overshot packer free sample

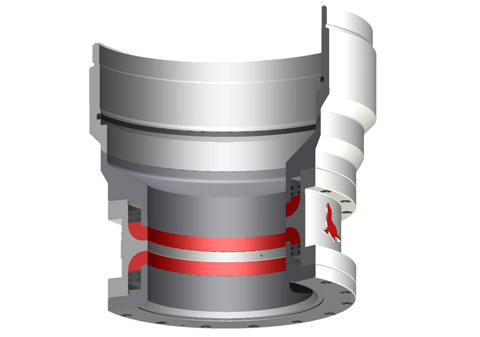

The RedSeal Dual Overshot Packer has been developed to provide a dual seal barrier in surface drilling systems used on jack-up and platform applications.

The RedSeal Dual Overshot Packer has been developed to provide a dual seal barrier in surface drilling systems used on jack-up and platform application. The system provides the operator with a primary and secondary seal system to mitigate potential environmental spills.

The system has been developed with a similar design philosophy to the RedSeal Packer system developed for drilling riser telescopic joints but does not include a facility for refill of the packer online as the seal element is a static seal and not subject to the dynamic motion associated to the RedSeal Packer system. Physically the RedSeal Dual Overshot Packer is shorter than traditional single packer systems allowing the system to be utilised in riser systems where stack-up heights are critical.

RedSeal Dual Overshot Packer can be supplied with a dedicated control system to monitor seal actuating pressure and (upon actuating pressure loss to primary seal element) switch automatically to the secondary seal, thereby minimising any environmental impact.

The fishing tool of the present disclosure is a type of retrieval tool or overshot which reaches around and grasps the fish. It is constructed with a soft set or soft touch mechanism. The soft set mechanism is especially desirable in light of the varied size and shape of the upper end of the fish. The shape of the fish may be known, but in some instances, it is completely unknown. Likely, it will be an elongate device having no particular anticipated shape. Whatever the case, the present device is constructed to reach over the fish and surround the upper end of the fish. The fish can be shredded, twisted, bent, or otherwise parted. It can just as easily be an elongate cylindrical member which simply has no shoulders, no threads, no undercut shoulder, no serrations or knurled surface, etc. It can be smooth metal or rough with no limit. This soft set structure reaches over the fish and conforms to the fish regardless of its shape. The fish is gripped by a surrounding resilient sleeve which is on the interior of the present overshot device. This sleeve fits around the fish with some clearance. The sleeve is on the interior of a cylindrical housing. By the proper actuation of the present device, fluid pressure is applied behind the sleeve so that the sleeve expands radially. It expands inwardly to grasp the fish which is enclosed within the sleeve. The upper end of the sleeve is free floating on a sealed surface of a stem which construction allows the sleeve to contract. The sleeve floats to enable it to conform to the fish. By having the top free floating, the sleeve material is in compressed when a pull is exerted. This allows for more strength in the tool. Also, the weight of the fish tends to help set the sleeve when coming out of the hole. While the present apparatus is able to transfer a tremendous amount of pulling force to the fish, there is the possibility that the fish will not break free. In that instance, it is then desirable that the fish be released. The present apparatus includes a mechanism by which release is accomplished. The soft set tool is set by pumping incompressible fluid behind the sleeve. That space is later evacuated of high pressure fluid and the pressure is released by dropping a ball to seat on a pinned sleeve. A predetermined pressure will shear the pins and move the sleeve downward to open access ports to the pressure chamber. The same movement opens ports to the annular area to eliminate the problems of pulling a wet string. This enables release of the fish and permits relaxation of the sleeve. In that instance, the sleeve will relax and expand radially outwardly for restoration to its original shape, and thereby release the fish. This makes retrieval of the fishing tool something easily done when the fish cannot be readily moved.

