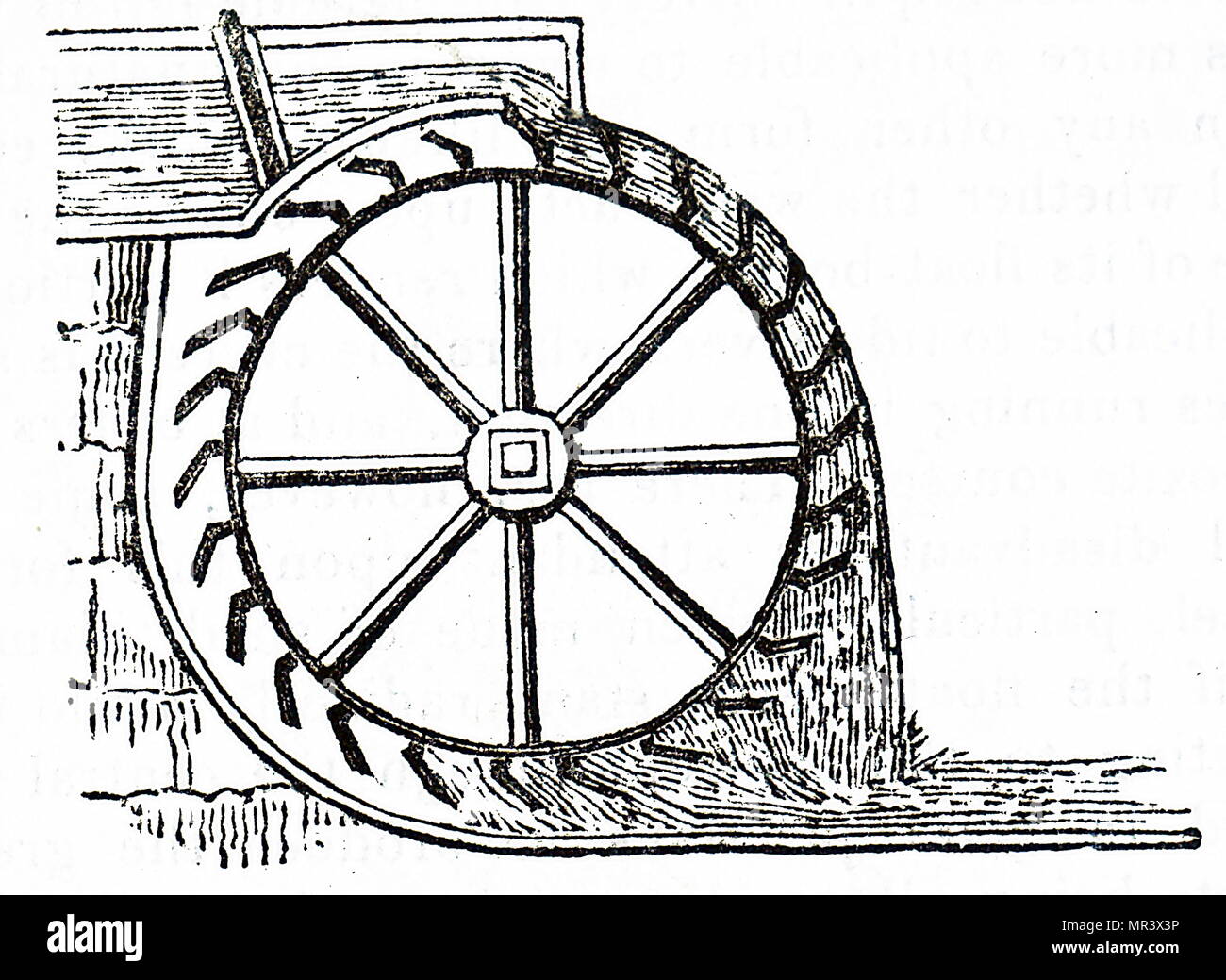

overshot wheel made in china

A water wheel is a machine for converting the energy of flowing or falling water into useful forms of power, often in a watermill. A water wheel consists of a wheel (usually constructed from wood or metal), with a number of blades or buckets arranged on the outside rim forming the driving car. Water wheels were still in commercial use well into the 20th century but they are no longer in common use. Uses included milling flour in gristmills, grinding wood into pulp for papermaking, hammering wrought iron, machining, ore crushing and pounding fibre for use in the manufacture of cloth.

Some water wheels are fed by water from a mill pond, which is formed when a flowing stream is dammed. A channel for the water flowing to or from a water wheel is called a mill race. The race bringing water from the mill pond to the water wheel is a headrace; the one carrying water after it has left the wheel is commonly referred to as a tailrace.

Waterwheels were used for various purposes from agriculture to metallurgy in ancient civilizations spanning the Hellenistic Greek world, Rome, China and India. Waterwheels saw continued use in the Post-classical age, like the Middle Ages of Europe and the Islamic Golden Age, but also elsewhere. In the mid to late 18th century John Smeaton"s scientific investigation of the water wheel led to significant increases in efficiency supplying much needed power for the Industrial Revolution.turbine, developed by Benoît Fourneyron, beginning with his first model in 1827.elevations, that exceed the capability of practical-sized waterwheels.

The main difficulty of water wheels is their dependence on flowing water, which limits where they can be located. Modern hydroelectric dams can be viewed as the descendants of the water wheel, as they too take advantage of the movement of water downhill.

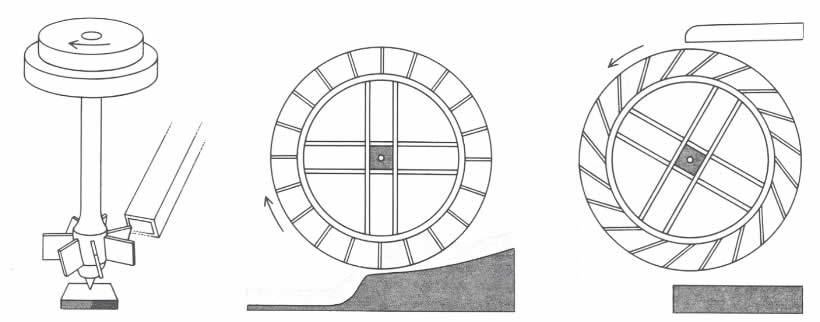

Overshot and backshot water wheels are typically used where the available height difference is more than a couple of meters. Breastshot wheels are more suited to large flows with a moderate head. Undershot and stream wheel use large flows at little or no head.

There is often an associated millpond, a reservoir for storing water and hence energy until it is needed. Larger heads store more gravitational potential energy for the same amount of water so the reservoirs for overshot and backshot wheels tend to be smaller than for breast shot wheels.

Overshot and pitchback water wheels are suitable where there is a small stream with a height difference of more than 2 metres (6.5 ft), often in association with a small reservoir. Breastshot and undershot wheels can be used on rivers or high volume flows with large reservoirs.

Stream wheels are cheaper and simpler to build and have less of an environmental impact, than other types of wheels. They do not constitute a major change of the river. Their disadvantages are their low efficiency, which means that they generate less power and can only be used where the flow rate is sufficient. A typical flat board undershot wheel uses about 20 percent of the energy in the flow of water striking the wheel as measured by English civil engineer John Smeaton in the 18th century.

Stream wheels mounted on floating platforms are often referred to as hip wheels and the mill as a ship mill. They were sometimes mounted immediately downstream from bridges where the flow restriction of the bridge piers increased the speed of the current.

