overshot bite manufacturer

As an overpull is applied to the tool, case hardened grapple teeth bite into the fish enabling it to be retrieved. The tool can be released from the fish by flowing through the tool.

The Coil Solutions Overshots are used to engage and pull a fish from the well bore. It uses a grapple to bite into the outside of the fish and releases by following through a predetermined rate to disengage the grapple. The tool comes with a range of grapples to accommodate various fish sizes.

I debated on where to go next, but at the end of the day the most widely used fishing tool has to be an overshot. Some will say why not a spear? Well if you must ask, always go with the strongest fishing tool you can run to catch the fish. And if you run a spear, never plug the I.D. of your fish by breaking it off. Done with that!

The info that follows has been taken from the manuals published on overshots. I realize that paper manuals are a thing of the past, yes, yes at one time fishing tool hands carried massive catalog brief cases full of reference material. Now you have the luxury of your laptop loaded with information. If you have never sat down and read an overshot manual, now might be a good time.

The overshot is highly versatile and efficient tool. There are several different types of overshots, however each overshot is designed to engage a specific size of tubing, pipe, coupling, tool joint, drill collar or smooth OD tool.

The original overshot was developed by Bowen Oil Tools, which is now part of NOV. One thing I will point out is that in the catalogs you will see more than one assembly number for a given OD of Overshot, this came about due to the two locations developing their own variations. I found this information on NOV’s website and thought it was interesting to share.

Bowen™ became a leader in innovation with the creation of the first overshot, the Series 150, in 1935. This tool set the standard for fishing equipment, and the quick acceptance of the tool assured the company partners that their business would be successful. The company continued to create new products, building a reputation for their well tool design and construction.

Currently there are several manufacturers of overshots, NOV (Bowen), Rubicon (Logan) and Applied Oil Tools (Gotco). These overshots are designated by a series number as follows:Series 10 - Sucker Rod Overshot

Overshots may be identified by one of the following, known as “type”:Full Strength (FS) - engineered to withstand all pulling, jarring and torsional strain

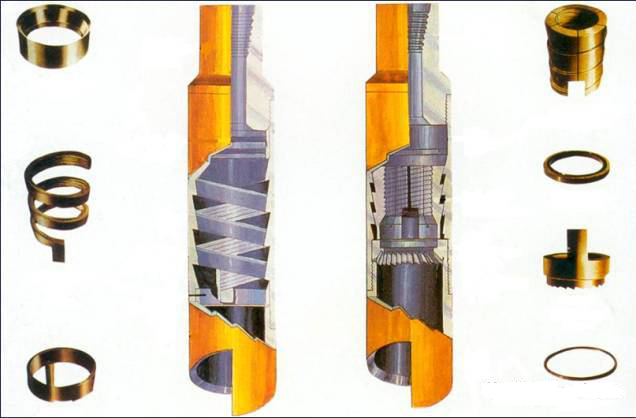

The basic overshot (from top down) consists of a top sub, a bowl, grapple, control, and a guide. In addition to the basic components, some overshots (Series 10 and 150) can be dressed with either a:Spiral grapple used if the fish diameter is near the maximum catch of the overshot, or a

The Series 150 Overshot features the ability to packoff on the fish. When the circulating packoff is not used, the fluid circulates down the drillpipe, aroundthe top outside of the fish, through the slip or grapple assembly, around the guide shoe and up the annulus.

When the circulating packoff is used, the annular space between the top outside of the fish and the inside of the lower part of the overshot is packed off, diverting the fluid flow down into the fish, making it easier to release and recover the fish. Packoffs usually are not high pressure devices but will often withstand sufficient pressure to establish circulation through the fish. Third party high pressure packoffs are available from various sources.

The extension can be installed between the top sub and the bowl of the Series 10, 70, and 150 overshots. It is used to extend the overshot bowl to:Allow the grapple to catch farther down on a fish that may be necked down at the top by having been pulled in two, or latched by an overshot and released several times, or to

A stop ring must be used where a fish OD reduces immediately below the catch area to allow the grapple to bite on full-size pipe.Example - catching a Hydril upset or EUE collar. If the upset of collar should pass completely through the grapple, the overshot may not be releasable.

The Series 10 Sucker Rod Overshot is designed to engage and recover sucker rods, couplings, and similar items from inside tubing strings.Basket grapples are recommended for fishing for hardened and ground boxes (Sucker Rod Box).

The Series 20 Sucker Rod Overshot is a short catch tool which provides a means for engaging the exposed portion of a fish too short to be engaged with a Series 10 overshot.Uses basket grapples only

The Series 70 Short Catch Overshot is designed to engage the exposed portion of a fish too short to engage with Series 150 overshots.Uses basket grapple only

The Series 150 Releasing and Circulating Overshot is used to engage, packoff, and retrieve twisted-off lost tubing, drillpipecoupling, tool joint, casing or other similar fish.

A right hand wicker grapple converts a normal right release overshot to left hand release. This grapple is used where you expect to apply excessive right hand torque to release a packer, safety joint, etc. Note: Overshot will have to be released by left hand rotation.