In very general terms, the tool of the present disclosure threads to a tubing string which enables the tool to be lowered in a well where a fishing job is to be conducted, and extend over the fish. The tool incorporates an elongate cylindrical upper end which has two internal sleeves which are selectively plugged by dropping a specifically sized ball in the tubing string. Dropping the smaller ball initiates seating on the lower sleeve, shutting off circulation thru the tool and allowing a predetermined pressure to be applied in the pressure chamber to set the soft set grapple. The same pressure will shear the sleeve pins. This allows the sleeve to move downwardly to open ports to the annular area, thereby establishing circulation. The setting pressure is retained in the setting chamber by back pressure valves. This ball stops flow axially of the tool and diverts the flow into a passage in the sidewall. This passage is ordinarily closed when flow is axially through the tool, closure being accomplished by a spring actuated check valve. When the check valve is overpowered, it delivers fluid under pressure controlled at the wellhead so that pressure build-up occurs in a chamber within the tool. The chamber is concentric around and coextensive along a resilient sleeve which is forced to shrink radially inwardly by the surrounding fluid pressure. This pressure causes the resilient material of the sleeve to conform against the surface of the fish and to grasp the fish so that it is held. As will be detailed substantially with the development of the present disclosure, the fish is held so that axial pulling can occur, hopefully retrieving the fish in the fashion of an overshot retrieval too. In the event that the procedure requires later release of the fish, a larger ball is dropped in the tubing string and lands on a larger bore seat at the upper end of the tool. By increasing pump pressure at the wellhead, this sphere in conjunction with a moveable sleeve is moved downwardly, breaking a set of shear pins. When it moves, the sleeve closes off or blocks the lateral passage by which fluid is introduced around the sleeve. Moreover, this enables a passage to be actuated which voids the chamber around the sleeve so that any build-up of pressure in that area is relieved. This permits the sleeve then to relax. Moreover, the downward movement opens a passage above the ball seat to establish circulation. This eliminates the necessity of pulling a wet string, reducing mud spillage. In this type of operation, the tool also has fill-up valves at the bottom of the tool and air release valves at the top. Both of these valves close when adequate pressure is achieved in the setting chamber.

A fish is indicated in dotted line by the numeral 50. This is typical of the type of device retrieved through the use of the present invention. Moreover, it is illustrated with no underside shoulder which enables a grappling tool or overshot having a bowl wedging inwardly a set of collet fingers with serrations to grasp the fish. Also, the fish may or may not have a conventional cylindrical shape, and the fish may or may not be smooth. Here, it will simply be assumed that the fish is difficult to grasp because it is an elongate member such as a pipe without a cylindrical shape. The resilient sleeve 48 is positioned about the fish by stabbing the fish into the soft set overshot 10 of this disclosure. At the juncture, no particular grip has been accomplished. The stabbing action can occur while drilling fluid is circulated downwardly through the passage 41 shown in FIG. 1B and flows over the fish to assure easy nesting of the fish in the sleeve 48. As shown now in FIG. 1C, the sleeve 48 is the primary component which surrounds and grasps the fish. To be sure, the outer body 38 extends around and below the fish, but it does not engage the fish in the sense of grasping it. The outer body or mandrel 38 threads to a bowl 51 which has an inner tapered face or surface 52. This connects with an enlarged skirt 53 which enables the device to surround part or most of the fish. The fish is aligned in the bowl 51 and is forced upwardly so that it registers in the resilient sleeve 48. The fish is permitted to stab as deeply as possible into the soft set overshot until it shoulders against the downwardly facing shoulder 54, better shown in FIG. 1B as part of the inner mandrel 36.

