimate definition of the technique thought that the name “overshot” was a derivative of the idea that “the last thread of one pattern block overshoots the first thread of the next pattern block.” I personally think it is because the pattern weft overshoots the ground warp and weft webbing.

Overshot gained popularity and a place in history during the turn of the 19th century in North America for coverlets. Coverlets are woven bedcovers, often placed as the topmost covering on the bed. A quote that I feel strengthens the craftsmanship and labor that goes into weaving an overshot coverlet is from The National Museum of the American Coverlet:

Though, popular in many states during the early to mid 19th centuries, the extensive development of overshot weaving as a form of design and expression was fostered in rural southern Appalachia. It remained a staple of hand-weavers in the region until the early 20th century. In New England, around 1875, the invention of the Jacquard loom, the success of chemical dyes and the evolution of creating milled yarns, changed the look of coverlets entirely. The designs woven in New England textile mills were predominantly pictorial and curvilinear. So, while the weavers of New England set down their shuttles in favor of complex imagery in their textiles, the weavers of Southern Appalachia continued to weave for at least another hundred years using single strand, hand spun, irregular wool yarn that was dyed with vegetable matter, by choice.

And, due to the nature of design, overshot can be woven on simpler four harness looms. This was a means for many weavers to explore this technique who may not have the financial means to a more complicated loom. With this type of patterning a blanket could be woven in narrower strips and then hand sewn together to cover larger beds. This allowed weavers to create complex patterns that spanned the entirety of the bed.

What makes overshot so incredibly interesting that it was fundamentally a development of American weavers looking to express themselves. Many of the traditional patterns have mysterious names such as “Maltese Cross”, “Liley of the West”, “Blooming Leaf of Mexico” and “Lee’s Surrender”. Although the names are curious, the patterns that were developed from the variations of four simple blocks are incredibly intricate and luxurious.

This is only the tip of the iceberg with regard to the history of this woven structure. If you are interested in learning more about the culture and meaning of overshot, check out these resources!

The National Museum of the American Coverlet- a museum located in Bedford, Pennsylvania that has an extensive collection of traditional and jacquard overshot coverlets. Great information online and they have a “Coverlet College” which is a weekend series of lectures to learn everything about the American coverlet. Check out their website - coverletmuseum.org

Textile Art of Southern Appalachia: The Quiet Work of Women – This was an exhibit that traveled from Lowell, Massachusetts, Morehead, Kentucky, Knoxville, Tennessee, Raleigh, North Carolina, and ended at the Royal Museum in Edinburgh, Scotland. The exhibit contained a large number of overshot coverlets and the personal histories of those who wove them. I learned of this exhibit through an article written by Kathryn Liebowitz for the 2001, June/July edition of the magazine “Art New England”. The book that accompanied the exhibit, written by Kathleen Curtis Wilson, contains some of the rich history of these weavers and the cloth they created. I have not personally read the book, but it is now on the top of my wish list, so when I do, you will be the first to know about it! The book is called Textile Art of Southern Appalachia: The Quiet Work of Women and I look forward to reading it.

This post is the third in a series introducing you to common weaving structures. We’ve already looked at plain weave and twill, and this time we’re going to dive into the magic of overshot weaves—a structure that’s very fun to make and creates exciting graphic patterns.

Overshot is a term commonly used to refer to a twill-based type of weaving structure. Perhaps more correctly termed "floatwork" (more on that later), these textiles have a distinctive construction made up of both a plain weave and pattern layer. Requiring two shuttles and at least four shafts, overshot textiles are built using two passes: one weaves a tabby layer and the other weaves a pattern layer, which overshoots or floats, above.

Readers in the United States and Canada may be familiar with overshot textiles through woven coverlets made by early Scottish and English settlers. Using this relatively simple technique, a local professional weaver with a four-shaft loom could easily make a near-infinite variety of equally beautiful and complex patterns. If you’d like to learn more about overshot coverlets and some of the traditions that settlers brought with them, please see my reading list at the bottom of this article!

As it is twill-based, overshot will be very familiar to 4 shaft weavers. It’s made up of a sequence of 2-thread repeats: 1-2, 2-3, 3-4, and 1-4. These sequences can be repeated any number of times to elongate and create lines, curves, and shapes. These 2-thread repeats are often referred to as blocks or threading repeats, IE: 1-2 = block 1/A, 2-3 = block 2/B.

There are three ways weft appears on the face of an overshot cloth: as a solid, half-tone, or blank. In the draft image I’ve shared here, you can see an example of each—the solid is in circled in blue, the half-tone in red, and the blank yellow. Pressing down the first treadle (shafts 1 and 2), for example, creates solid tones everywhere there are threads on shafts 1 and 2, half-tones where there is a 1 or 2 paired with 3 or 4, and nothing on the opposite block, shafts 3 and 4. Of course, there’s not really nothing—the thread is simply traveling on the back of the cloth, creating a reverse of what’s on the face.

Because overshot sequences are always made up of alternating shafts, plain weave can be woven by tying two treadles to lift or lower shafts 1-3 and 2-4. When I weave two-shuttle weaves like overshot, I generally put my tabby treadles to the right and treadle my pattern picks with my left foot and my tabby with my right. In the draft image I’ve shared above, I’ve omitted the tabby picks to make the overarching pattern clearer and easier to read. Below is a draft image that includes the tabby picks to show the structure of the fabric.

Traditional overshot coverlets used cotton or linen for warp and plain weave wefts, and wool pattern wefts—but there’s no rule saying you have to stick to that! In the two overshot patterns I’ve written for Gist, I used both Mallo and Beam as my pattern wefts.