An undershot wheel is a vertically mounted water wheel with a horizontal axle that is rotated by the water from a low weir striking the wheel in the bottom quarter. Most of the energy gain is from the movement of the water and comparatively little from the head. They are similar in operation and design to stream wheels.

The word breastshot is used in a variety of ways. Some authors restrict the term to wheels where the water enters at about the 10 o’clock position, others 9 o’clock, and others for a range of heights.

The small clearance between the wheel and the masonry requires that a breastshot wheel has a good trash rack ("screen" in British English) to prevent debris from jamming between the wheel and the apron and potentially causing serious damage.

Breastshot wheels are less efficient than overshot and backshot wheels but they can handle high flow rates and consequently high power. They are preferred for steady, high-volume flows such as are found on the Fall Line of the North American East Coast. Breastshot wheels are the most common type in the United States of America

A vertically mounted water wheel that is rotated by water entering buckets just past the top of the wheel is said to be overshot. The term is sometimes, erroneously, applied to backshot wheels, where the water goes down behind the wheel.

A typical overshot wheel has the water channeled to the wheel at the top and slightly beyond the axle. The water collects in the buckets on that side of the wheel, making it heavier than the other "empty" side. The weight turns the wheel, and the water flows out into the tail-water when the wheel rotates enough to invert the buckets. The overshot design is very efficient, it can achieve 90%,

Nearly all of the energy is gained from the weight of water lowered to the tailrace although a small contribution may be made by the kinetic energy of the water entering the wheel. They are suited to larger heads than the other type of wheel so they are ideally suited to hilly countries. However even the largest water wheel, the Laxey Wheel in the Isle of Man, only utilises a head of around 30 m (100 ft). The world"s largest head turbines, Bieudron Hydroelectric Power Station in Switzerland, utilise about 1,869 m (6,132 ft).

Overshot wheels require a large head compared to other types of wheel which usually means significant investment in constructing the headrace. Sometimes the final approach of the water to the wheel is along a flume or penstock, which can be lengthy.

A backshot wheel (also called pitchback) is a variety of overshot wheel where the water is introduced just before the summit of the wheel. In many situations, it has the advantage that the bottom of the wheel is moving in the same direction as the water in the tailrace which makes it more efficient. It also performs better than an overshot wheel in flood conditions when the water level may submerge the bottom of the wheel. It will continue to rotate until the water in the wheel pit rises quite high on the wheel. This makes the technique particularly suitable for streams that experience significant variations in flow and reduces the size, complexity, and hence cost of the tailrace.

The direction of rotation of a backshot wheel is the same as that of a breastshot wheel but in other respects, it is very similar to the overshot wheel. See below.

Some wheels are overshot at the top and backshot at the bottom thereby potentially combining the best features of both types. The photograph shows an example at Finch Foundry in Devon, UK. The head race is the overhead timber structure and a branch to the left supplies water to the wheel. The water exits from under the wheel back into the stream.

A special type of overshot/backshot wheel is the reversible water wheel. This has two sets of blades or buckets running in opposite directions so that it can turn in either direction depending on which side the water is directed. Reversible wheels were used in the mining industry in order to power various means of ore conveyance. By changing the direction of the wheel, barrels or baskets of ore could be lifted up or lowered down a shaft or inclined plane. There was usually a cable drum or a chain basket on the axle of the wheel. It is essential that the wheel have braking equipment to be able to stop the wheel (known as a braking wheel). The oldest known drawing of a reversible water wheel was by Georgius Agricola and dates to 1556.

The earliest waterwheel working like a lever was described by Zhuangzi in the late Warring States period (476-221 BC). It says that the waterwheel was invented by Zigong, a disciple of Confucius in the 5th century BC.Chinese of the Eastern Han Dynasty were using water wheels to crush grain in mills and to power the piston-bellows in forging iron ore into cast iron.

In the text known as the Xin Lun written by Huan Tan about 20 AD (during the usurpation of Wang Mang), it states that the legendary mythological king known as Fu Xi was the one responsible for the pestle and mortar, which evolved into the tilt-hammer and then trip hammer device (see trip hammer). Although the author speaks of the mythological Fu Xi, a passage of his writing gives hint that the water wheel was in widespread use by the 1st century AD in China (Wade-Giles spelling):

In the year 31 AD, the engineer and Prefect of Nanyang, Du Shi (d. 38), applied a complex use of the water wheel and machinery to power the bellows of the blast furnace to create cast iron. Du Shi is mentioned briefly in the Hou Han Shu) as follows (in Wade-Giles spelling):

Water wheels in China found practical uses such as this, as well as extraordinary use. The Chinese inventor Zhang Heng (78–139) was the first in history to apply motive power in rotating the astronomical instrument of an armillary sphere, by use of a water wheel.mechanical engineer Ma Jun (c. 200–265) from Cao Wei once used a water wheel to power and operate a large mechanical puppet theater for the Emperor Ming of Wei (r. 226–239).

The ancient Greeks invented the waterwheel independently and used it in nearly all of the forms and functions described above, including its application for watermilling.Hellenistic period between the 3rd and 1st century BC.

The compartmented water wheel comes in two basic forms, the wheel with compartmented body (Latin tympanum) and the wheel with compartmented rim or a rim with separate, attached containers.sakia gear.

The earliest literary reference to a water-driven, compartmented wheel appears in the technical treatise Pneumatica (chap. 61) of the Greek engineer Philo of Byzantium (ca. 280−220 BC).Parasceuastica (91.43−44), Philo advises the use of such wheels for submerging siege mines as a defensive measure against enemy sapping.dry docks in Alexandria under the reign of Ptolemy IV (221−205 BC).papyri of the 3rd to 2nd century BC mention the use of these wheels, but don"t give further details.Ancient Near East before Alexander"s conquest can be deduced from its pronounced absence from the otherwise rich oriental iconography on irrigation practices.

The earliest depiction of a compartmented wheel is from a tomb painting in Ptolemaic Egypt which dates to the 2nd century BC. It shows a pair of yoked oxen driving the wheel via a sakia gear, which is here for the first time attested, too.Museum of Alexandria, at the time the most active Greek research center, may have been involved in its invention.Alexandrian War in 48 BC tells of how Caesar"s enemies employed geared waterwheels to pour sea water from elevated places on the position of the trapped Romans.

Around 300 AD, the noria was finally introduced when the wooden compartments were replaced with inexpensive ceramic pots that were tied to the outside of an open-framed wheel.

The Romans used waterwheels extensively in mining projects, with enormous Roman-era waterwheels found in places like modern-day Spain. They were reverse overshot water-wheels designed for dewatering deep underground mines.Vitruvius, including the reverse overshot water-wheel and the Archimedean screw. Many were found during modern mining at the copper mines at Rio Tinto in Spain, one system involving 16 such wheels stacked above one another so as to lift water about 80 feet from the mine sump. Part of such a wheel was found at Dolaucothi, a Roman gold mine in south Wales in the 1930s when the mine was briefly re-opened. It was found about 160 feet below the surface, so must have been part of a similar sequence as that discovered at Rio Tinto. It has recently been carbon dated to about 90 AD, and since the wood from which it was made is much older than the deep mine, it is likely that the deep workings were in operation perhaps 30–50 years after. It is clear from these examples of drainage wheels found in sealed underground galleries in widely separated locations that building water wheels was well within their capabilities, and such verticals water wheels commonly used for industrial purposes.

