overshot tool oil and gas factory

PARVEEN Wireline Overshots are used retrieve a fish lost in the well that does not have a conventional fishing neck or a damaged fishing neck on it. The tool is operated by applying the weight of the tool string on to the fish. This will allow the slips to expand around the fish when the tool string is picked up, the slip will engage the fish. These are non releasable type overshots.

Tianhe Oil Group Co. Ltd. is a global group. We are specialized in the production of drilling tools, including R&D, production, selling, leasing, maintenance and services. Tianhe has 5 main businesses spread across the globe in more than 50 countries in the world.

Tianhe Oil Group management prioritize its people, technology, continuous improvement and building brand awareness. Our mission is to continuously strive innovation and improvement and expand our business in the oilfield. We increased the investment in technology research and development, always looking to provide our global customers with the best technical products and services.

Tianhe Oil Group strongly believes and promotes Total Quality Management, implements the ISO quality management system, HSE management system and API standards. Our manufacturing facilities are well equipped with four automated induction heat treatment lines and dozens of other types of heat treatment ovens and well furnaces (Box type, well type, carburizing heat treatment furnace) to ensure full coverage of heat treatment required by the different products.

So far, Tianhe Oil Group has established strong business relationships with over 200 international oil & gas companies in supporting the top 50 oil producing countries. For example, we have partnered with Schlumberger, Halliburton, Baker Hughes, Weatherford, Shell, NOV, etc.

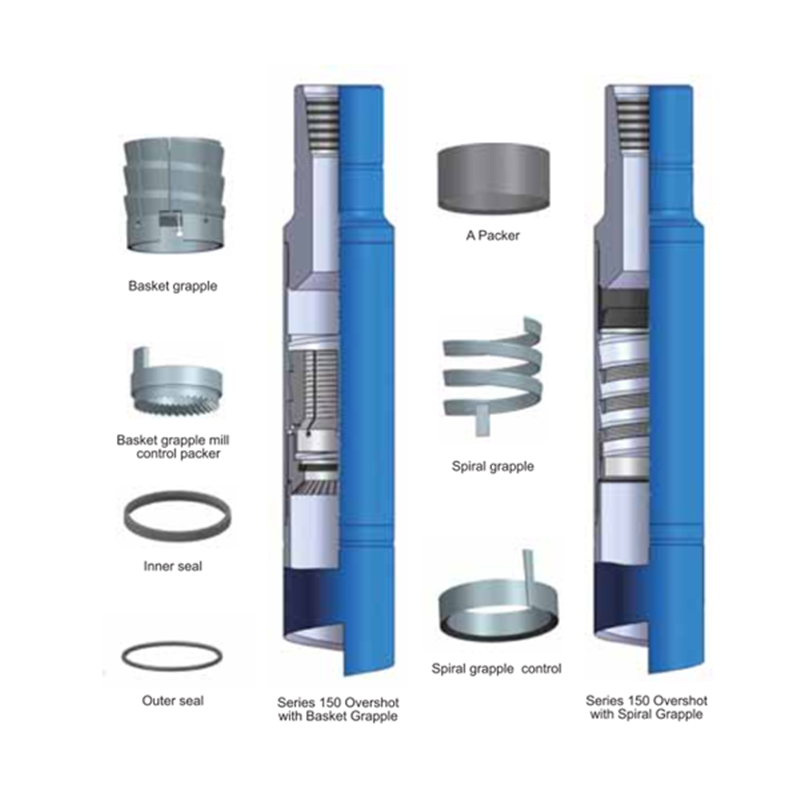

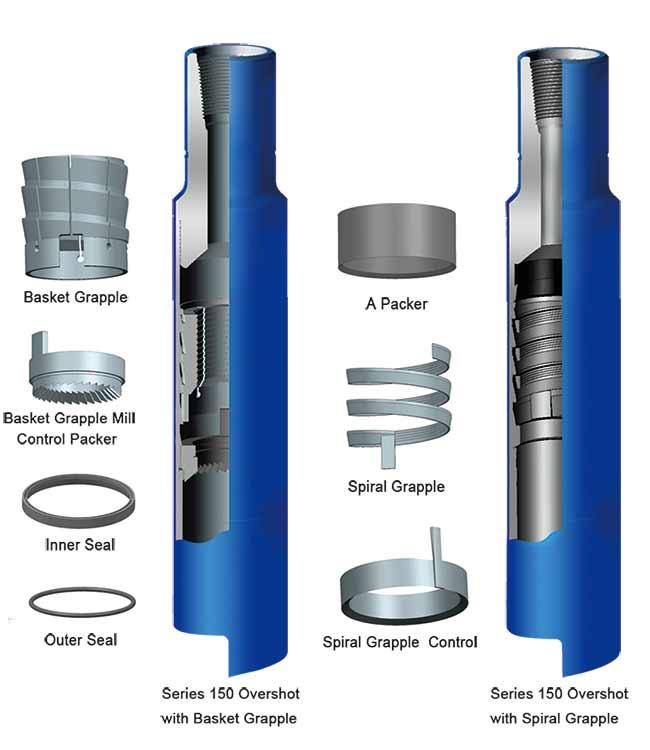

A downhole tool used in fishing operations to engage on the outside surface of a tube or tool. A grapple, or similar slip mechanism, on the overshot grips the fish, allowing application of tensile force and jarring action. If the fish cannot be removed, a release system within the overshot allows the overshot to be disengaged and retrieved.

This website uses cookies to improve your experience while you navigate through the website. Out of these cookies, the cookies that are categorized as necessary are stored on your browser as they are essential for the working of basic functionalities of the website. We also use third-party cookies that help us analyze and understand how you use this website. These cookies will be stored in your browser only with your consent. You also have the option to opt-out of these cookies. But opting out of some of these cookies may have an effect on your browsing experience.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Fishing tool is a special fishing drilling tool used to retrieve fallen objects from the borehole. At any stage of the operation, the drill rig operator will encounter unexpected situations, such as falling drill string, stuck pipe, missing drill bit, etc. The equipment that falls into the well is called "fish" or "trash", and the tools used to remove the equipment are called "fishing tools." Sometimes it may be necessary to use "fishing tools" to retrieve older wellbore equipment, such as packers, liners, tubing, or any stuck objects in the well. The drilling tools for fishing must be retrieved from the borehole in order to continue drilling operations.

