overshot mill made in china

Model "LT-T" Releasing and Circulating Overshot is an external fishing tool used for catching the fish with smooth external surface. Its circulation can be carried out under high pump pressure and the fish can be released on the inside of well. According to different uses, it may be equipped with some accessories, such as extension sub, wall hook, enlarged guide, etc.ModelOvershot OD mm(inch)MAX. Catch Sizes mm(inch)Conn.

There are many wheel configurations, vane/blade shapes and water-flow patterns. Undershot wheels and horizontal wheels were the most common choices for tide mills. Since the height of the impoundment area was the height of high tide, the head of water was probably not high enough to power an overshot wheel.

Probably the most important of the early engines which utilized water power was the vertical waterwheel. Its two basic forms are the undershot and the overshot. The undershot vertical wheel rotated in the vertical plane and had a horizontal axis. It normally had flat radial blades attached to its periphery and derived its motion from the impact of water flowing under the wheel and against these blades. While capable of working on any convenient stream without mill races (narrow artificial water channels, it worked most effectively in a race and with a stable volume of water running at a fairly high velocity. [Stronger than a Hundred Men: A History of the Vertical Water Wheel by Terry S. Reynolds Baltimore: The Johns Hopkins University Press, 1983.]

The Undershot Wheel worked in a running stream and could turn in shallow water. It was often built by the first settlers since it was relatively simple to set up … They were common in the early days when a dam could be built to compensate for dry periods … . [Mill: The History and Future of Naturally Powered Buildings by David Larkin. New York, 2000.]

The tub wheel could only work where the water flowed regularly throughout the year, and needed at least an eight-foot fall. The tub wheel was horizontal and was described as acted upon by percussion of water. The shaft is vertical, running the stone of top of it, and serves as a spindle. The water is shot on the upper side of the wheel in the direction of a tangent fitted with blades. It revolves in a sturdy tub, projecting far enough above the wheel to prevent the water from shooting over it, and whirls above it until it strikes the buckets. . [Mill: The History and Future of Naturally Powered Buildings by David Larkin. New York, 2000.]

The overshot vertical wheel was a much more efficient device. Water was fed at the top of the overshot wheel into “buckets” or containers built into the wheel’s circumference, and the weight of the impounded water, rather than its impact, turned the wheel. Each “bucket” discharged its water into the tail race at the lower portion of its revolution and ascended empty to repeat the process. The overshot wheel was usually more expensive than the undershot, since a dam and an elevated head race were normally required to build up a large fall of water and to lead the water to the wheel’s summit. It was suitable mainly to low water volumes and moderately high falls.

It is likely that the [emergence of undershot and overshot wheels] was at least partially influenced by several more primitive devices which tap the power of falling water – the water lever, the noria, and the primitive horizontal watermill. [Stronger than a Hundred Men: A History of the Vertical Water Wheel by Terry S. Reynolds Baltimore: The Johns Hopkins University Press, 1983.]

The overshot wheel required a dam above it so that the weight of water falling on it would make it turn. After one-third of a revolution, the water was spilled from the wheel. The water first striking the wheel gave it momentum, but the weight of the water in its buckets kept it turning. [Mill: The History and Future of Naturally Powered Buildings by David Larkin. New York, 2000.]

The difference between the pitch-back and the overshot wheels is that the trough stops shorter here and pours the water onto the wheel before the top of the wheel, or ‘on the near side’ as the millwrights used to say. The result therefore is that the wheel revolves in the opposite direction from the overshot, i.e. towards the flume or head-race. The buckets face in the opposite direction and the water therefore falls off at the same side as that on which it was received. [British Water-Mills by Leslie Syson. London, 1965]

The breast wheel, like the undershot wheel, turned in the opposite direction to the overshot wheel and received water above its center shaft at the nearest point of the water supply, and revolved easily because it was less loaded with water. . [Mill: The History and Future of Naturally Powered Buildings by David Larkin. New York, 2000.]

The flutter wheel was used when there was a large supply of water. It was small, low and wide—about three feet in diameter and up to eight feet wide. It got its attractive name from the sound it made. As the wheel went around, the blades cut through the entering water, making a noise like the fluttering wings of a bird. It was used almost entirely to power early sawmills. . [Mill: The History and Future of Naturally Powered Buildings by David Larkin. New York, 2000.]

The turbine with its curved blades, eventually replaced the waterwheel [in the mid-nineteenth century]. … Roy S. Hubbs pointed out that older undershot waterwheels presented a flat blade for the incoming water to impact, allowing half of the velocity to pass through unchecked. The Poncelet design [and the later resulting turbine] presented a curved blade with its lip angled tangentially to the incoming water … Benoit Fourneyron turned the wheel on its side and dropped the water into its center, allowing the water to flow simultaneously out of all the passages between the blades. … Since the turbine used all the openings between its blades simultaneously, it could be made much smaller. It turned much faster than the larger wheels. . [Mill: The History and Future of Naturally Powered Buildings by David Larkin. New York, 2000.]

The noria used for raising water, was form of undershot water wheel, but it activated no machinery (such as gears or millstones) beyond itself. It was simply a large vertically situated wheel, sometimes as much at 50-80 feet in diameter, equipped with radial blades which rotated the apparatus as they were impacted by the flowing water in which the lower portion of the wheel was immersed. Buckets of wood, bamboo, or pottery were attached to the rim of the wheel. As the device rotated, they were filed with water at the bottom of the wheel; the water was carried upwards in the buckets and emptied near the top of the wheel into a trough. The buckets were the returned empty to the bottom of the wheel to repeat the process.

Based on the surviving evidence, it would appear that the vertical undershot watermill, the horizontal watermill, and the noria appeared almost simultaneously in the Mediterranean world in the first century B.C. and that at approximately the same time some form of water-powered prime mover was developed in China.

By the close of the Middle Ages watermills were in use on streams of every type. They dammed up the rivers of medieval man; they were on the banks of his brooks and creeks, in the middle of his rivers, under his bridges, and along his coastlines. They impeded navigation and created streams (in the form of mill races and power canals) and lakes (in the form of storage reservoirs behind waterpower dams) where none had existed before.

Through all of antiquity and on into the early Middle Ages almost the only work to which the force of falling water was applied was grinding wheat. This was always to be one of its more important functions. But by the tenth century, European technicians had begun to adapt the vertical water wheel to other tasks. By the sixteenth century, in addition to flour mills, there were hydropowered mills for smelting, forging, sharpening , rolling slitting, polishing, grinding, , and shaping metals. Water wheels were available for hoisting materials and for crushing ores. There were mills for making beer, olive oil, poppy oil, mustard, coins, and wire. Water wheels were used in the preparation of pigment, paper, hemp, and tanning bark, and for fulling, sawing wood, boring pipes, and ventilating mines.

