overshot packer quotation

The Retrievable Bridge Plug(RBP) is a high-pressure packer style bridge plug used for multiple selective zone treating and testing operations. The RBP is designed to set in tension or compression, which makes it ideal for shallow applications to test wellhead for deep, high-pressure applications. The plug is designed with a large internal by-pass to prevent swabbing when running and retrieving. The by-pass closes during the setting of the plug and opens prior to releasing the upper slips to equalize pressure when unsetting.

Oil well completion tools include: Subsurface safety valve, wireline retrievable subsurface safety valve, single string production packer, dual strings production packer, ESP packer, mechanical set packer, permanent packer, compensation device, bridge plug, sliding sleeve, nipples etc.

K-packers are designed to provide a sand tight seal between the well screen and casing and are typically used on the top of telescope size screens in the water well, construction, and environmental drilling industries. Hole Products offers a wide range of neoprene rubber K-packers. Our standard K-packers are available in 2 styles; Right Hand x Right Hand Coupling and Weld On. Custom K-packers are available with the following options: Right Hand x Left Hand Coupling Blank Style (Designed for Gluing to PVC) Stainless Steel Construction Sizes Up to 24" Please contact your Hole Products representative for additional details and assistance selecting the right K-packer for your specific well installation.

By utilizing our time-tested SEALFAST® inflatable and mechanical seals and packers, we are able to offer many flexible and configurable drilling stack solutions. Our products allow users to adjust for the height, angular alignment, and eccentricities in the drilling stack with unparalleled speed and efficiency. Our, fixed, telescoping, and spherical adjustment riser and mud flow line systems can be designed to accommodate down hole pressures from 5-2000 psig pressure ratings, with process mud temperatures of up to 300° F. Our active sealing technology continues to provide optimal sealing on mandrels and reducing faces, even if they corrode and wear over time, leading to lower maintenance costs

• Design pressure ratings vary from 10 PSIG for some bell nipple overshot seal housings, to 2000 PSIG for higher pressure-rated diverter overshot packers.

These housings can be mounted under the drill floor or to under-deck structural beams, can integrate a full mud pan, as well as other process and flow lines necessary for managing mud elevations and quality during returns. These units are also ideal for use as weld or bolt-on adjustable low-pressure riser seal housings and diverter overshot seal housings. They allow rapid height adjustment during diverter change-out

• Bell Nipple Overshot Seal Housings: General drilling mud collection and containment housings with integral mud pan; bleed, fill, trip, flow, and swarf lines/nozzles available upon request.

• Diverter Overshot Packer Seal Housings: quick and easy installation and actuation for high-pressure applications – can have integral flow lines to act as a t-spool for diverter stacks.

• Telescoping LP Riser Seal Housings: Best for use with telescoping low-pressure riser systems that require flexible height adjustment and large angular make-up requirements. Often referred to as telescoping riser seal housings or packer seal housings.

These dynamic seal housings are often found on floating production oil rigs, barges, and on drillships. They are commonly paired up with our inflatable spherical packers on KFDS diverter systems or as conductor unions, allowing for the drilling stack to accommodate vertical displacement from standard wave and tidal action, as well as ocean swells. These units come with low-friction mandrels and specially formulated “wear rings” for maximum life.

Available in a wide array of sizes and pressures, our housings can be used laterally, vertically, or on inclines. These units come with and without integral mechanical restraint for full nozzle load requirements. Our new, cutting edge, inflatable and spherical seal housing packers allow for the ultimate flexibility for your mud transport, drill through, or flow line requirements.

Cut Production Tubing above production packer and pull/lay down production tubing and accessories. Design & execute fishing procedure to retrieve production packer and tubing.

Well required the existing production packer and tubing to be pulled for workover on well. There are always many contingencies and variables regarding the extraction of production packers and tubing.

E-Line found a restriction at 1672’, and a cut was required 1670’. The recovered production tubing was laid down, the originally planned cut at 3,200’ was performed, and the remainder of the production tubing pulled/laid down. Picked up with Overshot and tripped in hole. Latched and jarred production packer free and pulled out of hole. Monitored wellbore while pulling out of hole. Made a final bit and scraper run to 4600’ and circulated/conditioned the wellbore in preparation to continue Operator’s proposed work over procedures.

The Production Tubing and Packer were retrieved in one trip, thanks to the experienced Dynasty Fishing Supervisors on location, which allowed the Operator to continue workover operations on time and under budgeted AFE.

