fishing overshot free sample

Open hole fishing is one of the most critical operations in drilling. It involves a lot of expertise and experience of the personnel. This VDO by Weatherford Fishing Services demonstrates you about the open hole fishing. This is highly recommended for you to watch it. Additionally, the full VDO transcript is provided.

Openhole fishing involves the removal of unwanted objects from the wheel bore. The objects can be tools, equipment and broken pieces of drill pipe, bits or tubulins. Openhole fishing begins following a Backoff in the drill string at or above the stock point of the fish in the wellbore leaving an accessible fish top.

The fish can be removed using special tools and techniques. A Scew-in sub is one of the most common fishing tools. Its modified pin can be used to catch an undamaged fish. The overshot tool because of its versatility is frequently used in fish recoveries. Its simple design includes a circulating and releasing action as well as a 360 degree catch of the fish. Normally the overshot or screw-in sub is connected to the bottom of the bumper sub and fishing jars on the fishing assembly. As the tool is lowered over the fish the top of the fish passes through the tool into the bowl. When the assembly is raised grapples engage the fish at a lower point and it is work free and pulled upward.

In a washed out hole use of a hydraulic Knuckle joint located above the overshot kicks out under pump pressure to increase the sweep of the overshot to facilitate capture of an allusive fish. When the severe wash out, a Wall hook guide run on the bottom of the overshot further improves the search and capture of the fish.

When the fish cannot be dislodged by pulling with the overshot a jarring assembly run in the fishing string can be activated to strike heavy blows either up or down on a stuck fish to free it. The down action is achieved with a Bumper jar; essentially a slip joint with a sliding stroke. The impact enhanced by the weight of drill collars above the Bumper jar results in a sharp blow with the fishing string. Dropping the string quickly produces a sharp downward blow on the fish. This jarring action is especially effective in freeing PC Pipe or a string that is stuck as a result of an upward pull.

In many cases a stuck fish will require a powerful upward jar to free it. Hydraulic fishing jars permit an upward impact. The impact produced by a Hydraulic jar depends on the amount of pull taken on the tool before it trips. As indicated earlier the impact of a Hydraulic jar is enhanced by the weight of Drill collars placed above the tool. A jar accelerator further intensifies the effect of a jar at any depth. It is especially effective in shaft fishing operations where elasticity present in longer drill strings is not available. The use of an accelerator also keeps the energy of the jar impact form being lost a mole.

Essentially Washover operation involve a pipe string that slips over the stuck fish allowing fluid to circulate in the annalist between the fish and the inner wall of the Washover pipe. Fluid under pressure flushes out debris cut lose by the rotary shoe run on the bottom of the Washover pipe. The washed over fish secured by an overshot or a screw-in sub and then be backed and removed to the surface.

Openhole fishing also involves the retrieval of Junk at the well bottom. Junk is defined as any unwanted material in the hole that hampers operations; such as, accidentally dropped tools, metal debris, parts of equipment including cones from drill bits. A commonly used retrieval tool is the Fishing magnet. Fishing magnets are especially cost effective for retrieving smaller fairish objects such as bit cones, slips and mill cuttings.

Open hole fishing is one of the most time consumed operation because it involves a lot of unknown down hole conditions. In order to have successful fishing operation, it is imperative to fully understand about the open hole fishing tool. The video training below provided by Weatherfor is considered as one of the best fishing operation video training. Additionally, the full video transcription is provided to help people understand this topic.

Open hole fishing involves the removal of unwanted objects from the wellbore. The objects can be tools, equipment, and broken pieces of drill, pipe, bits or tribunals. Open hole fishing begins following a backoff and a drill string at or above the stock point of the fish in the wellbore leaving an accessible fish top. The fish can be removed using special tools and techniques.

A screw-in sub is one of the most common fishing tools. Its modified pin can be used to catch an undamaged fish. The overshot tool because of its versatility is frequently used in fish recoveries. Its simple design included circulating and releasing action as well as a 360 degree catch of the fish.