[In North America] the resort to water power usually came quickly after settlement [in colonial America]. The first permanent English settlement in North America was at Jamestown, Virginia, in 1607. Early in that settlement’s history the Virginia Company instructed its governor to build watermills on every plantation. By 1694 Virginia had five watermills. Maryland had a watermill in 1634, the very year it was first settled, and Swedish authorities responsible for settlements on the Delaware in the1640s made the erection of watermills one of their first concerns. The colony of Massachusetts, first settled in 1620, had a watermill at Dorchester by 1633, and mills at Roxbury, Lynn, and Watertown by 1635. These were all flour mills. But according to one authority, the Piscataqua River above Portsmouth, N.H., was dammed for a sawmill as early as 1623. In 1646, on the Saugus River, Massachusetts built an iron mill, complete with water-activated trip-hammers, blast furnace, bellows, rollers, and slitters. By 1700 there were few New England villages without a watermill.

This article is about a type of structure. For other locational uses, see Milldam. For details of the technologies, see Water wheel. For further details of the technologies, see Mill machinery. For other uses, see Water Mill.

A watermill or water mill is a mill that uses hydropower. It is a structure that uses a water wheel or water turbine to drive a mechanical process such as milling (grinding), rolling, or hammering. Such processes are needed in the production of many material goods, including flour, lumber, paper, textiles, and many metal products. These watermills may comprise gristmills, sawmills, paper mills, textile mills, hammermills, trip hammering mills, rolling mills, wire drawing mills.

One major way to classify watermills is by wheel orientation (vertical or horizontal), one powered by a vertical waterwheel through a gear mechanism, and the other equipped with a horizontal waterwheel without such a mechanism. The former type can be further divided, depending on where the water hits the wheel paddles, into undershot, overshot, breastshot and pitchback (backshot or reverse shot) waterwheel mills. Another way to classify water mills is by an essential trait about their location: tide mills use the movement of the tide; ship mills are water mills onboard (and constituting) a ship.

Watermills impact the river dynamics of the watercourses where they are installed. During the time watermills operate channels tend to sedimentate, particularly backwater.inundation events and sedimentation of adjacent floodplains increase. Over time however these effects are cancelled by river banks becoming higher.river incision increases and channels deepen.

There are two basic types of watermills, one powered by a vertical-waterwheel via a gear mechanism, and the other equipped with a horizontal-waterwheel without such a mechanism. The former type can be further divided, depending on where the water hits the wheel paddles, into undershot, overshot, breastshot and reverse shot waterwheel mills.

Model of a Roman water-powered grain-mill described by Vitruvius. The millstone (upper floor) is powered by an undershot waterwheel by the way of a gear mechanism (lower floor)

The Greeks invented the two main components of watermills, the waterwheel and toothed gearing, and used, along with the Romans, undershot, overshot and breastshot waterwheel mills.

Lewis assigns the date of the invention of the horizontal-wheeled mill to the Greek colony of Byzantium in the first half of the 3rd century BC, and that of the vertical-wheeled mill to Ptolemaic Alexandria around 240 BC.

The Greek geographer Strabon reports in his Geography a water-powered grain-mill to have existed near the palace of king Mithradates VI Eupator at Cabira, Asia Minor, before 71 BC.

The Roman engineer Vitruvius has the first technical description of a watermill, dated to 40/10 BC; the device is fitted with an undershot wheel and power is transmitted via a gearing mechanism.kneading machines.

Hold back your hand from the mill, you grinding girls; even if the cockcrow heralds the dawn, sleep on. For Demeter has imposed the labours of your hands on the nymphs, who leaping down upon the topmost part of the wheel, rotate its axle; with encircling cogs,Nisyrian millstones. If we learn to feast toil-free on the fruits of the earth, we taste again the golden age.

The 2nd century AD multiple mill complex of Barbegal in southern France has been described as "the greatest known concentration of mechanical power in the ancient world".flour mills. The capacity of the mills has been estimated at 4.5 tons of flour per day, sufficient to supply enough bread for the 12,500 inhabitants occupying the town of Arelate at that time.Janiculum hill, whose supply of flour for Rome"s population was judged by emperor Aurelian important enough to be included in the Aurelian walls in the late 3rd century.

The 3rd century AD Hierapolis water-powered stone sawmill is the earliest known machine to incorporate a crank and connecting rod mechanism.Gerasa and Ephesus.marble saws in what is now Germany can be found in Ausonius 4th century AD poem Mosella. They also seem to be indicated about the same time by the Christian saint Gregory of Nyssa from Anatolia, demonstrating a diversified use of water-power in many parts of the Roman Empire.

Roman turbine mill at Chemtou, Tunisia. The tangential water inflow of the millrace made the horizontal wheel in the shaft turn like a true turbine, the earliest known.

The earliest turbine mill was found in Chemtou and Testour, Roman North Africa, dating to the late 3rd or early 4th century AD.furnace has been identified at Marseille, France.

Mills were commonly used for grinding grain into flour (attested by Pliny the Elder), but industrial uses as fulling and sawing marble were also applied.

The Romans used both fixed and floating water wheels and introduced water power to other provinces of the Roman Empire. So-called "Greek Mills" used water wheels with a horizontal wheel (and vertical shaft). A "Roman Mill" features a vertical wheel (on a horizontal shaft). Greek style mills are the older and simpler of the two designs, but only operate well with high water velocities and with small diameter millstones. Roman style mills are more complicated as they require gears to transmit the power from a shaft with a horizontal axis to one with a vertical axis.

Although to date only a few dozen Roman mills are archaeologically traced, the widespread use of aqueducts in the period suggests that many remain to be discovered. Recent excavations in Roman London, for example, have uncovered what appears to be a tide mill together with a possible sequence of mills worked by an aqueduct running along the side of the River Fleet.

The surviving evidence for watermills sharply increases with the emergence of documentary genres such as monastic charters, Christian hagiography and Germanic legal codes. These were more inclined to address watermilling, a mostly rural work process, than the ancient urban-centered literary class had been.Carolingian times, references to watermills had become "innumerable" in Frankish records.Domesday Book, compiled in 1086, records 5,624 watermills in England alone.Ireland. A century later they began to spread across the former Roman Rhine and Danube frontier into the other parts of Germany.Ship mills and tide mills, both of which yet unattested for the ancient period,

In recent years, a number of new archaeological finds has consecutively pushed back the date of the earliest tide mills, all of which were discovered on the Irish coast: A 6th century vertical-wheeled tide mill was located at Killoteran near Waterford.horizontal-wheeled tide mill dating to c. 630 was excavated on Little Island.Nendrum Monastery mill from 787 was situated on an island in Strangford Lough in Northern Ireland. Its millstones are 830mm in diameter and the horizontal wheel is estimated to have developed 7/8HP at its peak. Remains of an earlier mill dated at 619 were also found at the site.