Overshot is a very common fishing tool. The main fishing object is a smooth tube fish, which belongs to the external fishing type (i.e. catching the external surface of the fish).

Taper tap and die collar are common fishing tools for fishing the inner hole of the string. They are used for fishing the inner hole with holes such as tubing, drill pipe, casing milling pipe, packer, water distributor, etc. It is made of high-quality alloy steel and especially heats treated. It has the advantages of high strength, high toughness, and simple buckle making.

When you can’t reliably engage your fish with drillpipe, rely on the reliability and flexibility of fishing internal and external engagement tools from Baker Hughes.

Externally engage, pack off, and pull a fish with our wide range of overshot tools. The first fishing choice when screwing into the fish is not an option, our overshot tools are simply designed but ruggedly built. Choose from options including:

Kelo socket overshots are proven to catch small-diameter workstrings and sucker rods inside casing as well as recover coiled tubing that has parted and remains in hole.

The t-dog, mouse-trap, and flipper-dog (TMF) overshot can be dressed in three different ways for different washover applications. Deploy the t-dog assembly option to washover and recover mud-stuck or sanded-up square-collared pipe in one trip. Use the mouse-trap assembly to catch sucker rods, integral joint tubing, or cables. And with the flipper-dog assembly, you can confidently catch a fish with different ODs.

If your fish cannot be externally engaged, our range of releasable spears provide a viable retrieval option. These internal engagement tools come in a variety of designs, including:

Hydraulic casing spears are run above a mechanical or hydraulic inside casing cutter, allowing cutting and casing pulling in one trip. The spears are set and released hydraulically for ease of operation and no need for mechanical intervention.

Type B™ and Type D™ casing and tubing spears retrieve a full range of casing sizes. The design of these spears affords easy dressing for alternate casing sizes, simple field-dressing to change the release setting, and fast, effective release—all of which help improve the efficiency of your fishing operations.

The Type E™ casing spearprovides effective casing retrieval in the most severe downhole environments. With its heavy-duty, high-strength design and simple construction you’re assured reliable performance and easy operation and maintenance for a wide variety of casing sizes and weights.

The business of “fishing” a well bore requires skill, technology—both new and tried-and-true—and a mechanical aptitude as well. Like everything else, this trade keeps changing, too.

The Oilfield Glossary compiled by Schlumberger explains a complicated industry process in a few simple words. Those words don’t explain how difficult the procedure can be or that it can involve several days of work. In these times when more wells are being drilled vertically and horizontally and into more plays and with older wells being re-opened, fishing companies are fielding more calls for a crew and equipment to retrieve a lost object in a hole.

Workers new to the industry often are confused when they hear someone talking about “fishing” and “fishermen.” Looking around the parched land that comprises the Permian Basin, they wonder where the best fishing hole is located.

Historically, fishing has played an important role in the drilling industry. Schlumberger’s glossary noted that “It does not matter whether the fish consists of junk metal, a hand tool, a length of drillpipe or drill collars, or an expensive MWD and directional drilling package. Typically, anything put into the hole is accurately measured and sketched, so that appropriate fishing tools can be selected if the item must be fished out of the hole.”

“In the drilling process, a well bore can heave in on them, or a boulder can fall in the bore. The pipe gets stuck and the crew can’t get the pipe out,” he said. Sometimes the fishermen, as the specialists are called, encounter hydrostatic stick. Fluid goes into the zone and pulls the item to the wall of the well bore, like paper being stuck to the wall.

Another situation is called “key seated,” said Johnson. “It’s like a keyhole in a doorknob. The drilling process hits a soft spot and the drill bit “walks off” and must be straightened back.

In some cases, a wireline truck is used to find out where the pipe is in the hole. “We go in with an overshot or use hydraulic jars to try to jar the pipe loose. We can go in with a wash pipe and wash over the string and pull it out of the hole.

“Sometimes there is pipe fatigue and the pipe will break off. We have to go in and retrieve it. Iron is iron and it’s going to break.” Another problem occurs when the earth’s magnetic field produces electrolysis and the pipes become stuck.

The Schlumberger Oilfield Glossary explains that special mechanical devices are used to help “fish” the equipment lost downhole. This equipment falls into four classes: diagnostic, inside grappling, outside grappling, and force intensifiers or jars.

The glossary explains that diagnostic tools can include a simple impression block to help the fisherman custom design a tool that can attach to the fish and remove it. Other diagnostic tools include electronic instruments and downhole sonic or visual-bandwidth cameras.

Inside grappling devices, called spears, usually have a tapered and threaded profile which enables a fisherman to guide the tool into the top of the fish and thread it into that top so the tool can be retrieved. Outside grappling devices, called overshots, are fitted with threads that “swallow” the fish and pull it out of the hole. Jars are mechanical downhole hammers that deliver high impact loads to the fish.

Problems also can occur once production is going. Johnson said a company will notice production is going down on a certain pumping unit and call in a fishing unit. “The pipe could be stuck, the hole might have collapsed, or there wasn’t a good cement job in the pressure zone,” he explained.

Nabors Well Services, Ltd., is among the biggest of the Permian Basin’s well servicing companies and responds to a steady stream of requests for fishing operations. Craig Fletcher, operations superintendent for Nabors’ yard in Denver City, said the company is very busy right now.

“There are many different scenarios and a variety of services associated with what we do,” Fletcher said. “The best way to describe it might be to say that we provide remedial repair and fishing services and can deepen wells with our equipment.” Their customers include Hess, Oxy, Sandridge, Devon, XTO, and Apache, and calls take their crews up to northern and western New Mexico, South Texas, and the Eagle Ford play near San Antonio.

“For one reason or another, the casing and the tubing can get in bad shape and that is where we come in,” Fletcher said. “We encounter a lot of bad casing and we stay busy repairing it.”