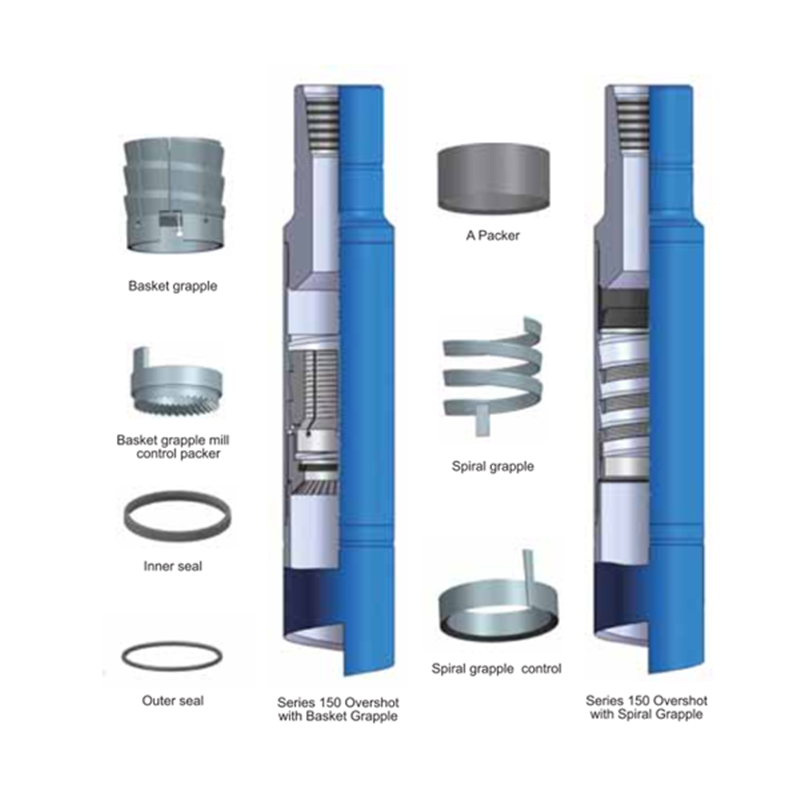

Series 150 Overshot consists of three outside parts: Top Sub, Bowl, and Standard Guide. The Basic Overshot may be dressed with either of two sets of internal parts, if the fish diameter is near the maximum catch of the Overshot, a Spiral Grapple, Spiral Grapple Control, and Type “A” Packer are used. If the fish diameter is considerably below maximum catch size (1/2” or more) a Basket Grapple and a Mill Control Packer are used.

The M.I. Hook-Up Nipple and Back-Off Sub are dual purpose components in the gravel pack assembly. Each serve as the release point for the completion service tool, and as the landing nipple for the Mitchell “L” Packer and Seal Stack Overshot. The standard H.U.N. is offered in 6 ft. and 8 ft. lengths, while the Back-Off Sub is typically 0.5 – 1 ft. in length. Both components have a left-handed square ACME threads machined into the top sub, allowing for a right-hand rotational release. Back-Off Subs are offered in low-alloy steel and 304L SS, and are used in conjunction with the M.I. “L” Isolation Packer. Our M.I. Hook-Up Nipples are offered in a polished 304L SS material and are used with the M.I. Seal Stack Overshot.

The M.I. Type “L” Isolation Packer is a tubing conveyed, mechanically set retrievable packer used in conjunction with gravel pack completions. The “L” Packer features a large internal by-pass that reduces swabbing when running or retrieving. The packer is designed to isolate the lower gravel pack completion by restricting annular flow, forcing all production through the screen. It is equipped with a lower seal extension that stings over our M.I. Hook-Up Nipple and/or Back-Off Sub.

The M.I. Seal Stack Production Overshot can be run under a production or permanent packer, and is designed to seal over our M.I. Hook-Up Nipple. The lower seal extension houses dual opposing molded seal sets that control pressure from above and below the seals. The overshot has a standard 6 ft. bore length to accommodate tubing movement while setting the packer and landing the production tubing at surface.

The AS1-X Double-Grip Packer is a mechanically set retrievable packer used in a wide range of production applications. When utilized in sand control completions, a production overshot is run below the AS1-X Packer as a seal extension. The overshot is landed on the hook-up nipple and the packer is set, either in tension or compression. The AS1-X packer can be run on the bottom of the production tubing, or can be equipped with a stigner and on/off tool for tubing detachment.

The MR-3D Double-Grip Packer is a mechanically set retrievable packer used in completion, stimulation, testing, and production applications. For gravel pack operations, the packer is equipped with a clutch joint/circulating kit and is used as a service tool. In production applications, an overshot is run below the packer as a seal extension and the packer is set with the upper production assembly.

Both the single and dual seal bore packers can be used for single or multiple zone completions. Each packer may be set hydraulically or on wireline, and are available in a variety of seal bore materials and elastomers.

Seal bore packers can be used as a gravel pack base, or in the upper completion assembly. Each packer is supported by a complete line of tubing seal accessories and elastomers.

Seal assemblies are used to land or lock into the polished bore of a packer, creating a leakproof seal. Locator subs are used in installations that require floating seals, allowing for slight tubing movement during expansion and contraction. Snap latch seal assemblies latch into the packer and provide a mechanical indication that the seal assembly is positioned properly in the packer bore. The sanp latch can be removed with a straight pull of 10-12K over tubing weight. The anchor latch assembly latches into the packer bore just like the snap latch, but is removed with 8-10 right-hand rotations. Each of these seal assemblies can be provided with mule shoe guides on bottom, and various length seal units depending on the application.

When sump packers are used in the gravel pack completion design, a seal assembly is required to prevent gravel pack sand from leaking past the packer. In the case of a multizone gravel pack completion, the seal assembly also provides zonal isolation.

The wireline entry guide has an internal bevel on the bottom of the tool that guides wireline or slickline tools back into the tubing. The re-entry guide can be run under various packers, but is most commonly utilized under the lower permanent packer in a gravel pack completion.

The safety joint allows for an emergency release of the tubing string in completions with expected retrieval challenges. The joint is typically used below the completion packer, or in between packers in dual completions. Safety joints are available in straight pull shear release, rotational release, and swivel shear release. These safety joints are keyed so torque through the tool does not load the shear screws.

8613371530291

8613371530291