In a 2005 survey the scholar Adam Lucas identified the following first appearances of various industrial mill types in Western Europe. Noticeable is the preeminent role of France in the introduction of new innovative uses of waterpower. However, he has drawn attention to the dearth of studies of the subject in several other countries.

The waterwheel was found in China from 30 AD onwards, when it was used to power trip hammers,bellows in smelting iron,armillary sphere for astronomical observation (see Zhang Heng).Joseph Needham speculates that the water-powered millstone could have existed in Han China by the 1st century AD, there is no sufficient literary evidence for it until the 5th century AD.Zu Chongzhi had a watermill erected which was inspected by Emperor Wu of Southern Qi (r. 482–493 AD).Sui Dynasty (581–618 AD) was said to operate hundreds of them by the beginning of the 6th century.Buddhist monks arguing over the revenues gained from watermills.Tang Dynasty (618–907 AD) "Ordinances of the Department of Waterways" written in 737 AD stated that watermills should not interrupt riverine transport and in some cases were restricted to use in certain seasons of the year.Buddhist abbeys that failed to acknowledge ordinances or meet government regulations.eunuch serving Emperor Xuanzong of Tang (r. 712–756 AD) owned a watermill by 748 AD which employed five waterwheels that ground 300 bushels of wheat a day.Japan via Korean Peninsula.Tibet by at least 641 AD.

According to Greek historical tradition, India received water-mills from the Roman Empire in the early 4th century AD when a certain Metrodoros introduced "water-mills and baths, unknown among them [the Brahmans] till then".

An Afghan water mill photographed during the Second Anglo-Afghan War (1878-1880). The rectangular water mill has a thatched roof and traditional design with a small horizontal mill-house built of stone or perhaps mud bricks

Engineers under the Caliphates adopted watermill technology from former provinces of the Byzantine Empire, having been applied for centuries in those provinces prior to the Muslim conquests, including modern-day Syria, Jordan, Israel, Algeria, Tunisia, Morocco, and Spain (see List of ancient watermills).

The industrial uses of watermills in the Islamic world date back to the 7th century, while horizontal-wheeled and vertical-wheeled watermills were both in widespread use by the 9th century.gristmills, hullers, sawmills, ship mills, stamp mills, steel mills, sugar mills, and tide mills. By the 11th century, every province throughout the Islamic world had these industrial watermills in operation, from al-Andalus and North Africa to the Middle East and Central Asia.crankshafts and water turbines, gears in watermills and water-raising machines, and dams as a source of water, used to provide additional power to watermills and water-raising machines.Al-Andalus to Christian Spain in the 12th century. Industrial watermills were also employed in large factory complexes built in al-Andalus between the 11th and 13th centuries.

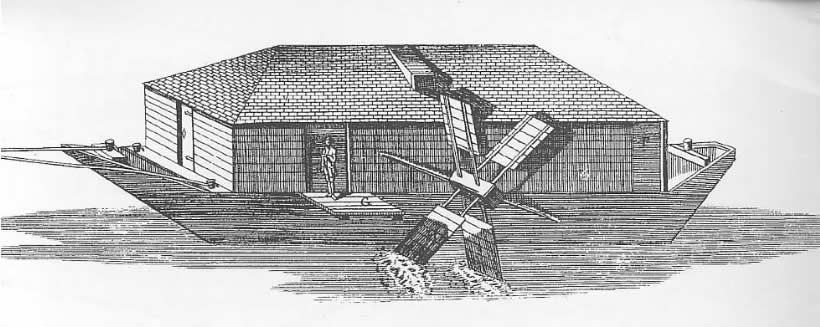

The engineers of the Islamic world used several solutions to achieve the maximum output from a watermill. One solution was to mount them to piers of bridges to take advantage of the increased flow. Another solution was the ship mill, a type of watermill powered by water wheels mounted on the sides of ships moored in midstream. This technique was employed along the Tigris and Euphrates rivers in 10th-century Iraq, where large ship mills made of teak and iron could produce 10 tons of flour from corn every day for the granary in Baghdad.

Typically, water is diverted from a river or impoundment or mill pond to a turbine or water wheel, along a channel or pipe (variously known as a flume, head race, mill race, leat, leet,penstock). The force of the water"s movement drives the blades of a wheel or turbine, which in turn rotates an axle that drives the mill"s other machinery. Water leaving the wheel or turbine is drained through a tail race, but this channel may also be the head race of yet another wheel, turbine or mill. The passage of water is controlled by sluice gates that allow maintenance and some measure of flood control; large mill complexes may have dozens of sluices controlling complicated interconnected races that feed multiple buildings and industrial processes.

Watermills can be divided into two kinds, one with a horizontal water wheel on a vertical axle, and the other with a vertical wheel on a horizontal axle. The oldest of these were horizontal mills in which the force of the water, striking a simple paddle wheel set horizontally in line with the flow turned a runner stone balanced on the rynd which is atop a shaft leading directly up from the wheel. The bedstone does not turn. The problem with this type of mill arose from the lack of gearing; the speed of the water directly set the maximum speed of the runner stone which, in turn, set the rate of milling.

Most watermills in Britain and the United States of America had a vertical waterwheel, one of four kinds: undershot, breast-shot, overshot and pitchback wheels. This vertical produced rotary motion around a horizontal axis, which could be used (with cams) to lift hammers in a forge, fulling stocks in a fulling mill and so on.

However, in corn mills rotation about a vertical axis was required to drive its stones. The horizontal rotation was converted into the vertical rotation by means of gearing, which also enabled the runner stones to turn faster than the waterwheel. The usual arrangement in British and American corn mills has been for the waterwheel to turn a horizontal shaft on which is also mounted a large pit wheel. This meshes with the wallower, mounted on a vertical shaft, which turns the (larger) great spur wheel (mounted on the same shaft). This large face wheel, set with pegs, in turn, turned a smaller wheel (such as a lantern gear) known as a stone nut, which was attached to the shaft that drove the runner stone. The number of runner stones that could be turned depended directly upon the supply of water available. As waterwheel technology improved mills became more efficient, and by the 19th century, it was common for the great spur wheel to drive several stone nuts, so that a single water wheel could drive as many as four stones.sluice gate and thus the flow of the water past the main wheel allowed the miller to compensate for seasonal variations in the water supply. Finer speed adjustment was made during the milling process by tentering, that is, adjusting the gap between the stones according to the water flow, the type of grain being milled, and the grade of flour required.

In many mills (including the earliest) the great spur wheel turned only one stone, but there might be several mills under one roof. The earliest illustration of a single waterwheel driving more than one set of stones was drawn by Henry Beighton in 1723 and published in 1744 by J. T. Desaguliers.

