power tong factory

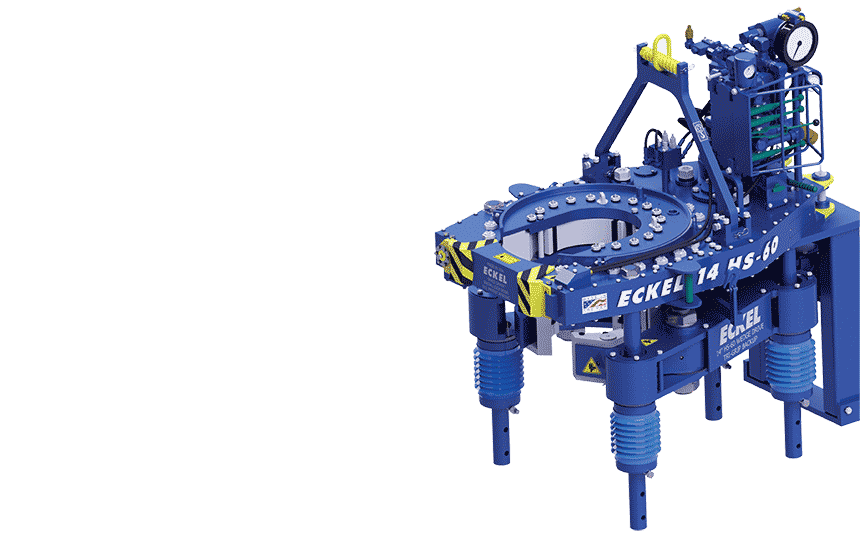

A two-speed Hydra-Shift® motor coupled with a two-speed gear train provides (4) torque levels and (4) RPM speeds. Easily shift the hydraulic motor in low speed to high speed without stopping the tong or tublar rotation, saving rig time.

A patented door locking system (US Patent 6,279,426) for Eckel tongs that allows for latchless locking of the tong door. The tong door swings easily open and closed and locks when torque

is applied to the tong. When safety is important this locking mechanism combined with our safety door interlock provides unparalleled safety while speeding up the turn around time between connections. The Radial Door Lock is patented protected in the following countries: Canada, Germany, Norway, United Kingdom, and the United States.

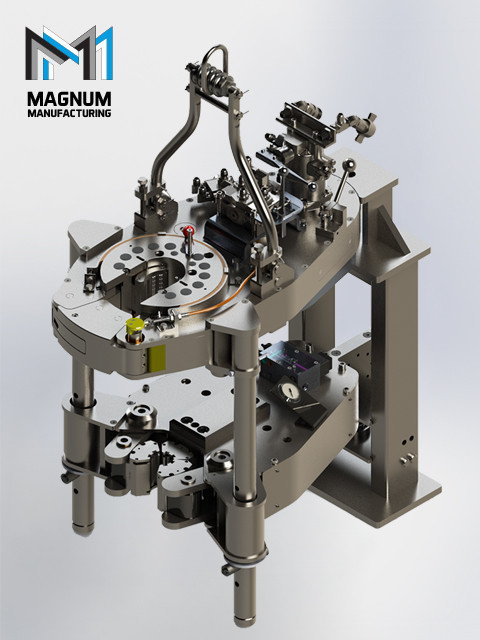

The field proven Tri-Grip® Backup features a three head design that encompasses the tubular that applies an evenly distributed gripping force. The Tri-Grip®Backup provides exceptional gripping capabilities with either Eckel True Grit® dies or Pyramid Fine Tooth dies. The hydraulic backup is suspended at an adjustable level below the power tong by means of three hanger legs and allowing the backup to remain stationary while the power tong moves vertically to compensate for thread travel of the connection.

2018 marks the 60th anniversary for Eckel. We are the oldest continuous leading manufacturer of world-class hydraulic power tongs and trusted for reliability, safety and high performance.

The Eckel Model 25 Hydra-Shift® HS-85 features a two-speed motor with two-speed gear train, producing 60,000, 80,000 and 125,000 ft-lb of torque respectively in low-low, at 2,500 psi. This tong easily handles ultra-heavy casing strings from 9 5/8 inches to 25 inches.

