overshot mill factory

This article is about a type of structure. For other locational uses, see Milldam. For details of the technologies, see Water wheel. For further details of the technologies, see Mill machinery. For other uses, see Water Mill.

A watermill or water mill is a mill that uses hydropower. It is a structure that uses a water wheel or water turbine to drive a mechanical process such as milling (grinding), rolling, or hammering. Such processes are needed in the production of many material goods, including flour, lumber, paper, textiles, and many metal products. These watermills may comprise gristmills, sawmills, paper mills, textile mills, hammermills, trip hammering mills, rolling mills, wire drawing mills.

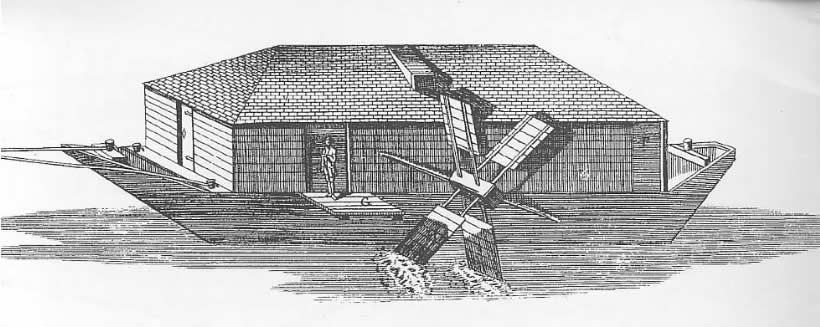

One major way to classify watermills is by wheel orientation (vertical or horizontal), one powered by a vertical waterwheel through a gear mechanism, and the other equipped with a horizontal waterwheel without such a mechanism. The former type can be further divided, depending on where the water hits the wheel paddles, into undershot, overshot, breastshot and pitchback (backshot or reverse shot) waterwheel mills. Another way to classify water mills is by an essential trait about their location: tide mills use the movement of the tide; ship mills are water mills onboard (and constituting) a ship.

Watermills impact the river dynamics of the watercourses where they are installed. During the time watermills operate channels tend to sedimentate, particularly backwater.inundation events and sedimentation of adjacent floodplains increase. Over time however these effects are cancelled by river banks becoming higher.river incision increases and channels deepen.

There are two basic types of watermills, one powered by a vertical-waterwheel via a gear mechanism, and the other equipped with a horizontal-waterwheel without such a mechanism. The former type can be further divided, depending on where the water hits the wheel paddles, into undershot, overshot, breastshot and reverse shot waterwheel mills.

Model of a Roman water-powered grain-mill described by Vitruvius. The millstone (upper floor) is powered by an undershot waterwheel by the way of a gear mechanism (lower floor)

The Greeks invented the two main components of watermills, the waterwheel and toothed gearing, and used, along with the Romans, undershot, overshot and breastshot waterwheel mills.

Lewis assigns the date of the invention of the horizontal-wheeled mill to the Greek colony of Byzantium in the first half of the 3rd century BC, and that of the vertical-wheeled mill to Ptolemaic Alexandria around 240 BC.

The Greek geographer Strabon reports in his Geography a water-powered grain-mill to have existed near the palace of king Mithradates VI Eupator at Cabira, Asia Minor, before 71 BC.

The Roman engineer Vitruvius has the first technical description of a watermill, dated to 40/10 BC; the device is fitted with an undershot wheel and power is transmitted via a gearing mechanism.kneading machines.

Hold back your hand from the mill, you grinding girls; even if the cockcrow heralds the dawn, sleep on. For Demeter has imposed the labours of your hands on the nymphs, who leaping down upon the topmost part of the wheel, rotate its axle; with encircling cogs,Nisyrian millstones. If we learn to feast toil-free on the fruits of the earth, we taste again the golden age.

The 2nd century AD multiple mill complex of Barbegal in southern France has been described as "the greatest known concentration of mechanical power in the ancient world".flour mills. The capacity of the mills has been estimated at 4.5 tons of flour per day, sufficient to supply enough bread for the 12,500 inhabitants occupying the town of Arelate at that time.Janiculum hill, whose supply of flour for Rome"s population was judged by emperor Aurelian important enough to be included in the Aurelian walls in the late 3rd century.

The 3rd century AD Hierapolis water-powered stone sawmill is the earliest known machine to incorporate a crank and connecting rod mechanism.Gerasa and Ephesus.marble saws in what is now Germany can be found in Ausonius 4th century AD poem Mosella. They also seem to be indicated about the same time by the Christian saint Gregory of Nyssa from Anatolia, demonstrating a diversified use of water-power in many parts of the Roman Empire.

Roman turbine mill at Chemtou, Tunisia. The tangential water inflow of the millrace made the horizontal wheel in the shaft turn like a true turbine, the earliest known.

The earliest turbine mill was found in Chemtou and Testour, Roman North Africa, dating to the late 3rd or early 4th century AD.furnace has been identified at Marseille, France.

Mills were commonly used for grinding grain into flour (attested by Pliny the Elder), but industrial uses as fulling and sawing marble were also applied.

The Romans used both fixed and floating water wheels and introduced water power to other provinces of the Roman Empire. So-called "Greek Mills" used water wheels with a horizontal wheel (and vertical shaft). A "Roman Mill" features a vertical wheel (on a horizontal shaft). Greek style mills are the older and simpler of the two designs, but only operate well with high water velocities and with small diameter millstones. Roman style mills are more complicated as they require gears to transmit the power from a shaft with a horizontal axis to one with a vertical axis.

Although to date only a few dozen Roman mills are archaeologically traced, the widespread use of aqueducts in the period suggests that many remain to be discovered. Recent excavations in Roman London, for example, have uncovered what appears to be a tide mill together with a possible sequence of mills worked by an aqueduct running along the side of the River Fleet.

The surviving evidence for watermills sharply increases with the emergence of documentary genres such as monastic charters, Christian hagiography and Germanic legal codes. These were more inclined to address watermilling, a mostly rural work process, than the ancient urban-centered literary class had been.Carolingian times, references to watermills had become "innumerable" in Frankish records.Domesday Book, compiled in 1086, records 5,624 watermills in England alone.Ireland. A century later they began to spread across the former Roman Rhine and Danube frontier into the other parts of Germany.Ship mills and tide mills, both of which yet unattested for the ancient period,

In recent years, a number of new archaeological finds has consecutively pushed back the date of the earliest tide mills, all of which were discovered on the Irish coast: A 6th century vertical-wheeled tide mill was located at Killoteran near Waterford.horizontal-wheeled tide mill dating to c. 630 was excavated on Little Island.Nendrum Monastery mill from 787 was situated on an island in Strangford Lough in Northern Ireland. Its millstones are 830mm in diameter and the horizontal wheel is estimated to have developed 7/8HP at its peak. Remains of an earlier mill dated at 619 were also found at the site.

In a 2005 survey the scholar Adam Lucas identified the following first appearances of various industrial mill types in Western Europe. Noticeable is the preeminent role of France in the introduction of new innovative uses of waterpower. However, he has drawn attention to the dearth of studies of the subject in several other countries.