Assume that a fish has been registered within the soft set overshot 10. Assume that fluid has been pumped through the tubing string from the surface and that the operator is then ready to retrieve the fish. The ball or sphere 29 is dropped in the mud flow and is delivered through the tubing string and ultimately lands as illustrated in FIG. 1A. Prior to that, fluid flow was down through the tool 10 so that the interior and exterior of the tool were at a common pressure. At that juncture, the tool is not set. When the sphere 29 lands at the illustrated location shown in FIG. 1A, continual pumping through the tubing string results in an increase in flow into the passage 20 shown in FIG. 1A, flowing downwardly past the check valve 21 and filling the annular chamber 22. It flows downwardly through the passages 39 to fill the annular chamber 40 shown in FIG. 1B. Any air that might have been captured in that area bubbles to the top and escapes through the bleed valve 23 provided for that purpose. When drilling fluid starts flowing in that area, the bleed valve element 23 closes, thereby capturing incompressible fluid in that chamber so that squeezing can occur. As the pressure at the wellhead is then increased, the increase in pressure is observed in the annular chamber 40 on the exterior of the resilient sleeve 48. Contrasting that sleeve in the relaxed state in FIG. 1B, it will be observed in FIG. 3 to expand, but the expansion forces the resilient material radially inwardly in response to pressure so that it grasps the fish and engages the fish 50 by taking on the shape of the fish. The setting pressure is sufficient to develop the force necessary to shear the pins and allow the sleeve 27 to move downward. The downward motion will expose the drain holes 28 to dump the fluid in the string so that the fish may be retrieved without pulling a wet string. Since the resilient sleeve will set around the fish, and the ball is in place atop the sleeve, the valve controlled passage 32 relieves the trapped pressure fluid caused by the downward travel of the sleeve 27. The fish is gripped around a very large portion of its area, and in particular that portion in registry with the sleeve so that the fish is firmly and tightly held. Moreover, the resilient sleeve, now in this gripping shape, is able to impart a lifting force to the fish. A pull is taken on the tubing string and the soft set overshot 10 is then raised, and this of course raises the fish 50 if it will break free. In the ordinary circumstance, it will break free and is retrieved, held snugly and firmly in the resilient sleeve as shown in FIG.3 of the drawings. Assuming this is successfully done, the tubing string is retrieved to the surface along with the soft set overshot 10 and the fish 50. The grip of the sleeve on the fish is enhanced by reaction of the resilient material holding tighter as it is pulled. The results from the tendency of the resilient sleeve to tighten around the fish when the tool 10 is pulled.

The Series 10 Sucker Rod Overshot is a small, rugged tool designed for engaging and retrieving sucker rods, couplings, and other items from inside tubing strings.

Series 20 Short Catch Sucker Rod Overshots are designed for conditions when sucker rods, couplings, and other portions of a fish are too short for retrieval with a standard overshot.

The Hydraulic Release Overshot was designed to aid in the recovery of a stuck fish in a horizontal drilling application where normal rotation for release is not obtainable.

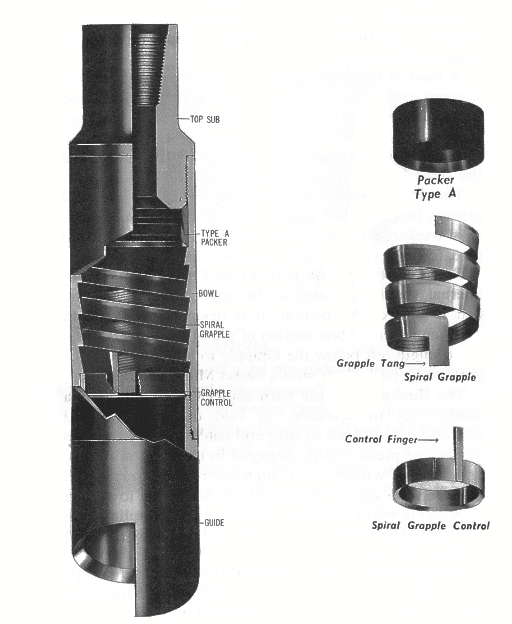

The Series 150 Releasing and Circulating Overshot consists of three main external parts: a Top Sub, a Bowl, and a Guide. Internal catch and pack-off parts are determined by the diameter of the fish. Each assembly is designed for a maximum catch diameter.

A Series 160 Side Door Overshot is recommended when fishing for cable tools or conductor lines in cased holes. The side door overshot is run in on tubing or drill pipe.

The Packer Retriever Spear is designed to remove drillable full-bore packers from the well casing. With appropriate dressing, the tool can mill through the packer if necessary.

High Pressure Type L Packer Type Casing Patches are designed to engage and seal off a properly prepared casing string. The Casing Patch design leaves the operator with a casing string that has a full-bore internal diameter.

High Pressure Type L Packer Type Casing Patches are designed to engage and seal off a properly prepared casing string. The Casing Patch design leaves the operator with a casing string that has a full-bore internal diameter.

8613371530291

8613371530291