The Eckel Model 25 Hydra-Shift® HT-200 Tri-Grip®introduced features a two-speed motor with two-speed gear train, producing 200,000 ft-lb of torque respectively in low-low, at 2,500 psi. This tong easily handles ultra-heavy casing strings from 9 5/8 inches to 25 inches - featuring a three head Tri-Grip®biting system design which like the Tri-Grip®New Revised Version Backup encompasses the tubular to apply an evenly distributed gripping force. The additional head in the tong reduces the risk of radial deformation, die penetration, marking, and wear of the tubular by 1/3 at extreme torques...

The new 7.25 HS HT-80 for Drill Pipe and High Torque Casing Tong takes on the toughest job with make-up and break-out of drill pipe, drill collars and high torque casing with a maximum torque of 80,000 ft-lbs. The 7.25 HS HT-80 is available with a two-speed Hydra-Shift® motor coupled with a two-speed gear train providing (4) torque levels and (4) RPM speeds. The variable speeds can slowly or quickly spin tubulars 2-3/8 through 7 1/4 inch as necessary. Having exceptional gripping capabilities with rig dies for drill pipe or wrap-around dies that securely encompass the tubular limit potential for damage. The 7.25 HS HT-80 is also available with either Eckel Pyramid Fine Tooth dies or True-Grit dies. The 7.25 HS HT-80 is another of our tongs models that exceeds the competition in its class.

The Eckel Model 30 Hydra-Shift® features a two-speed motor with a two-speed gear train, producing 130,000 ft-lb of torque in low-low at 2,500 psi. Weight 9,000 pounds, this tong easily handles ultra heavy casing strings from 14 inches to 30 inches.

Except for added torque (up to 24,000 ft-lb) and expanded pipe capacity (from 4 to 13 3/8 inches), the 13 3/8 Standard tong offers the same basic engineering and design as the smaller, lighter Model 10 3/4. Highly recommended where applications demand the ultimate in size range and torque output.

For casing up to 22 inches, here"s a tong that has strong torqueing ability and will handle pipe sizes down to 7 inch. The tong utilizes a two-speed motor and a two-speed gear train, allowing the operator to correctly adjust the tong for the optimum torque and RPM needed for the current application. Maximum torque for the 22 Hydra-Shift® is 80,000 ft-lb.

For casing up to 20 inches, here"s a tong that combines surprising speed with an ability to handle smaller sizes economically (as small as 7 inches). The 20 Standard reaches peak efficiency at just 38 horse power input, thus requiring no "souped-up" power unit. Available torque: 42,000 ft-lb.

An excellent choice where applications demand the combination of size range and high torque output, the Eckel Model 14 UHT handles pipe from 4 inches to 14 inches. Upgraded in design and performance over the Model 14 HS, this tong is capable of delivering 65,000 ft-lb of torque. Also, available with Wedge Drive Tri-Grip®backup which handles pipe from 4 inches to 15.5 inches.

When application demand a wide range of sizes, this tong handles pipe sizes 2 3/8 inches all the way to 7 5/8. Built around the 7 5/8 Standard, the 7 5/8 HS HD provides a thicker rotary gear for more added strength, an additional idler gear, a larger pinion gear, and stronger bearings for load bearing capacity and durability.

When application demand a wide range of sizes, this tong handles pipe sizes 2 3/8 inches all the way to 7 5/8. Built around the 7 5/8 Standard, the 7 5/8 Heavy Duty provides a thicker rotary gear for more added strength, an additional idler gear, a larger pinion gear, and stronger bearings for load bearing capacity and durability.

The Eckel Model 25 Hydra-Shift® features a two-speed motor with two-speed gear train, producing 60,000 ft-lb of torque in low-low, at 2,500 psi. Weighing 6,290 pounds, this tong easily handles ultra-heavy casing strings from 9 5/8 inches to 25 inches.

A maximum torque up to 25,000 ft-lb and a small foot print design this tong meets your application requirements. A two speed mechanical shift transmission in conjunction with the two speed Hydra-Shift® motor provides the operator a flexible choice of torque and rpm"s to work with during make-up or breakout. The 9 5/8 Hydra-Shift® HD is capable of handling a range of pipe from 2 3/8 inches to 9 5/8 inches.