Normally, the overshot or screw in sub is connected to the bottom of the bumper sub and fishing jars on the fishing assembly. As the tool is lowered over the fish, the top of the fish passes through the tool into the ball. When the assembly is raised, grapples engage the fish at a lower point and it is worked free and pulled upward. If the top of the fish is bad, twisted or broken, it should be dressed off to provided clean top so grapple can insecurity firmly. Dressing off is achieved with a skirted or hollow food mill. Several types of mills are available for this purpose and other jobs.

In a washed-out hole, use of a hydraulic knuckle joint located above the overshot kicks out under pump pressure to increase the sweep of the overshot to facilitate capture of an elusive fish. With a severe washout, a wall hook guide run on the bottom of the overshot, further improves the search and capture of the fish. When the fish cannot be dislodged by pulling with the overshot, a jarring assembly run in the fishing strain can be activated to strike heavy blows either up or down on a stock fish to freak. The down action is achieved with a bumper jar, essentially a slip joint with a sliding stroke. The impact, enhanced by the weight of drill collars above the bumper jar results in a sharp blow with the fishing string. Dropping the string quickly produces a sharp downward blow on the fish. This jarring action is especially effective in free e-seated pipe or a string that is stuck as a result of an upward blow.

The impact produced by hydraulic jar depends on the amount of pulled taken on the tour before it drips. As indicated earlier, the impact of a hydraulic jar is enhanced by the weight of drill collars placed above the tool. A jar accelerator further intensifies the effect of a jar at any depth. It is especially effective in shallow fishing operations where elasticity present in longer drill strings is not in any way. The use of an accelerator also keeps the energy of the jar impact from being lost up hole.

Essentially, washover operations involve a pipe string that slips over a stuck fish allowing fluid to circulate in the annulus between the fish in the inner wall of washover pipe. Fluid under pressure flushes out debris cut loos by the rotary shoe run on the bottom of the washover pipe. The washed over fish secured by an overshot or screw in sub and then he backed off and removed to the surface. The washover pipe selected requires an inside diameter large enough to accommodate the fish and an outside diameter they can rotate without sticking in the open hole and still allow circulation.

Open hole fishing also involves the retrieval of the junk at the well bottom. Junk is defined as any unwanted material in the hole that hampers operations such as accidentally dropped tools, metal debris and parts of equipment including cones from drill bits. A commonly used retrieval tool is the fishing magnet. Fishing magnets are especially cost effective for retrieving smaller ferrous objects such as bitcones, slips and mill cuttings. Permanent magnets have circulating ports around the outer edge so that fill and cuttings can be washed away exposing the junk for proper magnetic contact. Magnets are furnished with plush guides, lipped guides or mill guides which help in washing and securing the junk. The magnet is lowered to the well bottom while circulating and then pulled to the surface. This activity may be repeated until wellbore is cleared of all junks

Drilling tool fishing is probably every driller’s least favorite activity. But it happens. There are a huge number of tools available to fish almost anything out of the hole. For drill pipe and collars, there are overshots and spears — in many sizes for almost any job. But, when it comes to loose junk on the bottom of the hole, things get a little more interesting. It might be a loose bit, a wrench, a sledge hammer or tong dies. Anything that can fit in the hole will sooner or later end up on the bottom. I reckon it’s human nature, or Murphy’s law, but it happens.

Most commercial fishing tool companies have pretty sophisticated tools, such as reverse circulation junk baskets, and all kinds of well-engineered tools to do the job. But, sometimes, they are not quite what a customer needs. If the fish is large in relation to the hole size, such as a bit, a reverse basket will not pick it up because of the wall thickness. Something else is needed. Or, if the hole is just not worth the expense of using a commercial fishing company, a driller may opt to build his own fishing tool for the job.

This brings me to a tool that is often overlooked, but has been around forever and recovered a lot of junk in the hole: the poor-boy basket. Most fishing companies don’t push them because they are not fancy high-dollar tools that make great testimonials, but they work and can be built by the driller on location.

Last month, I wrote about jar bumpers. While not technically “fishing” tools, they may help a driller avoid a fishing job if the tools are slightly stuck. Of course, a true fishing job involves a drill string either badly stuck, or broken off the drill cable and lost down the hole. This month I talk about true fishing jobs and the tools needed to accomplish them. I find it best to discuss these things when we don’t have tools down the hole. We can take an objective look at what we might need before we need it.