The Permian Basin has its own unique challenges in terms of fishing services, and part of it is attributed to the success this region has known. The age of those wells and the drilling practices at that time can contribute to problems today. “The Permian wells have lasted so long and have been so prolific, that some of these wells have been producing over 60 years,” he said. “When these wells were drilled, it was never anticipated they would last this long. If the drillers had anticipated it, they would have run things differently, and made them even more durable than they did. They could have used thicker pipe, done better cement jobs.”

Fishing tools haven’t changed much over the decades, according to Hinton, who ventured in 1968 into the oil patch to first, plug wells, and then to service them before trying his hand at fishing.

“The changes have been very few,” he said. “Most of the tools are common: things like a grapple and a spear. We use a lot of mills that smooth the surface of the fish so we can get a better hold on it. Various sizes of tools are needed and we have to build up a good inventory.” In addition to sending crews out to the field, Hinton Enterprises offers equipment for rent. People who are experienced in oilfield work are the ones who will rent equipment and not hire a fishing crew with it.

Johnson with SERVCO added, “A lot of tools haven’t changed in years. You have a tool that works and nobody has come up with anything that works better.”

Weatherford International, a major player in the well servicing industry, also does a lot of fishing. Bobby Duncan, area manager for Weatherford’s Midland yard, said one of the biggest changes affecting the fishing trade is the trend toward more production work and away from as much “open hole” fishing.

Even as recently as five years ago, open hole work was more prevalent, he said. But the majority of new wells today are oil wells, and technological advances on those wells mean fewer reasons to fish.

Technology has changed some aspects of the business, though. Fletcher with Nabors noted that back when the wells were drilled in the 1940s and 1950s, “everything was rotary rigs. Now they have top-drive rigs and they can measure and log while they are drilling. They can steer the bit wherever they want.”

However, that can make the fishing more difficult, he noted. “If you drill a mile down and then a mile horizontal, you’ve got more frictions because the pipe is turned.”

Duncan, at Weatherford International, observed that newer technology has meant that fishing can be avoided entirely, in some instances. With steerable bits, drillers can turn the bit and can bypass the fishing chore. “They can simply back up the drill and take a different direction, bypassing the object that was lodged in the well bore.”

Another consideration that Duncan pointed out about horizontal wells is that the vertical portion, which is often shallower than vertical segments on the older wells, is easier to fish because the job “doesn’t take as long to make a trip.” Conversely, “with a 15,000-foot gas well, it takes a lot longer to go [to the bottom].” He sees more fishing activity concentrated on the production end as contrasted with the exploration side.

Johnson has encountered more difficulty when fishing on some horizontal wells. “Some stuck pipes on a horizontal wells can be cased and some are open. There are different situations when you have to clean up something: how steep of an angle you need to go and how far out it goes,” he said.

In August, Hinton’s company was fishing at a horizontal well and encountering some problems. “It’s more difficult. You need specialty tools to go in the hole at a certain direction,” he said.

During past decades when wells were shallower, fishing posed a relatively economical option. “It was more cost effective to fish the gas wells then,” said Weatherford’s area manager. “Today, instead of spending money in fishing, it is easier and more economical to drill around it.”

Johnson noted that the New Mexico Oil Commission could become involved if the fish can’t be pulled out and the well needs to be plugged. The commission wants to know “where the well is, what damage it might do in the future and if any chemicals could get into the freshwater zone. They might require the well bore to be cased and plugged properly.”

“I’ve had some old tools from the late 1940s and early 1950s fished out. Some were homemade tools. Nothing was built to specs. We had to go to some oldtimers to see what they were,” Johnson said. Other items include submersible pumps, sucker rods, electric cables, and even the fishing tools. “We’re on a job now where we’re fishing out a submersible pump. Those pumps can be expensive. We’ve been on the job a week now. It’s not an easy job.”

Hinton, too, has seen a variety of articles pulled out of the holes, including trees that were used to plug a hole. These were found when a company tried to go back into the hole. “Sometimes a crew gets mad and quits and they throw all their tools into the well,” he added.

The hardest thing to fish out of a well bore, according to Nabors’ Fletcher, “are the fishing tools themselves. Yes, it does happen. We take precautions: we inspect them and replace them if there is any doubt about the strength or integrity of the tool. We might do a magnaflux inspection, check the wall thickness. You do everything you can to see that losing a tool won’t happen, but sometimes it does.”

“You can teach someone the fundamentals of the tools and how to use them,” Johnson said. “But it takes time and experience for them to learn it. You can’t just take someone off the street to be a fisherman. Even someone who works on a well can’t jump into this overnight. Someone who is mechanically inclined might catch on faster. This is a skilled profession. I have several good hands and all of them work production and open hole fishing. My hands are pretty steady; some have been here 10 to 12 years.”

“While they were eating, the kid asked the other hands what happened. Pointing at the reserve pit, he said he thought they were going to be fishing. The hands laughed and told the kid there were no fish in that lake (the reserve pit). The hands explained they had lost some drill collars in the hole and the fishing part was trying to retrieve them.”

Here’s how Schlumberger’s Glossary defines a “fish”: Anything left in a wellbore. It does not matter whether the fish consists of junk metal, a hand tool, a length of drill pipe or drill collars, or an expensive MWD and directional drilling package. Once the component is lost, it is properly referred to as simply “the fish.” So much for definitions. What follows is the rest of the fish story.

Oil patch fishermen are a special breed. The fish they seek live deep down in the earth and require specially designed gear to coax them to the surface. The fish oil patch fishermen seek are not live creatures at all, although some might disagree because of their uncanny ability to evade capture. No, oilfield fish are items lost downhole in oil wells and the fishermen are those specialists who remove them from their environment.

Beginning with the 150- to 500-foot oil wells of the 1850s and continuing to those technologically sophisticated 20,000 foot projects of today, one of the most consistent oil well drilling problems has remained how to retrieve unwanted items lost down the well bore. Whoever first called those lost items “fish” or called those who retrieved them “fishermen” has been lost to history. But regardless of how those terms originated, it is acknowledged by oil men everywhere that the unique skills needed for fishing are earned through long experience by persons with the rare ability to visualize what is happening thousands of feet below the surface. That combination of experience and skill is necessary because every fishing job is different, often requiring specially fabricated tools ofttimes created on the spot and possibly used only once.

