automated power tong supplier

The 14-100 hydraulic power tong provides 100,000 ft-lb (135,600 N∙m) of torque capacity for running and pulling 7- to 14-in. casing. The tong has a unique gated rotary, a free-floating backup, and a hydraulic door interlock.

Our 14-50 high-torque casing tong provides 50,000 ft-lb (67,790 N∙m) of torque capacity for running and pulling 6 5/8- to 14-in. casing. The tong has a unique gated rotary, a free floating backup, and a hydraulic door interlock.

The 16-25 hydraulic casing tong provides 25,000 ft-lb (33,900 N∙m) of torque capacity for running and pulling 6 5/8- to 16-in. casing. The tong features a unique gated rotary and as many as seven contact points that create a positive grip without damaging the casing.

Rigged up without rig modifications, our 21-300 riser tong is the only tong capable of producing 300,000 ft-lb (406,746 N∙m) of continuous rotational torque in both makeup and breakout mode. The power it achieves in a compact size compares with a conventional 24-in. casing tong.

The 24-50 high-torque casing tong provides 50,000 ft-lb (67,790 N∙m) of torque capacity for running and pulling 10 3/4- to 24-in. casing. The tong features a unique gated rotary, a free-floating backup, and a hydraulic door interlock.

The 30-100 high-torque casing tong provides 100,000 ft-lb (135,600 N∙m) of torque capacity for running and pulling 16- to 30-in. casing. The tong features a unique gated rotary, a free-floating backup, and a hydraulic door interlock.

The 5.5-15 hydraulic tubing tong provides 15,000 ft-lb (20,340 N∙m) of torque capability for makeup and breakout of 1.66- to 5.5-in. tubing and premium or standard connections on corrosion‑resistant alloy tubulars. The tong features an ergonomic, lightweight design with a free-floating hydraulic backup.

The 7.6-30 hydraulic tubing tong provides 30,000 ft-lb (40,670 N∙m) of torque capability for makeup and breakout of 2 3/8- to 7 5/8-in. tubing and premium or standard connections on corrosion‑resistant alloy tubulars. The tong features an ergonomic, lightweight design with a free-floating hydraulic backup.

Our SpeedTork 8.0-70 tong provides torques up to 70,000 ft-lb (94,900 N∙m) and 360° rotation in makeup and breakout operations. It can torque drillpipe connections, drillstring components, drilling tools, packers, couplings, and valves.

Eckel"s standard diesel or electric power packages at 65 GPM and 2,500 psi (246 LPM / 172 bar) are dependability and long, trouble-free service. Eckel will customize hydraulic power systems in the shortest possible time to meet "nonstandard" requirements for space, fluid flow, auxiliary power, portability, etc.

We offer a full range of high quality casing and tubing, drill pipe tongs for use in all types of oil and gas drilling, well completion and well servicing activities. Our tongs have been engineered for the high operational torques today"s that premium connections require. Eckel tongs continue to advance the technology of tool service and setting industry standards.

Our renowned free floating Tri-Grip®hydraulic backup provides unparalleled backup performance and is one of the industry"s closest tong mounting backups that minimize pipe bending. The backup utilizes three biting surfaces to insure a secure grip on the tubular to prevent tubular rotation.

Our remotely operated tongs provides a mean to control the tong for make-up and break-out operations. The tong is based upon the standard tong and backup configuration with the exception of hydraulic cylinders on the unit for remote control of the operations of the tong and backup. The functions include the tong door, backing pin, mechanical gear shift, power tong rotation, motor speed and backup gripping. Totally hydraulic with no electrical or electronic devices.

Eckel"s standard diesel or electric power packages at 65 GPM and 2,500 psi (246 LPM / 172 bar) are widely recognized for dependability and long, trouble-free service. Eckel will customize hydraulic power systems in the shortest possible time to meet "nonstandard" requirements for space, fluid flow, auxiliary power, and portability. Diesel driven units are optionally supplied with automatic shutdown systems to prevent engine run away when explosive gases are present. Additional shut downs include engine oil temperature, oil pressure, and fan belt breakage. All controls are either air, mechanical or electrical.

Work smarter with real-time data acquisition and reap the benefits of having pertinent, accurate details of all your joints and work string with increased safety, accuracy and knowledge by adding any of Highwood’s tong packages. Complete with optional full data logging you can remotely and safely control your wrench while recording invaluable information from your string line. We can provide a fully automated tong brand-new or incorporate it into your existing equipment.

Have remote operation and full data logging to bring maximum control to your power tong. Highwood’s Automated Tong Package works on any tong so that you don"t need to change your current equipment. Bring safety and data acquisition to your rig fleet.