The Eckel 870 DPT combine power tong and Wedg Drive Tri-Grip®Backup, providing a single piece of equipment to replace several...one smooth continuous operation instead of numerous time-wasting steps at each connection...and a quick, safe means of tripping, replacing methods that endanger crew members and pipe string a like. For drill strings up to 8 inch collars, the model 870 offers over 75,000 ft-lb of torque for break-out and make-up operations, plus ample speed for spinning joints.

The Eckel Model 24 UHT features a two-speed motor with single-speed gear train, producing 95,000 ft-lb of torque in low speed, 25,000 ft-lb in high, both at 2,500 psi. Weighing 8,000 pounds, this tong easily handles ultra-heavy casing strings from 13 3/8 inches to 24 inches.

Except for added torque (up to 24,000 ft-lb) and expanded pipe capacity (from 4 to 13 3/8 inches), the 13 3/8 Standard tong offers the same basic engineering and design as the smaller, lighter Model 10 3/4. Highly recommended where applications demand the ultimate in size range and torque output.

An excellent choice where applications demand the combination of size range and high torque output, the Eckel Model 14 UHT handles pipe from 4 inches to 14 inches. Upgraded in design and performance over the Model 14 HS, this tong is capable of delivering 65,000 ft-lb of torque. Also, available with Wedge Drive Tri-Grip®backup which handles pipe from 4 inches to 15.5 inches.

When applications require the combination of size and torque up to 18,000 ft-lbs, the Eckel 9 5/8 Hydra-Shift® (Narrow Body) meets these requirements. The narrow body design allows this tong to easily operate on smaller rig configurations. A two speed mechanical shift transmission in conjunction with the two speed Hydra-Shift® motor provides the operator a flexible choice of torque and RPM"s to work with during make-up or breakout. The 9 5/8 Hydra-Shift® is capable of handling a range of pipe from 2 3/8 inches to 9 5/8 inches.

When applications require the combination of size and torque up to 18,000 ft-lbs, the Eckel 9 5/8 Hydra-Shift® (Narrow Body) meets these requirements. The narrow body design allows this tong to easily operate on smaller rig configurations. A two speed mechanical shift transmission in conjunction with the two speed Hydra-Shift® motor provides the operator a flexible choice of torque and RPM"s to work with during make-up or breakout. The 9 5/8 Hydra-Shift® is capable of handling a range of pipe from 2 3/8 inches to 9 5/8 inches.

The 14 HS HT Tri-Grip®Tong is used for making up and break out casing and risers. Capable of handling tubulars from 4 in. to 14 in. (101.6 - 355.6 mm) in diameter with a maximum torque of 135,000 ft-lbs (183035.4) of torque capacity. A two-speed Hydra-Shift® motor coupled with a two-speed gear train provides (4) torque levels and (4) RPM speeds. The tong features a three head - Tri-Grip®biting system design which like the Tri-Grip®Backup encompasses the tubular to apply an evenly distributed gripping force. The additional head in the tong reduces the risk of radial deformation, die penetration, marking, and wear of the tubular by 1/3 at extreme torques. The tong performs exceptional gripping capabilities with either Eckel True-Grit dies or Pyramid Fine Tooth dies.