In the very earliest days of the industry the drilling was done exclusively with cable tool rigs. It is known that they suffered numerous fishing problems but there are very few descriptions of the tools they used. It was not until 1884, with the publication of the Oilwell Supply Catalog of that year, that the first known illustrations of fishing tools came to light. Those listed in that catalog were considered standard devices used for common problems encountered in the retrieving items lost in the hole. There is little doubt that those standard tools were the result of thousands of predecessors created in local machine and blacksmith shops throughout the oil patch during the preceding decades and abandoned once the fishing job was completed.

Although designated as standard fishing tools, the items sold by the various supply houses such as Oilwell were not by any means used exactly for the specific purpose for which they were advertised. Many of them were modified on the job to fit the particular problem presented. By far the greatest problem encountered by the cable tool rigs involved lost manila rope or steel cable drilling line from which was suspended the drilling string. When one of those lines broke or for whatever reason got lost down the hole it had to be fished out. The most common tool used for that purpose was a spear.

The simple fishing spear was just what its name indicates. It was a long shaft from three to ten feet in length with a series of barbs welded to its sides facing toward the top of the tool. When the spear was lowered into the tangled mess of a broken drilling line at the bottom of the hole the barbs captured the line as the spear was withdrawn. Sometimes the single shaft spear would not grasp the lost line tightly and it slipped off the barbs. In that case there were spears featuring two or possibly three shafts arranged in a circle with the barbs welded to the inside of the circle in order to get a better grip and prevent losing the line through slippage.

Other implements for handling lost lines were the knife and the hook tools. The hooks worked similar to the spears only they were shaped like a fishhook. The knives on the other hand were simply designed to cut the drilling line in case it was so entangled the spears could not pull it out of the hole. Sometimes a combination knife and hook tool was used so the line could be grabbed by the hook and pulled to the inside of its bend, where there was a sharp cutting edge. Once the line was cut away from the tangled mess it could be fished out of the hole in smaller lengths. Also sometimes the drilling string became stuck fast, in which case those cutting tools were used to shear the drilling line as close as possible to the drilling string so a whipstock could be set to drill around the offending items.

Beyond drilling line retrieval tools there were a variety of grabs utilized to remove various cable tool items lost downhole. In the case of a string of tools lost but not stuck beyond removal there were several overshot tools that could be lowered over the string and when pulled upward would tighten around the jars—or whatever the top lost tool was—and pull the string out of the hole. Then there was the bailer grab, which was simply a tool similar to a two pronged spear without the barbs. At its bottom was a hinged pin that, when lowered over the bail of the bailer, would swing open and once past would drop back and latch into place, allowing the bailer to be withdrawn from the hole.

Those then were the basic tools used for fishing cable tool wells, along with a host of variations. They were all simple, common sense solutions developed over the years by hundreds of unheralded drillers, tool dressers, and a variety of other oilfield hands. As already mentioned there were literally thousands of variations on those basic tools all designed for problems encountered as well as to suit the particular inclinations of the fishermen who employed them.

When rotary rigs entered the mix about 1894 the downhole fishing problems tended to change somewhat with the advent of the new technology. The lost cable problem practically disappeared with the advent of the rotaries due to their using pipe instead of cable, but the numbers and variety of items lost downhole was absolutely amazing. They ranged from a roughneck simply dropping a wrench in the well bore to bit cones being broken off or maybe the drill pipe being twisted off.

It is from those types of incidents that have fostered some of the best illustrations of oilfield culture. For example the story of the boll weevil who dropped a wrench into the well bore that resulted in a five day fishing job. When the battered tool was finally retrieved the driller handed it to the hapless hand and proceeded to give him a real oil patch dressing down. When he was through the driller told the man he was fired, whereupon the roughneck looked the driller right in the eye and pitched the tool back into the hole. Some say that indicates the graduation from boll weevil to hand, but I can guarantee you it would cause a fistfight right then and there on the rig floor. Then of course there is the term “twisting off” in regard to accidentally severing the drill pipe. That term has come down over time to describe anything a hand might do to cause him undue grief, usually things involving imbibing large quantities of alcoholic beverages.

But I digress. Back to the subject at hand of fishing on rotary jobs. One of the most frequently utilized tools, at least in those early days, was a device called a junk basket designed to remove small objects lost downhole. A junk basket was constructed by cutting slender fingers in the sides of a piece of pipe, fastening it to the drill pipe in lieu of a bit, and lowering it into the hole until it touched bottom. Then the pipe was slowly rotated and weight gradually applied to the drill string. The weight increase and rotation caused the fingers to collapse inward and hopefully clutch the fish within its grasp. Over time that crude device was engineered into a more sophisticated tool, causing it to remain an important fishing tool for many years. In later times powerful magnets were sometimes attached to the bottom of the drill pipe in an effort to remove small items lost downhole.

The most serious of the fishing jobs, like those of the cable tools, revolved around lost suspension devices, which in the case of rotaries was drill pipe instead of cable. In the case of stuck pipe, either drill pipe or casing that could not be withdrawn from the hole, it might be necessary to save as much of the stuck pipe as possible. In the very earliest days that was accomplished by a nitro shooter lowering a shot inside the stuck pipe and shooting it apart. Or a device called a cutter could be lowered into the hole and actually cut the pipe apart. In either case the well might be saved if, after the severed pipe was removed, it was feasible to back uphole a little ways and use a whipstock to deviate the hole enough to bypass the stuck pipe. Otherwise the well was simply abandoned and at least some valuable pipe was saved.

The problem more often associated with lost pipe is that it is twisted off at some point downhole. In that case it is never certain what sort of situation exists at the bottom of the hole in regard to just exactly what is sticking upward for the fishing device to grasp. It might be a jagged piece of pipe, it might be a smooth surface, it might be leaning one way or another, it might be open, it might be collapsed, or whatever. So an important aspect of the fishing process is to discover what is the exact disposition of the object, which in turn will help determine the type of tool needed for the job.