The waterwheel was found in China from 30 AD onwards, when it was used to power trip hammers,bellows in smelting iron,armillary sphere for astronomical observation (see Zhang Heng).Joseph Needham speculates that the water-powered millstone could have existed in Han China by the 1st century AD, there is no sufficient literary evidence for it until the 5th century AD.Zu Chongzhi had a watermill erected which was inspected by Emperor Wu of Southern Qi (r. 482–493 AD).Sui Dynasty (581–618 AD) was said to operate hundreds of them by the beginning of the 6th century.Buddhist monks arguing over the revenues gained from watermills.Tang Dynasty (618–907 AD) "Ordinances of the Department of Waterways" written in 737 AD stated that watermills should not interrupt riverine transport and in some cases were restricted to use in certain seasons of the year.Buddhist abbeys that failed to acknowledge ordinances or meet government regulations.eunuch serving Emperor Xuanzong of Tang (r. 712–756 AD) owned a watermill by 748 AD which employed five waterwheels that ground 300 bushels of wheat a day.Japan via Korean Peninsula.Tibet by at least 641 AD.

According to Greek historical tradition, India received water-mills from the Roman Empire in the early 4th century AD when a certain Metrodoros introduced "water-mills and baths, unknown among them [the Brahmans] till then".

An Afghan water mill photographed during the Second Anglo-Afghan War (1878-1880). The rectangular water mill has a thatched roof and traditional design with a small horizontal mill-house built of stone or perhaps mud bricks

Engineers under the Caliphates adopted watermill technology from former provinces of the Byzantine Empire, having been applied for centuries in those provinces prior to the Muslim conquests, including modern-day Syria, Jordan, Israel, Algeria, Tunisia, Morocco, and Spain (see List of ancient watermills).

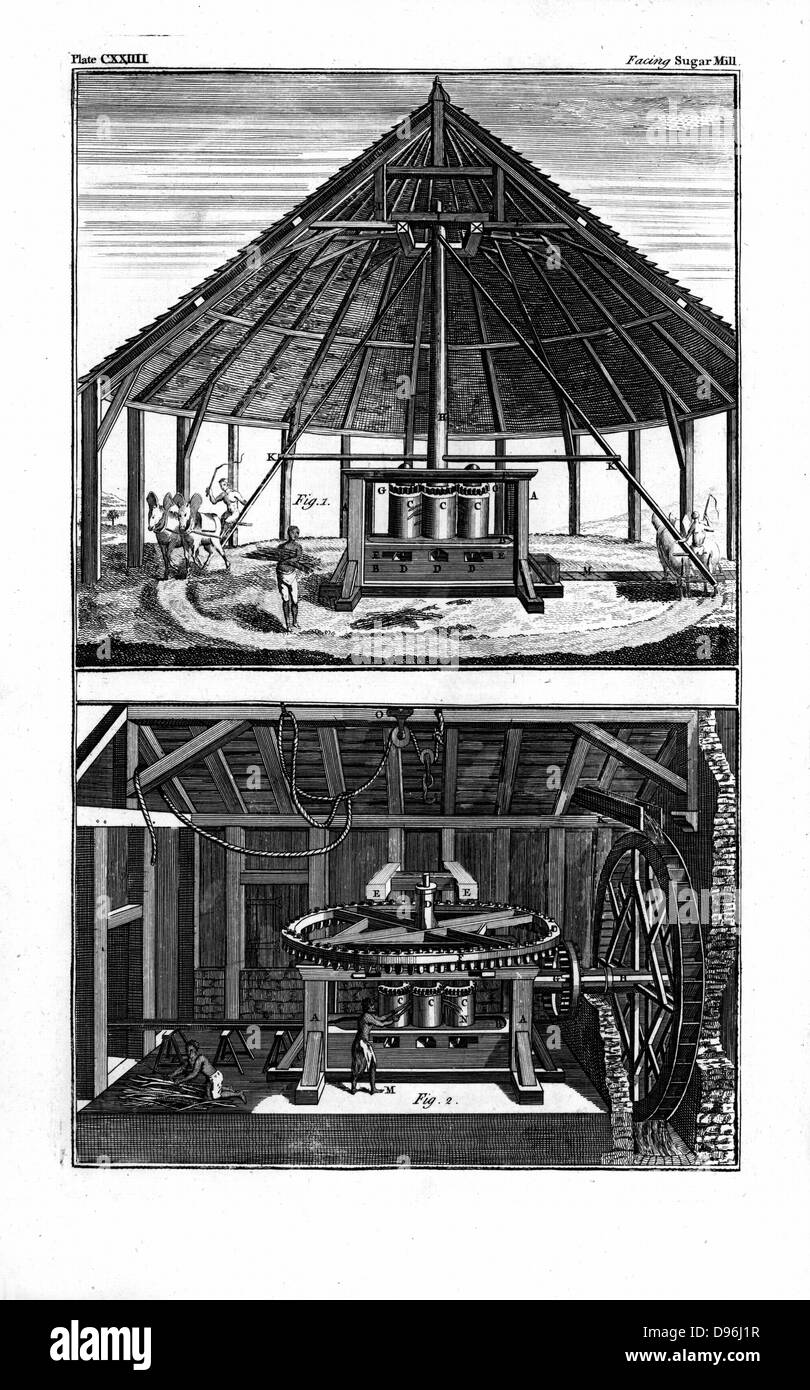

The industrial uses of watermills in the Islamic world date back to the 7th century, while horizontal-wheeled and vertical-wheeled watermills were both in widespread use by the 9th century.gristmills, hullers, sawmills, ship mills, stamp mills, steel mills, sugar mills, and tide mills. By the 11th century, every province throughout the Islamic world had these industrial watermills in operation, from al-Andalus and North Africa to the Middle East and Central Asia.crankshafts and water turbines, gears in watermills and water-raising machines, and dams as a source of water, used to provide additional power to watermills and water-raising machines.Al-Andalus to Christian Spain in the 12th century. Industrial watermills were also employed in large factory complexes built in al-Andalus between the 11th and 13th centuries.

The engineers of the Islamic world used several solutions to achieve the maximum output from a watermill. One solution was to mount them to piers of bridges to take advantage of the increased flow. Another solution was the ship mill, a type of watermill powered by water wheels mounted on the sides of ships moored in midstream. This technique was employed along the Tigris and Euphrates rivers in 10th-century Iraq, where large ship mills made of teak and iron could produce 10 tons of flour from corn every day for the granary in Baghdad.

Typically, water is diverted from a river or impoundment or mill pond to a turbine or water wheel, along a channel or pipe (variously known as a flume, head race, mill race, leat, leet,penstock). The force of the water"s movement drives the blades of a wheel or turbine, which in turn rotates an axle that drives the mill"s other machinery. Water leaving the wheel or turbine is drained through a tail race, but this channel may also be the head race of yet another wheel, turbine or mill. The passage of water is controlled by sluice gates that allow maintenance and some measure of flood control; large mill complexes may have dozens of sluices controlling complicated interconnected races that feed multiple buildings and industrial processes.

