overshot card punch factory

If you’ve been reading my articles for any length of time, you probably know I load a lot of shotgun shells using Lyman and other published data. Over the years I’ve also developed a large number of custom loads, many of which require filler wads or overshot cards to get the correct shot column and a good crimp. Although these aren’t the most expensive components on the market, they still add up, particularly if you need several per shell. To make matters worse, they’re often difficult to find, particularly if your local gun store stops stocking the brands you’re accustomed to.

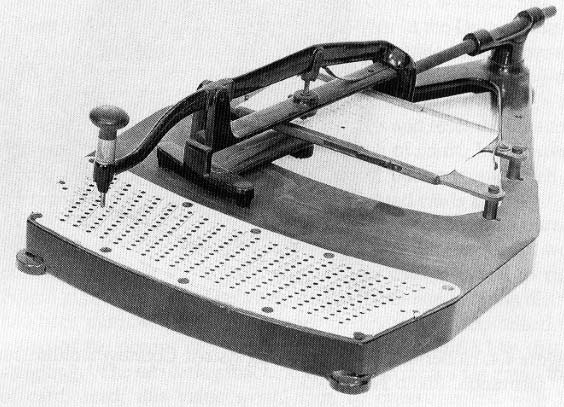

With this in mind I’ve designed and manufactured my own custom punch for producing 12 gauge filler wads and overshot cards. The model shown in the video above represents my prototype, which I’ve been using and testing for quite a while now.

Beginning with construction you’ll note it’s composed of just two parts; a die and punch. The die is made from stainless steel so that it won’t rust or corrode, while the punch is hardened tool steel that’s rigid enough to remain perfectly straight, and maintain an edge.

I also specifically designed this punch to fit in standard Lee reloading presses to help keep the cost low, and better utilize the equipment I’ve already got.

To install this tool, we simply insert the punch into the press’s ram, raising it up to it’s maximum height. Next we’ll thread the die in place overtop; this helps keep things aligned properly.

Operation is likewise extremely simple. If you check out the video above, you’ll see there’s a slot cut in the side to allow a multitude of different materials to be fed. So far I’ve used cardboard and vegetable fiber, in the future I’ll likely try cork as well.

With the material in place it’s a simple matter of operating the press handle, and punching filler wads. Each one comes out the exact internal diameter of a standard 12 gauge shotshell wad. If I need to produce a lot and don’t want to make a mess, I just place a margarine container with a hole in the bottom onto the nozzle at the top of the die, and punch as many as I need.

With a good supply of these on hand, it’s no trouble at all to customize my shot columns by placing them above or below my shot or slugs. Likewise, if I’ve got a difficult load to crimp well, like low-volume birdshot or roundball slugs, adding one to the top as an overshot card makes things a snap.

I’m really happy with how my punch turned out, and already working on designs for a 20G model. If things go well I may try some others like a 410, 16 or 28 gauge.

Purely by accident I discovered what for me is the best backing for punching wads. We built our deck from Timber-Tek, (I think that"s the right name). Consequently we had left over ends and butts just as if it was built of wood. I couldn"t find my piece of industrial belting I had used for years and got to examining a piece of the deck material. Seemed little hard to me but figured I didn"t have anything to lose so I "gave it a whack" with my punch and a florist box. Doggone stuff works great and didn"t dull the punch at all, which I thought it would do. Been using it ever since and have yet to sharpen a punch. What we used has one side in wood grain and the back side is smooth.

Place an overshot card on top of the shot charge just before crimping to improve overall crimp quality and seal in small shot and/or buffer. Excellent for use with BPI Roll Crimpers.

Our testing lab has proven that poor crimps can alter the performance of an otherwise good load. Overshot cards always produce better, more consistent crimps and this consistency is demonstrated in the standard deviation of loads in our lab. Our ballistic lab recommends overshot cards for better crimps in all loads.

Clear Overshot Disks(either plain or printed with shot size) are also offered for great roll crimping options. See pictures in Additional Images or click on this link.

Shotshell size selection: Use the same size gauge as your hull. Smaller diameter cards also work if your particular size is out of stock. For example, a 20ga overshot card works in a 16-gauge shotshell and so on.

While reloading shot shells and using roll crimps, overshot cards are placed on top of the shot/buffer media to keep everything in the shell. ...Why buy them when you can print them for about 2 cents each?

This is an overshot/wad card cutting die. Insert this die upside down inside your press using a L-N-L bushing adapter. I"ve made provisions for adding a metal washer or other insert to beef up the cutting area. Reem the metal insert to 18.67mm.

This one is an overshot waterwheel, printed as a flat pack then glued together. ...I have included 2 versions of the paddles a single piece on and a 3 piece on that can be printed flat

This one is an overshot waterwheel, printed as a flat pack then glued together. ...I have included 2 versions of the paddles a single piece on and a 3 piece on that can be printed flat

Overshot water wheels In an overshot water wheel the mill race brings the water to the top of the wheel, where it strikes the paddles or buckets and turns the wheel. This is more efficient because as well as the force of the flowing water, the...

12g (12 gauge) Template for cutting out Overshot Cards for Shotgun Rollcrimp Shot Shells If you like my models please consider supporting me on Patreon : https://www.patreon.com/bigmrtong

Friend wanted to know if I could make business cards for him. After some trial and error this what he got. ...Of corse scaled down to .3 so it will be about the size of your palm.

http://www.thingiverse.com/apps/customizer/run?thing_id=66327 Instructions Using the following options: bottom_text_rotation = 0 Move_Image_Left_Right = 30 card_type = 56 top_text_rotation = 0 build_plate_selector = 3 bottom_text_label =...