Sometimes a heavy lead plug is lowered into the hole to get an impression of the nature of the top of the fish. If it is retrieved and the fish is shown to be all ragged and bent and generally a mess, as is often the case, it is possible to lower a special tool to grind the item down to a manageable size. When it is reasonably clear what the situation is, there are a variety of tools that can be utilized. They generally fall into the category of undershot or overshot in nature. That is, the undershot, which is lowered inside the offending pipe, or the overshot, which is lowered over the outside of it. Once in place those items have a variety of grabbing mechanisms to grasp and hold the pipe while it is removed from the hole.

Regardless of the exact nature of oilwell fishing jobs, two things are certain. First they normally take a long time. At the least a few days and some of them stretch into weeks. The second thing is that shutting down a drilling operation is an expensive operation and the least amount of time it takes the better. Hence the value of a good fisherman who can figure out what is going on way down below the surface.

Fishing is a term used to recover lost, damaged or stuck objects from the wellbore in oil and gas drilling and completion operations. The item lost down the well is generally referred to as a “fish”. The key elements of planning a successful fishing job include an understanding of the type and dimensions of the “fish”, the nature in which it became lost or stuck, and the borehole geometry and wellbore conditions. Fishing jobs can last anywhere from a few hours or can continue on for weeks. Generally when determining if it is worthwhile to fish rather than “sidetrack” around the fish or “abandon” the well things like “likelihood of success” and the rig daily operations costs must be compared to the cost to sidetrack or the cost of the equipment lost in hole.

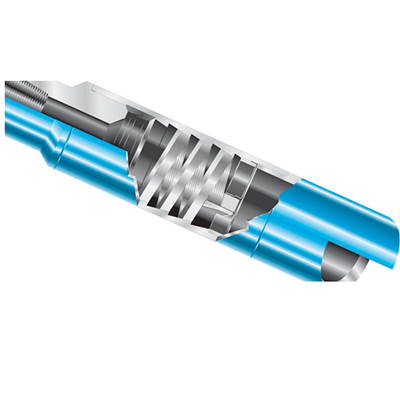

Different tools are required to “catch” various types of “fish”. The most common tools used to fish are overshots and spears which are run with grapples sized for the particular outside or inside diameters of the fish. The primary difference is the overshot goes outside of the fish whereas the spear goes inside the fish. (See pictures). When the overshot or spear engages the wicker profile on the grapple bites into the surface of the fish. The harder the fish is pulled the hard the grapple digs into the fish.

In certain cases simply pulling on the fish may not be enough to free the stuck item. In such cases Jars and even Accelerators are used to add additional force to free the stuck fish. When the Jar is activated it creates “impact” hammer action downhole. The energizer effectively magnifies this by increasing the duration the force (“impulse”) created by the jar applies. Jar placement programs can be run to simulate proper placement of the Jar and Accelerator in the tool string and give an indication of the magnitude of the anticipated “impact” and “impulse”.

In cases where the wellbore has collapsed or there is significant debris trapping the fish it may be required to “wash over” the outside of the fish to clear the debris. Examples include sanded up tubing anchors in cased hole situations and packed off bottom hole assemblies in drilling applications.

Reverse circulating junk baskets (RCJB) or magnets are often used to catch medium sized debris like tong dies, broken cutters or teeth off of drill bits or sometimes even entire drill bit cones. The tool are run on drill pipe to within a few meters of where the suspected junk is located. Circulation is established to wash on top of the junk.

The RCJB works much differently trapping loose metal in a basket inside the tool. To “suck” metal inside the tool a ball is dropped while circulating. When this ball reaches the RCJB it lands in a ball seat redirecting the flow from through the tool into the annulus to into the annulus and back up the inside of the tool. This sudden change in flow direction can lift small metal objects up into the RCJB. The spring loaded fingers in the basket at the bottom of the RCJB then prevent the object from falling back down the well. (See picture)

Mills are used to “mill up” lost metal into smaller pieces which can be circulated out of the hole. There are a range of sizes, dressing types, and configurations depending on what is being milled and whether it is in open hole or cased hole. Example off different mills are shown. Specifics of the job should be discussed with a Tango representative before choosing the appropriate mill.

Hydraulic or Mechanical Cutting Tools are generally used to cut casing or tubing where the upper section is pulled from the well and the lower section is either left or subsequently fished out.

Section mills are often used when permanently abandoning a well. A “section” of the casing is milled away allowing for a cement plug to be set isolating both the inside of the casing and the casing annulus. This generally results in better annular isolation than simply perforating the casing and squeezing cement into the annulus.

Tango has a full range of fishing tools sized to fish inside 12-1/4” Open Hole down to 2-3/8” Tubing and catch anything from 9-5/8” Casing to ¾” Sucker Rods. Tango is backed by over 100 years of industry experience covering drilling, completions, and fishing operations both in Australia and Internationally. Tango can provide pre-job planning, fishing recommendations, and fishing tool supervisors as required.

Tango can also provide customized well intervention support in the form of multi-lateral systems, sidetracking/whipstocks, and specialty tool design. Please contact us 24/7 for more details on 1300 082 646.

6 Claims. (Cl. 294-102) This invention relates to iishing tools for oil wells and more particularly, but not by way of limitation, to a mechanically operated overshot for retrieving lost objects in drilled wells or the like.

Various apparatuses are being used throughout the oil industry for recovering lost fish, such as broken off drill pipe, sticker rods, drilling tools and other objects that may he dropped in the drilled well which must be removed before the drilling operation can proceed. However, none of the present devices, as far as is known, can release and re-engage the overshot with the ish by continneus movement in a right hand rotation without pulling the overshot tool and the fishing string from the Well bore. Furthermore, it is apparent that certain present day overshot devices can engage and release from a fish, but then must be pulled from the well if it is desired to re-engage the overshot with the lost fish.

The present invention provides an overshot for retrieving lost fish in a well bore which is always turned in a right hand motion either for releasing or reengaging the lost fish. The right hand rotation is desirable because the iishing string or drill pipe is joined together with right hand threads and any operation requiring a left hand rotation may have sufficient torque to provide for an unthreading of the tool joint connections of the drill pipe fishing string, whereupon the lower portion Would fall into the well bore and necessitate a further fishing job therefor.