Watermills can be divided into two kinds, one with a horizontal water wheel on a vertical axle, and the other with a vertical wheel on a horizontal axle. The oldest of these were horizontal mills in which the force of the water, striking a simple paddle wheel set horizontally in line with the flow turned a runner stone balanced on the rynd which is atop a shaft leading directly up from the wheel. The bedstone does not turn. The problem with this type of mill arose from the lack of gearing; the speed of the water directly set the maximum speed of the runner stone which, in turn, set the rate of milling.

Most watermills in Britain and the United States of America had a vertical waterwheel, one of four kinds: undershot, breast-shot, overshot and pitchback wheels. This vertical produced rotary motion around a horizontal axis, which could be used (with cams) to lift hammers in a forge, fulling stocks in a fulling mill and so on.

However, in corn mills rotation about a vertical axis was required to drive its stones. The horizontal rotation was converted into the vertical rotation by means of gearing, which also enabled the runner stones to turn faster than the waterwheel. The usual arrangement in British and American corn mills has been for the waterwheel to turn a horizontal shaft on which is also mounted a large pit wheel. This meshes with the wallower, mounted on a vertical shaft, which turns the (larger) great spur wheel (mounted on the same shaft). This large face wheel, set with pegs, in turn, turned a smaller wheel (such as a lantern gear) known as a stone nut, which was attached to the shaft that drove the runner stone. The number of runner stones that could be turned depended directly upon the supply of water available. As waterwheel technology improved mills became more efficient, and by the 19th century, it was common for the great spur wheel to drive several stone nuts, so that a single water wheel could drive as many as four stones.sluice gate and thus the flow of the water past the main wheel allowed the miller to compensate for seasonal variations in the water supply. Finer speed adjustment was made during the milling process by tentering, that is, adjusting the gap between the stones according to the water flow, the type of grain being milled, and the grade of flour required.

In many mills (including the earliest) the great spur wheel turned only one stone, but there might be several mills under one roof. The earliest illustration of a single waterwheel driving more than one set of stones was drawn by Henry Beighton in 1723 and published in 1744 by J. T. Desaguliers.

An inherent problem in the overshot mill is that it reverses the rotation of the wheel. If a miller wishes to convert a breastshot mill to an overshot wheel all the machinery in the mill has to be rebuilt to take account of the change in rotation. An alternative solution was the pitchback or backshot wheel. A launder was placed at the end of the flume on the headrace, this turned the direction of the water without much loss of energy, and the direction of rotation was maintained. Daniels Mill near Bewdley, Worcestershire is an example of a flour mill that originally used a breastshot wheel, but was converted to use a pitchback wheel. Today it operates as a breastshot mill.

Larger water wheels (usually overshot steel wheels) transmit the power from a toothed annular ring that is mounted near the outer edge of the wheel. This drives the machinery using a spur gear mounted on a shaft rather than taking power from the central axle. However, the basic mode of operation remains the same; gravity drives machinery through the motion of flowing water.

Toward the end of the 19th century, the invention of the Pelton wheel encouraged some mill owners to replace over- and undershot wheels with Pelton wheel turbines driven through penstocks.

A different type of watermill is the tide mill. This mill might be of any kind, undershot, overshot or horizontal but it does not employ a river for its power source. Instead a mole or causeway is built across the mouth of a small bay. At low tide, gates in the mole are opened allowing the bay to fill with the incoming tide. At high tide the gates are closed, trapping the water inside. At a certain point a sluice gate in the mole can be opened allowing the draining water to drive a mill wheel or wheels. This is particularly effective in places where the tidal differential is very great, such as the Bay of Fundy in Canada where the tides can rise fifty feet, or the now derelict village of Tide Mills, East Sussex.Eling, Hampshire and at Woodbridge, Suffolk.

Run of the river schemes do not divert water at all and usually involve undershot wheels the mills are mostly on the banks of sizeable rivers or fast flowing streams. Other watermills were set beneath large bridges where the flow of water between the stanchions was faster. At one point London bridge had so many water wheels beneath it that bargemen complained that passage through the bridge was impaired.

A few historic mills such as the Water Mill, Newlin Mill and Yates Mill in the US and The Darley Mill Centre in the UK still operate for demonstration purposes. Small-scale commercial production is carried out in the UK at Daniels Mill, Little Salkeld Mill and Redbournbury Mill. This was boosted to overcome flour shortages during the Covid pandemic.

In some developing countries, watermills are still widely used for processing grain. For example, there are thought to be 25,000 operating in Nepal, and 200,000 in India.

Blast furnaces, finery forges, and tinplate works were, until the introduction of the steam engine, almost invariably water powered. Furnaces and Forges were sometimes called iron mills.

Cotton mills were driven by water. The power was used to card the raw cotton, and then to drive the spinning mules and ring frames. Steam engines were initially used to increase the water flow to the wheel, then as the industrial revolution progressed, to directly drive the shafts.

Maaß, Anna-Lisa; Schüttrumpf, Holger (2019). "Elevated floodplains and net channel incision as a result of the construction and removal of water mills". 101 (2): 157–176. doi:10.1080/04353676.2019.1574209. S2CID 133795380.

The translation of this word is crucial to the interpretation of the passage. Traditionally, it has been translated as "spoke" (e.g. Reynolds, p. 17), but Lewis (p. 66) points out that, while its primary meaning is "ray" (as a sunbeam), its only concrete meaning is "cog". Since a horizontal-wheeled corn mill does not need gearing (and hence has no cogs), the mill must have been vertical-wheeled.

Adam Robert Lucas, "Industrial Milling in the Ancient and Medieval Worlds. A Survey of the Evidence for an Industrial Revolution in Medieval Europe", Technology and Culture, Vol. 46, (Jan. 2005), pp. 1-30 (17).

Wikander 2000, p. 400: This is also the period when water-mills started to spread outside the former Empire. According to Cedrenus (Historiarum compendium), a certain Metrodoros who went to India in c. AD 325 "constructed water-mills and baths, unknown among them [the Brahmans] till then".

Adam Robert, Lucas (2005). "Industrial Milling in the Ancient and Medieval Worlds: A Survey of the Evidence for an Industrial Revolution in Medieval Europe". Technology and Culture. 46 (1): 1–30 [10]. doi:10.1353/tech.2005.0026. S2CID 109564224.

Adam Robert, Lucas (2005). "Industrial Milling in the Ancient and Medieval Worlds: A Survey of the Evidence for an Industrial Revolution in Medieval Europe". Technology and Culture. 46 (1): 1–30 [11]. doi:10.1353/tech.2005.0026. S2CID 109564224.

