what is overshot weaving manufacturer

After returning from a fabulous time at the New England Weavers Seminar in July, I found myself rewriting the beginning of this article. I was so lucky to spend two days in a round-robin style class taught by Marjie Thompson entitled 18th & 19th Century High Fashion for the Middle Class. To say that Marjie knows an extraordinary amount about historic textiles seems to be an understatement. Oh, to have an hour swimming about in her brain!

There were ten of us in the class, and we rotated, weaving a new sample at each loom. Marjie shared her knowledge of the patterns we sampled, and I came away with an even greater interest in this subject in addition to a binder filled with samples. There really is no greater way to learn than a hands-on workshop. I am already preparing to wind a warp for a dimity project. I’ll keep you posted on my progress.

One interesting piece of information I learned is that overshot is a fairly modern term. Originally this type of weaving would have been referred to as floats or floatwork. It seems that many people are returning to this original terminology, though the weaving world has thus far shown little interest in making the change back. Personally, I like it. Floatwork sounds a bit less frenetic than overshot – as though I’m peacefully hitting my mark rather than missing it in a wild fashion.

Until recently, my floatwork experience was limited to one project. This was created using Cascade 220 back in April 2008. The pattern is Leaves on p. 118 of The Handweaver’s Pattern Directory by Anne Dixon. I was criticized for having floats that were too long and would easily snag, but I loved my fabric. I turned it into a little tote that fit perfectly into my bike basket and never experienced a snag. Thankfully I took a photo back then, as the bag is currently in storage and missing the bike paths of Boulder.

When I first considered writing this article, I wasn’t confident enough with my weaving vocabulary to write something that a true beginner might actually understand. The information out there assumed, and still assumes, a certain level of weaving knowledge. I learn best by seeing something demonstrated, not by trying to translate written instructions. So how does one write an article for people like me? Let’s start with some basic terminology.

Floatwork, formerly known as overshot which was originally known as floatwork, is a block design traditionally woven on four shafts where a heavier pattern yarn floats above a plain weave ground cloth and creates a raised pattern. Your plain weave background cloth is woven using a finer yarn in your warp and in every other weft pick (these weft picks being the ‘use tabby’ part of your pattern.)

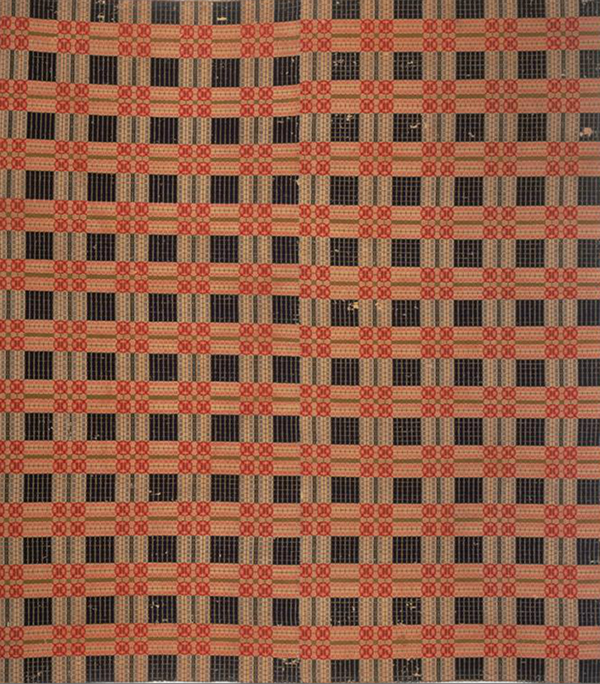

This finer yarn is hidden in places by the thicker yarn floats, blended in places with the thicker yarn (as plain weave) creating areas that are shaded (referred to as halftone), and woven across itself to create delicate areas of plain weave. Most of us think of antique coverlets when we hear ‘overshot.’

For some reason the term tabby has always annoyed me. It made me think of cats (I’ve got two – one of whom decided to take my seat when I got up to get a quick snack – and I love them both dearly) not weaving until I looked up the origin of the word on etymonline.com.