If the first attempt at a fishing job fails, the job becomes 20 to 50 times more complicated. I have talked to drillers who got a tool string stuck and, through a series of errors, got their fishing string stuck too. I even knew one driller — who passed away quite a few years ago — who got his second fishing string stuck. He had the original drilling string, with two fishing strings on top of that. At that point, he abandoned the hole. He later changed to rotary drilling. He had a plan to rotary down alongside the stuck tools and retrieve them from the hole, but I think he passed away before he tried.

It may sound defeatist, but if the first or second try at fishing tools fails in a shallow domestic or commercial well, the smart move may be to abandon the job and start over. Yes, you have to buy new drilling tools, but you may save hours and days of time — and a fair amount of money. I know this goes against the makeup of the typical driller, but sometimes abandonment is the smart choice.

Extensive fishing operations can make sense for deeper, larger-diameter holes, but not always. A good driller once told me of a 1,000-foot rotary hole. The driller was running a down the hole hammer when he twisted off his drill pipe. Apparently, the wall of the drill pipe had worn thin. He invested a lot of time and money to get the pipe and, especially, the hammer back out. Eventually, he called it a lost cause and abandoned the hole, but he told me he wished he would have made the decision sooner.

If the first attempt at a fishing job fails, the job becomes 20 to 50 times more complicated. I have talked to drillers who got a tool string stuck and, through a series of errors, got their fishing string stuck too.

Your first consideration when you “go fishing”? A proper fishing string. A rope socket tops this string. For fishing, many veteran drillers prefer a solid socket to the swivel type used for normal drilling. With a solid socket, you fasten the fishing line directly to the socket with hot zinc (just as the drilling line fastens to the swivel of a drilling socket). Below the socket comes a drill stem. You can usually use a shorter stem than the one used in drilling operations. In my part of the country, the stem used in drilling will generally run from 12 to 18 feet in length. For fishing, I would recommend a stem 8 to 12 feet in length, although you can use a longer stem. You want a stem long enough to exert a jarring force strong enough to get the stuck tools loose, but you want to keep the combined weight of the fishing string and the drilling string within the rig’s lifting capacity.

The next part of the fishing string is very important: a set of fishing jars. Fishing jars are just like drilling jars except they have a longer stroke. Popular cable-tool rigs in my area have a short stroke of around 18 inches — the fishing stroke. On a rig like this, you would want fishing jars with a workable stroke of 24 inches at a bare minimum, and a 30-inch stroke might not be a bad idea. Even larger rigs will have a fishing stroke as short as 24 inches, so those 30-inch-stroke fishing jars will work.

Let me offer a word of caution. Faced with a fishing job, some drillers may resort to using a set of nearly worn-out drilling jars. While the length and stroke due to wear may work, resist this dangerous option. These older jars could break. A set of broken jars in any hole presents a huge problem.

Fishing for stuck cable tools can prove frustrating and, sometimes, very expensive. The best advice I can give? Avoid fishing at all costs. Sometimes, however, it cannot be avoided. If you, sadly, have a fishing job on your hands, think carefully about it before you send fishing tools down the hole. Next time, I will write about some of those many tools that grab the stuck string.

We have had a beautiful fall here in southern Michigan, but a lack of rain has left the ground parched. This, however, has helped the farmers harvest their soybeans and corn. Most all the leaves have fallen from the trees and a fierce wind a couple days ago blew them to wherever — sometimes into big piles. Most lawns are still green, though not growing at all. Until next time, continue to work hard, enjoy life and think carefully about any fishing job you have on a cable-tool rig.

I debated on where to go next, but at the end of the day the most widely used fishing tool has to be an overshot. Some will say why not a spear? Well if you must ask, always go with the strongest fishing tool you can run to catch the fish. And if you run a spear, never plug the I.D. of your fish by breaking it off. Done with that!

The info that follows has been taken from the manuals published on overshots. I realize that paper manuals are a thing of the past, yes, yes at one time fishing tool hands carried massive catalog brief cases full of reference material. Now you have the luxury of your laptop loaded with information. If you have never sat down and read an overshot manual, now might be a good time.