Donners, K.; Waelkens, M.; Deckers, J. (2002), "Water Mills in the Area of Sagalassos: A Disappearing Ancient Technology", Anatolian Studies, vol. 52, pp. 1–17, doi:10.2307/3643076, JSTOR 3643076, S2CID 163811541

McErlean, Thomas; Crothers, Norman (2007), Harnessing the Tides: The Early Medieval Tide Mills at Nendrum Monastery, Strangford Lough, Belfast: Stationery Office Books, ISBN 978-0-337-08877-3

Munro, John H. (2003), "Industrial energy from water-mills in the European economy, 5th to 18th Centuries: the limitations of power", Economia ed Energia, Seccoli XIII - XVIII, Atti delle "Settimane di Studi" e Altrie Convegni, Istituto Internazionale di Storia Economica, F. Datini, vol. 34, no. 1, pp. 223–269

Murphy, Donald (2005), Excavations of a Mill at Killoteran, Co. Waterford as Part of the N-25 Waterford By-Pass Project (PDF), Estuarine/ Alluvial Archaeology in Ireland. Towards Best Practice, University College Dublin and National Roads Authority, archived from the original (PDF) on 2007-11-18

Ritti, Tullia; Grewe, Klaus; Kessener, Paul (2007), "A Relief of a Water-powered Stone Saw Mill on a Sarcophagus at Hierapolis and its Implications", Journal of Roman Archaeology, vol. 20, pp. 138–163

Wikander, Örjan (2000), "The Water-Mill", in Wikander, Örjan (ed.), Handbook of Ancient Water Technology, Technology and Change in History, vol. 2, Leiden: Brill, pp. 371–400, ISBN 90-04-11123-9

A water wheel is a machine for converting the energy of flowing or falling water into useful forms of power, often in a watermill. A water wheel consists of a wheel (usually constructed from wood or metal), with a number of blades or buckets arranged on the outside rim forming the driving car. Water wheels were still in commercial use well into the 20th century but they are no longer in common use. Uses included milling flour in gristmills, grinding wood into pulp for papermaking, hammering wrought iron, machining, ore crushing and pounding fibre for use in the manufacture of cloth.

Some water wheels are fed by water from a mill pond, which is formed when a flowing stream is dammed. A channel for the water flowing to or from a water wheel is called a mill race. The race bringing water from the mill pond to the water wheel is a headrace; the one carrying water after it has left the wheel is commonly referred to as a tailrace.

Overshot and backshot water wheels are typically used where the available height difference is more than a couple of meters. Breastshot wheels are more suited to large flows with a moderate head. Undershot and stream wheel use large flows at little or no head.

There is often an associated millpond, a reservoir for storing water and hence energy until it is needed. Larger heads store more gravitational potential energy for the same amount of water so the reservoirs for overshot and backshot wheels tend to be smaller than for breast shot wheels.

Overshot and pitchback water wheels are suitable where there is a small stream with a height difference of more than 2 metres (6.5 ft), often in association with a small reservoir. Breastshot and undershot wheels can be used on rivers or high volume flows with large reservoirs.

Stream wheels mounted on floating platforms are often referred to as hip wheels and the mill as a ship mill. They were sometimes mounted immediately downstream from bridges where the flow restriction of the bridge piers increased the speed of the current.

Breastshot wheels are less efficient than overshot and backshot wheels but they can handle high flow rates and consequently high power. They are preferred for steady, high-volume flows such as are found on the Fall Line of the North American East Coast. Breastshot wheels are the most common type in the United States of America

A vertically mounted water wheel that is rotated by water entering buckets just past the top of the wheel is said to be overshot. The term is sometimes, erroneously, applied to backshot wheels, where the water goes down behind the wheel.

A typical overshot wheel has the water channeled to the wheel at the top and slightly beyond the axle. The water collects in the buckets on that side of the wheel, making it heavier than the other "empty" side. The weight turns the wheel, and the water flows out into the tail-water when the wheel rotates enough to invert the buckets. The overshot design is very efficient, it can achieve 90%,

Overshot wheels require a large head compared to other types of wheel which usually means significant investment in constructing the headrace. Sometimes the final approach of the water to the wheel is along a flume or penstock, which can be lengthy.

A backshot wheel (also called pitchback) is a variety of overshot wheel where the water is introduced just before the summit of the wheel. In many situations, it has the advantage that the bottom of the wheel is moving in the same direction as the water in the tailrace which makes it more efficient. It also performs better than an overshot wheel in flood conditions when the water level may submerge the bottom of the wheel. It will continue to rotate until the water in the wheel pit rises quite high on the wheel. This makes the technique particularly suitable for streams that experience significant variations in flow and reduces the size, complexity, and hence cost of the tailrace.

The direction of rotation of a backshot wheel is the same as that of a breastshot wheel but in other respects, it is very similar to the overshot wheel. See below.

Some wheels are overshot at the top and backshot at the bottom thereby potentially combining the best features of both types. The photograph shows an example at Finch Foundry in Devon, UK. The head race is the overhead timber structure and a branch to the left supplies water to the wheel. The water exits from under the wheel back into the stream.

A special type of overshot/backshot wheel is the reversible water wheel. This has two sets of blades or buckets running in opposite directions so that it can turn in either direction depending on which side the water is directed. Reversible wheels were used in the mining industry in order to power various means of ore conveyance. By changing the direction of the wheel, barrels or baskets of ore could be lifted up or lowered down a shaft or inclined plane. There was usually a cable drum or a chain basket on the axle of the wheel. It is essential that the wheel have braking equipment to be able to stop the wheel (known as a braking wheel). The oldest known drawing of a reversible water wheel was by Georgius Agricola and dates to 1556.

The earliest waterwheel working like a lever was described by Zhuangzi in the late Warring States period (476-221 BC). It says that the waterwheel was invented by Zigong, a disciple of Confucius in the 5th century BC.Chinese of the Eastern Han Dynasty were using water wheels to crush grain in mills and to power the piston-bellows in forging iron ore into cast iron.

Water wheels in China found practical uses such as this, as well as extraordinary use. The Chinese inventor Zhang Heng (78–139) was the first in history to apply motive power in rotating the astronomical instrument of an armillary sphere, by use of a water wheel.mechanical engineer Ma Jun (c. 200–265) from Cao Wei once used a water wheel to power and operate a large mechanical puppet theater for the Emperor Ming of Wei (r. 226–239).

The ancient Greeks invented the waterwheel independently and used it in nearly all of the forms and functions described above, including its application for watermilling.Hellenistic period between the 3rd and 1st century BC.

The Romans used waterwheels extensively in mining projects, with enormous Roman-era waterwheels found in places like modern-day Spain. They were reverse overshot water-wheels designed for dewatering deep underground mines.Vitruvius, including the reverse overshot water-wheel and the Archimedean screw. Many were found during modern mining at the copper mines at Rio Tinto in Spain, one system involving 16 such wheels stacked above one another so as to lift water about 80 feet from the mine sump. Part of such a wheel was found at Dolaucothi, a Roman gold mine in south Wales in the 1930s when the mine was briefly re-opened. It was found about 160 feet below the surface, so must have been part of a similar sequence as that discovered at Rio Tinto. It has recently been carbon dated to about 90 AD, and since the wood from which it was made is much older than the deep mine, it is likely that the deep workings were in operation perhaps 30–50 years after. It is clear from these examples of drainage wheels found in sealed underground galleries in widely separated locations that building water wheels was well within their capabilities, and such verticals water wheels commonly used for industrial purposes.

Taking indirect evidence into account from the work of the Greek technician Apollonius of Perge, the British historian of technology M.J.T. Lewis dates the appearance of the vertical-axle watermill to the early 3rd century BC, and the horizontal-axle watermill to around 240 BC, with Byzantium and Alexandria as the assigned places of invention.Strabon (ca. 64 BC–AD 24) to have existed sometime before 71 BC in the palace of the Pontian king Mithradates VI Eupator, but its exact construction cannot be gleaned from the text (XII, 3, 30 C 556).