About the same time, the overshot wheel appears for the first time in a poem by Antipater of Thessalonica, which praises it as a labour-saving device (IX, 418.4–6).Lucretius (ca. 99–55 BC) who likens the rotation of the waterwheel to the motion of the stars on the firmament (V 516).central Gaul.Barbegal watermill complex a series of sixteen overshot wheels was fed by an artificial aqueduct, a proto-industrial grain factory which has been referred to as "the greatest known concentration of mechanical power in the ancient world".

In Roman North Africa, several installations from around 300 AD were found where vertical-axle waterwheels fitted with angled blades were installed at the bottom of a water-filled, circular shaft. The water from the mill-race which entered tangentially the pit created a swirling water column that made the fully submerged wheel act like true water turbines, the earliest known to date.

Apart from its use in milling and water-raising, ancient engineers applied the paddled waterwheel for automatons and in navigation. Vitruvius (X 9.5–7) describes multi-geared paddle wheels working as a ship odometer, the earliest of its kind. The first mention of paddle wheels as a means of propulsion comes from the 4th–5th century military treatise

Ancient water-wheel technology continued unabated in the early medieval period where the appearance of new documentary genres such as legal codes, monastic charters, but also hagiography was accompanied with a sharp increase in references to watermills and wheels.

The earliest excavated water wheel driven by tidal power was the Nendrum Monastery mill in Northern Ireland which has been dated to 787, although a possible earlier mill dates to 619. Tide mills became common in estuaries with a good tidal range in both Europe and America generally using undershot wheels.

Cistercian monasteries, in particular, made extensive use of water wheels to power watermills of many kinds. An early example of a very large water wheel is the still extant wheel at the early 13th century Real Monasterio de Nuestra Senora de Rueda, a Cistercian monastery in the Aragon region of Spain. Grist mills (for corn) were undoubtedly the most common, but there were also sawmills, fulling mills and mills to fulfil many other labour-intensive tasks. The water wheel remained competitive with the steam engine well into the Industrial Revolution. At around the 8th to 10th century, a number of irrigation technologies were brought into Spain and thus introduced to Europe. One of those technologies is the Noria, which is basically a wheel fitted with buckets on the peripherals for lifting water. It is similar to the undershot water wheel mentioned later in this article. It allowed peasants to power watermills more efficiently. According to Thomas Glick"s book, Irrigation and Society in Medieval Valencia, the Noria probably originated from somewhere in Persia. It has been used for centuries before the technology was brought into Spain by Arabs who had adopted it from the Romans. Thus the distribution of the Noria in the Iberian peninsula "conforms to the area of stabilized Islamic settlement".Spaniards, the technology spread to the New World in Mexico and South America following Spanish expansion

The type of water wheel selected was dependent upon the location. Generally if only small volumes of water and high waterfalls were available a millwright would choose to use an overshot wheel. The decision was influenced by the fact that the buckets could catch and use even a small volume of water.

Harnessing water-power enabled gains in agricultural productivity, food surpluses and the large scale urbanization starting in the 11th century. The usefulness of water power motivated European experiments with other power sources, such as wind and tidal mills.canals, put Europe on a hydraulically focused path, for instance water supply and irrigation technology was combined to modify supply power of the wheel.feudal state.

The water mill was used for grinding grain, producing flour for bread, malt for beer, or coarse meal for porridge.fulling mill, which was used for cloth making. The trip hammer was also used for making wrought iron and for working iron into useful shapes, an activity that was otherwise labour-intensive. The water wheel was also used in papermaking, beating material to a pulp. In the 13th century water mills used for hammering throughout Europe improved the productivity of early steel manufacturing. Along with the mastery of gunpowder, waterpower provided European countries worldwide military leadership from the 15th century.

Millwrights distinguished between the two forces, impulse and weight, at work in water wheels long before 18th-century Europe. Fitzherbert, a 16th-century agricultural writer, wrote "druieth the wheel as well as with the weight of the water as with strengthe [impulse]".Leonardo da Vinci also discussed water power, noting "the blow [of the water] is not weight, but excites a power of weight, almost equal to its own power".laws of force. Evangelista Torricelli"s work on water wheels used an analysis of Galileo"s work on falling bodies, that the velocity of a water sprouting from an orifice under its head was exactly equivalent to the velocity a drop of water acquired in falling freely from the same height.

The water wheel was a driving force behind the earliest stages of industrialization in Britain. Water-powered reciprocating devices were used in trip hammers and blast furnace bellows. Richard Arkwright"s water frame was powered by a water wheel.

The most powerful water wheel built in the United Kingdom was the 100 hp Quarry Bank Mill water wheel near Manchester. A high breastshot design, it was retired in 1904 and replaced with several turbines. It has now been restored and is a museum open to the public.

The biggest working water wheel in mainland Britain has a diameter of 15.4 m (51 ft) and was built by the De Winton company of Caernarfon. It is located within the Dinorwic workshops of the National Slate Museum in Llanberis, North Wales.

The largest working water wheel in the world is the Laxey Wheel (also known as Lady Isabella) in the village of Laxey, Isle of Man. It is 72 feet 6 inches (22.10 m) in diameter and 6 feet (1.83 m) wide and is maintained by Manx National Heritage.

During the Industrial Revolution, in the first half of the 19th century engineers started to design better wheels. In 1823 Jean-Victor Poncelet invented a very efficient undershot wheel design that could work on very low heads, which was commercialized and became popular by late 1830s. Other designs, as the Sagebien wheel, followed later. At the same time Claude Burdin was working on a radically different machine which he called turbine, and his pupil Benoît Fourneyron designed the first commercial one in the 1830s.

Development of water turbines led to decreased popularity of water wheels. The main advantage of turbines is that its ability to harness head is much greater than the diameter of the turbine, whereas a water wheel cannot effectively harness head greater than its diameter. The migration from water wheels to modern turbines took about one hundred years.

Water wheels were used to power sawmills, grist mills and for other purposes during development of the United States. The 40 feet (12 m) diameter water wheel at McCoy, Colorado, built in 1922, is a surviving one out of many which lifted water for irrigation out of the Colorado River.

Two early improvements were suspension wheels and rim gearing. Suspension wheels are constructed in the same manner as a bicycle wheel, the rim being supported under tension from the hub- this led to larger lighter wheels than the former design where the heavy spokes were under compression. Rim-gearing entailed adding a notched wheel to the rim or shroud of the wheel. A stub gear engaged the rim-gear and took the power into the mill using an independent line shaft. This removed the rotative stress from the axle which could thus be lighter, and also allowed more flexibility in the location of the power train. The shaft rotation was geared up from that of the wheel which led to less power loss. An example of this design pioneered by Thomas Hewes and refined by William Armstrong Fairburn can be seen at the 1849 restored wheel at the Portland Basin Canal Warehouse.

Australia has a relatively dry climate, nonetheless, where suitable water resources were available, water wheels were constructed in 19th-century Australia. These were used to power sawmills, flour mills, and stamper batteries used to crush gold-bearing ore. Notable examples of water wheels used in gold recovery operations were the large Garfield water wheel near Chewton—one of at least seven water wheels in the surrounding area—and the two water wheels at Adelong Falls; some remnants exist at both sites.Walhalla once had at least two water wheels, one of which was rolled to its site from Port Albert, on its rim using a novel trolley arrangement, taking nearly 90 days.water wheel at Jindabyne, constructed in 1847, was the first machine used to extract energy—for flour milling—from the Snowy River.