Sometimes what you do can"t be put on a business card. Maybe you design custom Oilfield Software for fluid management. Maybe you are a photographer or graphic design artist. Perhaps you write code or film porn. Any way it goes a few samples of your...

Wanted a case for business cards. ...Prints quickly on mk MK2s. Fusion 360. I suggest you slightly size the top up a hair so its a snugger fit. 85mmx55mm business card.

http://www.thingiverse.com/apps/customizer/run?thing_id=66327 Instructions Using the following options: Move_Bottom_Text_Up_Down = 43 build_plate_manual_y = 100 build_plate_manual_x = 100 card_type = 71.1 Move_Image_Up_Down = 40 card_count = 40...

Summary Sometimes what you do can"t be put on a business card. Maybe you design custom Oilfield Software for fluid management. Maybe you are a photographer or graphic design artist. Perhaps you write code or film porn. Any way it goes a few samples...

Sometimes what you do can"t be put on a business card. Maybe you design custom Oilfield Software for fluid management. Maybe you are a photographer or graphic design artist. Perhaps you write code or film porn. Any way it goes a few samples of your...

Place an overshot card on top of the shot charge just before crimping to improve overall crimp quality and seal in small shot and/or buffer. Excellent for use with BPI Roll Crimpers.

Our testing lab has proven that poor crimps can alter the performance of an otherwise good load. Overshot cards always produce better, more consistent crimps and this consistency is demonstrated in the standard deviation of loads in our lab. Our ballistic lab recommends overshot cards for better crimps in all loads.

Clear Overshot Disks(either plain or printed with shot size) are also offered for great roll crimping options. See pictures in Additional Images or click on this link.

Shotshell size selection: Use the same size gauge as your hull. Smaller diameter cards also work if your particular size is out of stock. For example, a 20ga overshot card works in a 16-gauge shotshell and so on.

Place an overshot card on top of the shot charge just before crimping to improve overall crimp quality and seal in small shot and/or buffer. Excellent for use with BPI Roll Crimpers.

Our testing lab has proven that poor crimps can alter the performance of an otherwise good load. Overshot cards always produce better, more consistent crimps and this consistency is demonstrated in the standard deviation of loads in our lab. Our ballistic lab recommends overshot cards for better crimps in all loads.

Clear Overshot Disks(either plain or printed with shot size) are also offered for great roll crimping options. See pictures in Additional Images or click on this link.

Shotshell size selection:Use the same size gauge as your hull. Smaller diameter cards also work if your particular size is out of stock. For example, a 20ga overshot card works in a 16-gauge shotshell and so on.

We do accept gift cards, but for security measures, some gift card sellers require the recipient to activate the card before it can be used. Though stores often activate gift cards at the cash register, online gift card sellers generally require the recipient to activate the card once it is received in the mail or via email. If your gift card does not work online, check to see if it needs to be registered before use. Registration usually involves linking a name and billing address to the prepaid card. Though you generally are not required to register a gift card in order to use it in stores or restaurants, the process is important if you intend to use the gift card online.

Custom Shop shotshell loads use high-quality plastic hulls built to the needs of specific gauges. Colors are the same as standard Federal shotshell ammunition: Brown for 10 gauge, purple for 16 gauge, yellow for 20 gauge and Burgundy (red) for 12 gauge, 28 gauge and .410. Hulls have the length and payload information printed using a high-quality Apex printer, not a print stamp that can wear off. Wads and over-powder or over-shot cards (when appropriate) are the best available. Some loads feature FLITECONTROL wads while others might feature standard wads, depending on gauge and other criteria. Card materials depend on availability for each specific gauge. Some cards might be plain and others might be clear with Federal branding.

My brass uses large pistol primers. I made a deprimer punch that just fits inside the case and I use a hammer to knock the old primer out. I made a holder with recess for the case head and a hole for the spent primer. Then I made a plug to support the primer pocket inside while pushing the shell down on a new primer which I just rest on a flat aluminum plate under a small arbor press. I never resize and push the wads down with a piece of wooden dowel. I still use water glass, (stop leak from Wal-Mart), to hold the over-shot card in.

Hi Roy. I have a question for you about the height of the wad column and shot. I see that on your shells the over shot card appears to be about 3/8" below the mouth of the hull. Is that because that where top of the shot happened to be or did you choose to use a total wad height that would terminate that deep in the hull?

I"ve got a 12 gauge muzzleloading shotgun that I"ve hunted with for over 30 years. I use a 3/4" hole punch for making wads from cardboard. Thin cardboard like cereal boxes for the overshot and thick cardboard boxes (with the corrugated inner layer) for overpowder wads (I use two of those for light loads and three for heavy loads). The .750" wads are a nice tight fit in the 12 gauge barrels. Seems to me like they would also work in a brass 12 gauge shotshell.

Hi Roy. I have a question for you about the height of the wad column and shot. I see that on your shells the over shot card appears to be about 3/8" below the mouth of the hull. Is that because that where top of the shot happened to be or did you choose to use a total wad height that would terminate that deep in the hull?

You can buy a "gasket" punch, a "cobbler"s" punch, a "shoemaker"s" punch, a "leather" punch, a "craft" punch, a "saddlemaker"s" punch, or an "arch" punch. ebay has them:

Long ago and far away I had a Lee hammer and tong shotshell loader. This was in 20 ga and it worked quite well for dealing with the 20g a. If I recall the wads I used were Herter"s, and eventually I made or modified a punch to suit. These were used w/ smokeless powder and worked vey well, in both an Ithaca pump and a O/U. Keep them shiny and you dont loose them, the Ithica put the empties at your feet.

8613371530291

8613371530291