The first clear description of a geared watermill offers the late 1st century BC Roman architect Vitruvius who tells of the sakia gearing system as being applied to a watermill.

About the same time, the overshot wheel appears for the first time in a poem by Antipater of Thessalonica, which praises it as a labour-saving device (IX, 418.4–6).Lucretius (ca. 99–55 BC) who likens the rotation of the waterwheel to the motion of the stars on the firmament (V 516).central Gaul.Barbegal watermill complex a series of sixteen overshot wheels was fed by an artificial aqueduct, a proto-industrial grain factory which has been referred to as "the greatest known concentration of mechanical power in the ancient world".

In Roman North Africa, several installations from around 300 AD were found where vertical-axle waterwheels fitted with angled blades were installed at the bottom of a water-filled, circular shaft. The water from the mill-race which entered tangentially the pit created a swirling water column that made the fully submerged wheel act like true water turbines, the earliest known to date.

Apart from its use in milling and water-raising, ancient engineers applied the paddled waterwheel for automatons and in navigation. Vitruvius (X 9.5–7) describes multi-geared paddle wheels working as a ship odometer, the earliest of its kind. The first mention of paddle wheels as a means of propulsion comes from the 4th–5th century military treatise

Ancient water-wheel technology continued unabated in the early medieval period where the appearance of new documentary genres such as legal codes, monastic charters, but also hagiography was accompanied with a sharp increase in references to watermills and wheels.

The earliest excavated water wheel driven by tidal power was the Nendrum Monastery mill in Northern Ireland which has been dated to 787, although a possible earlier mill dates to 619. Tide mills became common in estuaries with a good tidal range in both Europe and America generally using undershot wheels.

Cistercian monasteries, in particular, made extensive use of water wheels to power watermills of many kinds. An early example of a very large water wheel is the still extant wheel at the early 13th century Real Monasterio de Nuestra Senora de Rueda, a Cistercian monastery in the Aragon region of Spain. Grist mills (for corn) were undoubtedly the most common, but there were also sawmills, fulling mills and mills to fulfil many other labour-intensive tasks. The water wheel remained competitive with the steam engine well into the Industrial Revolution. At around the 8th to 10th century, a number of irrigation technologies were brought into Spain and thus introduced to Europe. One of those technologies is the Noria, which is basically a wheel fitted with buckets on the peripherals for lifting water. It is similar to the undershot water wheel mentioned later in this article. It allowed peasants to power watermills more efficiently. According to Thomas Glick"s book, Irrigation and Society in Medieval Valencia, the Noria probably originated from somewhere in Persia. It has been used for centuries before the technology was brought into Spain by Arabs who had adopted it from the Romans. Thus the distribution of the Noria in the Iberian peninsula "conforms to the area of stabilized Islamic settlement".Spaniards, the technology spread to the New World in Mexico and South America following Spanish expansion

The assembly convened by William of Normandy, commonly referred to as the "Domesday" or Doomsday survey, took an inventory of all potentially taxable property in England, which included over six thousand mills spread across three thousand different locations.

The type of water wheel selected was dependent upon the location. Generally if only small volumes of water and high waterfalls were available a millwright would choose to use an overshot wheel. The decision was influenced by the fact that the buckets could catch and use even a small volume of water.

Harnessing water-power enabled gains in agricultural productivity, food surpluses and the large scale urbanization starting in the 11th century. The usefulness of water power motivated European experiments with other power sources, such as wind and tidal mills.canals, put Europe on a hydraulically focused path, for instance water supply and irrigation technology was combined to modify supply power of the wheel.feudal state.

The water mill was used for grinding grain, producing flour for bread, malt for beer, or coarse meal for porridge.fulling mill, which was used for cloth making. The trip hammer was also used for making wrought iron and for working iron into useful shapes, an activity that was otherwise labour-intensive. The water wheel was also used in papermaking, beating material to a pulp. In the 13th century water mills used for hammering throughout Europe improved the productivity of early steel manufacturing. Along with the mastery of gunpowder, waterpower provided European countries worldwide military leadership from the 15th century.

Millwrights distinguished between the two forces, impulse and weight, at work in water wheels long before 18th-century Europe. Fitzherbert, a 16th-century agricultural writer, wrote "druieth the wheel as well as with the weight of the water as with strengthe [impulse]".Leonardo da Vinci also discussed water power, noting "the blow [of the water] is not weight, but excites a power of weight, almost equal to its own power".laws of force. Evangelista Torricelli"s work on water wheels used an analysis of Galileo"s work on falling bodies, that the velocity of a water sprouting from an orifice under its head was exactly equivalent to the velocity a drop of water acquired in falling freely from the same height.

The most powerful water wheel built in the United Kingdom was the 100 hp Quarry Bank Mill water wheel near Manchester. A high breastshot design, it was retired in 1904 and replaced with several turbines. It has now been restored and is a museum open to the public.

Water wheels were used to power sawmills, grist mills and for other purposes during development of the United States. The 40 feet (12 m) diameter water wheel at McCoy, Colorado, built in 1922, is a surviving one out of many which lifted water for irrigation out of the Colorado River.

Two early improvements were suspension wheels and rim gearing. Suspension wheels are constructed in the same manner as a bicycle wheel, the rim being supported under tension from the hub- this led to larger lighter wheels than the former design where the heavy spokes were under compression. Rim-gearing entailed adding a notched wheel to the rim or shroud of the wheel. A stub gear engaged the rim-gear and took the power into the mill using an independent line shaft. This removed the rotative stress from the axle which could thus be lighter, and also allowed more flexibility in the location of the power train. The shaft rotation was geared up from that of the wheel which led to less power loss. An example of this design pioneered by Thomas Hewes and refined by William Armstrong Fairburn can be seen at the 1849 restored wheel at the Portland Basin Canal Warehouse.

Australia has a relatively dry climate, nonetheless, where suitable water resources were available, water wheels were constructed in 19th-century Australia. These were used to power sawmills, flour mills, and stamper batteries used to crush gold-bearing ore. Notable examples of water wheels used in gold recovery operations were the large Garfield water wheel near Chewton—one of at least seven water wheels in the surrounding area—and the two water wheels at Adelong Falls; some remnants exist at both sites.Walhalla once had at least two water wheels, one of which was rolled to its site from Port Albert, on its rim using a novel trolley arrangement, taking nearly 90 days.water wheel at Jindabyne, constructed in 1847, was the first machine used to extract energy—for flour milling—from the Snowy River.

The early history of the watermill in India is obscure. Ancient Indian texts dating back to the 4th century BC refer to the term cakkavattaka (turning wheel), which commentaries explain as arahatta-ghati-yanta (machine with wheel-pots attached). On this basis, Joseph Needham suggested that the machine was a noria. Terry S. Reynolds, however, argues that the "term used in Indian texts is ambiguous and does not clearly indicate a water-powered device." Thorkild Schiøler argued that it is "more likely that these passages refer to some type of tread- or hand-operated water-lifting device, instead of a water-powered water-lifting wheel."