The early history of the watermill in India is obscure. Ancient Indian texts dating back to the 4th century BC refer to the term cakkavattaka (turning wheel), which commentaries explain as arahatta-ghati-yanta (machine with wheel-pots attached). On this basis, Joseph Needham suggested that the machine was a noria. Terry S. Reynolds, however, argues that the "term used in Indian texts is ambiguous and does not clearly indicate a water-powered device." Thorkild Schiøler argued that it is "more likely that these passages refer to some type of tread- or hand-operated water-lifting device, instead of a water-powered water-lifting wheel."

Around 1150, the astronomer Bhaskara Achārya observed water-raising wheels and imagined such a wheel lifting enough water to replenish the stream driving it, effectively, a perpetual motion machine.Arabic and Persian works. During medieval times, the diffusion of Indian and Persian irrigation technologies gave rise to an advanced irrigation system which bought about economic growth and also helped in the growth of material culture.

After the spread of Islam engineers of the Islamic world continued the water technologies of the ancient Near East; as evident in the excavation of a canal in the Basra region with remains of a water wheel dating from the 7th century. Hama in Syria still preserves some of its large wheels, on the river Orontes, although they are no longer in use.Murcia in Spain, La Nora, and although the original wheel has been replaced by a steel one, the Moorish system during al-Andalus is otherwise virtually unchanged. Some medieval Islamic compartmented water wheels could lift water as high as 30 metres (100 ft).Muhammad ibn Zakariya al-Razi"s Kitab al-Hawi in the 10th century described a noria in Iraq that could lift as much as 153,000 litres per hour (34,000 imp gal/h), or 2,550 litres per minute (560 imp gal/min). This is comparable to the output of modern norias in East Asia, which can lift up to 288,000 litres per hour (63,000 imp gal/h), or 4,800 litres per minute (1,100 imp gal/min).

The industrial uses of watermills in the Islamic world date back to the 7th century, while horizontal-wheeled and vertical-wheeled water mills were both in widespread use by the 9th century. A variety of industrial watermills were used in the Islamic world, including gristmills, hullers, sawmills, shipmills, stamp mills, steel mills, sugar mills, and tide mills. By the 11th century, every province throughout the Islamic world had these industrial watermills in operation, from al-Andalus and North Africa to the Middle East and Central Asia.crankshafts and water turbines, gears in watermills and water-raising machines, and dams as a source of water, used to provide additional power to watermills and water-raising machines.factory complexes built in al-Andalus between the 11th and 13th centuries.

The engineers of the Islamic world developed several solutions to achieve the maximum output from a water wheel. One solution was to mount them to piers of bridges to take advantage of the increased flow. Another solution was the shipmill, a type of water mill powered by water wheels mounted on the sides of ships moored in midstream. This technique was employed along the Tigris and Euphrates rivers in 10th-century Iraq, where large shipmills made of teak and iron could produce 10 tons of flour from corn every day for the granary in Baghdad.flywheel mechanism, which is used to smooth out the delivery of power from a driving device to a driven machine, was invented by Ibn Bassal (fl. 1038–1075) of Al-Andalus; he pioneered the use of the flywheel in the saqiya (chain pump) and noria.Al-Jazari in the 13th century and Taqi al-Din in the 16th century described many inventive water-raising machines in their technological treatises. They also employed water wheels to power a variety of devices, including various water clocks and automata.

A recent development of the breastshot wheel is a hydraulic wheel which effectively incorporates automatic regulation systems. The Aqualienne is one example. It generates between 37 kW and 200 kW of electricity from a 20 m3 (710 cu ft) waterflow with a head of 1 to 3.5 m (3 to 11 ft).

Overshot (and particularly backshot) wheels are the most efficient type; a backshot steel wheel can be more efficient (about 60%) than all but the most advanced and well-constructed turbines. In some situations an overshot wheel is preferable to a turbine.

The development of the hydraulic turbine wheels with their improved efficiency (>67%) opened up an alternative path for the installation of water wheels in existing mills, or redevelopment of abandoned mills.

The kinetic energy can be accounted for by converting it into an equivalent head, the velocity head, and adding it to the actual head. For still water the velocity head is zero, and to a good approximation it is negligible for slowly moving water, and can be ignored. The velocity in the tail race is not taken into account because for a perfect wheel the water would leave with zero energy which requires zero velocity. That is impossible, the water has to move away from the wheel, and represents an unavoidable cause of inefficiency.

The power is how fast that energy is delivered which is determined by the flow rate. It has been estimated that the ancient donkey or slave-powered quern of Rome made about one-half of a horsepower, the horizontal waterwheel creating slightly more than one-half of a horsepower, the undershot vertical waterwheel produced about three horsepower, and the medieval overshot waterwheel produced up to forty to sixty horsepower.

From the cross sectional area and the velocity. They must be measured at the same place but that can be anywhere in the head or tail races. It must have the same amount of water going through it as the wheel.

A parallel development is the hydraulic wheel/part reaction turbine that also incorporates a weir into the centre of the wheel but uses blades angled to the water flow.

The University of Southampton School of Civil Engineering and the Environment in the UK has investigated both types of Hydraulic wheel machines and has estimated their hydraulic efficiency and suggested improvements, i.e. The Rotary Hydraulic Pressure Machine. (Estimated maximum efficiency 85%).

These type of water wheels have high efficiency at part loads / variable flows and can operate at very low heads, < 1 m (3 ft 3 in). Combined with direct drive Axial Flux Permanent Magnet Alternators and power electronics they offer a viable alternative for low head hydroelectric power generation.

The Editors of Encyclopædia Britannica. "Waterwheel". Britannica.com. Encyclopædia Britannica, Inc. Retrieved 19 January 2018. |last1= has generic name (help)

Müller, G.; Wolter, C. (2004). "The breastshot waterwheel: design and model tests" (PDF). Proceedings of the Institution of Civil Engineers - Engineering Sustainability. 157 (4): 203–211. doi:10.1680/ensu.2004.157.4.203. ISSN 1478-4629 – via Semantic Scholar.

Wikander 2000, p. 395; Oleson 2000, p. 229It is no surprise that all the water-lifting devices that depend on subdivided wheels or cylinders originate in the sophisticated, scientifically advanced Hellenistic period, ...

Oleson 2000, pp. 235: The sudden appearance of literary and archaological evidence for the compartmented wheel in the third century B.C. stand in marked contrast to the complete absence of earlier testimony, suggesting that the device was invented not long before.

An isolated passage in the Hebrew Deuteronomy (11.10−11) about Egypt as a country where you sowed your seed and watered it with your feet is interpreted as an metaphor referring to the digging of irrigation channels rather than treading a waterwheel (Oleson 2000, pp. 234).

As for a Mesopotamian connection: Schioler 1973, p. 165−167: References to water-wheels in ancient Mesopotamia, found in handbooks and popular accounts, are for the most part based on the false assumption that the Akkadian equivalent of the logogram GIS.APIN was nartabu and denotes an instrument for watering ("instrument for making moist").As a result of his investigations, Laessoe writes as follows on the question of the saqiya: "I consider it unlikely that any reference to the saqiya will appear in ancient Mesopotamian sources." In his opinion, we should turn our attention to Alexandria, "where it seems plausible to assume that the saqiya was invented."