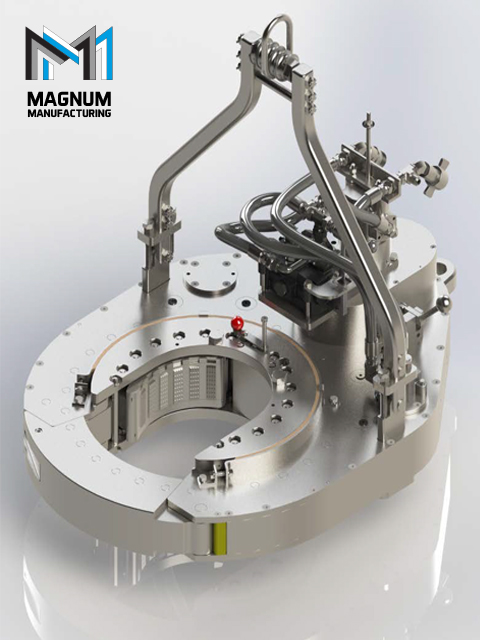

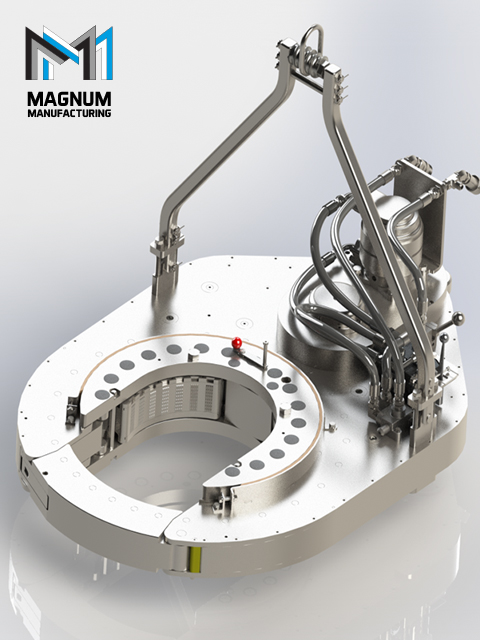

The Eckel Top Drive Casing Tong is a tool developed for use on hydraulic top drive rigs to provide a high quality connection while reducing tubular damage and providing a safer enviroment for crews. With an operating capacity of 4 1/2 inch through 10 5/8 inch, is connected to the output stem of the power swivel. After installation the tong becomes an integral part of the swivel, raising and lowering as a unit and transfering the power swivel"s RPM and torque to the pipe/connection. A guide attached beneath the top drive tong simplifies alignment of the collar within the tong. Once the collar of the pipe is enclosed within the top drive tong, the tong will grip the collar by operating the power swivel. Torque and rotational speed are controlled through the operation of the power swivel. Reversal of the power swivel will cause the tong jaws to release. Tong jaws are spring loaded to retract away from the collar. Utilizing three gripping jaws and a patented Eckel Cam Biting System to grip the pipe collar. The same type of proven biting system found in the industry leading Eckel Power Tongs. These jaws are spaced evenly about the circumference of the collar to provide even distribution of the gripping forces

The Oil & Gas Industry has needed a specialized power tong with an integral backup. This tong is sized small enough and has the right amount of controlable torque output. It is designed so as to properly grip small tubulars such as small macaroni type strings of tubing.

This tong incorporates Eckel"s Hydra-Shift® technology for smooth tranfers of power and speed directly to the tubular. Special built in torque control valving allows the operator to pre-set the maximum desired torque for the connection. This tong also incorporates our new Radial Lock Door. If you are looking for a tong for this lighter type of word look no further.

Except for added torque (up to 24,000 ft-lb) and expanded pipe capacity (from 4 to 13 3/8 inches), the 13 3/8 Standard tong offers the same basic engineering and design as the smaller, lighter Model 10 3/4. Highly recommended where applications demand the ultimate in size range and torque output.

An excellent choice where applications demand the combination of size range and high torque output, the Eckel Model 14 UHT handles pipe from 4 inches to 14 inches. Upgraded in design and performance over the Model 14 HS, this tong is capable of delivering 65,000 ft-lb of torque. Also, available with Wedge Drive Tri-Grip®backup which handles pipe from 4 inches to 15.5 inches.

When applications require the combination of size and torque up to 18,000 ft-lbs, the Eckel 9 5/8 Hydra-Shift® (Narrow Body) meets these requirements. The narrow body design allows this tong to easily operate on smaller rig configurations. A two speed mechanical shift transmission in conjunction with the two speed Hydra-Shift® motor provides the operator a flexible choice of torque and RPM"s to work with during make-up or breakout. The 9 5/8 Hydra-Shift® is capable of handling a range of pipe from 2 3/8 inches to 9 5/8 inches.

An excellent choice where applications demand the combination of size range and high torque output, the Eckel Model 14 UHT handles pipe from 4 inches to 14 inches. Upgraded in design and performance over the Model 14 HS, this tong is capable of delivering 65,000 ft-lb of torque. Also, available with Wedge Drive Tri-Grip®backup which handles pipe from 4 inches to 15.5 inches.

When application demand a wide range of sizes, this tong handles pipe sizes 2 3/8 inches all the way to 7 5/8. Built around the 7 5/8 Standard, the 7 5/8 Heavy Duty provides a thicker rotary gear for more added strength, an additional idler gear, a larger pinion gear, and stronger bearings for load bearing capacity and durability.