An inherent problem in the overshot mill is that it reverses the rotation of the wheel. If a miller wishes to convert a breastshot mill to an overshot wheel all the machinery in the mill has to be rebuilt to take account of the change in rotation. An alternative solution was the pitchback or backshot wheel. A launder was placed at the end of the flume on the headrace, this turned the direction of the water without much loss of energy, and the direction of rotation was maintained. Daniels Mill near Bewdley, Worcestershire is an example of a flour mill that originally used a breastshot wheel, but was converted to use a pitchback wheel. Today it operates as a breastshot mill.

Larger water wheels (usually overshot steel wheels) transmit the power from a toothed annular ring that is mounted near the outer edge of the wheel. This drives the machinery using a spur gear mounted on a shaft rather than taking power from the central axle. However, the basic mode of operation remains the same; gravity drives machinery through the motion of flowing water.

Toward the end of the 19th century, the invention of the Pelton wheel encouraged some mill owners to replace over- and undershot wheels with Pelton wheel turbines driven through penstocks.

A different type of watermill is the tide mill. This mill might be of any kind, undershot, overshot or horizontal but it does not employ a river for its power source. Instead a mole or causeway is built across the mouth of a small bay. At low tide, gates in the mole are opened allowing the bay to fill with the incoming tide. At high tide the gates are closed, trapping the water inside. At a certain point a sluice gate in the mole can be opened allowing the draining water to drive a mill wheel or wheels. This is particularly effective in places where the tidal differential is very great, such as the Bay of Fundy in Canada where the tides can rise fifty feet, or the now derelict village of Tide Mills, East Sussex.Eling, Hampshire and at Woodbridge, Suffolk.

Run of the river schemes do not divert water at all and usually involve undershot wheels the mills are mostly on the banks of sizeable rivers or fast flowing streams. Other watermills were set beneath large bridges where the flow of water between the stanchions was faster. At one point London bridge had so many water wheels beneath it that bargemen complained that passage through the bridge was impaired.

A few historic mills such as the Water Mill, Newlin Mill and Yates Mill in the US and The Darley Mill Centre in the UK still operate for demonstration purposes. Small-scale commercial production is carried out in the UK at Daniels Mill, Little Salkeld Mill and Redbournbury Mill. This was boosted to overcome flour shortages during the Covid pandemic.

In some developing countries, watermills are still widely used for processing grain. For example, there are thought to be 25,000 operating in Nepal, and 200,000 in India.

Blast furnaces, finery forges, and tinplate works were, until the introduction of the steam engine, almost invariably water powered. Furnaces and Forges were sometimes called iron mills.

Cotton mills were driven by water. The power was used to card the raw cotton, and then to drive the spinning mules and ring frames. Steam engines were initially used to increase the water flow to the wheel, then as the industrial revolution progressed, to directly drive the shafts.

Maaß, Anna-Lisa; Schüttrumpf, Holger (2019). "Elevated floodplains and net channel incision as a result of the construction and removal of water mills". 101 (2): 157–176. doi:10.1080/04353676.2019.1574209. S2CID 133795380.

The translation of this word is crucial to the interpretation of the passage. Traditionally, it has been translated as "spoke" (e.g. Reynolds, p. 17), but Lewis (p. 66) points out that, while its primary meaning is "ray" (as a sunbeam), its only concrete meaning is "cog". Since a horizontal-wheeled corn mill does not need gearing (and hence has no cogs), the mill must have been vertical-wheeled.

Adam Robert Lucas, "Industrial Milling in the Ancient and Medieval Worlds. A Survey of the Evidence for an Industrial Revolution in Medieval Europe", Technology and Culture, Vol. 46, (Jan. 2005), pp. 1-30 (17).

Wikander 2000, p. 400: This is also the period when water-mills started to spread outside the former Empire. According to Cedrenus (Historiarum compendium), a certain Metrodoros who went to India in c. AD 325 "constructed water-mills and baths, unknown among them [the Brahmans] till then".

Adam Robert, Lucas (2005). "Industrial Milling in the Ancient and Medieval Worlds: A Survey of the Evidence for an Industrial Revolution in Medieval Europe". Technology and Culture. 46 (1): 1–30 [10]. doi:10.1353/tech.2005.0026. S2CID 109564224.

Adam Robert, Lucas (2005). "Industrial Milling in the Ancient and Medieval Worlds: A Survey of the Evidence for an Industrial Revolution in Medieval Europe". Technology and Culture. 46 (1): 1–30 [11]. doi:10.1353/tech.2005.0026. S2CID 109564224.

Donners, K.; Waelkens, M.; Deckers, J. (2002), "Water Mills in the Area of Sagalassos: A Disappearing Ancient Technology", Anatolian Studies, vol. 52, pp. 1–17, doi:10.2307/3643076, JSTOR 3643076, S2CID 163811541

McErlean, Thomas; Crothers, Norman (2007), Harnessing the Tides: The Early Medieval Tide Mills at Nendrum Monastery, Strangford Lough, Belfast: Stationery Office Books, ISBN 978-0-337-08877-3

Munro, John H. (2003), "Industrial energy from water-mills in the European economy, 5th to 18th Centuries: the limitations of power", Economia ed Energia, Seccoli XIII - XVIII, Atti delle "Settimane di Studi" e Altrie Convegni, Istituto Internazionale di Storia Economica, F. Datini, vol. 34, no. 1, pp. 223–269

Murphy, Donald (2005), Excavations of a Mill at Killoteran, Co. Waterford as Part of the N-25 Waterford By-Pass Project (PDF), Estuarine/ Alluvial Archaeology in Ireland. Towards Best Practice, University College Dublin and National Roads Authority, archived from the original (PDF) on 2007-11-18

Ritti, Tullia; Grewe, Klaus; Kessener, Paul (2007), "A Relief of a Water-powered Stone Saw Mill on a Sarcophagus at Hierapolis and its Implications", Journal of Roman Archaeology, vol. 20, pp. 138–163

Wikander, Örjan (2000), "The Water-Mill", in Wikander, Örjan (ed.), Handbook of Ancient Water Technology, Technology and Change in History, vol. 2, Leiden: Brill, pp. 371–400, ISBN 90-04-11123-9

Releasing and circulating overshot is an external fishing tool for engage, pack off and retrieve tublar fish, especially for fishing drill collar and drill pipe. The grapple of the overshot can be designed for different sizes of fish, so one overshot can be dressed wih different size of grapple components for fishing different sizes of fish.

RMTXH39N–Multiple suction pumps, powered by an overshot water wheel through a spur wheel and lantern, being used to raise water from a mine. From "De re metallica", by Agricola, pseudonym of Georg Bauer (Basle, 1556). Woodcut.