High Pressure Packoff Assemblies:The High Pressure Packoff Assembly is an accessory to the Series 150 Overshots. It is used when high pressure circulation to the fish is required. It consists of a packoff sub with packing and packing rings and is installed between the top sub and bowl of the overshot. By running the packoff sub above the bowl, this design prevents the application of high internal pressures to the overshot bowl. The design of the High Pressure Packoff Assembly allows pressures two to three times the standard overshot packoff to be applied to the fish.

This information comes directly from the NOV manual for the Wide Catch Overshot. This is probably the first and only change to this common tool I know of in my career.

The Wide Catch Overshot provides the strongest tool available to externally engage, pack-off, and pull a fish that has been significantly worn. This tool has similar rugged design features and construction as the industry standard, Bowen Series 150 overshot, with the ability to interchange the Bottom Guide with the full range of existing components used with the standard Bowen Series 150 overshot.

In service, the Wide Catch Overshot (WCOS) takes a positive grip over a large area of fish and is capable of withstanding heavy pulling, torsion, and jarring strains without damage to the tools or the fish.

The WCOS has been designed to significantly increase the catch range of the OD of the fish to be caught, compared to the standard overshot. This enables a greater opportunity for a successful fishing operation in a reduced number of trips, thus reducing overall intervention costs for the operator. In addition to the large catch range, the WCOS has the ability to seal across very large extrusion gaps at both standard and high pressure and provide full circulation through the fish, should it be required.

Connections between the Top Sub/Bowl and Extension Sub have been designed to create a seal. This will prevent the connection from washing out should the overshot be required to be flowed through for a long period of time. In order to lock the Top Sub/Extension Sub to the Bowl from backing off during operation, set screws have become standard and will gall the threads should the connection break free.

The operation of all overshots is identical. The exception being that the Series 150 carries a packoff which provides circulation through the fish. First, determine that the overshot is properly assembled and dressed with the proper size grapple. Make up the overshot on the fishing string (normally it is run connected to the bottom of the bumper sub) and run it into the well. As the top of the fish is reached make sure circulation has been established to clear overshot ID of any plugging. Lower the overshot onto the top of the fish with no rotation at first. A 5,000 pound set down weight will be sufficient to engage the grapple. While lowering the overshot over the top of the fish watch for pressure build up, shut off pumps if any pressure build up is noticed. Should any back pressure be noticed, release the back pressure to allow the grapple to engage the fish. By elevating the string it can be determined, if the grapple went over and engaged the fish. If unable to work overshot over top of fish without rotation, then slowly rotate the fishing string to the right and gradually lower the overshot over the fish. Combined rotation and lowering over top of the fish are important to keep the grapple in the release position. This provides the maximum clearance between the grapple and fish. While lowering the overshot over the top of the fish, watch for torque build up and an increase in pump pressure. A pump pressure build up indicates the overshot has gone over the top of the fish thereby reducing the flow area. Stop rotation (continued rotation could dull the wickers of the grapple) enabling the grapple to set. Allow the right hand torque to slack out of the string and then pull on the string by elevating the string to set the grapple.

To release from the fish, bump down, then simultaneously rotate to the right and slowly elevate the fishing string. It is best to have a clean fishing top before running the overshot.

Overshot sockets are useful for retrieving hardened couplings, which resist capture by ordinary wickered slips. They employ a lower slip unit that opens as it passes over the coupling, then closes below the coupling to firmly grip the rod string.

Our Type B slip socket is a reliable, economic answer to fishing jobs for rod body breaks, pin shoulders or threads, boxes, non-hardened couplings, and polished rods. All slips are heat treated, quenched and tempered to ensure a positive bite and long service life.

Intraoral devices (IODs) are widely used to minimize setup uncertainty of the tongue and reduce the dose of the OC and tongue. In clinical practice, tongue depressors or bite blocks, mainly those that press the entire tongue, have been commonly used as IODs in bilateral HN RT [11–13]. However, these techniques are less effective when applying RT for unilateral HNCs, especially OC and tonsil cancers. Forced displacement of the tongue from the target using IODs is an effective and reliable approach to minimize the radiation dose to the tongue in unilateral HN RT using either IMRT or IMPT. For this reason, there is a great need for customized IOD in RT for HNC because of the anatomical complexity of the HN region. There have been a few reports regarding the effectiveness of custom-made mouthpieces as tongue depressors and elevators for carbon-ion RT [14–16]. However, no studies have investigated whether 3D-printed semi-customized IODs can be used to displace the tongue laterally from the target volume in unilateral HN IMPT. A unique, semi-customized intraoral tongue displacement device (SCTDD) treated with helical tomotherapy (HT) was previously developed and showed a significant decrease in the radiation dose to the tongue compared with a standard mouthpiece (SMP) in HT for OC and tonsil cancer [17]. Most HNCs are candidates for IMRT or IMPT alone or in combination [11]. Most centers use the same IODs for both proton and photon therapy. Therefore, it is very important to evaluate the usefulness and dosimetric effect of IODs in IMPT because proton beams behave completely differently from megavoltage photon beams [18, 19].