Compact Size...Big Torque...if this is what you are looking for in a power tong, look no further. Our 5-1/2 Hydra-Shift® is sized smaller in width than our 5-1/2 Standard model. Like all of our newly developed tongs, the 5-1/2 incorporates the Hydra-Shift® technology, allowing the operator to shift from high speed to low speed without having to manually shift the tong. You will see many years of trouble free operation, not to mention the smoother hydraulic shifting. With two models to choose from, Eckel has the right 5-1/2 Hydra-Shift® for your needs. The 5-1/2 Hydra-Shift® LS with a two-speed motor and a single-speed gear train is the original 5-1/2 Hydra-Shift® which has gained wide acceptance in the industry. Slide heads with rig dies are available for handling drill pipe tool joints.

Special applications and tough requirements demanded that we respond with a new tong designed and built with today"s pipe handling challenges in mind, the 8 5/8 Hydra-Shift® HT. By utilizing a two speed mechanical shift transmission in conjunction with the two speed Hydra-Shift® motor, the operator has a more flexible choice of torque/RPM"s to work with during make-up or break-out. At the beginning of the job, the operator will choose a tong gear ratio that is most appropriate for the current tubular connection and shift the variable speed motor handle into high or low as required. This tong also offers sliding heads with wrap-around dies which provides an evenly applied pressure to the pipe and a greater pipe gripping coverage which in return reduce tubular damage. This tong not only offers the operator the speed options down to the slow speed parameter now demanded by the pipe manufactures and oil companies, it also has the option of speeds of 100 RPM"s when required. Available torque: 40,000 ft-lb

When application demand a wide range of sizes, this tong handles pipe sizes 2 3/8 inches all the way to 7 5/8. Built around the 7 5/8 Standard, the 7 5/8 Heavy Duty provides a thicker rotary gear for more added strength, an additional idler gear, a larger pinion gear, and stronger bearings for load bearing capacity and durability.

Eckel Tri-Grip®an industry standard for reliable backup in make-up and break-out of tubular connections and optionally supplied with Eckel tongs. Eckel backups utilize hydraulic cylinders and a head arrangement that insures slip-free operation. The hydraulic backup is suspended at an adjustable level below the power tong by means of three hanger legs and allowing the backup to remain stationary while the power tong moves vertically to compensate for thread travel of the connection. The Tri-Grip®uses two pivoting heads and one stationary while the cam backup uses two head to grip tubulars using a head and cam configuration that is similar to the method the tong grips tubulars.

The Eckel Closed Mouth Tongs uses three sliding heads with each head equipped with a wide angle wrap-around die. This provides a maximum gripping area of 342 degrees; on the pipe. The CMT"s utilizes the Hydra-Shift® shifting technology which allows the operator to shift from high to low speed without stopping the tong. Reversing the pipe rotation is effortless and done simply by pulling the tong control in the opposite direction. There is no need to physically take out the jaws and turn them over as there is with other brands of closed head tongs. The CMT"s also come with an optional backup that utilizes the same heads/dies as the tong.

The Model 4 1/2 UHT-13 is rugged, light weight tong capable of providing 8,500 ft-lb of torque at 2,500 PSI. The tong will handle pipe from 1.050 inches to 4 1/2 inches. A notable feature is the Eckel patented quick-change sliding head biting system that compensates for worn or under gauge pipe. Also available with an optional rod package for sizes 5/8 inch through 1-1/8 inches and your choice of manual type or hydraulic type backups.

For casing up to 17 inches, here"s a tong that combines speed and the ability to handle smaller sizes economically. If you are running 17 inch casing, give this tong a try. The 17 Hydra-Shift® features the two-speed motor and the two-speed gear train which allows for multiple selections of torque or RPM, not to mention the smoother operation of the tong.

The Eckel 3500 Hydra-Shift® DTT (Dual Tubing Tong) provides fast, easy running on dual strings of 3 1/2 inch or smaller tubing. It grabs from the side, or head-on. Go ahead and torque it up; this tong is Eckel tough. And speed shifts are no problem, thanks to a patented Hydra-Shift® concept that eliminates clutching. The Model 3500 DTT Hydra-Shift® is packed with all the features you"ve come to expect from Eckel: quick-change sliding heads, self-aligning open throat.