RMMPAKW1–. Deutsch: Wassermühle mit einem oberschlächtigen Wasserrad. British Library, Cotton Manuscript Cleopatra C XI, fol 10. English: Mill with overshoot wheel. British Library, Cotton Manuscript Cleopatra C XI, fol 10. between circa 1220 and circa 1230. Unknown 879 Medieval mill with overshot wheel

RF2B770CM–An image of the overshot wheel that operates machinery by water power, receiving water at the top, it shows the water wheel power of generation in it,

RM2AMM7ET–the overshot water wheel at the Maiermühle in TeisendorfThe mill has been in the possession of the Mühlbacher family since 1769 - the 8th generation - the oldest machine family from 1920the mill has existed at least since the Middle Ages - the water wheel was bought second-hand in 1930 (at that time it was already 50 years old and comes from Franconia) - the arms are made of oak wood, the wheel itself is made of iron - a centimetre thick layer of lime protects against rust20 grinding passes are made from the grain fine more [automated translation]

RMTXH3F5–Draining mine workings by means of a battery of three pumps. The axle, B, is powered by an overshot water wheel. The cams on the axle raise and lower the piston rods by means of tappets. C is the bottom of the pipe which is encased in the basket, D. From "De re metallica", by Agricola, pseudonym of Georg Bauer (Basle, 1556). Woodcut.

RF2C9CE04–Overshot wheel, gives the greatest power with the least quantity of waterand so mainly used when circumstances will permit, or where there is a consid

RMP774N6–. English: Mining operation, Glacier Creek, July 14, 1906 . English: Caption on image: Overshot wheel and China pump operated by A.F. Guinan. Glacier Creek, July 14th 1906. Photo by F.H. Nowell, Nome, 4961 Subjects (LCTGM): Mining equipment--Alaska Subjects (LCSH): Gold mines and mining--Alaska . 1906 9 Mining operation, Glacier Creek, July 14, 1906 (NOWELL 182)

RM2EAERG7–Bagging up the flour produced by Lurgashall Mill. Weald and Downland Open Air Museum, Singleton, Nr. Chichester, West Sussex. The overshot wheel powe

RMTXH39C–A rag-and-chain pump powered by an overshot water wheel being used to drain a mine. On the right is a detail of the tube of the pump. From "De re metallica", by Agricola, pseudonym of Georg Bauer (Basle, 1556). Woodcut.

RF2CB7RM0–Overshot water wheel and flume at historic Oblazy Water Mill at Kvacianka river, Kvacany Valley (Kvačianska dolina), Liptov area, Zilina Region, Slovakia

RMPPEK4E–The overshot waterwheel on the Maiermuehle in Teisendorf. Since 1769 the mill is owned by the Muehlbach family - in the 8th generation - the oldest machine dates back to 1920. The mill has existed at least since the Middle Ages - the waterwheel was used in 1930 (it was already 50 years old and Comes from the Franconian region). The arms are made of oak, the wheel itself is made of iron - a 1 centimeter thick layer protects it against rust. Fine flour is obtained from the grain after 20 grinding processes.

RF2D74G56–Paternoster work with overshot water wheel / Paternosterwerk mit oberschlächtigem Wasserrad, Historisch, historical, digital improved reproduction of an original from the 19th century / digitale Reproduktion einer Originalvorlage aus dem 19. Jahrhundert

RMMR3X1X–Diagram depicting various forms of water wheels including at Fig. 5, a pitch back overshot wheel. Created by Abraham Rees (1743-1825) a Welsh nonconformist minister, and compiler of Rees"s Cyclopædia. Dated 19th century

RF2CB7RMG–Tourist coming out under flume, leaking water, overshot water wheel at historic Oblazy Water Mill at Kvacianka river, Kvacany Valley (Kvačianska dolina), Liptov area, Zilina Region, Slovakia

RMRJHB0B–Drawing showing Pump driven by overshot water wheel, used to raise water into a reservoir, to operate the ornamental fountain in the background. From Georg Andreas Bockler; Theatrum Machinarum Novum, Nuremberg, 1673

RMD95KFA–A rag-and-chain pump powered by an overshot water wheel being used to drain a mine. On the right is a detail of the tube of the pump. From "De re metallica", by Agricola, pseudonym of Georg Bauer (Basle, 1556). Woodcut.

RMTX1CWX–The overshot water wheel and lade at Coldstream Mill in North Ayrshire. Circa 1999.; 11 February 2007 (original upload date); Transferred from en.pedia to Commons.; Rosser1954 at English pedia;

RMD95KD7–Stamping mills powered by and overshot water wheel being used to crush ore to begin the process of extracting metal from the ore won from a mine. From "De re metallica", by Agricola, pseudonym of Georg Bauer (Basle, 1556). Woodcut. Mining. Metal. Power. Water.

RMTXGY3X–Mine being drained by a rag-and-chain pump powered by overshot water wheel. At right is detail of section of pipe K From "Agricola De re metallica" 1556 Basle

RM2BA554H–"Deutsch: Oberschlächtiges Wasserrad neben dem Alten Rathaus in Tambach-Dietharz, Deutschland, 2007.English: Overshot water wheel next to old townhall in Tambach-Dietharz, Germany, 2007.; 29 September 2007; Own work; Sebastian Wallroth; "

RM2C218J9–Swansea, Wales, UK. 16th June 2020. The historic water mill at the Gower Heritage centre in south Wales, which is still turning despite the popular tourist attraction being closed due to the Coronavirus pandemic restrictions. There has been a mill at the location on the peninsular since 1160, and it is still in operation today, with flour going into the locally produced bread and being sold online for collection and delivery. Pictured is Richie Saunders who helps maintain the 12th century mill, pulling a bag of grain to the top of the mill with the sack hoist. Credit : Robert Melen/Alamy Liv

Long before the industrial revolution withSpinning Jenny,James Wattand hissteam engine, there was a mill revolution. One might call it a mini-industrial revolution. Windmills and waterwheels all over Europe were powering a large variety of mills.

This revolution began around 900 AD and was a uniquely European phenomena that would later have major repercussions in terms of European technological lead over other great civilizations. Terry Reynolds, the leading technological historian of the watermill, hascontendedthat:If there was a single key element distinguishing western European technology from the technologies of Islam, Byzantium, India, or even China after around 1200 CE, it was the West’s extensive commitment to and use of water power.

Max Pfingstengives someexamplesof how rapid the usage of mills grew in Europe.In a single French province, watermill production increased from an average of a mill every 5 years (from 850-1080) to a mill a year (from 1080-1125) to 5 mills a year (from 1125-1175).

After William the Conqueror had invaded Britain, he wanted a survey of everything that had come under his possession. In 1086 AD he had all of this info recorded in the oddly ominously sounding Domesday book. The book records 6,082 watermills in England. Let us put that into perspective. Early watermills, grinding grain, did the work of up to 60 men. That means the watermills in 1086 did the work of almost 400,000 people at a time when England had no more than1.25 million inhabitants. That means doing as much work as almost 30 percent of the English population.