Back to business. Tabby is a plain weave pick that anchors your pattern pick in place. When weaving floatwork, every other weft pick is tabby. Your pattern pick needs the tabby pick to stabilize the cloth and keep the pattern picks from becoming distorted. This also means that you are working with two shuttles, one holding your tabby yarn and one holding your pattern yarn. This two-shuttle thing can be a bit awward at first, but you’ll get the hang of it with a little practice.

Initially, the concept of a block was the toughest one for me to grasp because I was looking at the pattern as a complete unit rather than a combination of units. The block is simply a unit or part of a particular pattern in the shape of a rectangle or a square. There are usually at least four threads in a block, two pattern and two tabby. So you treadle the same pattern pick two or more times in sequence (alternating with your anchoring tabby picks) to create a solid shape in your pattern. Think about coloring in graph paper. If you color in four squares in a row, it just looks like a thick line, right?

But if you color in four squares in a row directly on top of the first four squares to create an eight square rectangle, suddenly you have something that stands out on the page. This is your block, and of course it can be some number of threads wider and longer to create various shapes. Keep in mind how you plan to use your fabric and plan your blocks accordingly. In other words, manage your float length.

Here is the thing about floatwork that really helped it to make sense for me. It is basically a twill weave. As Mary Black puts it, “An examination of an overshot draft shows it to be made up of a repetitive sequence of the 1 and 2, 2 and 3, 3 and 4, and 4 and 1 twill blocks”.

Let’s look at the pattern picks only. When weaving, your pattern blocks should overlap by one thread. This creates a pattern that flows from unit to unit instead of making a sharp step. It also means that the last thread of a given block is the first thread of the next block, and as you are initially threading your loom, your threads will move from odd shaft to even shaft.

Choosing yarns to weave floatwork can be challenging. Generally speaking you want your pattern yarn to be about twice the diameter, or grist, of your tabby/warp yarn. Your tabby yarn and your warp yarn are generally the same yarn. I say generally because I can see so many non-traditional ways to weave floatwork that involve breaking the rules. Imagine, for example, taking a small part of a given pattern and blowing it up to a massive scale to do a wall hanging or using three different yarns to create a completely different visual experience!

When choosing your yarns, you can always search online to see what other folks have used successfully. Ravelry.com, Weavolution.com and Weavezine.com are all good places to start. You could also double your tabby yarn to create a pattern yarn. I did this with my bike basket, using a different colorway to create the contrast. And of course there is our friend the sample. Pick a warp and experiment with your weft.

When treadling a block pattern with tabby picks, I find it helpful to tie my tabby treadles on one side and my pattern treadles on the other. This way you can dance back and forth from left to right as the treadling sequence is always going to be pattern-tabby-pattern-tabby. It feels more like walking or pedaling a bicycle to alternate in this manner.

Probably the trickier part of treadling is keeping track of where you are in the sequence. Like many traditional floatwork patterns, the pattern I used is meant to be woven tromp as writ or as drawn in. This means that your treadling is the same as your threading. So if your threading is 1-2-1-2-3-2-3-4, then your pattern picks are treadled 1-2-1-2-3-2-3-4. You will be throwing tabby picks after each pattern pick, so your actual treadling looks like (inthis example let’s consider your tabby picks to be ‘a’ and ‘b’) 1-a-2-b-1-a-2-b-3-a-2-b-3-a-4-b. If this looks a bit intimidating, don’t fret. At first it might feel that way, but the pattern really does start to make sense after you get going.

In the case of my draft, the threading sequence is 134 threads long. This is a lot to remember, but I used an index card to write out the sequence. I marked my place by sliding a second card down the pattern as I progressed, keeping it in place with a paperclip.

It is most helpful not to wind too much of your cloth onto the cloth beam when advancing your warp so that you have a little shelf to hold the shuttle not in use.

I used a pattern from Mary Meigs Atwater’s Shuttle-Craft book listed in the Resources section. The draft is No. 18 Name Unknown and is on various pages depending on which printing of the book you have. (See the Resources section on the next page for an image of the draft.)

You can find it listed in the chapter or sub-chapter entitled ‘Notes on the Overshot Drafts.’ As someone who generally cheers on the underdog, I was drawn to this pattern without a name.

Atwater’s patterns are written for a sinking shed loom. For a rising shed loom, like the Baby Wolf I used, simply tie up the shafts left blank in the draft instead of the shafts she tells you to tie up. For all of her traditional floatwork patterns, including the pattern I used, this tie-up would be 3-4, 1-4, 1-2, 2-3. Your tabby tie up should be 1-3 and 2-4.