According to Greek historical tradition, India received water-mills from the Roman Empire in the early 4th century AD when a certain Metrodoros introduced "water-mills and baths, unknown among them [the Brahmans] till then".ancient India, predating, according to Pacey, its use in the later Roman Empire or China,

The industrial uses of watermills in the Islamic world date back to the 7th century, while horizontal-wheeled and vertical-wheeled water mills were both in widespread use by the 9th century. A variety of industrial watermills were used in the Islamic world, including gristmills, hullers, sawmills, shipmills, stamp mills, steel mills, sugar mills, and tide mills. By the 11th century, every province throughout the Islamic world had these industrial watermills in operation, from al-Andalus and North Africa to the Middle East and Central Asia.crankshafts and water turbines, gears in watermills and water-raising machines, and dams as a source of water, used to provide additional power to watermills and water-raising machines.factory complexes built in al-Andalus between the 11th and 13th centuries.

The engineers of the Islamic world developed several solutions to achieve the maximum output from a water wheel. One solution was to mount them to piers of bridges to take advantage of the increased flow. Another solution was the shipmill, a type of water mill powered by water wheels mounted on the sides of ships moored in midstream. This technique was employed along the Tigris and Euphrates rivers in 10th-century Iraq, where large shipmills made of teak and iron could produce 10 tons of flour from corn every day for the granary in Baghdad.flywheel mechanism, which is used to smooth out the delivery of power from a driving device to a driven machine, was invented by Ibn Bassal (fl. 1038–1075) of Al-Andalus; he pioneered the use of the flywheel in the saqiya (chain pump) and noria.Al-Jazari in the 13th century and Taqi al-Din in the 16th century described many inventive water-raising machines in their technological treatises. They also employed water wheels to power a variety of devices, including various water clocks and automata.

Overshot (and particularly backshot) wheels are the most efficient type; a backshot steel wheel can be more efficient (about 60%) than all but the most advanced and well-constructed turbines. In some situations an overshot wheel is preferable to a turbine.

The development of the hydraulic turbine wheels with their improved efficiency (>67%) opened up an alternative path for the installation of water wheels in existing mills, or redevelopment of abandoned mills.

The power is how fast that energy is delivered which is determined by the flow rate. It has been estimated that the ancient donkey or slave-powered quern of Rome made about one-half of a horsepower, the horizontal waterwheel creating slightly more than one-half of a horsepower, the undershot vertical waterwheel produced about three horsepower, and the medieval overshot waterwheel produced up to forty to sixty horsepower.

Smeaton, "An Experimental Inquiry Concerning the Natural Powers of Water and Wind to Turn Mills, and Other Machines, depending on Circular Motion," Royal Society, Philosophical Transactions of the Royal Society of London 51 (1759); 124–125

Wikander 2000, p. 400: This is also the period when water-mills started to spread outside the former Empire. According to Cedrenus (Historiarum compendium), a certain Metrodoros who went to India in c. A.D. 325 "constructed water-mills and baths, unknown among them [the Brahmans] till then".

Donners, K.; Waelkens, M.; Deckers, J. (2002), "Water Mills in the Area of Sagalassos: A Disappearing Ancient Technology", Anatolian Studies, Anatolian Studies, Vol. 52, vol. 52, pp. 1–17, doi:10.2307/3643076, JSTOR 3643076, S2CID 163811541

Lucas, A.R. (2005). "Industrial Milling in the Ancient and Medieval Worlds: A Survey of the Evidence for an Industrial Revolution in Medieval Europe". Technology and Culture. 46 (1): 1–30. doi:10.1353/tech.2005.0026. S2CID 109564224.

Murphy, Donald (2005), Excavations of a Mill at Killoteran, Co. Waterford as Part of the N-25 Waterford By-Pass Project (PDF), Estuarine/ Alluvial Archaeology in Ireland. Towards Best Practice, University College Dublin and National Roads Authority

Wikander, Örjan (2000), "The Water-Mill", in Wikander, Örjan (ed.), Handbook of Ancient Water Technology, Technology and Change in History, vol. 2, Leiden: Brill, pp. 371–400, ISBN 978-90-04-11123-3

Waterwheel Factory shares it"s knowledge about waterwheels and displays the inherent beauty of a moving waterwheel. Explore; water wheels in history; waterwheel calculations; waterwheels for energy, and gristmill restorations. Explore the many ways you can enjoy having your own waterwheel for landscape decoration or any project you may have in mind.Sit back, relax, and enjoy the many exciting photo’s and options we offer.

Here is a company that is building a modern version of a ship mill for the purpose of - picking up garbage. This ship mill in Baltimore, Maryland, USA, uses a water wheel to run a conveyor screen that picks debris out of the river it sits in - a self power cleaner!

When I looked at the picture of the "Last ship mill on the Rhine, 1925", I thought that something was odd in the appearance of the wheel. Closer examination and enhancement reveals that you can see the side of the ship through the wheel, suggesting netting. Is it possible that this was actually a fish trap rather than a mill? Similar land-based wheels have been used by Alaskan natives for centuries.

Why would a floating tidemill have to work with the water moving against it in either direction. Just moor the bow to a single point and let the flow turn the bow into the current.

In Hungary, boat mills were very common on Tisza and Danube rivers in the 19th century. In 1863 4,301 boat mills, 9,173 stream mills, 475 windmills and 147 steam mills were operating in Hungary (not including Transylvania, Slavonia, Croatia).

Several boat mills were working on the Danube at Ráckeve (a town 50 kms South from Budapest) as well, where the last ship mill of Hungary sank during the hard winter of 1968, when the ice broke the houseboat with the milling equipment. In 2006 the Municipality of Ráckeve initiated the idea of rebuilding the boat mill, and enthusiastic local residents, workers, entrepreneurs prepared a full-functional replica of the float mill based on written records, photos and drawings.

Site Characteristics: The mill used water power from a small pond on George’s Brook created by a 160 foot stone dam oriented in a north south direction. The pond area, clearly visible on 1934 aerial photos, is now totally filled in behind the dam and has returned to a wetland and field condition. Remnants of the dam and mill site buildings remain today. It is unclear if water power was used for this button factory in addition to the saw mill. The remnants of an old saw mill on the east end of the site and a dam upstream are clearly visible. The mill site was a fairly intricate site requiring an 800 foot sluiceway to power the mill. Its characteristics are indicative that the site may have supported additional mill activities. The construction methods used typical of those used in the late 1700s and early to mid-1800s suggesting that there may have been an early mill there.

These vertical waterwheels were vastly superior to the earlier horizontal waterwheel design by the ancient Greeks and Egyptians, because they could operate more efficiently translating the hydrokinetic energy of the moving water into mechanical power. Pulleys and gearing was then attached to the waterwheel which allowed a change in direction of a rotating shaft from horizontal to vertical in order to operate millstones, saw wood, crush ore, stamping and cutting etc.