By 1500, the far more powerful overshot waterwheel became prevalent in Europe.Wikipedia has detailson how powerful different types of mills were:It has been estimated that the ancient donkey or slave-powered quern of Rome made about one-half of a horsepower, the horizontal waterwheel creating slightly more than 1.5 of a horsepower, the undershot vertical waterwheel produced about 3 horsepower, and the medieval overshot waterwheel produced up to 40 - 60 horsepower.

Low-tech magazinegives some numbersfor the power of Dutch windmills, which suggest they were comparable to overshot waterwheels:windmill constructed in 1648, showed that the mill generated around 40 horsepower at the windshaft but only 15.6 horsepower at the machines

Towards the end of the Dutch Golden age (1588 to 1672) there were9,000 windmillsin operation in the Netherlands, which must have significantly reduced the amount of work which had to be done by humans and animals. Keep in mind that the Netherlands in this period has from 1.5 to 2.0 million inhabitants. The windmills could easily have done more work than all the citizens could have done combined manually.

The number of waterwheels kept rising rapidly in the United Kingdom as well. It has been estimated that the United Kingdom had between 10,000 and 13,000 mills in 1300. All of Europe benefitted tremendously from wind and water power. FromLow-tech magazine:The total amount of wind powered mills in Europe was estimated to be around 200,000 (at its peak), compared to some 500,000 waterwheels

Today, we think of factories are things with complex machinery with numerous moving parts. Mills in contrast were quite simple. Mills were primarily designed to grind, crush and beat things, which doesn"t sound very exciting and important. However, numerous important labour intensive processes require exactly those things.

For crushing, one places the millstones in a vertical position and create an "edge roller" following a circular path around a central axis. Grain needs grinding but a lot of other food processing needs crushing, such as producing olive oil by crushing olive seeds. The same technique can be used for: mustard, poppy seeds, linseeds, hempseeds, and peanuts. Linseed oil had important application in lubrication of machinery, guns, and weapon.

There are also numerous minerals and rocks which are useful to crush. Making gunpowder involves crushing sulfur and charcoal, for instance. Dyes are made from crushed minerals. The Dutch built hundreds of windmills in the West Indies for crushing sugar cane.

Traditional paper making is essentially about beating cloth soaked in water. The Netherlands used windmills extensively to produce paper . For literacy and the scientific revolution this was a crucial development as it allowed Europeans to make paper much more cheaply.

To get a sense of how labour saving mills could be, we can take an example from the fulling process. This is a process related to wool processing. Basically, you beat the wool soaked in water. Today, you could probably use a washing machine for much the same task. A fulling mill could in a couple of hours does what took 3 workers a whole year of hard work to accomplish. These facts give an inkling of why the Netherlands could be so much richer than everybody else.

The Netherlands was a windmill powerhouse. Huge number of windmills were employed in all sorts of processing. Half the sugar imported to Europe got processed in the Netherlands. The Dutch didn"t grow olives, but they crushed the seeds to make olive oil. Raw materials from all over Europe got imported to the Netherlands for processing and further export.

Perhaps an even more visible example of the implications of mills in the European economy is how windmills helped the Netherlands dominate seafaring and trade in the 1600s.

How could a country with such a tiny population crank out more ships every year than even huge empires? The Dutch had a trick up their sleeve:A wind-powered sawmill, invented byCornelis Corneliszoon van Uitgeestin 1594.Low-Tech magazinegives moredetails:The first sawmill ("Het juffertje" or "The missy") was built in the town of Zaandam by Cornelis Corneliszoon in 1596. By 1630, there were 83 sawmills north of Amsterdam, of which 53 were located in the Zaan district. The peak was reached in 1731 when there were 450 sawmills in the Netherlands, 256 of them in the Zaan district.

These sawmills powered by windmills allowed the Dutch todramatically cut the amount of labourrequired to process wood for shipbuilding:The importance of the wind-powered sawmill taking off in the Netherlands cannot be understated. Wood production didn"t double, triple or quadruple; it grew by a factor of thirty, or 3,000%.

It was all in the time savings: Using the pit-saw method, sawyers could process 60 logs over a span of 120 days. Using a wind-powered sawmill, they could break down 60 logs in four or five days. What used to take four months now took less than a week.

The Dutch Zaan district was like a large industrial hub powered by a huge number of windmills, where wooden ships got built in a manner that looked a lot like assembly line production. Ships at different stage of assembly would pass from one station to the next, where a new team of specialists would perform tasks they were specialized on. Multiple ships at different stage of development would get worked on in parallel.

TheVenetian Arsenalin the renaissance has by many been regarded as the first assembly line production, hundreds of years before Henry Ford. The Dutch took this a step further by using the inanimate power of windmills. The result was that countries all over Europe began ordering ships from the Netherlands. The Dutch were not merely transporting goods for other nations, but also buildings ships for them.

The motivation behind this story was to give more background to help explain why a mill and machinery revolution did not happen in China before the industrial revolution. Before answering that question, we have to clarify that something significant was actually happening in Europe with water and windmills. They played a significant role in setting the stage for the later industrial revolution. However, the steam engine and textile mills of the late 1700s and early 1800s tend to overshadow the important developments that came before.

As shown in Figure 1, the light junk cover of a kind of weak point mills fishing socket and mainly is made up of tool joint 1, light-wall pipe inward dipper 2, milling bit 3, thick pin 4 and thick pin 5; light-wall pipe inward dipper 2 tops and the thick pin 4 of tool joint 1 usefulness are connected with 5 one-tenth assorted words of pin slightly, and milling bit 3 is that welding-on tungsten nitride wolfram steel powder is made on the serrated teeth that is slit in light-wall pipe inward dipper 2 bottoms.

When the junk of card is buried in salvaging, can apply certain the pressure of the drill and rotate drilling tool and overlap and mill; when light-wall pipe inward dipper 2 progressively packs into junk under the guiding of milling bit 4; can in time hold easily because of inward clamp tool enters the intrinsic junk of the dipper of windowing; have the junk of shoulder to form to fall to support in the clamp of windowing of light-wall pipe inward dipper 2, can realize salvaging, removing bottom hole falling article easily.

For water wheels used to drive boats, see paddle wheel. For wheels used solely to lift water see noria. For factories or industries driven by water wheels see watermill.

A water wheel is a hydropower system; a machine for extracting power from the flow of water. Water wheels and hydropower was widely used in the Middle Ages, powering most industry in Europe, along with the windmill. The most common use of the water wheel was to mill flour in gristmills, but other uses included foundry work and machining, and pounding linen for use in paper.

The technology of the water wheel had long been known, but it was not put into widespread use until the Middle Ages when an acute shortage of labor made machines such as the water wheel cost effective. However, the water wheels in ancient Rome and ancient China found many practical uses in powering mills for pounding grain and other substances. The Romans used both fixed and floating water wheels and introduced water power to other countries of the Roman Empire. The Romans were known to use waterwheels extensively in mining projects, with enormous Roman-era waterwheels found in places like modern-day Spain. In the 1st century BC, the Greek epigrammatist Antipater of Thessalonica was the first to make a reference to the waterwheel.