No. 18 Name Unknown is woven tromp as writ, as I mentioned earlier. Weave it in the order it’s threaded, alternating each pattern pick with a tabby pick. Your pattern shuttle will hold the thicker yarn and your tabby shuttle will hold the finer yarn that was also used in your warp.

I washed this in my front-loading washing machine on the wool setting and air-dried it on the clothesline. There was a note in the book that No. 18 Name Unknown, and its friend No. 17, are “plain patterns and suitable for couch covers or the coverlet for a man’s room, rather than for more frivolous purposes”. Perfect. I’m not much for frivolous, and I had been looking for the perfect fabric to re-cover an old chair.

Here is a list of books and magazines that might be of interest if you’d like to learn more about floatwork/overshot. Many of these references include patterns in addition to thorough instructions.

Atwater, Mary Meigs. The Shuttle-Craft Book of American Handweaving. New York: The Macmillan Company, 1928. Just scored a first edition on ebay for $9! I now have three copies and am seriously in love with this book (taken with a grain of salt as she is rather traditional.)

If you can find this issue anywhere, I’d recommend picking it up. It’s full of great information on historic weaving, but also has a super article on understanding and writing drafts by Debbie Redding (aka Deborah Chandler).

If you have a particular interest in old coverlets, Eliza Calvert Hall’s A Book of Hand-Woven Coverlets and The Coverlet Book by Helene Bress are both interesting resources, the later being particularly thorough. I can only imagine the time and research that went into this pair of tomes. And if you are simply looking for patterns, The Handweaver’s Pattern Book by Marguerite Porter Davison and The Handweaver’s Pattern Directory by Anne Dixon are just for you.

Overshot: The earliest coverlets were woven using an overshot weave. There is a ground cloth of plain weave linen or cotton with a supplementary pattern weft, usually of dyed wool, added to create a geometric pattern based on simple combinations of blocks. The weaver creates the pattern by raising and lowering the pattern weft with treadles to create vibrant, reversible geometric patterns. Overshot coverlets could be woven domestically by men or women on simple four-shaft looms, and the craft persists to this day.

Summer-and-Winter: This structure is a type of overshot with strict rules about supplementary pattern weft float distances. The weft yarns float over no more than two warp yarns. This creates a denser fabric with a tighter weave. Summer-and-Winter is so named because one side of the coverlet features more wool than the other, thus giving the coverlet a summer side and a winter side. This structure may be an American invention. Its origins are somewhat mysterious, but it seems to have evolved out of a British weaving tradition.

Twill:Twill along with plain and satin weave is one of the three simple weave structures. Twill is created by repetition of a regular ratio of warp and weft floats, usually 1:2, 1:3, or 2:4. Twill weave is identifiable by the diagonal orientation of the weave structure. This diagonal can be reversed and combined to create herringbone and diamond effects in the weave.

Double Cloth: Usually associated with professional weavers, double cloth is formed from two plain weave fabrics that swap places with one another, interlocking the textile and creating the pattern. Coverlet weavers initially used German, geometric, block-weaving patterns to create decorative coverlets and ingrain carpeting. These coverlets contain twice the yarn and are twice as heavy as other coverlets.

Beiderwand: Weavers in Northern Germany and Southern Denmark first used this structure in the seventeenth century to weave bed curtains and textiles for clothing. Beiderwand is an integrated structure, and the design alternates sections of warp-faced and weft-faced plain weave. Beiderwand coverlets can be either true Beiderwand or the more common tied-Beiderwand. This structure is identifiable by the ribbed appearance of the textile created by the addition of a supplementary binding warp.

Figured and Fancy: Although not a structure in its own right, Figured and Fancy coverlets can be identified by the appearance of curvilinear designs and woven inscriptions. Weavers could use a variety of technologies and structures to create them including, the cylinder loom, Jacquard mechanism, or weft-loop patterning. Figured and Fancy coverlets were the preferred style throughout much of the nineteenth century. Their manufacture was an important economic and industrial engine in rural America.