The overshot is highly versatile and efficient tool. There are several different types of overshots, however each overshot is designed to engage a specific size of tubing, pipe, coupling, tool joint, drill collar or smooth OD tool.

The original overshot was developed by Bowen Oil Tools, which is now part of NOV. One thing I will point out is that in the catalogs you will see more than one assembly number for a given OD of Overshot, this came about due to the two locations developing their own variations. I found this information on NOV’s website and thought it was interesting to share.

Bowen™ became a leader in innovation with the creation of the first overshot, the Series 150, in 1935. This tool set the standard for fishing equipment, and the quick acceptance of the tool assured the company partners that their business would be successful. The company continued to create new products, building a reputation for their well tool design and construction.

Currently there are several manufacturers of overshots, NOV (Bowen), Rubicon (Logan) and Applied Oil Tools (Gotco). These overshots are designated by a series number as follows:Series 10 - Sucker Rod Overshot

Overshots may be identified by one of the following, known as “type”:Full Strength (FS) - engineered to withstand all pulling, jarring and torsional strain

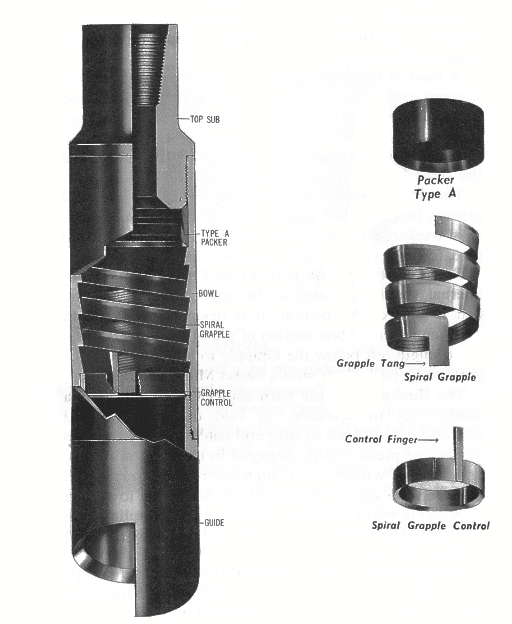

The basic overshot (from top down) consists of a top sub, a bowl, grapple, control, and a guide. In addition to the basic components, some overshots (Series 10 and 150) can be dressed with either a:Spiral grapple used if the fish diameter is near the maximum catch of the overshot, or a

The Series 150 Overshot features the ability to packoff on the fish. When the circulating packoff is not used, the fluid circulates down the drillpipe, aroundthe top outside of the fish, through the slip or grapple assembly, around the guide shoe and up the annulus.

When the circulating packoff is used, the annular space between the top outside of the fish and the inside of the lower part of the overshot is packed off, diverting the fluid flow down into the fish, making it easier to release and recover the fish. Packoffs usually are not high pressure devices but will often withstand sufficient pressure to establish circulation through the fish. Third party high pressure packoffs are available from various sources.

The extension can be installed between the top sub and the bowl of the Series 10, 70, and 150 overshots. It is used to extend the overshot bowl to:Allow the grapple to catch farther down on a fish that may be necked down at the top by having been pulled in two, or latched by an overshot and released several times, or to

A stop ring must be used where a fish OD reduces immediately below the catch area to allow the grapple to bite on full-size pipe.Example - catching a Hydril upset or EUE collar. If the upset of collar should pass completely through the grapple, the overshot may not be releasable.

The Series 10 Sucker Rod Overshot is designed to engage and recover sucker rods, couplings, and similar items from inside tubing strings.Basket grapples are recommended for fishing for hardened and ground boxes (Sucker Rod Box).

The Series 20 Sucker Rod Overshot is a short catch tool which provides a means for engaging the exposed portion of a fish too short to be engaged with a Series 10 overshot.Uses basket grapples only

The Series 70 Short Catch Overshot is designed to engage the exposed portion of a fish too short to engage with Series 150 overshots.Uses basket grapple only

The Series 150 Releasing and Circulating Overshot is used to engage, packoff, and retrieve twisted-off lost tubing, drillpipecoupling, tool joint, casing or other similar fish.