Adriana de Miranda (2007), Water architecture in the lands of Syria: the water-wheels, L"Erma di Bretschneider, pp. 48f, ISBN 978-8882654337 concludes that the Akkadian passages "are counched in terms too general too allow any conclusion as to the excat structure" of the irrigation apparatus, and states that "the latest official Chicago Assyrian Dictionary reports meanings not related to types of irrigation system".

Terry S, Reynolds, Stronger than a Hundred Men; A History of the Vertical Water Wheel. Baltimore; Johns Hopkins University Press, 1983. Robert, Friedel, A Culture of Improvement. MIT Press. Cambridge, Massachusetts. London, England. (2007). p. 33.

Davies, Peter; Lawrence, Susan (2013). "The Garfield water wheel: hydraulic power on the Victorian goldfields" (PDF). Australasian Historical Archaeology. 31: 25–32.

Gies, Frances; Gies, Joseph (1994). Cathedral, Forge, and Waterwheel: Technology and Invention in the Middle Ages. HarperCollins Publishers. p. 115. ISBN 0060165901.

Quaranta Emanuele, Revelli Roberto (2015), "Performance characteristics, power losses and mechanical power estimation for a breastshot water wheel", Energy, Energy, Elsevier, 87: 315–325, doi:10.1016/j.energy.2015.04.079

Reynolds, T.S. (1983) Stronger Than a Hundred Men: A History of the Vertical Water Wheel, Johns Hopkins studies in the history of technology: New Series 7, Baltimore: Johns Hopkins University Press, ISBN 0-8018-2554-7

Wilson, Andrew (1995), "Water-Power in North Africa and the Development of the Horizontal Water-Wheel", Journal of Roman Archaeology, vol. 8, pp. 499–510

Illustration 4. Transformation of rotary motion into linear motion can be achieved by having a cam on the axle of the wheel (drawing from Scientific American).

There are many wheel configurations, vane/blade shapes and water-flow patterns. Undershot wheels and horizontal wheels were the most common choices for tide mills. Since the height of the impoundment area was the height of high tide, the head of water was probably not high enough to power an overshot wheel.

Probably the most important of the early engines which utilized water power was the vertical waterwheel. Its two basic forms are the undershot and the overshot. The undershot vertical wheel rotated in the vertical plane and had a horizontal axis. It normally had flat radial blades attached to its periphery and derived its motion from the impact of water flowing under the wheel and against these blades. While capable of working on any convenient stream without mill races (narrow artificial water channels, it worked most effectively in a race and with a stable volume of water running at a fairly high velocity. [Stronger than a Hundred Men: A History of the Vertical Water Wheel by Terry S. Reynolds Baltimore: The Johns Hopkins University Press, 1983.]

The Undershot Wheel worked in a running stream and could turn in shallow water. It was often built by the first settlers since it was relatively simple to set up … They were common in the early days when a dam could be built to compensate for dry periods … . [Mill: The History and Future of Naturally Powered Buildings by David Larkin. New York, 2000.]

The tub wheel could only work where the water flowed regularly throughout the year, and needed at least an eight-foot fall. The tub wheel was horizontal and was described as acted upon by percussion of water. The shaft is vertical, running the stone of top of it, and serves as a spindle. The water is shot on the upper side of the wheel in the direction of a tangent fitted with blades. It revolves in a sturdy tub, projecting far enough above the wheel to prevent the water from shooting over it, and whirls above it until it strikes the buckets. . [Mill: The History and Future of Naturally Powered Buildings by David Larkin. New York, 2000.]

The overshot vertical wheel was a much more efficient device. Water was fed at the top of the overshot wheel into “buckets” or containers built into the wheel’s circumference, and the weight of the impounded water, rather than its impact, turned the wheel. Each “bucket” discharged its water into the tail race at the lower portion of its revolution and ascended empty to repeat the process. The overshot wheel was usually more expensive than the undershot, since a dam and an elevated head race were normally required to build up a large fall of water and to lead the water to the wheel’s summit. It was suitable mainly to low water volumes and moderately high falls.

It is likely that the [emergence of undershot and overshot wheels] was at least partially influenced by several more primitive devices which tap the power of falling water – the water lever, the noria, and the primitive horizontal watermill. [Stronger than a Hundred Men: A History of the Vertical Water Wheel by Terry S. Reynolds Baltimore: The Johns Hopkins University Press, 1983.]

The overshot wheel required a dam above it so that the weight of water falling on it would make it turn. After one-third of a revolution, the water was spilled from the wheel. The water first striking the wheel gave it momentum, but the weight of the water in its buckets kept it turning. [Mill: The History and Future of Naturally Powered Buildings by David Larkin. New York, 2000.]

The difference between the pitch-back and the overshot wheels is that the trough stops shorter here and pours the water onto the wheel before the top of the wheel, or ‘on the near side’ as the millwrights used to say. The result therefore is that the wheel revolves in the opposite direction from the overshot, i.e. towards the flume or head-race. The buckets face in the opposite direction and the water therefore falls off at the same side as that on which it was received. [British Water-Mills by Leslie Syson. London, 1965]

The breast wheel, like the undershot wheel, turned in the opposite direction to the overshot wheel and received water above its center shaft at the nearest point of the water supply, and revolved easily because it was less loaded with water. . [Mill: The History and Future of Naturally Powered Buildings by David Larkin. New York, 2000.]

The flutter wheel was used when there was a large supply of water. It was small, low and wide—about three feet in diameter and up to eight feet wide. It got its attractive name from the sound it made. As the wheel went around, the blades cut through the entering water, making a noise like the fluttering wings of a bird. It was used almost entirely to power early sawmills. . [Mill: The History and Future of Naturally Powered Buildings by David Larkin. New York, 2000.]

The turbine with its curved blades, eventually replaced the waterwheel [in the mid-nineteenth century]. … Roy S. Hubbs pointed out that older undershot waterwheels presented a flat blade for the incoming water to impact, allowing half of the velocity to pass through unchecked. The Poncelet design [and the later resulting turbine] presented a curved blade with its lip angled tangentially to the incoming water … Benoit Fourneyron turned the wheel on its side and dropped the water into its center, allowing the water to flow simultaneously out of all the passages between the blades. … Since the turbine used all the openings between its blades simultaneously, it could be made much smaller. It turned much faster than the larger wheels. . [Mill: The History and Future of Naturally Powered Buildings by David Larkin. New York, 2000.]

Operating on the seesaw principle, the water lever utilized the power of falling water, but without the continuous rotary motion of water wheels. One end of a pivoted beam was equipped with a spoon-shaped bucket. On the other end was a hammerlike counterweight used for pounding or crushing. Water was directed into the bucket from a falling stream; the bucket filled, overweighed the hammer, and lifted it. The ascent of the bucket caused the water to spill; the hammer than overbalanced the bucket and fell. The cycle was then repeated to produce a steady pounding action.

The noria used for raising water, was form of undershot water wheel, but it activated no machinery (such as gears or millstones) beyond itself. It was simply a large vertically situated wheel, sometimes as much at 50-80 feet in diameter, equipped with radial blades which rotated the apparatus as they were impacted by the flowing water in which the lower portion of the wheel was immersed. Buckets of wood, bamboo, or pottery were attached to the rim of the wheel. As the device rotated, they were filed with water at the bottom of the wheel; the water was carried upwards in the buckets and emptied near the top of the wheel into a trough. The buckets were the returned empty to the bottom of the wheel to repeat the process.