Highwood"s closed face back-up tong provides safety and efficiency to any closed faced tong on the market. Operate without flipping or changing dies, up to 5-1/2” pipe. Add optional control to a closed face tong to keep operators out of hazardous work zones. Add safety and control without replacing your tong.

K&S Power Tongs offers inspection services to ensure that the manufacturers’ running procedures are followed and that every connection is visually and/or mechanically inspected prior to makeup.

K&S Power Tongs offers a complete self-contained power thread washing unit to professionally clean the thread and seal areas of both the box and pin ends on any API, Premium Connection and Drill Pipe. All connections, prior to make-up should be free of all foreign material to ensure proper thread engagement and seal integrity. Thread washing can prevent costly connection leaks and/or recuts, while extending the life of the threads and seal areas of the box and pin end. This unit can be used on the rig floor or at the pipe racks. Catch basins and drain hoses enable all solvents to be disposed of properly.

Automated hydraulic drill tong with software control GKSh-8000 Timerkul is designed for fast, safe making up and breaking out of drill pipes and casing with rated sizes from Ø73 mm (7/8") up to Ø219 mm (8 5/8"), controlled by an industrial PC controller with a real-time operating system Windows CE 7.0. Highly recommended for high-precision connections. Articulated arm, PLC control and a remote control function offer the optimum in safety and operational efficiency while simultaneously increasing drill pipe life.

The Tong is mounted on the regular place of drilling tong AKB. Changing of the design of the drilling platform and procedure for approval are not required;

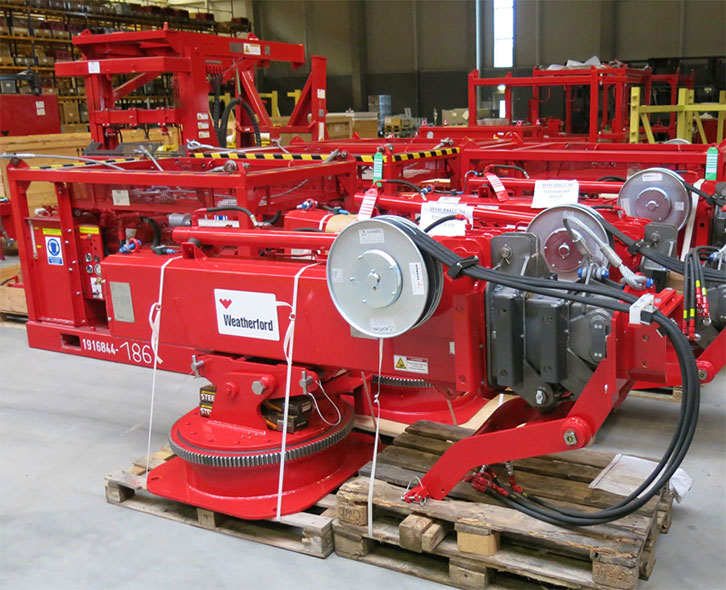

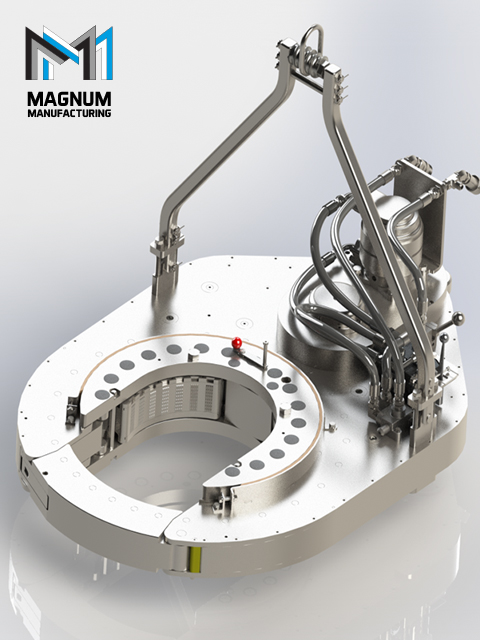

Casing tong handling tools (CTHTs) improve safety and efficiency by reducing the time to complete casing running operations. The CTHT automatically moves the casing tongs to and from well center, which decreases the personnel required to make up casing on the rig floor. Additionally, the CTHT increases the speed of running the casing tong to and from well center. Operations are faster and more consistent, from shift to shift, crew to crew.

The CTHT is an upgrade to an existing offshore drilling rig. This tool lifts and handles casing tongs, ranging in size from 7 5/8 in to 30 in, to and from the well center during casing running operations. And it can be used on any Cameron SmartRacker vertical pipe handling system or any other brand of column racker.

8613371530291

8613371530291