Except for added torque (up to 24,000 ft-lb) and expanded pipe capacity (from 4 to 13 3/8 inches), the 13 3/8 Standard tong offers the same basic engineering and design as the smaller, lighter Model 10 3/4. Highly recommended where applications demand the ultimate in size range and torque output.

The big, capable Model 36 UHT easily produces 100,000 ft-lb of torque for makeup or break-out operations involving casing in sizes 16 inches through 36 inches. Weighing approximately 13,000 pounds, this casing tong is 81 inches wide and 135 inches in length. A two-speed motor delivers 16 RPM in high, 3 1/2 RPM in low range, both at 70 GPM.

The Eckel 870 DPT combine power tong and Wedg Drive Tri-Grip®Backup, providing a single piece of equipment to replace several...one smooth continuous operation instead of numerous time-wasting steps at each connection...and a quick, safe means of tripping, replacing methods that endanger crew members and pipe string a like. For drill strings up to 8 inch collars, the model 870 offers over 75,000 ft-lb of torque for break-out and make-up operations, plus ample speed for spinning joints.

Eckel has been at the forefront of this developing technology with the development of larger wrap-around type dies for many of its tong models. Wrap-Around Dies are symmetrically spaced from each other at all times insuring an equally distributed load on the tubular.

An excellent choice where applications demand the combination of size range and high torque output, the Eckel Model 14 UHT handles pipe from 4 inches to 14 inches. Upgraded in design and performance over the Model 14 HS, this tong is capable of delivering 65,000 ft-lb of torque. Also, available with Wedge Drive Tri-Grip®backup which handles pipe from 4 inches to 15.5 inches.

The Model 5 1/2 Standard is the first open-throat design in its size range to generate 12,000 ft-lb of available torque. Versatility is the name of the game here as this tong works well whether powered by a workover rig or a portable casing tong power unit. Options include manual backup or cam-type hydraulic backups.

When applications demand a wide range of sizes, the 7-5/8 Standard tong handles pipe sizes 2-1/16 inches all the way to 7-5/8. Its rugged design is based upon knowledge gained from the 5-1/2 model...combining an extremely compact, high torque concept with added versatility. Options include either manual backup or Tri-Grip®backup. Available torque: 15,000 ft-lb

For casing up to 20 inches, here"s a tong that combines surprising speed with an ability to handle smaller sizes economically (as small as 7 inches). The 20 Standard reaches peak efficiency at just 38 horse power input, thus requiring no "souped-up" power unit. Available torque: 42,000 ft-lb.

The Eckel Model 24 UHT features a two-speed motor with single-speed gear train, producing 95,000 ft-lb of torque in low speed, 25,000 ft-lb in high, both at 2,500 psi. Weighing 8,000 pounds, this tong easily handles ultra-heavy casing strings from 13 3/8 inches to 24 inches.

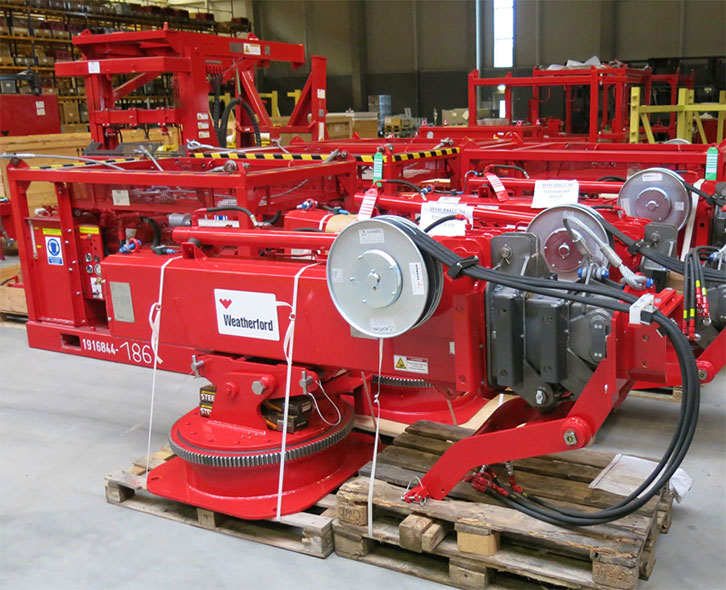

The 14-100 hydraulic power tong provides 100,000 ft-lb (135,600 N∙m) of torque capacity for running and pulling 7- to 14-in. casing. The tong has a unique gated rotary, a free-floating backup, and a hydraulic door interlock.