In the Tidal Towels, a very simple overshot threading creates an undulating wave motif across the project. It’s easy and repetitive to thread, and since the overshot section is relatively short, it’s an easy way to get a feel for the technique.

The Bloom Table Squares are designed to introduce you to a slightly more complex threading—but in a short, easy-to-read motif. When I was a new weaver, one of the most challenging things was reading and keeping track of overshot threading and treadling—but I’ve tried to make it easy to practice through this narrow and quick project.

Overshot works best with a pattern weft that 2-4 times larger than your plain weave ground, but I haven’t always followed that rule, and I encourage you to sample and test your own wefts to see how they look! In the samples I wove for this article, I used 8/2 Un-Mercerized Cotton weaving yarn in Beige for my plain weave, and Duet in Rust, Mallo in Brick, and Beam in Blush for my pattern wefts.

The Bloom Table Squares are an excellent example of what weavers usually mean when they talk about traditional overshot or colonial overshot, but I prefer to use the term "floatwork" when talking about overshot. I learned this from the fantastic weaver and textile historian Deborah Livingston-Lowe of Upper Canada Weaving. Having researched the technique thoroughly for her MA thesis, Deborah found that the term "overshot" originated sometime in the 1930s and that historical records variably called these weaves "single coverlets’ or ‘shotover designs.’ Deborah settled on the term "floatwork" to speak about these textiles since it provides a more accurate description of what’s happening in the cloth, and it’s one that I’ve since adopted.

Overshot wheels are a type of waterwheel that can be built if there is a significant height drop in the river or body of water being used to move the wheel. Generally, these are built on the side of a hill as a drop of at least 4.5 meters.

The action of the water pushing against the wheels buckets or paddles develops torque on the axle but by directing the water at these paddles and buckets from different positions on the wheel the speed of rotation and its efficiency can be improved. The two most common types of waterwheel design is the “undershot waterwheel” and the “overshot waterwheel”.

The Overshot Water Wheel Design is the most common type of waterwheel design. The overshot waterwheel is more complicated in its construction and design than the previous undershot waterwheel as it uses buckets or small compartments to both catch and hold the water.

This type of water wheel uses gravity to improve output as well as the water itself, thus overshot waterwheels are much more efficient than undershot designs as almost all of the water and its weight is being used to produce output power. However as before, the waters energy is used only once to rotate the wheel, after which it flows away with the rest of the water.

Overshot waterwheels are suspended above a river or stream and are generally built on the sides of hills providing a water supply from above with a low head (the vertical distance between the water at the top and the river or stream below) of between 5-to-20 metres. A small dam or weir can be constructed and used to both channel and increase the speed of the water to the top of the wheel giving it more energy but it is the volume of water rather than its speed which helps rotate the wheel.

Generally, overshot waterwheels are built as large as possible to give the greatest possible head distance for the gravitational weight of the water to rotate the wheel. However, large diameter waterwheels are more complicated and expensive to construct due to the weight of the wheel and water.

Once the bucket is empty of water it continues around the rotating wheel until it gets back up to the top again ready to be filled with more water and the cycle repeats. One of the disadvantages of an overshot waterwheel design is that the water is only used once as it flows over the wheel.

The Pitchback Water Wheel Design is a variation on the previous overshot waterwheel as it also uses the gravitational weight of the water to help rotate the wheel, but it also uses the flow of the waste water below it to give an extra push. This type of waterwheel design uses a low head infeed system which provides the water near to the top of the wheel from a pentrough above.

Unlike the overshot waterwheel which channelled the water directly over the wheel causing it to rotate in the direction of the flow of the water, the pitchback waterwheel feeds the water vertically downwards through a funnel and into the bucket below causing the wheel to rotate in the opposite direction to the flow of the water above.

Just like the previous overshot waterwheel, the gravitational weight of the water in the buckets causes the wheel to rotate but in an anti-clockwise direction. As the angle of rotation nears the bottom of the wheel, the water trapped inside the buckets empties out below. As the empty bucket is attached to the wheel, it continues rotating with the wheel as before until it gets back up to the top again ready to be filled with more water and the cycle repeats.

The Breastshot Water Wheel Design is another vertically-mounted waterwheel design where the water enters the buckets about half way up at axle height, or just above it, and then flows out at the bottom in the direction of the wheels rotation. Generally, the breastshot waterwheel is used in situations were the head of water is insufficient to power an overshot or pitchback waterwheel design from above.

Breastshot waterwheels use about the same gravitational weight of the water to rotate the wheel but as the head height of the water is around half that of a typical overshot waterwheel, the buckets are a lot wider than previous waterwheel designs to increase the volume of the water caught in the buckets.

Wasted investment due to poor project performance — missed deadlines, overshot budgets, and scope creep, for example — declined to 9.4% from 11.4% in 2020.

Value is the first Lean principle, and it is defined as the right capability, at the right price, at the right time. Essentially, value is what the customer says, not what you may think.

Figure 4: A filter is defined by a pass-band, transition band, and stop band. The cut-off frequency (Fco) delineates the pass-band and transition band, and is usually defined at the 3dB attenuation point of the pass-band.

Type defines its shape and phase response in passband, transition band and stopband. There are some well-known classical filter types, most of them originating as analog versions like Butterworth, Bessel, Chebyshev, Elliptic, etc as shown in Figure 5.

If a fast-growing country like China accepted an emissions cap and then overshot it, they would have to purchase carbon credits on the international market.—

8613371530291

8613371530291