Multi-harness/Star and Diamond: This group of coverlets is characterized not by the structure but by the intricacy of patterning. Usually executed in overshot, Beiderwand, or geometric double cloth, these coverlets were made almost all made in Eastern Pennsylvania by professional weavers on looms with between twelve and twenty-six shafts.

America’s earliest coverlets were woven in New England, usually in overshot patterns and by women working collectively to produce textiles for their own homes and for sale locally. Laurel Thatcher Ulrich’s book, Age of Homespun examines this pre-Revolutionary economy in which women shared labor, raw materials, and textile equipment to supplement family incomes. As the nineteenth century approached and textile mills emerged first in New England, new groups of European immigrant weavers would arrive in New England before moving westward to cheaper available land and spread industrialization to America’s rural interior.

The coverlets from New York and New Jersey are among the earliest Figured and Fancy coverlets. NMAH possesses the earliest Figured and Fancy coverlet (dated 1817), made on Long Island by an unknown weaver. These coverlets are associated primarily with Scottish and Scots-Irish immigrant weavers who were recruited from Britain to provide a skilled workforce for America’s earliest woolen textile mills, and then established their own businesses. New York and New Jersey coverlets are primarily blue and white, double cloth and feature refined Neoclassical and Victorian motifs. Long Island and the Finger Lakes region of New York as well as Bergen County, New Jersey were major centers of coverlet production.

German immigrant weavers influenced the coverlets of Pennsylvania, Virginia (including West Virginia) and Maryland. Tied-Beiderwand was the structure preferred by most weavers. Horizontal color-banding, German folk motifs like the Distelfinken (thistle finch), and eight-point star and sunbursts are common. Pennsylvania and Mid-Atlantic coverlets tend to favor the inscribed cornerblock complete with weaver’s name, location, date, and customer. There were many regionalized woolen mills and factories throughout Pennsylvania. Most successful of these were Philip Schum and Sons in Lancaster, Pennsylvania, and Chatham’s Run Factory, owned by John Rich and better known today as Woolrich Woolen Mills.

Coverlet weavers were among some of the earliest European settler in the Northwest Territories. After helping to clear the land and establish agriculture, these weavers focused their attentions on establishing mills and weaving operations with local supplies, for local markets. This economic pattern helped introduce the American interior to an industrial economy. It also allowed the weaver to free himself and his family from traditional, less-favorable urban factory life. New land in Ohio and Indiana enticed weavers from the New York and Mid-Atlantic traditions to settle in the Northwest Territories. As a result, coverlets from this region hybridized, blending the fondness for color found in Pennsylvania coverlets with the refinement of design and Scottish influence of the New York coverlets.

Southern coverlets almost always tended to be woven in overshot patterns. Traditional hand-weaving also survived longest in the South. Southern Appalachian women were still weaving overshot coverlets at the turn of the twentieth century. These women and their coverlets helped in inspire a wave of Settlement Schools and mail-order cottage industries throughout the Southern Appalachian region, inspiring and contributing to Colonial Revival design and the Handicraft Revival. Before the Civil War, enslaved labor was often used in the production of Southern coverlets, both to grow and process the raw materials, and to transform those materials into a finished product.

Because so many coverlets have been passed down as family heirlooms, retaining documentation on their maker or users, they provide a visual catalog of America’s path toward and response to industrialization. Coverlet weavers have sometimes been categorized as artisan weavers fighting to keep a traditional craft alive. New research, however, is showing that many of these weavers were on the forefront of industry in rural America. Many coverlet weavers began their American odyssey as immigrants, recruited from European textile factories—along with their families—to help establish industrial mills in America. Families saved their money, bought cheaper land in America’s rural interior and took their mechanical skills and ideas about industrial organization into the American heartland. Once there, these weavers found options. They could operate as weaver-farmers, own a small workshop, partner with a local carding mill, or open their own small, regional factories. They were quick to embrace new weaving technologies, including power looms, and frequently advertised in local newspapers. Coverlet weavers created small pockets of residentiary industry that relied on a steady flow of European-trained immigrants. These small factories remained successful until after the Civil War when the railroads made mass-produced, industrial goods more readily available nationwide.

This project was really popular when I posted it on Instagram, so I thought I would share it here also. It is a simple overshot pattern - with a twist. Also a great way to show off some special yarn. The yarn I used for my pattern was a skein of hand spun camel/silk blend. I wove the fabric on my Jack loom but you could also use your four or eight shaft loom.