Most Waterwheels also known as Watermills or simply Water Wheels, are vertically mounted wheels rotating about a horizontal axle, and these types of waterwheels are classified by the way in which the water is applied to the wheel, relative to the wheel’s axle. As you may expect, waterwheels are relatively large machines which rotate at low angular speeds, and have a low efficiency, due to losses by friction and the incomplete filling of the buckets, etc.

The action of the water pushing against the wheels buckets or paddles develops torque on the axle but by directing the water at these paddles and buckets from different positions on the wheel the speed of rotation and its efficiency can be improved. The two most common types of waterwheel design is the “undershot waterwheel” and the “overshot waterwheel”.

The Overshot Water Wheel Design is the most common type of waterwheel design. The overshot waterwheel is more complicated in its construction and design than the previous undershot waterwheel as it uses buckets or small compartments to both catch and hold the water.

This type of water wheel uses gravity to improve output as well as the water itself, thus overshot waterwheels are much more efficient than undershot designs as almost all of the water and its weight is being used to produce output power. However as before, the waters energy is used only once to rotate the wheel, after which it flows away with the rest of the water.

Overshot waterwheels are suspended above a river or stream and are generally built on the sides of hills providing a water supply from above with a low head (the vertical distance between the water at the top and the river or stream below) of between 5-to-20 metres. A small dam or weir can be constructed and used to both channel and increase the speed of the water to the top of the wheel giving it more energy but it is the volume of water rather than its speed which helps rotate the wheel.

Generally, overshot waterwheels are built as large as possible to give the greatest possible head distance for the gravitational weight of the water to rotate the wheel. However, large diameter waterwheels are more complicated and expensive to construct due to the weight of the wheel and water.

Once the bucket is empty of water it continues around the rotating wheel until it gets back up to the top again ready to be filled with more water and the cycle repeats. One of the disadvantages of an overshot waterwheel design is that the water is only used once as it flows over the wheel.

The Pitchback Water Wheel Design is a variation on the previous overshot waterwheel as it also uses the gravitational weight of the water to help rotate the wheel, but it also uses the flow of the waste water below it to give an extra push. This type of waterwheel design uses a low head infeed system which provides the water near to the top of the wheel from a pentrough above.

Unlike the overshot waterwheel which channelled the water directly over the wheel causing it to rotate in the direction of the flow of the water, the pitchback waterwheel feeds the water vertically downwards through a funnel and into the bucket below causing the wheel to rotate in the opposite direction to the flow of the water above.

Just like the previous overshot waterwheel, the gravitational weight of the water in the buckets causes the wheel to rotate but in an anti-clockwise direction. As the angle of rotation nears the bottom of the wheel, the water trapped inside the buckets empties out below. As the empty bucket is attached to the wheel, it continues rotating with the wheel as before until it gets back up to the top again ready to be filled with more water and the cycle repeats.

The Breastshot Water Wheel Design is another vertically-mounted waterwheel design where the water enters the buckets about half way up at axle height, or just above it, and then flows out at the bottom in the direction of the wheels rotation. Generally, the breastshot waterwheel is used in situations were the head of water is insufficient to power an overshot or pitchback waterwheel design from above.

Breastshot waterwheels use about the same gravitational weight of the water to rotate the wheel but as the head height of the water is around half that of a typical overshot waterwheel, the buckets are a lot wider than previous waterwheel designs to increase the volume of the water caught in the buckets.

Historically water wheels have been used for milling flour, cereals and other such mechanical tasks. But water wheels can also be used for the generation of electricity, called a Hydro Power system.

Constructed in 1930, the Old Mill boasts an iron hub which had originally been of service at Hermitage, an early manufacturing community near the Shannon village between Rome and Calhoun, Georgia, and was a gift to Berry from The Republic Mining (bauxite) and Manufacturing Company. Henry Ford had the hub moved to Berry where the wheel was rebuilt.

The wooden overshot waterwheel, considered one of the largest in the world at 42 feet in diameter, was constructed by student workers. For many years, the mill was operated by Mr. Green Berry Goodson, a white-bearded miller who ground Berry-grown corn into meal and grits. Water is piped directly from Berry"s reservoir lake to the wheel. Once primed, the force of gravity is strong enough to push the water up the stone column and over the wheel, causing it to turn.

During 1985, physical plant staff and student volunteers restored the mechanism and made grinding of corn meal once again possible. The Old Mill is operated on special occasions such as Mountain Day. When available, the Oak Hill Gift Shop sells cornmeal ground at the Old Mill.

Waterpower grew to be a central element in Western technology, industry, and society during the medieval and early modern periods of history primarily because it was a more intensive or concentrated form of power than man or animal power. For most of the era of waterpower, the typical horizontal watermill was capable of generating little more power than a donkey or horse and often not that much. It could be used only for a single task like milling grain and it was wasteful of water. The horizontal wheel did not make possible the performance of large-scale industrial work, work that would have been either impossible or marginal with the animate power sources that were its alternatives. It remained largely an item of peasant culture. The vertical waterwheel, on the other hand, was usually the best means of economically and reliably securing a relatively large amount of mechanical power from a shaft. It was more easily adapted to tasks other than grain milling. And it was capable of delivering more power from a given volume and fall of water than the horizontal wheel. Thus the vertical wheel became the mainstay of European power technology in the medieval period and remained the mainstay well into the 19th century.

It must be remembered also that the vertical wheel does not operate in isolation. It is part of a power system. Dams and reservoirs are required to build up a workable head of water and to help insure regularity of flow. Canals or mill races are needed to lead water from reservoirs or streams to the waterwheel. Sluice gates, flumes, and chutes are often used to control and direct the flow of water onto the wheel. Tail races are needed to carry water away from the wheel once it has been used. Gearing, cams, cranks, and shafts transmit the motion of the waterwheel to the machinery it activates.

Taking this information and applying it to the development of Bethlehem is an interesting exercise. The Moravians were apparently aware of the best technology, including water technology, of their time. They included among their community members men who could apply this technology to their settlement. Hans Christensen, the Danish millwright, for example, transferred a great deal of this knowledge when he designed the waterworks and oil mill buildings and machinery. In the early years of Bethlehem, the flow of the Monocacy Creek was fast enough and the drop deep enough to provide the head of water needed to operate waterwheels in various industries. Undershot wheels were employed in the saw mill, waterworks, and oil mill with one breast wheel (or perhaps two breast wheels) used in the grist mill-fulling mill complex.

The waterpower system employed by the Moravians (see map) encompassed an area of the Monocacy Creek just north of the grist mill-fulling mill complex and extended to the saw mill on Sand Island where the Monocacy emptied into the Lehigh River. It included a dam constructed around the location of the current Broad Street Bridge and a raceway leading to the grist mill-fulling mill complex that provided the water for the grist mill-fulling mill waterwheels then exited the building, passed in front of the butchery, tannery, and tawery, and emptied back into the Monocacy just north of the oil mill where a small island (no longer extant) was located in the creek. A second dam and raceways system was then constructed to service the waterworks and the oil mill complex. The tail race of the waterworks emptied back into the Monocacy in the area of the current Hill-to-Hill Bridge. It is interesting to note that by the time the waterworks and oil mill were running at peak capacity in the 1770s and 1780s, the regulation of the water supply had become a community problem. There were many discussions and disagreements among the master millers about whose industry should take priority in using the water. It was finally decided that tile waterworks needed to take precedence for most of the day and that the other mills would have to work around that schedule.