A right hand wicker grapple converts a normal right release overshot to left hand release. This grapple is used where you expect to apply excessive right hand torque to release a packer, safety joint, etc. Note: Overshot will have to be released by left hand rotation.

High Pressure Packoff Assemblies:The High Pressure Packoff Assembly is an accessory to the Series 150 Overshots. It is used when high pressure circulation to the fish is required. It consists of a packoff sub with packing and packing rings and is installed between the top sub and bowl of the overshot. By running the packoff sub above the bowl, this design prevents the application of high internal pressures to the overshot bowl. The design of the High Pressure Packoff Assembly allows pressures two to three times the standard overshot packoff to be applied to the fish.

This information comes directly from the NOV manual for the Wide Catch Overshot. This is probably the first and only change to this common tool I know of in my career.

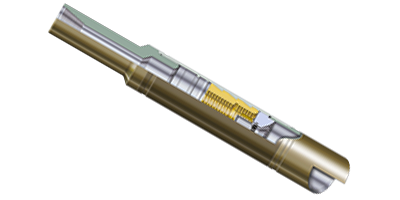

The Wide Catch Overshot provides the strongest tool available to externally engage, pack-off, and pull a fish that has been significantly worn. This tool has similar rugged design features and construction as the industry standard, Bowen Series 150 overshot, with the ability to interchange the Bottom Guide with the full range of existing components used with the standard Bowen Series 150 overshot.

In service, the Wide Catch Overshot (WCOS) takes a positive grip over a large area of fish and is capable of withstanding heavy pulling, torsion, and jarring strains without damage to the tools or the fish.

The WCOS has been designed to significantly increase the catch range of the OD of the fish to be caught, compared to the standard overshot. This enables a greater opportunity for a successful fishing operation in a reduced number of trips, thus reducing overall intervention costs for the operator. In addition to the large catch range, the WCOS has the ability to seal across very large extrusion gaps at both standard and high pressure and provide full circulation through the fish, should it be required.

Connections between the Top Sub/Bowl and Extension Sub have been designed to create a seal. This will prevent the connection from washing out should the overshot be required to be flowed through for a long period of time. In order to lock the Top Sub/Extension Sub to the Bowl from backing off during operation, set screws have become standard and will gall the threads should the connection break free.

The operation of all overshots is identical. The exception being that the Series 150 carries a packoff which provides circulation through the fish. First, determine that the overshot is properly assembled and dressed with the proper size grapple. Make up the overshot on the fishing string (normally it is run connected to the bottom of the bumper sub) and run it into the well. As the top of the fish is reached make sure circulation has been established to clear overshot ID of any plugging. Lower the overshot onto the top of the fish with no rotation at first. A 5,000 pound set down weight will be sufficient to engage the grapple. While lowering the overshot over the top of the fish watch for pressure build up, shut off pumps if any pressure build up is noticed. Should any back pressure be noticed, release the back pressure to allow the grapple to engage the fish. By elevating the string it can be determined, if the grapple went over and engaged the fish. If unable to work overshot over top of fish without rotation, then slowly rotate the fishing string to the right and gradually lower the overshot over the fish. Combined rotation and lowering over top of the fish are important to keep the grapple in the release position. This provides the maximum clearance between the grapple and fish. While lowering the overshot over the top of the fish, watch for torque build up and an increase in pump pressure. A pump pressure build up indicates the overshot has gone over the top of the fish thereby reducing the flow area. Stop rotation (continued rotation could dull the wickers of the grapple) enabling the grapple to set. Allow the right hand torque to slack out of the string and then pull on the string by elevating the string to set the grapple.

To release from the fish, bump down, then simultaneously rotate to the right and slowly elevate the fishing string. It is best to have a clean fishing top before running the overshot.

The present disclosure is directed to a fluid operated fishing tool and more particularly to one which has a soft contact or a soft set tool. It is especially adapted for use in grasping and holding a fish (an item to be retrieved) which does not necessarily have an easily gripped upper end such as a drilling motor stem. It will be discussed in the context of retrieving a typical elongate cylindrical device that may have a smooth upper end, and particularly one which does not have a spear head, or indeed, a fish of any shape.