The present invention provides a combination overshot having a control head maintained in operating position by a coil spring wherein the control head is designed so that any rotation of the overshot in a right hand motion will continuously provide for successive engagement of slip members carried by the control head and disengagement by release of the slip members with a further rotation. The rotation of the overshot to provide the successive engagement and release of the slip members with the fish is provided by applying a prenited States atent O determined weight on the overshot at the top of the Well.

A certain amount of pre-determined weight is applied to the overshot string to cause a disengagement of the biting Contact of the slips against the lost fish, and with a onequarter right hand rotation thereof maintains the slips in a released condition. An application of predetermined weight of lesser amount permits a continued right hand rotation of the control lugs in the control head slots to a position to effect a re-engagement of the slips with the lost fish. It will thus be seen that the release of the slips and the re-engagement thereof is with a con tinuous right hand rotation of the control lugs with respect to the control head in the overshot. This is very effective in the case of accidental release of the slips from the fish, the driller can take a right hand rotation on the fishing string and the overshot to bring the overshot back ly rotated in a right hand direction to eiect a milling operation of the top jagged edges of the fish or to straighten the fish up in the body of the overshot.

it is an important object of this invention to provide an overshot shing tool which may engage a lost sh in the drilled well, yet be released from the lost fish, and caused to re-engage it by a continuous right hand motion of the overshot.

A further object of this invention is to provide an overshot lishing tool for the drilling of oil wells which has an easy and positive connection for release and reengagement with the lost fish in the well bore.

An additional object of this invention is to provide an overshot fishing tool for oil well bores having Working parts which are not likely to be damaged and are so arranged and constructed as to provide positive contact with the fish, as well as positive release thereof and positive re-engagement.

And still another object of this invention is to provide an overshot fishing tool for oil well bores which is etiiciently packed oil below the slips and which also provides for milling off the top of the fish and prevent injury or damage to the packer, thereby eliminating an extra trip into the well bore to replace the working parts of the overshot.

And still another object of this invention is to provide an overshot fishing tool which is simple and efiicient in operation and particularly provides for easy engagement and release of the slips with the fish and yet prevents any possibility of unjointing the threaded connections of the drill pipe string supporting the overshot in the well bore.

Other objects and advantages of the invention will be evident from the following detailed description, read in conjunction with the accompanying drawings, which illustrate my invention.

Referring to the drawings in detail, reference character 2, designates the overshot apparatus generally which provides an upper head member 3 secured to the shing string of drill pipe in any suitable manner, preferably threaded. The head is provided with a cylindrical exension member 5 threaded at 6 to a lower cylindrical body or bowl member "7 acting as a main housing for the over shot proper. A control head d is disposed within the body "7 and has the upper portion thereof extending into the sleeve for purposes as will be hereinafter set forth. The lower end of the sleeve 5 acts as shoulders for anchoring one end of a helical spring 9 encircling the control head, wherein the opposite lower end of the spring 9 is anchored on shoulders itl provided by the circular fiange portion of the control head ti. The lower portion of the control head al is provided with a recessed portion il forming a lower shoulder l2 for the reception of a circular fiange portion i3 acting as a lug on each of the plurality of slips i4 (preferably three or four) held in ICC p suspension thereby on the control head. 8.

The slips are provided with serrated teeth for purposes as will be hereinafter set forth. Furthermore, the lowerrnost portion of the outer circumference of the slips is provided with a downwardly extending tapered portion 16 adapted to cooperate with a tapered portion 17 provided on the inner periphery of the body member 7 as is clearly shown in Figs. l, 2 and 3. Immediately below the tapered portion- 17 an inner projecting shoulder portion 128 is provided in the bowl 7. A rubber packing ring is disposed below the shoulder 18, which acts to restrict any vertical upward movement of the packingy ring 1"9 therein. A retaining ring 20 for the packer 1"9 isV held in position in the bowl 7 by a mill holder body member 21 threadedly secured at 22 to the lower portion of the bowl 7. The top of the mill body 21 restricts any downward movement of the packer ring 20. The -millbody 21 is threadedly engaged at 23 with the lower" guide member 24 of the overshot.

The mill body s provided with a cut-away portion 25 providing shoulders 26. A mill insert 27 is disposed in the cut-away 25 and restricted in its upward movement by the shoulders 26. The lower guide member 24 is provided with shoulders 29 restricting downward movement *of the mill insert 27. The lower portion of the guide 24 is cut away at 30 to provide for easy access of the fish 31 in-to the overshot, as will be hereinafter set forth.

Control head Referring to Figs. 4, 5 and 6 specifically setting forth the. structure of the control head, it will be apparent that this comprises a cylindrical member 8 having a pair of diametrically vertically disposed slot or .groove portions 34 extending substantially through half of the length of the control member 8. A horizontally disposed slot portion 35 connects with one side of one of the vertical slots 34- "(Fig. 6), while a second horizontal slot portion 36 connects with the other vertical slot 3.4 at the opposite side thereof, as is clearly shown in Fig. 6. The slots 35 `and 36 are interconnected by the groove 37 (Fig. 5) for purposes as Will be hereinafter set forth.. The passage- *way- 38--of the cylindrical. control head 8 is of sutiicient fdiarneter at 39.1totpermit entry of the iish 31 in a manner as will be hereinafter set forth.

The-extension sleeve 5 is provided with a pair of kiixed "diametri"callyopposedi lug members 40 normally adapted Operation In Operation, the overshot is lowered into the well bore (not shown) on the drill pipe string 4 until it makes a contact with the lost"iish 31 in the well bore, such as a broken off drill pipe or the like, and the fish 31 is directed through the guide"24 into the body of the overshot. As the overshot makes a contact it is rotated in a right hand direction so that the cut away portion 30 will assist the entry of the iish 31 into the overshot. As the overshot 2 moves vertically downward over the iish 31, the jagged edges 42 of the broken off top portion will contact the mill teeth 43 of the mill. insert 27, which with rotation of the overshot 2` mill off the jagged edges thereof, and thereby prevent any damage or injury to the rubber packing ring, which would necessitate replacement thereof.