Through all of antiquity and on into the early Middle Ages almost the only work to which the force of falling water was applied was grinding wheat. This was always to be one of its more important functions. But by the tenth century, European technicians had begun to adapt the vertical water wheel to other tasks. By the sixteenth century, in addition to flour mills, there were hydropowered mills for smelting, forging, sharpening , rolling slitting, polishing, grinding, , and shaping metals. Water wheels were available for hoisting materials and for crushing ores. There were mills for making beer, olive oil, poppy oil, mustard, coins, and wire. Water wheels were used in the preparation of pigment, paper, hemp, and tanning bark, and for fulling, sawing wood, boring pipes, and ventilating mines.

RMD96J1R–Mule-powered sugar mill with vertical rollers (top). Sugar mill with vertical rollers powered by overshot waterwheel (bottom) West Indies. Copperplate engraving, London, 1764.

RMPPEK4E–The overshot waterwheel on the Maiermuehle in Teisendorf. Since 1769 the mill is owned by the Muehlbach family - in the 8th generation - the oldest machine dates back to 1920. The mill has existed at least since the Middle Ages - the waterwheel was used in 1930 (it was already 50 years old and Comes from the Franconian region). The arms are made of oak, the wheel itself is made of iron - a 1 centimeter thick layer protects it against rust. Fine flour is obtained from the grain after 20 grinding processes.

RMHTMK4N–Mule-powered sugar mill with vertical rollers (top). Sugar mill with vertical rollers powered by overshot waterwheel (bottom) West Indies. Copperplate engraving, London, 1764

RMTX1CYY–The overshot waterwheel and Water Wall at Coldstream Mill in North Ayrshire near Beith, circa 1999.; 11 February 2007 (original upload date); Transferred from en.pedia to Commons.; Rosser1954 at English pedia;

RMTXGY73–Reversible hoist for raising leather buckets from mine shaft powered by overshot waterwheel. Man in hut at O opens and shuts water races to stop and start double row of buckets From Agricola "De re metallica" 1556 Woodcut Basle

RM2DJ3DWW–An Overshot Mill, James Ward, 1769–1859, British, between 1802 and 1807, Oil on panel, Support (PTG): 10 7/8 x 13 1/8 inches (27.6 x 33.3 cm), costume, cottage, genre subject, ladder, landscape, man, peasants, straw, stream, washing, water mill, waterwheel, woman, workers

RMHEK71X–This is the 40-foot overshot waterwheel Oct. 27, 2010 at Mill Springs Mill, which is a historical gristmill from the 1800s that is preserved and administered by the U.S. Army Corps of Engineers Nashville District. The mill is located off Kentucky Highway 90 between Burnside and Monticello on the banks of scenic Lake Cumberland in Mill Springs, Ky. (USACE photo by Lee Roberts) Public get historic treat at Corps gristmill 338173

RM2A5YMD2–Reversible hoist for raising leather buckets from mine shaft powered by overshot waterwheel. Man in hut at O opens and shuts water races to stop and start double row of buckets. From Agricola "De re metallica" Basle 1556. Woodcut.

RMD98MMR–Landscape with Village Fete" (detail). Oil on canvas. Centre right is a forge or furnace powered by an overshot waterwheel. Lucas van Valckenhorgh (1530-1597) Flemish painter. Rocks Industry Leat

RM2EAERHM–Inside Lurgashall Water Mill, showing the mechanism working. Overshot waterwheel powers two pairs of mill stones, a sack hoist and a grain sifter, or

RFPYH2JC–STELLENBOSCH, SOUTH AFRICA, AUGUST 16, 2018: Information board for the historic overshot waterwheel of the Nieuwe Molen (mill) in Stellenbosch in the

RMD969NG–Reversible hoist for raising leather buckets from mine shaft powered by overshot waterwheel. Man in hut at O opens and shuts water races to stop and start double row of buckets. From Agricola "De re metallica" Basle 1556. Woodcut.

RF2CB7RX0–Overshot water wheel at historic Oblazy Water Mill at Kvacianka river, Kvacany Valley (Kvačianska dolina), Liptov area, Zilina Region, Slovakia

RFPYFT3P–STELLENBOSCH, SOUTH AFRICA, AUGUST 16, 2018: The historic overshot waterwheel of the Nieuwe Molen (mill) in Stellenbosch in the Western Cape Province.

RF2CB7RT6–Overshot water wheel at historic Oblazy Water Mill at Kvacianka river, Kvacany Valley (Kvačianska dolina), Liptov area, Zilina Region, Slovakia

RMP6HBP0–Overshot and undershot waterwheels, 19th century, including examples designed by John Smeaton and Peter Nouaille. Copperplate engraving by W. Lowry after an Illustration by J. Farey from Abraham Rees" "Cyclopedia or Universal Dictionary," London, 1817.

RMTDHWBY–OVERSHOT, METAL WATERWHEEL THAT DROVE COFFEE HUSKER - Hacienda Cafetalera Santa Clara, Coffee Mill, KM 19, PR Route 372, Hacienda La Juanita, Yauco Municipio, PR; Cary, Brian, transmitter; Boucher, Jack E, photographer

RFRKJHJG–STELLENBOSCH, SOUTH AFRICA, AUGUST 16, 2018: The historic overshot waterwheel of the Nieuwe Molen (mill) in Stellenbosch in the Western Cape Province.

RM2BEWR4N–Century-old wooden waterwheel grist mill at Stone Mountain Park in Atlanta, Georgia. The grist mill was originally located in Ellijay, Georgia.

RMRFFTMN–An Overshot Mill. Date/Period: Between 1802 and 1807. Painting. Oil on panel. Height: 276 mm (10.86 in); Width: 333 mm (13.11 in). Author: James Ward.

RMTXH39N–Multiple suction pumps, powered by an overshot water wheel through a spur wheel and lantern, being used to raise water from a mine. From "De re metallica", by Agricola, pseudonym of Georg Bauer (Basle, 1556). Woodcut.

RMMPAKW1–. Deutsch: Wassermühle mit einem oberschlächtigen Wasserrad. British Library, Cotton Manuscript Cleopatra C XI, fol 10. English: Mill with overshoot wheel. British Library, Cotton Manuscript Cleopatra C XI, fol 10. between circa 1220 and circa 1230. Unknown 879 Medieval mill with overshot wheel

RF2B770CM–An image of the overshot wheel that operates machinery by water power, receiving water at the top, it shows the water wheel power of generation in it,

RM2AMM7ET–the overshot water wheel at the Maiermühle in TeisendorfThe mill has been in the possession of the Mühlbacher family since 1769 - the 8th generation - the oldest machine family from 1920the mill has existed at least since the Middle Ages - the water wheel was bought second-hand in 1930 (at that time it was already 50 years old and comes from Franconia) - the arms are made of oak wood, the wheel itself is made of iron - a centimetre thick layer of lime protects against rust20 grinding passes are made from the grain fine more [automated translation]

RMTXH3F5–Draining mine workings by means of a battery of three pumps. The axle, B, is powered by an overshot water wheel. The cams on the axle raise and lower the piston rods by means of tappets. C is the bottom of the pipe which is encased in the basket, D. From "De re metallica", by Agricola, pseudonym of Georg Bauer (Basle, 1556). Woodcut.