The fishing tool of the present disclosure is a type of retrieval tool or overshot which reaches around and grasps the fish. It is constructed with a soft set or soft touch mechanism. The soft set mechanism is especially desirable in light of the varied size and shape of the upper end of the fish. The shape of the fish may be known, but in some instances, it is completely unknown. Likely, it will be an elongate device having no particular anticipated shape. Whatever the case, the present device is constructed to reach over the fish and surround the upper end of the fish. The fish can be shredded, twisted, bent, or otherwise parted. It can just as easily be an elongate cylindrical member which simply has no shoulders, no threads, no undercut shoulder, no serrations or knurled surface, etc. It can be smooth metal or rough with no limit. This soft set structure reaches over the fish and conforms to the fish regardless of its shape. The fish is gripped by a surrounding resilient sleeve which is on the interior of the present overshot device. This sleeve fits around the fish with some clearance. The sleeve is on the interior of a cylindrical housing. By the proper actuation of the present device, fluid pressure is applied behind the sleeve so that the sleeve expands radially. It expands inwardly to grasp the fish which is enclosed within the sleeve. The upper end of the sleeve is free floating on a sealed surface of a stem which construction allows the sleeve to contract. The sleeve floats to enable it to conform to the fish. By having the top free floating, the sleeve material is in compressed when a pull is exerted. This allows for more strength in the tool. Also, the weight of the fish tends to help set the sleeve when coming out of the hole. While the present apparatus is able to transfer a tremendous amount of pulling force to the fish, there is the possibility that the fish will not break free. In that instance, it is then desirable that the fish be released. The present apparatus includes a mechanism by which release is accomplished. The soft set tool is set by pumping incompressible fluid behind the sleeve. That space is later evacuated of high pressure fluid and the pressure is released by dropping a ball to seat on a pinned sleeve. A predetermined pressure will shear the pins and move the sleeve downward to open access ports to the pressure chamber. The same movement opens ports to the annular area to eliminate the problems of pulling a wet string. This enables release of the fish and permits relaxation of the sleeve. In that instance, the sleeve will relax and expand radially outwardly for restoration to its original shape, and thereby release the fish. This makes retrieval of the fishing tool something easily done when the fish cannot be readily moved.

In very general terms, the tool of the present disclosure threads to a tubing string which enables the tool to be lowered in a well where a fishing job is to be conducted, and extend over the fish. The tool incorporates an elongate cylindrical upper end which has two internal sleeves which are selectively plugged by dropping a specifically sized ball in the tubing string. Dropping the smaller ball initiates seating on the lower sleeve, shutting off circulation thru the tool and allowing a predetermined pressure to be applied in the pressure chamber to set the soft set grapple. The same pressure will shear the sleeve pins. This allows the sleeve to move downwardly to open ports to the annular area, thereby establishing circulation. The setting pressure is retained in the setting chamber by back pressure valves. This ball stops flow axially of the tool and diverts the flow into a passage in the sidewall. This passage is ordinarily closed when flow is axially through the tool, closure being accomplished by a spring actuated check valve. When the check valve is overpowered, it delivers fluid under pressure controlled at the wellhead so that pressure build-up occurs in a chamber within the tool. The chamber is concentric around and coextensive along a resilient sleeve which is forced to shrink radially inwardly by the surrounding fluid pressure. This pressure causes the resilient material of the sleeve to conform against the surface of the fish and to grasp the fish so that it is held. As will be detailed substantially with the development of the present disclosure, the fish is held so that axial pulling can occur, hopefully retrieving the fish in the fashion of an overshot retrieval too. In the event that the procedure requires later release of the fish, a larger ball is dropped in the tubing string and lands on a larger bore seat at the upper end of the tool. By increasing pump pressure at the wellhead, this sphere in conjunction with a moveable sleeve is moved downwardly, breaking a set of shear pins. When it moves, the sleeve closes off or blocks the lateral passage by which fluid is introduced around the sleeve. Moreover, this enables a passage to be actuated which voids the chamber around the sleeve so that any build-up of pressure in that area is relieved. This permits the sleeve then to relax. Moreover, the downward movement opens a passage above the ball seat to establish circulation. This eliminates the necessity of pulling a wet string, reducing mud spillage. In this type of operation, the tool also has fill-up valves at the bottom of the tool and air release valves at the top. Both of these valves close when adequate pressure is achieved in the setting chamber.