Overshot is a weave structure where the weft threads jump over several warp threads at once, a supplementary weft creating patterns over a plain weave base. Overshot gained popularity in the turn of the 19th century (although its origins are a few hundred years earlier than that!). Coverlets (bed covers) were woven in Overshot with a cotton (or linen) plain weave base and a wool supplementary weft for the pattern. The plain weave base gave structure and durability and the woollen pattern thread gave warmth and colour/design. Designs were basic geometric designs that were handed down in families and as it was woven on a four shaft loom the Overshot patterns were accessible to many. In theory if you removed all the pattern threads form your Overshot you would have a structurally sound piece of plain weave fabric.

I was first drawn to Overshot many years ago when I saw what looked to me like "fragments" of Overshot in Sharon Aldermans "Mastering Weave Structures".

I have not included details of number of warp ends, sett and yarn requirements for my project - you can do your calculations based on the sett required for plain weave in the yarn you wish to use.

I wanted to use my handspun - but I only had a 100gms skein, I wanted to maximise the amount of fabric I could get using the 100gms. I thought about all the drafts I could use that would show off the weft and settled on overshot because this showcases the pattern yarn very nicely. I decided to weave it “fragmented” so I could make my handspun yarn go further. I chose a honeysuckle draft.

When doing the treadle tie-up I used 3 and 8 for my plain weave and started weaving from the left, treadle 3 - so you always know which treadle you are up to - shuttle on the left - treadle 3, shuttle on the right treadle 8. I then tied up the pattern on treadles 4,5,6 and 7. You can work in that order by repeating the sequence or you can mix it up and go from 4 to 7 and back to 4 again etc. You will easily see what the pattern is doing.

While it looks like it would be a very time-intensive and difficult technique to weave – it really isn’t! You just have to understand how and why it works the way it does. (We will get to that.)

This page may contain affiliate links. If you purchase something through these links then I will receive a small commission – at no extra cost to you! Please read our

In its simplest form – overshot is a weaving technique that utilizes at least 2 different types of weft yarns and floats to create a pattern. These patterns are often heavily geometric.

Ground weft– plain weave pattern that is used between each row of your overshot pattern. This plain weave gives the textile structure and allows for large areas of overshot to be woven without creating an overly sleazy fabric. Without the use of a ground weft on an overshot pattern, the weaving would not hold together because there would not be enough warp and weft intersections to create a solid weaving.

They were most popular though in southern Appalachia and continued to be so even after textile technologies advanced. When other parts of colonial America moved to jacquard weaving, the weavers of southern Appalachia continued to weave their overshot coverlets by hand.

Since the overshot coverlets were most often woven at home on smaller looms they usually had a seam down the middle where two woven panels were sewn together.

The thing about overshot is that no matter the application, it is pretty impressive. Perhaps that is just my opinion, but due to how complex it can look, I feel that it is pretty safe to say.

Just because it was originally used for coverlets, does not mean it can only be used for coverlets. Changing aspects of the pattern like the colors used, or the way you use your ground weft can drastically change the look and feel of your weaving.

In the image below you can see the ground weft is not the same color throughout. Instead, I wove the ground weft as discontinuous so that I could add extra pattern and design into the weavings. In this case, you may be wondering how to deal with your weft yarns when they are in the middle of the weaving and not at the selvage.

The discontinuous weft yarns will float onto the back of the weaving until you are ready for them in their next pick. This does make your overshot weaving one sided since it will have vertical floats on the back. Keep this in mind if you want to try this technique out.

Also seen in the image above, the overshot yarn that I used was not all one color! This is a really simple way to get extra dimension and interest in your overshot if that is something you are looking for.

This makes it simple to be able to only weave overshot in certain parts of your weaving. If you want to do this then you can continue to weave your plain weave across the entire width of your weaving, but only weave overshot in specific areas. This creates a overshot section that functions similar to inlay.

Since the overshot pattern is strongly influenced by the weft yarns that are used it is important to choose the right yarns. Your weaving will be set up to the specification needed for a balanced plain weave. Make sure you understand EPI in order to get the right warp sett for your overshot weaving.

The ground weft used is almost always the same yarn as your warp. This allows the overshot weft to really be able to shine without contrasting warp and weft plain weave yarns.