We designed and developed a unique patient-specific intraoral device, the scTDD, using a 3D printer (3DP) for use in patients with unilateral HNC (Figure 1). A detailed description of the SCTDD has been previously published [17]. Briefly, to reduce the radiation dose to the tongue, an SCTDD was designed to displace the tongue to the contralateral side of the target. In terms of functionality, the scTDD consists of an airway, tongue displacer, and tongue position verification window. When the patient bites the scTDD and sticks out his tongue until the tongue tip touches the tongue position verification window, the tongue is naturally displaced along the guide groove of the displacer to the contralateral side of the target (blue dotted arrows in Figure 1). The patient can breathe comfortably during RT through the airway, and the radiation therapist can simply check the reproducibility of the patient’s tongue-tip position through the verification window during the RT session. The two connectors were designed to attach and secure to the thermoplastic immobilization mask to improve the reproducibility of the patient setup. To ensure that every patient’s tongue would fit in the device and account for the variety of jaw-opening dimensions that naturally occur, we fabricated 16 different sizes of the SCTDD with varying combinations of thicknesses (5–20 mm, in 5 mm increments) and lengths (40–70 mm, in 10 mm increments). The scTDD was printed using a fused deposition modeling (FDM) 3DP (3DISON Multi, Rokit, Korea) with a biocompatible 3DP material (Kitchen and Deco, Rokit, Korea). Printing was performed at an extruder temperature of 260°C, a layer height of 0.3 mm, and infill of 100% at a printing speed of 60 mm/s. The manufacturing process using 3DP is quite similar to that reported in previous studies [17, 22].

28. Huang Y-M, Lee J-C, Chu C-M, Tai H-C, Hou T-C, Chen F, et al. Three-Dimensional Printed Silicone Bite Blocks for Radiotherapy of Head and Neck Cancer-A Preliminary Study. Appl Sci (2020) 10(5):1688. doi:10.3390/app10051688

For those of you not familiar with the Ice-Age Atlantic crossing hypothesis, basically the idea is that during the Last Glacial Maximum (at approx. 26.500-19.000 years ago) glacial ice build up in the north Atlantic allowed European populations to cross over to North America and to colonize this virgin territory. The archaeological “cultures” typically cited in relationship to this hypothesis are Clovis in North America and the Solutrean in Western Europe. In particular, apparent similarities in the manufacture of bifacial tools between these two archaeological entities, and their reported use of overshot flaking (flakes that travel across the face of a tool to remove part of the opposing margin) to thin bifaces, have been frequently used to argue for their being a connection between Western Europe and the first peopling of the Americas. A basic introduction to the debate can be found here

In recent years considerable genetic, archaeological and paleoanthropological evidence has accrued suggesting that the first human societies in North America came from Asia, not Europe. Never the less, this debate still continues in the academic arena and 2013/2014 has thus far been a particularly productive period for publications on the topic utilizing experimental research to discuss the merits of the Ice-Age Atlantic crossing hypothesis. Three recent publications are of particular interest for those interested in the role that experimental archaeology can play in major debates such as this. The first of these contains experimental data designed to test the effectiveness of overshot flaking in thinning bifaces:

Eren et al’s results suggest that overshot flakes are by products of a general biface thinning technique and in and of themselves are not very reliable or optimal at thinning bifaces. This conclusion seems to suggest that Solutrean and Clovis bifaces were produced using similar, simple, biface thinning techniques that resulted in occasional, accidental, overshot flakes. The article also contains a discussion of the existing archaeological evidence for overshot flaking in Clovis assemblages, not much, and the lack of comparable data in Solutrean assemblages.

Lohse, J.C., Collins, M.B., Bradley, B., 2014. Controlled overshot flaking: a response to Eren, Patten, O’Brien, and Meltzer. Lithic Technology 39, 46-54.

Eren, M.I., Patten, R.J., O’Brien, M.J., Meltzer, D.J., 2014. More on the rumour of “intentional overshot flaking” and the purported Ice-Age Atlantic crossing. Lithic Technology 39, 55-63.

Buying show or breeding stock under eight months of age can be a gamble. Skyes are very slow in developing, reaching maturity at about three years of age. Correct ear carriage and mouths can be especially difficult to determine before five or six months. Both types of ear carriage may appear in the same litter. Prick ears, if up by six months of age, usually remain so. Overshot or undershot mouths are a serious fault; however, a slightly overshot bite of the puppy teeth might correct itself when the permanent teeth come in. Look for a long body; short, sturdy legs, a tail not carried constantly above the topline; good length of head, neck and muzzle in proportion to the overall dog; dark eyes; and a double coat. Between three and five months there might be an abundance of soft puppy coat, but eventually there should be the beginnings of a straight overcoat growing out which on maturity will cover the undercoat. A coat that is predominately fluffy or curly is a major fault.

8613371530291

8613371530291