RF2C9CE04–Overshot wheel, gives the greatest power with the least quantity of waterand so mainly used when circumstances will permit, or where there is a consid

RMP774N6–. English: Mining operation, Glacier Creek, July 14, 1906 . English: Caption on image: Overshot wheel and China pump operated by A.F. Guinan. Glacier Creek, July 14th 1906. Photo by F.H. Nowell, Nome, 4961 Subjects (LCTGM): Mining equipment--Alaska Subjects (LCSH): Gold mines and mining--Alaska . 1906 9 Mining operation, Glacier Creek, July 14, 1906 (NOWELL 182)

RM2EAERG7–Bagging up the flour produced by Lurgashall Mill. Weald and Downland Open Air Museum, Singleton, Nr. Chichester, West Sussex. The overshot wheel powe

RMTXH39C–A rag-and-chain pump powered by an overshot water wheel being used to drain a mine. On the right is a detail of the tube of the pump. From "De re metallica", by Agricola, pseudonym of Georg Bauer (Basle, 1556). Woodcut.

RF2CB7RM0–Overshot water wheel and flume at historic Oblazy Water Mill at Kvacianka river, Kvacany Valley (Kvačianska dolina), Liptov area, Zilina Region, Slovakia

RMPPEK4E–The overshot waterwheel on the Maiermuehle in Teisendorf. Since 1769 the mill is owned by the Muehlbach family - in the 8th generation - the oldest machine dates back to 1920. The mill has existed at least since the Middle Ages - the waterwheel was used in 1930 (it was already 50 years old and Comes from the Franconian region). The arms are made of oak, the wheel itself is made of iron - a 1 centimeter thick layer protects it against rust. Fine flour is obtained from the grain after 20 grinding processes.

RF2D74G56–Paternoster work with overshot water wheel / Paternosterwerk mit oberschlächtigem Wasserrad, Historisch, historical, digital improved reproduction of an original from the 19th century / digitale Reproduktion einer Originalvorlage aus dem 19. Jahrhundert

RMMR3X1X–Diagram depicting various forms of water wheels including at Fig. 5, a pitch back overshot wheel. Created by Abraham Rees (1743-1825) a Welsh nonconformist minister, and compiler of Rees"s Cyclopædia. Dated 19th century

RF2CB7RMG–Tourist coming out under flume, leaking water, overshot water wheel at historic Oblazy Water Mill at Kvacianka river, Kvacany Valley (Kvačianska dolina), Liptov area, Zilina Region, Slovakia

RMRJHB0B–Drawing showing Pump driven by overshot water wheel, used to raise water into a reservoir, to operate the ornamental fountain in the background. From Georg Andreas Bockler; Theatrum Machinarum Novum, Nuremberg, 1673

RMD95KFA–A rag-and-chain pump powered by an overshot water wheel being used to drain a mine. On the right is a detail of the tube of the pump. From "De re metallica", by Agricola, pseudonym of Georg Bauer (Basle, 1556). Woodcut.

RMTX1CWX–The overshot water wheel and lade at Coldstream Mill in North Ayrshire. Circa 1999.; 11 February 2007 (original upload date); Transferred from en.pedia to Commons.; Rosser1954 at English pedia;

RMD95KD7–Stamping mills powered by and overshot water wheel being used to crush ore to begin the process of extracting metal from the ore won from a mine. From "De re metallica", by Agricola, pseudonym of Georg Bauer (Basle, 1556). Woodcut. Mining. Metal. Power. Water.

RMTXGY3X–Mine being drained by a rag-and-chain pump powered by overshot water wheel. At right is detail of section of pipe K From "Agricola De re metallica" 1556 Basle

RM2BA554H–"Deutsch: Oberschlächtiges Wasserrad neben dem Alten Rathaus in Tambach-Dietharz, Deutschland, 2007.English: Overshot water wheel next to old townhall in Tambach-Dietharz, Germany, 2007.; 29 September 2007; Own work; Sebastian Wallroth; "

Korean Peninsula is a mountainous region where a significant portion of the landscape is shaped by fast-flowing rivers. Given this basic geographical fact about Korea, it would be reasonable to assume that the Koreans would have actively utilized the water as an energy source. In the past when the steam engines and electricity did not exist, one of the most popular methods of generating energy was through the usage of the waterwheel. Therefore, it would be expected that Koreans would have built many waterwheels to take advantage of the numerous rivers that flowing at perfect rates to rotate them. Surprisingly, one can completely undermine this assumption by simply traveling around Korean countryside. Figure 1 on the left side represents the typical type of waterwheel found in current day Korea. Although this waterwheel looks fine at a glance, it has one major problem. The water has to move uphill in order to rotate the wheel, a phenomenon which goes against the natural law of gravitation. As shown in this example, many waterwheels in Korea nowadays are merely decorative, technically not functional. Moreover, only few waterwheels from the past still stand as historical remnants. Only two waterwheels are currently registered as the official Korean historical heritages. This small number does suggest a significant trend. It implies that the Koreans had little interest in preserving traditional waterwheels that presumably have been considered not that important. This implication ultimately leads to a claim that the waterwheels did not play a major role in Korean history. In contrast, "China during Song Dynasty was on the verge of industrial revolution when its waterwheel technology had reached its zenith" (1). The major force that drove the industrial revolution in Europe before the invention of steam engine was the waterwheels tied to machines through belts. In this historical context, there exists an obvious discrepancy between how the Koreans treated the waterwheel technology and how the Chinese and Europeans treated it.

The purpose of this research is to comparatively analyze the history of waterwheel in mainly three regions: Korea, China and Europe in general. Although the history of the waterwheel dates back to ancient Rome, or even further back, this paper puts significant emphasis on the periods from 960 when Song Dynasty and Goryeo Dynasty flourished in China and Korea respectively. Please understand that there may exist gaps between each periods addressed in this paper. Some of the in-between history of waterwheel in China is purposely omitted to maintain a focus. Because this research focuses mainly on the interaction between China and Korea, the history of waterwheel in Europe is only briefly mentioned to establish a balanced comparison. The history of waterwheel in Japan is also briefly mentioned because there was a major exchange of waterwheel technology between Korean and Japan during the Japanese invasion of Korea in the 16th century. However, Japan is not one of the main regions addressed in this paper because the influence was ephemeral and not continuous throughout history. Through analytic comparison of these three regions, this research ultimately aims to answer three questions listed below.

2) Why did the advanced waterwheel technology of China not spread to Goryeo and Joseon, despite their intimate cultural and military affiliation with China?

The paper is first categorized by the three main regions(China, Korea, Europe). In each chapter, the history of the waterwheel is narrated chronologically, covering a general history but emphasizing certain periods. Most importantly, in chapter V, the different histories of each region will be comparatively analyzed to answer the questions mentioned above.

(Korea) The definition is similar to that in Europe, but it technically includes only the wheels that are used for irrigational purpose. However, this term is often vaguely used by Korean scholars to mean any machine that contains a rotating wheel associated with water power (2). The Spanish called this type of irrigational waterwheel a noria - "a machine for lifting water into a small aqueduct, either for the purpose of irrigation or, in at least one known instance, to feed seawater into a saltern."

A Korean traditional watermill that does not use a waterwheel but instead uses a wooden lever that is pulled down by a water container. The container is constantly filled with water until the water inside is eventually released due to the gravity and pulls the lever down. The lever goes back up slowly as the water inside the container empties. The repeated cycle of the lever moving up and down pounds the grain placed in a hole as shown in the above photo.