Continued lowering of the overshot 2 over the iish 31 will bring the top thereof vinto contact with the slips 14, and since the control head 8 is free to movevertically a limited` distance within the body member 7, the slips and control head are moved upwardly by the force of the contacted fish, thereby disengagingV the outer taper 16 from seating relation with the taper 17 `of the body. This upward movement will cause expansion of the slips outwardly so that the fish 31 might enter therein and pass upwardly in the body 7 until it makes Contact with the upper mill teeth 44 provided in the passageway 39 of the control head 8. Lower teeth 45 are provided at the lowermost portion of the control head 8 (Fig. 2) to assist the upper teeth in holding the iish against rotation by contacting the upper "edge thereof.

As the fish 31 makes contact with the mill teeth 44, the force of this contact is felt by the operator at the surface of the well, whereupon the overshot is raised upward to bring the taper 17 simultaneously upward into contact with the outer taper 16 of the slips 14 causing the slips to move inwardly into biting engagement with the fish in the position shown in Fig. 2.

It will be apparent that during the upward movement of the overshot 2 that the helical spring 9 maintains a downward thrust on the control head 8 and engagement of they mill teeth 44 against the top of the iish 31 so that any" simultaneous downward movement of the control head is precluded, and the taper 17 upon contacting the taper 16 will move the teeth 15 of the slips 14 into biting engagement with the outer periphery of the sh 31. In this operation the lugs 40 on the extension sleeve 5l are disposed in the vertical slots 34 permitting the. upward telescoping movement of the body 7 relative. to` the control head 8. With the slips 14 in biting engagement with the fish: 31, any continued upward movement of the overshot will carry the fish 31 therewith unless the fish is stuck sufficiently in the bore to resist removal thereof. In such an instance, it may be desired to release the overshot from the fish 31 in order to take another bite at it.

In order to prevent any retrograde or left hand rotation of the overshot proper for the release action, thereby subjecting the drill" pipe string to possible unthreading at any of the tool joint sections, the release action of the slips from the fish 31 is provided by a continued right hand motion of the overshot. This is done by application of a pre-determined weight on the overshot string which causes the diametrically opposite lugs 4"0 to move vertically downward in the diametrically opposed, slots 34 until `brought into contact with the bottom wall-47" (Figs. 1 and" 6) this downward movement of overshot 2 causes the tension from the spring `9 to act against the control head to force the teeth 44 into biting engagement with the topof the iish 31. The teeth 44 in contact with the fish 31 preclude a rotating movement by they controlV head 8, so that when a quarter right yhand turnv motion is made with the overshot 2, the lugs 40 are permittedy to move into the groove 36 of the stationary control head 8. In this position, a slight upward movement of the overshot will allow the lugs to move vertically upward Ainto the groove 37" and abut against the top wall 48 of the slots 35"and 37 (Fig. 5), thereby the overshot is in a released condition and can be removed from the well if desired".

`In the event that the slips 14V are desired to be reengaged` with the sh 31 from this position, a predetermined weight of lesser amount than the original pre-determined weight is applied to the fishing string thereby movingthe lugs 40- away from contact with the top wall-48 of the slots 3S, 37, and" in this position the tension of the spring 9 causes the teeth 44 to engage the topof the sh 31 preventing rotation of the control head 8 whereuponv a further one-quarter right hand `turn will move Ithe lugs l40 .into .the second diametrically opposed slot 34 whereupon the lugs 40 are permitted to move Avertically upward therein to cause engagement of the slips through4 seating of the tapers 17 and 16 of the bowl 7 and siips.1"4 respectively. The amount of weight necessary to eiect the last operation is only enough to overcome the ftictional resistance due to the engagement of the ylugs .40 with the. topY wall 48 of the control "head slot "37; It will be apparent that the considerable weight of the fishing string and the overshot apparatus is bearing against the lugs to provide considerable frictional resistance, and in order to efficiently effect a right hand rotation of the body 7, this pre-determined weight is placed on the overshot string to overcome the frictional resistance and move the lugs 40 away from contact with the top wall 48.

lt will be apparent that vertical movement of the lugs 40 in the various slots, such as the operating slots 34 for engagement of the slips, or the releasing slots and 36 permitting disengagement of the slips, provides variable conditions on the helical spring 9 due to the anchoring of the extension sleeve S against the upper end thereof. However, the control head 8 is in substantially rigid position relative to the fish 31 and is maintained there by the tension of the helical spring 9 which is always bearing against the flanges l@ of the control head to eect this condition. The amount of spring tension may be variable relative to the position of the sleeve 5, nevertheless tension is always present to provide this downward thrust on the control head.

lt will thus be apparent that in case of accidental release ot` the slips from the fish, the driller can take a right hand turn on the fishing string, raise up very slowly until a pre-determined weight is indicated on the weight indicator (not shown) at the top of the well to position the lugs back into the slots 34 for re-engagement ot" the slips with the fish. Furthermore, during the milling operation of the top jagged edges of the fish, the overshot string is rotated in a right hand direction, and sometimes these jagged edges are quickly removed, and this factor plus the weight of the overshot and fishing string will cause the overshot to be released, particularly if during the rotation the lugs di) are positioned in the slots 34. However, it will be apparent that whether the overshot is purposely or accidentally released, it can be easily re-engaged with the fish by a continued right hand motion without any danger of unthreading the fishing string.

The packer ring i9 provides a seal around the outer periphery of the fish 3l when mud is pumped through the overshot by forcing the inside diameter of the ring i9 to close around and against the fish, thereby sealing ofi" any openings and assuring that all wasliings will be through the inner passageway of the cylindrical fish 3i and out through the bottom to provide a washing action directed at the bottom of the fish and thereby assist a stuck fish in becoming free.