In order to get the full effect of the overshot, it must be thick enough that when you are weaving your pattern it covers up the ground weft between each pass. If it is not thick enough to do this, it will still be overshot, but the full effect will not be seen.

What this warp thread does is serve as an all-purpose selvedge that does not correspond with your pattern. Instead, you would make sure to go around this warp thread every time to make sure that you are able to weave fully to the selvedge. Without this, your overshot weft will float awkwardly on the back of your weaving whenever the pattern does not take it to the edge.

I have mentioned this book multiple times because it really is such a great resource for any weaver looking to weave patterns of all types. It contains 23 pages of different overshot patterns (among so many other patterns) that you can set up on your floor or table loom.

Like a lot of different types of weaving, it is possible to do it on almost any type of loom that you have. The difference being that it might take you a little bit longer or require a bit more effort than if you did it on a traditional floor loom.

Weaving overshot on a frame loom or rigid heddle loom will require the use of string heddles and pick-up sticks that you have to manually use to create a shed.

In the video, I mention learning how to weave Krokbragd. If you are interested in learning about this weaving technique, I encourage you to check out our course at the School of SweetGeorgia, Weaving Krokbragd, taught by Debby Greenlaw.

The overshot weaving project shown is woven on a 16″ Ashford Table Loom 8 shaft, The yarns used are Ashford 100% mercerised cotton in 10/2 and 5/2. (We don’t have this yarn currently listed on our site, but we’re able to order it in for you. Send us an email at: info@sweetgeorgiayarns.com!) The pattern is Overshot Sampler from the book Next Steps in Weaving by Pattie Graver

Congratulations to Katrina at Crafty Jaks as she just hit publish on the Crafty Jaks – The Inquisitive Crafter YouTube channel! If you love spinning, dyeing and wool, please go check it out and subscribe.

Many years ago, I finally got to try weaving. I took the Beginning to Weave workshop through the Ottawa guild. At that time, 1989, the OVWSG did not have a studio space to house what guild equipment we had acquired. (The Guild had an old second-hand 100 inch loom and 6 or 7 table looms. There may have been a floor loom too but I was distracted by the 100 inches of loom, so do not remember). All the looms lived in one of our guild members’ very big basements. On weekends, she either taught weaving workshops or hosted weavers working on the 100 inch loom. It sounded like a busy basement! I remember 4 weekends of driving to a little town just east of Ottawa. I took the table loom home each week to do homework. I still remember the sound of the mettle heddles rattling as I drove down the highway, back and forth to the classes. Then I think there were two more weekends of Intermediate weaving and Dona sent me off and I was weaving!

It all starts with yarn, wind it carefully, attach it to the back beam, wind on, thread the heddles, slay the reed, tie on to the front beam, check the tension and then start to weave. It sounds like a lot of work but it is all worth it as you start to pass the shuttle through the shed and the cloth begins to appear. Weaving was like Magic! From a pile of string to POOF, actual cloth!!!

During the workshop, I found pickup seemed strangely familiar as my brain watched my fingers happily lifting and twisting threads for the various lace and decorative weave patterns. The other thing that my brain went “ooh this is cool!” was Overshot. It is a weave structure that requires a ground and a pattern thread, (two shuttles). One is fine like the warp and the pattern thread is thicker and usually wool. I was still reacting to wool so I used cotton for both. My original goal was to draft and weave a Viking textile for myself but I put that aside for a moment, I will get back to that later.

The first thing I wove after my instruction was a present for my Mom. she had requested fabric to make a vest. I looked through A Handweaver’s Pattern Bookby Marguerite Porter Davison and found an overshot pattern that I thought we both would like. I wove it in two shades of blue (Mom’s favourite colour), at a looser thread count than usual. (Originally the overshot weave structure was used to make coverlets, so were tightly woven and a bit stiff, while I liked the pattern I wanted the fabric to be much more drapey.) Even worse, I did not want it to be as hard-edged in the pattern as it was originally intended so I tried a slub cotton as a test and loved it.

So, for any sane weaver, it was all wrong! Wrong set, wrong fibre, wrong colour choices! It was fabulous and perfect. I kept the sample as a basket cover and at either the end of 1989 or the beginning of 1990, I gave Mom the yardage for her vest. “Oh this is too nice to cut” Mom Said, so it lived on the back of her favourite reading chair as a headrest until her most recent move (2015?) it never did get to be a vest but it has been well enjoyed.