By at least the 1st century AD, the Chinese of the Eastern Han Dynasty began to use waterwheels to crush grain in mills and to power the piston-bellows in forging iron ore into cast iron.

In the year 31 AD, the engineer and Prefect of Nanyang, Du Shi, applied a complex use of the waterwheel and machinery to power the bellows of the blast furnace to create cast iron. Waterwheels in China found practical uses such as this, as well as extraordinary use. The inventor Zhang Heng (78–139) was the first in history to apply motive power in rotating the astronomical instrument of an armillary sphere, by use of a waterwheel. The mechanical engineer Ma Jun (200–265) once used a waterwheel to power and operate a large mechanical puppet theater for Emperor Ming of Wei.

Cistercian monasteries, in particular, made extensive use of water wheels to power mills of many kinds. An early example of a very large waterwheel is still extant at the early 13th century Real Monasterio de Nuestra Senora de Rueda, a Cistercian monastery in the Aragon region of Spain. Grist mills (for corn) were undoubtedly the most common, but there were also sawmills, fulling mills and mills to fulfill many other labor-intensive tasks. The water wheel remained competitive with the steam engine well into the Industrial Revolution.

The main difficulty of water wheels was their inseparability from water. This meant that mills often needed to be located far from population centers and away from natural resources. Water mills were still in commercial use well into the twentieth century, however.

Overshot & pitchback waterwheels are suitable where there is a small stream with a height difference of more than 2 meters, often in association with a small reservoir. Breastshot and undershot wheels can be used on rivers or high volume flows with large reservoirs.

The most powerful waterwheel built in the United Kingdom was the 100 hp Quarry Bank Mill Waterwheel near Manchester. A high breastshot design, it was retired in 1904 and replaced with several turbines. It has now been restored and is a museum open to the public.

This article is about a type of structure. For other locational uses, see Milldam. For details of the technologies, see Water wheel. For further details of the technologies, see Mill machinery. For Jerome Robbins" 1972 ballet, see Watermill (ballet).

A watermill or water mill is a mill that uses hydropower. It is a structure that uses a water wheel or water turbine to drive a mechanical process such as milling (grinding), rolling, or hammering. Such processes are needed in the production of many material goods, including flour, lumber, paper, textiles, and many metal products. These watermills may be comprise gristmills, sawmills, paper mills, textile mills, hammermills, trip hammering mills, rolling mills, wire drawing mills.

One major way to classify watermills is by wheel orientation (vertical or horizontal), one powered by a vertical waterwheel through a gearing mechanism, and the other equipped with a horizontal waterwheel without such a mechanism. The former type can be further divided, depending on where the water hits the wheel paddles, into undershot, overshot, breastshot and pitchback (backshot or reverse shot) waterwheel mills. Another way to classify water mills is by an essential trait about their location: tide mills use the movement of the tide; ship mills are water mills onboard (and constituting) a ship.

According to Terry S. Reynolds and R. J. Forbes, the water wheel may have originated from the ancient Near East in the 3rd century BC for use in moving millstones and small-scale corn grinding.Norias and, by the 2nd century BC, evolved into the vertical watermill in Syria and Asia Minor, from where it spread to ancient Greece and the Roman Empire.

Engineers in the Hellenistic world used the two main components of watermills, the waterwheel and toothed gearing, and, along with the Roman Empire, operated undershot, overshot and breastshot waterwheel mills.

Lewis assigns the date of the invention of the horizontal-wheeled mill to the Greek colony of Byzantium in the first half of the 3rd century BC, and that of the vertical-wheeled mill to Ptolemaic Alexandria around 240 BC.

The Greek geographer Strabon reports in his Geography a water-powered grain-mill to have existed near the palace of king Mithradates VI Eupator at Cabira, Asia Minor, before 71 BC.

The Roman engineer Vitruvius has the first technical description of a watermill, dated to 40/10 BC; the device is fitted with an undershot wheel and power is transmitted via a gearing mechanism.kneading machines.

Hold back your hand from the mill, you grinding girls; even if the cockcrow heralds the dawn, sleep on. For Demeter has imposed the labours of your hands on the nymphs, who leaping down upon the topmost part of the wheel, rotate its axle; with encircling cogs,Nisyrian millstones. If we learn to feast toil-free on the fruits of the earth, we taste again the golden age.

It is likely that a water-powered stamp mill was used at Dolaucothi to crush gold-bearing quartz, with a possible date of the late 1st century to the early 2nd century. The stamps were operated as a batch of four working against a large conglomerate block, now known as Carreg Pumpsaint. Similar anvil stones have been found at other Roman mines across Europe, especially in Spain and Portugal.

The 1st-century AD multiple mill complex of Barbegal in southern France has been described as "the greatest known concentration of mechanical power in the ancient world".flour mills. The capacity of the mills has been estimated at 4.5 tons of flour per day, sufficient to supply enough bread for the 12,500 inhabitants occupying the town of Arelate at that time.Janiculum hill, whose supply of flour for Rome"s population was judged by emperor Aurelian important enough to be included in the Aurelian walls in the late 3rd century.

The 3rd-century AD Hierapolis water-powered stone sawmill is the earliest known machine to incorporate a crank and connecting rod mechanism.Gerasa and Ephesus.marble saws in what is now Germany can be found in Ausonius 4th-century poem Christian saint Gregory of Nyssa from Anatolia, demonstrating a diversified use of water-power in many parts of the Roman Empire.

The earliest turbine mill was found in Chemtou and Testour, Roman North Africa, dating to the late 3rd or early 4th century AD.furnace has been identified at Marseille, France.

Mills were commonly used for grinding grain into flour (attested by Pliny the Elder), but industrial uses as fulling and sawing marble were also applied.

The Romans used both fixed and floating water wheels and introduced water power to other provinces of the Roman Empire. So-called "Greek Mills" used water wheels with a horizontal wheel (and vertical shaft). A "Roman Mill" features a vertical wheel (on a horizontal shaft). Greek style mills are the older and simpler of the two designs, but only operate well with high water velocities and with small diameter millstones. Roman style mills are more complicated as they require gears to transmit the power from a shaft with a horizontal axis to one with a vertical axis.

Although to date only a few dozen Roman mills are archaeologically traced, the widespread use of aqueducts in the period suggests that many remain to be discovered. Recent excavations in Roman London, for example, have uncovered what appears to be a tide mill together with a possible sequence of mills worked by an aqueduct running along the side of the River Fleet.