The drawings above show the three basic types of vertical waterwheels: undershot, breast, and overshot. The undershot wheel was used in most of early Bethlehem"s industrial buildings because of the low head of water available from the Monocacy Creek. One or possibly two breast wheels were used in the grist mill-fulling complex, however.

A British engineer named John Smeaton analyzed the relative efficiency of two forms of waterwheels, the undershot and the overshot. The average overshot wheel was far more efficient than the undershot, about 65% as opposed to 25%. The undershot wheel is an impulse wheel, since the water imparts its energy by pushing. If the hillside is steep, the water moves fast at the bottom and can push impressively against the paddles of an undershot wheel. The overshot wheel is a gravity wheel. It is a series of buckets attached to the outside of a big circle. The water goes into a container at the top and drops all the way down.

The growth of mills was accompanied by the growth in the power of waterwheels. From the first half of the 18th century to the first half of the 19th century, the average horsepower increased 300% to 12-18 horsepower. the largest wheels were 60 and 70 feet in diameter and capable of producing upwards of 250 horsepower. Taking advantage of America"s abundance of wood, most waterwheels were constructed of wood. Usually, only the bearings and teeth were made of metal. However, wooden wheels needed replacement roughly every 10 years.

A mill race, millrace or millrun, mill lade (Scotland) or mill leat (Southwest England) is the current of water that turns a water wheel, or the channel (sluice) conducting water to or from a water wheel. Compared with the broad waters of a mill pond, the narrow current is swift and powerful. The race leading to the water wheel on a wide stream or mill pond is called the head race (or headrace), and the race leading away from the wheel is called the tail race (or tailrace.

A mill race has many geographically specific names, such as leat, lade, flume, goit, penstock. These words all have more precise definitions and meanings will differ elsewhere. The original undershot waterwheel, described by Vitruvius, was a "run of the river wheel" placed so a fast flowing stream would press against and turn the bottom of a bucketed wheel. In the first meaning of the term, the millrace was the stream; in the sense of the word, there was no separate channel, so no race. The example of Mill Lade in Godmanchester refers to a wide channel leading to moorings where laden vessels unload, similar waterways known by the similar name of Lode exist in neighbouring districts.

As technology advanced, the stream was dammed by a weir. This increased the head of water. Behind the weir was the millpond, or lodge. The water was channelled to the waterwheel by a sluice or millrace- this was the head race. From the waterwheel, the water was channelled back to the course of the stream by a sluice known as the tail race. When the tail race from one mill led to another mill where it acted as the head race this was known as the mid race. The level of water in the millrace could be controlled by a series of sluice gates.

During the October Tryst (as the cattle gathering was known), Crieff was a prototype "wild west" town. Milling with the cattle were horse thieves, bandits and drunken drovers. The inevitable killings were punished on the Kind Gallows, for which Crieff became known throughout Europe.

Waterwheels are usually positioned vertically over a water source. This means that the axle is positioned horizontally. This axle transfers the energy from the falling water to a drive belt or a system of gears that then operates some sort of machine. These wheels require some source of falling or flowing water, and these sources can include streams or rivers. Sometimes special ponds known as mill ponds were created by damming a flowing stream. This creates a special channel known as a

Overshot wheels are a type of waterwheel that can be built if there is a significant height drop in the river or body of water being used to move the wheel. Generally, these are built on the side of a hill as a drop of at least 4.5 meters.

RM2A5YKXP–Overshot water wheel turning the cam-shaft of a stamping mill being used to turn the crush ore to begin the process of extracting metal from the ore won from a mine. From "De re metallica", by Agricola, pseudonym of Georg Bauer (Basle, 1556). Woodcut

RM2JG6FG7–Gelligroes Mill near Pontllanfraith South Wales which sits alongside the River Sirhowy and an old packhorse bridge over the river.Former home of

RMD95KE5–Draining mine workings by means of a battery of three pumps. The axle, B, is powered by an overshot water wheel. The cams on the axle raise and lower the piston rods by means of tappets. C is the bottom of the pipe which is encased in the basket, D. From "De re metallica", by Agricola, pseudonym of Georg Bauer (Basle, 1556). Woodcut.

RMTXGY73–Reversible hoist for raising leather buckets from mine shaft powered by overshot waterwheel. Man in hut at O opens and shuts water races to stop and start double row of buckets From Agricola "De re metallica" 1556 Woodcut Basle

RM2AWT0RW–The analysis of fuel, gas, water, and lubricants . Fig. 24.—Continuous water purification apparatus.*A—Wood fiber filter M—Reaction chamber E—Overshot water-wheel N—Spiral accelerator plates G—Soda ash solution tank P—Sludge catchers J—Lime saturating tank Y—Treated water reservoir S and U—Flushing valves coagulants are exceedingly effective in carrying down suspendedmatter. The approximate amount usually employed is 1 grainper gallon or about 1 lb. per 5,000 gal. of water. The equivalent1 Supplied by the Dodge Manufacturing Co., Mishawaka, Ind. 128 FUEL, GAS, WATER AND LUBRICATION quantity of

RM2JG6FJB–Gelligroes Mill near Pontllanfraith South Wales which sits alongside the River Sirhowy and an old packhorse bridge over the river.Former home of

RF2C9C6EM–A water wheel is a machine for converting the energy of flowing or falling water into useful forms of power, often in a watermill, vintage line drawin

RM2BEWR4N–Century-old wooden waterwheel grist mill at Stone Mountain Park in Atlanta, Georgia. The grist mill was originally located in Ellijay, Georgia.

RMRJN0BC–Illustration showing, Multiple suction pumps, powered by an overshot water wheel through a toothed wheel and drum (C,D,E) being used to raise water from a mine. From Agricola "De re metallica", Basle, 1556

RMMR3X1X–Diagram depicting various forms of water wheels including at Fig. 5, a pitch back overshot wheel. Created by Abraham Rees (1743-1825) a Welsh nonconformist minister, and compiler of Rees"s Cyclopædia. Dated 19th century

RM2JG6FG1–Gelligroes Mill near Pontllanfraith South Wales which sits alongside the River Sirhowy and an old packhorse bridge over the river.Former home of

RF2B770CM–An image of the overshot wheel that operates machinery by water power, receiving water at the top, it shows the water wheel power of generation in it,

RM2AG80G0–. A dictionary of arts, manufactures and mines : containing a clear exposition of their principles and practice. furnaces so common in the Hartz. The example is taken from the Mandelholz works,in the neighborhood of Elbingerode. Fig. 602 is an elevation of this forge, d is therefinery hearth, provided with two pairs of bellows. Fig. 601 is a vertical section,showing particularly the construction of the crucible or hearth in the refinery forge d.c is an overshot water wheel, which gives an alternate impulsion to the two bellows a bby means of the revolving shaft c, and the cams or tappets d f e

RMP6HBP0–Overshot and undershot waterwheels, 19th century, including examples designed by John Smeaton and Peter Noua

8613371530291

8613371530291