A fish is indicated in dotted line by the numeral 50. This is typical of the type of device retrieved through the use of the present invention. Moreover, it is illustrated with no underside shoulder which enables a grappling tool or overshot having a bowl wedging inwardly a set of collet fingers with serrations to grasp the fish. Also, the fish may or may not have a conventional cylindrical shape, and the fish may or may not be smooth. Here, it will simply be assumed that the fish is difficult to grasp because it is an elongate member such as a pipe without a cylindrical shape. The resilient sleeve 48 is positioned about the fish by stabbing the fish into the soft set overshot 10 of this disclosure. At the juncture, no particular grip has been accomplished. The stabbing action can occur while drilling fluid is circulated downwardly through the passage 41 shown in FIG. 1B and flows over the fish to assure easy nesting of the fish in the sleeve 48. As shown now in FIG. 1C, the sleeve 48 is the primary component which surrounds and grasps the fish. To be sure, the outer body 38 extends around and below the fish, but it does not engage the fish in the sense of grasping it. The outer body or mandrel 38 threads to a bowl 51 which has an inner tapered face or surface 52. This connects with an enlarged skirt 53 which enables the device to surround part or most of the fish. The fish is aligned in the bowl 51 and is forced upwardly so that it registers in the resilient sleeve 48. The fish is permitted to stab as deeply as possible into the soft set overshot until it shoulders against the downwardly facing shoulder 54, better shown in FIG. 1B as part of the inner mandrel 36.

Assume that a fish has been registered within the soft set overshot 10. Assume that fluid has been pumped through the tubing string from the surface and that the operator is then ready to retrieve the fish. The ball or sphere 29 is dropped in the mud flow and is delivered through the tubing string and ultimately lands as illustrated in FIG. 1A. Prior to that, fluid flow was down through the tool 10 so that the interior and exterior of the tool were at a common pressure. At that juncture, the tool is not set. When the sphere 29 lands at the illustrated location shown in FIG. 1A, continual pumping through the tubing string results in an increase in flow into the passage 20 shown in FIG. 1A, flowing downwardly past the check valve 21 and filling the annular chamber 22. It flows downwardly through the passages 39 to fill the annular chamber 40 shown in FIG. 1B. Any air that might have been captured in that area bubbles to the top and escapes through the bleed valve 23 provided for that purpose. When drilling fluid starts flowing in that area, the bleed valve element 23 closes, thereby capturing incompressible fluid in that chamber so that squeezing can occur. As the pressure at the wellhead is then increased, the increase in pressure is observed in the annular chamber 40 on the exterior of the resilient sleeve 48. Contrasting that sleeve in the relaxed state in FIG. 1B, it will be observed in FIG. 3 to expand, but the expansion forces the resilient material radially inwardly in response to pressure so that it grasps the fish and engages the fish 50 by taking on the shape of the fish. The setting pressure is sufficient to develop the force necessary to shear the pins and allow the sleeve 27 to move downward. The downward motion will expose the drain holes 28 to dump the fluid in the string so that the fish may be retrieved without pulling a wet string. Since the resilient sleeve will set around the fish, and the ball is in place atop the sleeve, the valve controlled passage 32 relieves the trapped pressure fluid caused by the downward travel of the sleeve 27. The fish is gripped around a very large portion of its area, and in particular that portion in registry with the sleeve so that the fish is firmly and tightly held. Moreover, the resilient sleeve, now in this gripping shape, is able to impart a lifting force to the fish. A pull is taken on the tubing string and the soft set overshot 10 is then raised, and this of course raises the fish 50 if it will break free. In the ordinary circumstance, it will break free and is retrieved, held snugly and firmly in the resilient sleeve as shown in FIG.3 of the drawings. Assuming this is successfully done, the tubing string is retrieved to the surface along with the soft set overshot 10 and the fish 50. The grip of the sleeve on the fish is enhanced by reaction of the resilient material holding tighter as it is pulled. The results from the tendency of the resilient sleeve to tighten around the fish when the tool 10 is pulled.

8613371530291

8613371530291