Traditional Korean terminology for the waterwheel used for irrigation, especially in the salt ponds. Very similar to "Noria" and "Dragon-bone wheel" in style.

Xin Lun written by Huan Tan, the first text that mentions the existence of waterwheels in China, implies that the waterwheel was already in widespread use in China by 1st century. It also mentions a mythological figure Fu Xi who lived in about 20 AD. He developed a tool that very much resembled the pestle and mortar - very essential parts that probably evolved into the trip hammer (mentioned in the history of waterwheel in Song Dynasty). Although the mention of such devices is merely mythological, it is inappropriate to disregard the possibility that such tools actually existed in ancient China.

According to Xin Lun, Du Shi, the engineer and Prefect of Nanyang, in 31 AD, used waterwheel to develop a machine that powers an automated furnace to create cast iron. Joseph Needham"s supports this by saying,

Chinese not only invented technological waterwheels but also developed waterwheels for agriculture. The Dragon-bone wheel, Chinese traditional irrigational waterwheel, was invented during Han Dynasty

As shown in the above examples, the extraordinary usages of ancient Chinese waterwheel stretched into various fields including science, metallurgy, and agriculture.

During Tang Dynasty, the water-mill spread to other countries under Chinese influence, including Korea, Japan and Tibet (7). But it seems like only the agriculture function of the waterwheel got transferred to these regions, for none of the records from these regions during that time period mentions any manfacuring function of the waterwheels.

However, they were adept at using water as their energy source. The photo above is an automated bellow powered by a horizontal waterwheel. While the conventional bellow required a person pumping air with his own hands and feet, this type did not need any human labor. Not only it helped reduce the burden of Chinese workers, it also made it possible for Chinese to deal with more sophisticated metallurgy, for the repeated influx of air into the bellow raised up the temperature inside higher than ever before. One noticeable structure in this bellow is the linear structure that transforms the rotational motion of the waterwheel rotating along with the river located below. The fact that the ancient Chinese already had almost identical device is something to be noted.

More remarkably, there is additional evidence which indicates that the Song could manufacture metal. The below is a trip hammer connected to a long shaft rotating with a waterwheel.

The waterwheel could produce 400kg of force per single rotation. So these could not only crush grain, but also pound metal. This technology is also a revival of ancient Chinese thought as mentioned in the previous chapter. While the ancient people did not provide pictorial models for such devices, later Chinese scholars were generous enough to provide such explanation for their inventions. These mega waterwheels still remain in some regions in China. Chinese during the Song Dynasty could both melt and pound metals in industrial scale - a crucial prerequisite of industrial revolution.

"Particularly remarkable was the use, at least as early as +1313, of water-power for textile machinery. The Nung Shu illustrates a spinning-mill in which we see a vertical undershot waterwheel and a large driving wheel with a belt-drive on the same shaft working a multiple-bobbin spinning-machine for hemp and ramie, perhaps also for cotton�� This should be enough to give pause to any economic historian, especially as Wang Chen clearly says that such installations were common in his time." (11) The textile machinery is shown on the figure above.

Gearing technology is another key to industrial revolution, for it allows intricate operation of metal machines. Also, gears play a crucial role in handling the magnitude of power applied to certain machines. They also help machines to operate in larger scales. It is surprising that the Chinese applied such technologies to their waterwheels. Although the gearing technology had been existing since ancient times, nobody was faster than the Chinese in combining waterwheel and gears (Europeans began to attach gears to waterwheels in 13th century, a century after Song Dynasty). Nine Millstones are attached to the waterwheel below, rotating simultaneously to pound grains. In other words, The Chinese knew how to create maximum efficiency with limited power supply.

The mechanical clockworks for Su Song"s astronomical tower featured a great driving-wheel that was 11 feet in diameter, carrying 36 scoops on its circumference, into each of which water would pour at uniform rate from the "constant-level tank. The main driving shaft of iron, with its cylindrical necks supported on iron crescent-shaped bearings, ended in a pinion which engages with a gear-wheel at the lower end of the main vertical transmission-shaft��

(Su Song"s) clockwork, driven by a water-wheel, and fully enclosed within the tower, rotated an observational armillary sphere on the top platform and a celestial globe in the upper story. Its time-announcing function was further fulfilled visually and audibly by the performances of numerous jacks mounted on the eight superimposed wheels of a time-keeping shaft and appearing at windows in the pagoda-like structure at the front of the tower. Within the building, some 40 ft. high, the driving-wheel was provided with a special form of escapement, and the water was pumped back into the tanks periodically by manual means. The time-annunciator must have included conversion gearing, since it gave "unequal" as well as equal time signals, and the sphere probably had this. Su Sung"s treatise on the clock, the Hsin I Hsiang Fa Yao, constitutes a classic of horological engineering (13)

As shown in the above enumeration of technologies, Song Dynasty had almost everything ready for industrial revolution. They had all the materialistic prerequisites: oil drilling technology, metal manufacturing, and gearing. As mentioned in the later section "Brief History of waterwheel in Europe", what they had is very similar to the technologies found in Europe just before it reached industrial revolution. Some of the inventions, such as the gearing technology and the Su Sung water clock, were perhaps more advanced than the contemporary European technologies. Then what caused such huge big difference? The answer will be addressed in section V : Comparative Analysis.

By the Yuan (1271-1368) and Ming (1368-1644) dynasties, the waterwheel technology had further improved. Nonetheless, there was no more distinct development of Chinese waterwheels after the Yuan and Ming dynasties. What is observed is a shift in the usage of waterwheels from the verge of industrial revolution to merely agricultural state. Although some records of technological waterwheels remain from Qing Dynasty, most of them are simply about the agriculture waterwheels that had been used since ancient times.

After 16th century, Chinese began to adopt the European style irrigational waterwheel named "diancha" for irrigating water. This is a re-adoption of a technology that was long forgotten by the Chinese. They already had a very similar style waterwheel called the "dragon-bone wheel" in Han Dynasty and Song Dynasty. Unfortunately, the reason why such technologies had to be readopted is not clearly answered. The frequent changes of ruling authority and the foreign invasions might serve as a reason that caused the regression of waterwheel technology in China.

In Korean history, the word "waterwheel" first appears in a book from Goryeo Dynasty. According to Goryeosa (the history of Goryeo) (17), in 1362, one liege named Baek Mun Bo of king Gongmin suggested that the adoption of waterwheel technology from the Jiangnan province of China would be helpful for the farmers who often struggle with irrigation during drought periods. He explains to the king that the advantage of Chinese farmers over drought. He said, "the farmers in Jiangnan are not afraid of droughts because they have the waterwheel. Our farmers struggle during droughts because they don"t know how to irrigate water from the river just a meter below the farmland. It would be a great help for the farmers if we would adopt the waterwheel from Jiangnan and enlighten our farmers with it so that they can fight the droughts more easily" (18) . The waterwheel which Baek Mun Bo observed should have been the chain-wheel type, called dragon-bone wheel, for these type of waterwheels is still used in modern day Jiangnan. Although it would have been reasonable for the king to take some action upon such request, not much is known about how the king reacted to this proposal afterward. No documents of Goryeo after 1362 show any trace of waterwheel.

About a century earlier than 1362, there is a record of the King and Queen sightseeing a waterwheel in 1276, but this records lacks any detailed support. (19)

There is a so

8613371530291

8613371530291