Our 14-50 high-torque casing tong provides 50,000 ft-lb (67,790 N∙m) of torque capacity for running and pulling 6 5/8- to 14-in. casing. The tong has a unique gated rotary, a free floating backup, and a hydraulic door interlock.

The 16-25 hydraulic casing tong provides 25,000 ft-lb (33,900 N∙m) of torque capacity for running and pulling 6 5/8- to 16-in. casing. The tong features a unique gated rotary and as many as seven contact points that create a positive grip without damaging the casing.

Rigged up without rig modifications, our 21-300 riser tong is the only tong capable of producing 300,000 ft-lb (406,746 N∙m) of continuous rotational torque in both makeup and breakout mode. The power it achieves in a compact size compares with a conventional 24-in. casing tong.

The 24-50 high-torque casing tong provides 50,000 ft-lb (67,790 N∙m) of torque capacity for running and pulling 10 3/4- to 24-in. casing. The tong features a unique gated rotary, a free-floating backup, and a hydraulic door interlock.

The 30-100 high-torque casing tong provides 100,000 ft-lb (135,600 N∙m) of torque capacity for running and pulling 16- to 30-in. casing. The tong features a unique gated rotary, a free-floating backup, and a hydraulic door interlock.

The 5.5-15 hydraulic tubing tong provides 15,000 ft-lb (20,340 N∙m) of torque capability for makeup and breakout of 1.66- to 5.5-in. tubing and premium or standard connections on corrosion‑resistant alloy tubulars. The tong features an ergonomic, lightweight design with a free-floating hydraulic backup.

The 7.6-30 hydraulic tubing tong provides 30,000 ft-lb (40,670 N∙m) of torque capability for makeup and breakout of 2 3/8- to 7 5/8-in. tubing and premium or standard connections on corrosion‑resistant alloy tubulars. The tong features an ergonomic, lightweight design with a free-floating hydraulic backup.

Our SpeedTork 8.0-70 tong provides torques up to 70,000 ft-lb (94,900 N∙m) and 360° rotation in makeup and breakout operations. It can torque drillpipe connections, drillstring components, drilling tools, packers, couplings, and valves.

Model XQ28/2.6 hydraulic power tong is an improved type of XYQ1.8 which is used to make up and break out sucker rod thread in Well Service. This product has the following features:

A. The structure is compact, concise and light. Master tong is driven by a low-speed large torque hydraulic motor that matches with a manual control valve. The backup tong is just like a spanner. The total weight is approximately equal to XYQ1.8.

B. The operating is briefness and convenience with high efficiency. Put the respondence size jaw set into master tong and the respondence size glutting into backup tong, turning the reset knob incorrect direction then can make up and break out sucker rod by operating manual control valve. Two speed, snapping at low speed, spinning at high speed.

ZQ series Drill pipe tong is applied for making-up and breaking-out in offshore and onshore drilling operations and work over operations. Open-throat design of the ZQ series allows the tongs to escape from drilling pipe freely with high mobility. The tong is a combination of spinning tong and torque tong. It substitutes cat head, manual tong and rotary rope in making-up and breaking-out. Using this drill pipe tong could be safe, save labor and increase drilling efficiency.

Within those famous China oil and gas power tong manufacturers, GAOTON is a professional such supplier, producer and provider, welcome to wholesale petroleum and oilfield API power tong from our factory.

Find parts you need to repair or maintain your machines. At Alibaba.com, you can shop for power tong at affordable rates to tackle new obstacles and challenges. In the ever-changing industry, you can find what you need and speak to the supplier directly. Thanks to Alibaba’s collection of wholesale power tong you also get to buy these parts at lower prices, which means you can explore new levels every day more comfortably. From bulldozers to dragline excavators, wheel tractor scrapers to shotcrete machines, any part you need for a heavy-duty mining machinery; you can find it at Alibaba.com.