My sample piece, which became my main demo basket cover, has been in the background of many demo photos. This year it was used as an Old example in part of the guild Exhibition. You can see the subtle distortion of the pattern when a slub yarn is used.

In the Exhibition The Inkle band, hanging beside the overshot, I wove much more recently. I used an Inkle loom and a supplemental warp thread. This means weaving with an extra separate thread that was not part of the main warp on the loom. I used a yarn with a fuzzy caterpillar-like slub.

You may be able to see how I wove the weird slubby supplemental warp. The yarn is weighted and left hanging over the back peg of the Inkle loom. It comes over the top peg (usually labelled B in diagrams) and floats above the weaving. In the areas where the Caterpillar (Slub) is not present I catch the yarn with the shuttle and weave it into the band. In the area the caterpillar appears I would leave the yarn above the warp and then start weaving it in again as I reached the end of the caterpillar. I hope that explanation doesn’t sound like mud and makes a bit of sense. Using a supplemental warp on an Inkle loom is not quite normal but it is a lot of fun.

I was going to tell you about my original goal in learning to weave, the mysterious Fragment #10 from a Viking excavation from around the year 1000, but I have likely confused you with weaving enough for one day. So I will save that for another chat. (don’t forget the Inkle loom I would like to tell you a bit more about that in another post too. I promise I will get back to felting in the not-too-distant future)

I had the privilege of teaching in Washington state for 8 days in March this year. I found out how to pronounce names like Skagitt and Whatcom. I enjoyed meeting some fascinating weavers. I also experienced the wonderful community of weavers in the Puget Sound area, and of course I saw some lovely scenery.

I didn’t know that the Skagit Valley is one of the top producers of flower bulbs in the world. The bulbs I order from Holland often originate in the Skagit Valley. While I was there the daffodils were in bloom.

My first teaching assignment was a lecture to the Whidbey Weavers Guild. During this time of emerging corona virus activity, the guild was well attended. My lecture on Overshot: Past and Present was a warm-up for the three-day workshop I would begin the following day.

We had an eager 15 attendees in the overshot workshop. The work was very creative. I send out instructions for preparing the looms ahead of time. In the workshop, everyone follows the same treadling order, but each weaver chooses their own colors to bring. Sometimes the thickness varies from one weaver to the next, also. The result is that everyone’s artistic decisions and sense of design are apparent. No two set of samples are identical. The students work through a certain set of treadling patterns and go home with a variety of samples. Some of their work is pictured below.

It was fun getting to know this weaving group. They are so supportive of each other and encouraging. I have never taught in an area where I needed to plan my presentation around the ferry schedule so that was a new experience. I said my good-byes at the end of the weekend class, knowing that I’d see some of them the next day.

The day after my overshot workshop, two wonderful ladies took me up to my next assignment: a lecture on Summer and Winter to the Skagit Valley Weavers Guild. Many of the guild members were also members of Whidbey Weavers Guild and of the Whatcom Weavers Guild, who would host me for my next workshop. A couple of my overshot workshop students brought in their samples. They had cut them from the loom and washed them the day before, after the overshot workshop was finished. It was fun to see their completed work and talk about what their next steps would be.

The three-day Early American Textiles workshop was presented at the Jansen Art Center and hosted by the Whatcom Weavers Guild. Nine students wove round robin style on ten different looms. Each loom had been warped by one of the students in a traditional weaving pattern using thread similar to what early American weavers would have used. Throughout the workshop we stopped to talk about production practices within the US and Europe during the 17th, 18th and 19th centuries. One of the students brought in a lovely coverlet she had found in a thrift store. Another shared stories of her aunt and uncle who were weavers. My students were very knowledgeable and, as usual, I learned as much from them as they did from me.

The Whatcom group was a tight-knit community of weavers, too. Many have known each other for years and they constantly share ideas and encouragement. The Jansen Art Center provides studio space for their collection of looms as well as library and meeting space. The staff at the Jansen Center was very welcoming and the cafe served some dynamite lunches–plus afternoon lattes to keep us all going.