The waterwheel was found in China from 30 AD onwards, when it was used to power trip hammers,bellows in smelting iron,armillary sphere for astronomical observation (see Zhang Heng).Zu Chongzhi had a watermill erected which was inspected by Emperor Wu of Southern Qi (r. 482–493 AD).Sui Dynasty (581–618 AD) was said to operate hundreds of them by the beginning of the 6th century.Buddhist monks arguing over the revenues gained from watermills.Tang Dynasty (618–907 AD) "Ordinances of the Department of Waterways" written in 737 AD stated that watermills should not interrupt riverine transport and in some cases were restricted to use in certain seasons of the year.Buddhist abbeys that failed to acknowledge ordinances or meet government regulations.eunuch serving Emperor Xuanzong of Tang (r. 712–756 AD) owned a watermill by 748 AD which employed five waterwheels that ground 300 bushels of wheat a day.Japan via Korean Peninsula.Tibet by at least 641 AD.

According to Greek historical tradition, India received water-mills from the Roman Empire in the early 4th century AD when a certain Metrodoros introduced "water-mills and baths, unknown among them [the Brahmans] till then".

Muslim engineers adopted watermill technology from former provinces of the Byzantine Empire, having been applied for centuries in those provinces prior to the Muslim conquests, including modern-day Syria, Jordan, Israel, Algeria, Tunisia, Morocco, and Spain (see List of ancient watermills).

The industrial uses of watermills in the Islamic world date back to the 7th century, while horizontal-wheeled and vertical-wheeled watermills were both in widespread use by the 9th century.gristmills, hullers, sawmills, shipmills, stamp mills, steel mills, sugar mills, and tide mills. By the 11th century, every province throughout the Islamic world had these industrial watermills in operation, from al-Andalus and North Africa to the Middle East and Central Asia.crankshafts and water turbines, gears in watermills and water-raising machines, and dams as a source of water, used to provide additional power to watermills and water-raising machines.Al-Andalus to Christian Spain in the 12th century. Industrial watermills were also employed in large factory complexes built in al-Andalus between the 11th and 13th centuries.

The engineers of the Islamic world used several solutions to achieve the maximum output from a watermill. One solution was to mount them to piers of bridges to take advantage of the increased flow. Another solution was the shipmill, a type of watermill powered by water wheels mounted on the sides of ships moored in midstream. This technique was employed along the Tigris and Euphrates rivers in 10th-century Iraq, where large shipmills made of teak and iron could produce 10 tons of flour from corn every day for the granary in Baghdad.

At the time of the compilation of the Domesday Book (1086), there were 5,624 watermills in England alone, only 2% of which have not been located by modern archeological surveys.Ireland, and began to spread from the former territory of the empire into the non-romanized parts of Germany a century later.Ship mills and tide mill were introduced in the 6th century.

In recent years, a number of new archaeological finds has consecutively pushed back the date of the earliest tide mills, all of which were discovered on the Irish coast: A 6th-century vertical-wheeled tide mill was located at Killoteran near Waterford.horizontal-wheeled tide mill dating to c. 630 was excavated on Little Island.Nendrum Monastery mill from 787 was situated on an island in Strangford Lough in Northern Ireland. Its millstones are 830mm in diameter and the horizontal wheel is estimated to have developed 7–8 hp at its peak. Remains of an earlier mill dated at 619 were also found at the site.

In a 2005 survey the scholar Adam Lucas identified the following first appearances of various industrial mill types in Western Europe. Noticeable is the preeminent role of France in the introduction of new innovative uses of waterpower. However, he has drawn attention to the dearth of studies of the subject in several other countries.

Typically, water is diverted from a river or impoundment or mill pond to a turbine or water wheel, along a channel or pipe (variously known as a flume, head race, mill race, leat, leet,penstock). The force of the water"s movement drives the blades of a wheel or turbine, which in turn rotates an axle that drives the mill"s other machinery. Water leaving the wheel or turbine is drained through a tail race, but this channel may also be the head race of yet another wheel, turbine or mill. The passage of water is controlled by sluice gates that allow maintenance and some measure of flood control; large mill complexes may have dozens of sluices controlling complicated interconnected races that feed multiple buildings and industrial processes.

Watermills can be divided into two kinds, one with a horizontal water wheel on a vertical axle, and the other with a vertical wheel on a horizontal axle. The oldest of these were horizontal mills in which the force of the water, striking a simple paddle wheel set horizontally in line with the flow turned a runner stone balanced on the rynd which is atop a shaft leading directly up from the wheel. The bedstone does not turn. The problem with this type of mill arose from the lack of gearing; the speed of the water directly set the maximum speed of the runner stone which, in turn, set the rate of milling.

Most watermills in Britain and the United States of America had a vertical waterwheel, one of four kinds: undershot, breast-shot, overshot and pitchback wheels. This vertical produced rotary motion around a horizontal axis, which could be used (with cams) to lift hammers in a forge, fulling stocks in a fulling mill and so on.

However, in corn mills rotation about a vertical axis was required to drive its stones. The horizontal rotation was converted into the vertical rotation by means of gearing, which also enabled the runner stones to turn faster than the waterwheel. The usual arrangement in British and American corn mills has been for the waterwheel to turn a horizontal shaft on which is also mounted a large pit wheel. This meshes with the wallower, mounted on a vertical shaft, which turns the (larger) great spur wheel (mounted on the same shaft). This large face wheel, set with pegs, in turn, turned a smaller wheel (such as a lantern gear) known as a stone nut, which was attached to the shaft that drove the runner stone. The number of runner stones that could be turned depended directly upon the supply of water available. As waterwheel technology improved mills became more efficient, and by the 19th century, it was common for the great spur wheel to drive several stone nuts, so that a single water wheel could drive as many as four stones.sluice gate and thus the flow of the water past the main wheel allowed the miller to compensate for seasonal variations in the water supply. Finer speed adjustment was made during the milling process by tentering, that is, adjusting the gap between the stones according to the water flow, the type of grain being milled, and the grade of flour required.

In many mills (including the earliest) the great spur wheel turned only one stone, but there might be several mills under one roof. The earliest illustration of a single waterwheel driving more than one set of stones was drawn by Henry Beighton in 1723 and published in 1744 by J. T. Desaguliers.

An inherent problem in the overshot mill is that it reverses the rotation of the wheel. If a miller wishes to convert a breastshot mill to an overshot wheel all the machinery in the mill has to be rebuilt to take account of the change in rotation. An alternative solution was the pitchback or backshot wheel. A launder was placed at the end of the flume on the headrace, this turned the direction of the water without much loss of energy, and the direction of rotation was maintained. Daniels Mill near Bewdley, Worcestershire is an example of a flour mill that originally used a breastshot wheel, but was converted to use a pitchback wheel. Today it operates as a breastshot mill.

Larger water wheels (usually overshot steel wheels) transmit the power from a toothed annular ring that is mounted near the outer edge of the wheel. This drives the machinery using a spur gear mounted on a shaft rather than taking power from the central axle. However, the basic mode of

8613371530291

8613371530291