Looking for purpose-built machine parts? Find them at Alibaba.com. From new components to used parts straight from the manufacturers. Plus, if you need custom-made pieces, you can chat with the supplier, give specifications and wait on delivery. From stone crushers to excavator undercarriage parts, buckets, and even drill bits to get you through the rocks, the power tong from Alibaba offers you the chance to continue operating without a hitch. Whether you are looking to introduce concrete into the rock walls for more consistency and safety during mining, then power tong that goes at wholesale prices at Alibaba will be an excellent addition to your machinery.

Before buying a component, you’d want the equipment to suit your application and offer value. The list of power tong at Alibaba.com lets you dig into earth deposits, and the compare tool checks out other similar parts to give you the information you need to make a purchasing decision. You’ll get wholesale power tong that specializes in mining, with reinforced chassis, and run on more powerful engines. Whether you want to transport minerals or the workers to the mining site, introduce explosives or arms to help you remove materials from your mine pits, Alibaba.com has it all.

Hydraulic power tong is an open type power tong which is used to lift and discharge oil pipe, casing pipe, drill pipe and similar screw thread pipe column in oil filed well service. This power tong features impact structure, convenient operation, reliable performance, good durability, wide applications and large output torque. With this product, the labour intensity of workers can be lowered, besides, the working efficiency and oil service quality can be increased.

Hydraulic casing tong - casing power tong is a wellhead handling tool which is using for quick and safe making up and breaking out of casing,they are strictly designed and manufactured in according with API 7K,size ranges available to meet your casing size.

Type Q2 3/8~10 3/4-48 C Manual Tong is an essential tool in oil drilling operation to fasten or remove the screws of drill pipe and casing joint or coupling. It can be adjusted by changing latch lug jaws and latch steps.

Type Q2 3/8~7-22 LF Manual Tong is used for making breaking out the screws of drill tools and casing in drilling and well servicing operation. The handling size of this type tong can be adjusted by changing latch lug jaws and handling shoulders.

Type Q4~17-135 SDD Manual Tong is used for making up or breaking out the screws of drill tools and casing joint or coupling. It can be adjusted by changing latch lug jaws and handling shoulders.

FYPE Rigid Machinery is one of the leading China manufacturers and suppliers in oil and gas industry. Our company now brings you high quality and competitive price oilfield manual tools drilling power tong, pipe, casing, tubing tong, hydraulic power tong for sale, which is widely used in oilfield. And quick delivery is also offered, please be free to contact our factory.

TQ series of casing tongs are widely used for making-up or breaking-out of casings or pipes. The casing tong features high-efficiency, safety, reliability, labor-saving, and can ensure connection quality.

Tong head is designed as open and is fitted with two jaws which can ensure reliable gripping. Air tyre clutch is utilized as gearshifting mechanism, so it is possible to change gear under running.

The series of casing tongs can be configured with torque device to perform computer monitoring and managing on pressure, torque and rounds. The casing tong has been granted with National Invention Patent.

We"re professional hydraulic sucker rod tong manufacturers in China, providing customized products made in China with competitive price. If you are going to wholesale bulk hydraulic sucker rod tong in stock, welcome to get quotation from our factory.

XQ140 micro-marking and no-marking hydraulic power tongs is a special equipment and open power tongs which is applicable to make up or break out 41/2"-51/2" casing during oil field work over operation.

We"re professional hydraulic low stress power tong manufacturers in China, providing customized products made in China with competitive price. If you are going to wholesale bulk hydraulic low stress power tong in stock, welcome to get quotation from our factory.

Hydraulic Power Tong GKSh-1500MT is designed to handle drill strings and tubing sizes ∅50 mm (1.99"), ∅60 mm (23/8"), ∅73 mm (27/8"), ∅89 mm (31/2"), ∅95 mm (33/4"), ∅108 mm (41/4"), ∅114 mm (41/2"), 120 mm (4 3/4"). According to GOST 15150 climatic version is UKHL1. Designed for moderately cold climate with ambient temperatures -40 to 50 �C.

We are suppliers of all kind of China workover hydraulic power tong factory moved in market place for fantastic sales, we"ve China workover hydraulic power tong factory type and specification"s which will suit our customer"s satisfaction. We"ve also attached China workover hydraulic power tong factory samples and other of our requires with the above attached catalog sample.

8613371530291

8613371530291