I hope I get a chance to visit the area again. I wish everyone had such a nurturing weaving community. We all need connections and we benefit from seeing each others work. I’ll leave with a couple of photos from the ferry to Whidbey Island from Mukilteo.

I had the privilege of teaching in Washington state for 8 days in March this year. I found out how to pronounce names like Skagitt and Whatcom. I enjoyed meeting some fascinating weavers. I also experienced the wonderful community of weavers in the Puget Sound area, and of course I saw some lovely scenery.

I didn’t know that the Skagit Valley is one of the top producers of flower bulbs in the world. The bulbs I order from Holland often originate in the Skagit Valley. While I was there the daffodils were in bloom.

My first teaching assignment was a lecture to the Whidbey Weavers Guild. During this time of emerging corona virus activity, the guild was well attended. My lecture on Overshot: Past and Present was a warm-up for the three-day workshop I would begin the following day.

We had an eager 15 attendees in the overshot workshop. The work was very creative. I send out instructions for preparing the looms ahead of time. In the workshop, everyone follows the same treadling order, but each weaver chooses their own colors to bring. Sometimes the thickness varies from one weaver to the next, also. The result is that everyone’s artistic decisions and sense of design are apparent. No two set of samples are identical. The students work through a certain set of treadling patterns and go home with a variety of samples. Some of their work is pictured below.

It was fun getting to know this weaving group. They are so supportive of each other and encouraging. I have never taught in an area where I needed to plan my presentation around the ferry schedule so that was a new experience. I said my good-byes at the end of the weekend class, knowing that I’d see some of them the next day.

The day after my overshot workshop, two wonderful ladies took me up to my next assignment: a lecture on Summer and Winter to the Skagit Valley Weavers Guild. Many of the guild members were also members of Whidbey Weavers Guild and of the Whatcom Weavers Guild, who would host me for my next workshop. A couple of my overshot workshop students brought in their samples. They had cut them from the loom and washed them the day before, after the overshot workshop was finished. It was fun to see their completed work and talk about what their next steps would be.

The three-day Early American Textiles workshop was presented at the Jansen Art Center and hosted by the Whatcom Weavers Guild. Nine students wove round robin style on ten different looms. Each loom had been warped by one of the students in a traditional weaving pattern using thread similar to what early American weavers would have used. Throughout the workshop we stopped to talk about production practices within the US and Europe during the 17th, 18th and 19th centuries. One of the students brought in a lovely coverlet she had found in a thrift store. Another shared stories of her aunt and uncle who were weavers. My students were very knowledgeable and, as usual, I learned as much from them as they did from me.

The Whatcom group was a tight-knit community of weavers, too. Many have known each other for years and they constantly share ideas and encouragement. The Jansen Art Center provides studio space for their collection of looms as well as library and meeting space. The staff at the Jansen Center was very welcoming and the cafe served some dynamite lunches–plus afternoon lattes to keep us all going.

I hope I get a chance to visit the area again. I wish everyone had such a nurturing weaving community. We all need connections and we benefit from seeing each others work. I’ll leave with a couple of photos from the ferry to Whidbey Island from Mukilteo.

Over 50 instructional videos that guide you through making a warp, dressing your loom, weaving, finishing your cloth, and troubleshooting. View product images for course outline.

The course is built so you can watch from beginning to end, or jump around to the lessons you need. Video learning is supported by downloadable handouts and quality illustrations.

Amanda has been creating with fiber for almost twenty years. After taking numerous art classes in college including ceramics, intaglio printing, and wood carving, Amanda became a self-taught crocheter in 2003. She picked up the love of weaving and knitting over the last several years through classes at Alamitos Bay Yarn Company. Amanda has taught rigid heddle weaving with Carla since 2019.

This post is the third in a series introducing common weaving structures. We’ve already looked at plain weave and twill, and this time we’re going to dive into the magic of overshot weaves—a structure that’s very fun to make and creates exciting graphic patterns.

Pattern is designed to use our Organic cottolin (Cotolin) to weave 4 placemats- finished size 14"X20", 4 napkins 14"X14" and a runner with a finished size 14"X38". Requires an 8 shaft loom, 24 epi, 15" wide. 1 tube each of our 4 Ruby Anniversary colors Vendor item: HYPattern

8613371530291

8613371530291