From the foregoing, it is apparent that the present invention contemplates an overshot fishing tool for use in recovering lost fish elements in a well bore which may be easily engaged and disengaged with the fish and that the engagement and disengagement are both accomplished by a subsequent turning in a right hand direction in or ler to prevent any possibility of retrograde rotation of the fishing string and unthreading of any portions thereof. Furthermore, it will be apparent that the overshot fishing tool is provided with a novel control head permitting the uniform rotation of the overshot body to provide for the engagement or disengagement of lthe attaching members of the overshot from the lost fish without any retrograde movement whatsoever.

Changes may be made in the combination and arrangement of parts as heretofore set forth in the specification and shown in the drawings, it being understood that any modification in the precise embodiment of the invention may be made within the scope of the following claims without departing from the spirit of the invention.

l. ln an overshot fishing tool for retrieving broken ofi drill pipe and the like in a well bore comprising a sectional cylindrical body member adapted to be lowered over the pipe, a control head carried in the body member, a plurality of serrated slips carried thereby, a tapered portion provided in the body member cooperatping engagement of the slips with the broken drill pipe, a helical spring anchored between a shoulder of the control head and the body member for urging the control member into substantially rigid contact with the broken drill pipe disposed therein, a plurality of diametrically opposed lugs provided in the body, a plurality of diametrically opposed vertical slots provided in the control head, for telescopic reception of the lugs, a peripheral slot provided in the control head and communicating with the diametrically opposed vertical slots to provide for movement of the lugs therethrough and facilitate engagement and release of the overshot tool with the broken pipe by a continuous rotation in the same direction.

2. ln an overshot iishing tool for removing broken off drill pipe and the like from oil well bores comprising a cylindrical body adapted to be lowered over the pipe, a control head disposed in the body, a plurality" of serrated slips carried by the control head, cooperating taper means between the slips and the body to eiect a gripping engagement of the slips with the drill pipe, a plurality of longitudinal groves provided in the control head, a plurality of lugs provided in the body and cooperating with the grooves to provide longitudinal movement between the body and the control head, said lugs responsive to a pre-determined weight for movement in the grooves to disengage the tapering means and release the slips from the pipe, a horizontal groove provided in the control head and disposed conterminous with the bottom of the vertical grooves and responsive to a right hand rotation of the body relative to the control head to move the lugs from the vertical groove into the lowermost horizontal groove for maintaining a release of the slips with the pipe.

3. in an overshot iishing tool for removing broken oft" drill pipe and the like from oil well bores comprising a cylindrical body adapted to be lowered over the pipe, a control head disposed in the body, a plurality of serrated slips carried by the control head, cooperating taper means between the slips and the body to effect a gripping engagement of the slips with the drill pipe, a plurality ot longitudinal slots provided in the control head, a plurality of lugs provided in the body and cooperating with the slots to provide longitudinal movement between the body and the control head, said lugs responsive to a pre-determined weight for movement in the slots to disengage the tapering means and release the slips from the pipe, means in the control head cooperating with the lugs to provide a continuous right hand rotation ot the body relative to the control head for rca-engagement of the slips with the pipe, said means being a horizontal slot provided in the control head and disposed conterminous with the bottom of the vertical siot to move the lugs from the vertical slot into the lowermost horizontal slot for maintaining a release of the slips with the pipe, a second horizontal slot in the control head disposed above the first mentioned horizontal slot and communicating therewith, said lugs responsive to a decrease in the pre-determined weight to be moved vertically upward from the first .mentioned holizontal slot to the top of the second mentioned horizontal slot to provide for continuous right hand rotation of the body relative to the head for effecting 1re-engagement of the slips with the pipe.

4. ln a combination release overshot and control head utilized for retrieving lost fish in a well bore including a cylindrical body disposed over the fish, a control head movably disposed in the upper portion of the body, a helical spring anchored between the body and a shoulder of the control head for urging the control head constantly in one direction, a plurality of slip members carried by the head, taper means provided between the body member and the slips for moving the slips in one direction to provide engagement of the slips with the ing with a tapered portion on the slips to elect a gripdrill pipe, a plurality of diametrically opposed grooves provided in lthe head, a pair of diametrically opposed lugs provided in the body cooperating with the grooves to provide longitudinal movement between the body and the headfsaidtapering means responsive to one position of the vlugs in the grooves to cause engagement of the slips with the lost fish, and in another position of the lugs in the grooves to provide for release of the slips with the fish, a pair of vertically spaced connecting horizontally .disposed slots provided in the head between the opposed grooves, said horizontal slots providing for disposition .of `the lugs from the grooves into the slots after release of the slips from the lish, said lugs so disposed in the slots responsive to a right hand rotation of the body member for movement through the slots for reinsertion into the grooves.

5. In an overshot fishing tool for removing broken drill pipe and the like. from oil well bores comprising a cylindrical body to be lowered over the pipe, a control heady disposed in the body, a plurality of serrated slips carried by the control head, cooperating taper means between the slips and the body to effect a gripping engagement ofA the slips with the drill pipe, a plurality of longitudin-al slots provided. in the control head, a plurality of lugs provided in the body and cooperating with the slots to provide longitudinal movement between the body and the control head, a peripheral slot provided in the control head having portions thereof disposed at spaced vertical planes, said peripheral slot communicating with the longitudinal slots, said lugs responsive to a predetermined weight for movement into the peripheral slot providing disengagement of the slips from the pipe, and

6, in an overshot fishing tool for removing broken drill pipe and the like from oil well bores comprising a cylindrical body to be lowered over the pipe, a movable control head disposed in the body, gripping means carried by the control head, taper means between the gripping means and the body to provide for engagement of the gripping means with the pipe, a pair of diametrically opposed lugs provided on the body and cooperating with the slots to provide longitudinal movement between the body and the control head, said lugs in one position of the slots providing for seating the taper means causing engagement of the gripping means with the drill pipe, and responsive to a predetermined weight moving the lugs to a lower position in the slots to disengage the taper means and release the gripping means from the pipe, and a peripheral slot disposed in the control head and having portions thereof disposed at spaced vertical planes and cooperating with the first mentioned longitudinal slots in response to a right hand rotation of the body member in relation to the control head to move the lugs therethrough.

8613371530291

8613371530291