casing power tong in stock

A two-speed Hydra-Shift® motor coupled with a two-speed gear train provides (4) torque levels and (4) RPM speeds. Easily shift the hydraulic motor in low speed to high speed without stopping the tong or tublar rotation, saving rig time.

A patented door locking system (US Patent 6,279,426) for Eckel tongs that allows for latchless locking of the tong door. The tong door swings easily open and closed and locks when torque

is applied to the tong. When safety is important this locking mechanism combined with our safety door interlock provides unparalleled safety while speeding up the turn around time between connections. The Radial Door Lock is patented protected in the following countries: Canada, Germany, Norway, United Kingdom, and the United States.

The field proven Tri-Grip® Backup features a three head design that encompasses the tubular that applies an evenly distributed gripping force. The Tri-Grip®Backup provides exceptional gripping capabilities with either Eckel True Grit® dies or Pyramid Fine Tooth dies. The hydraulic backup is suspended at an adjustable level below the power tong by means of three hanger legs and allowing the backup to remain stationary while the power tong moves vertically to compensate for thread travel of the connection.

Eckel offers several models of torque control systems that are used to monitor the torque turn values when making up tubular connections (Tubing, Casing, & Drill Pipe). Any flaws in the make-up process will be readily shown in a graph.

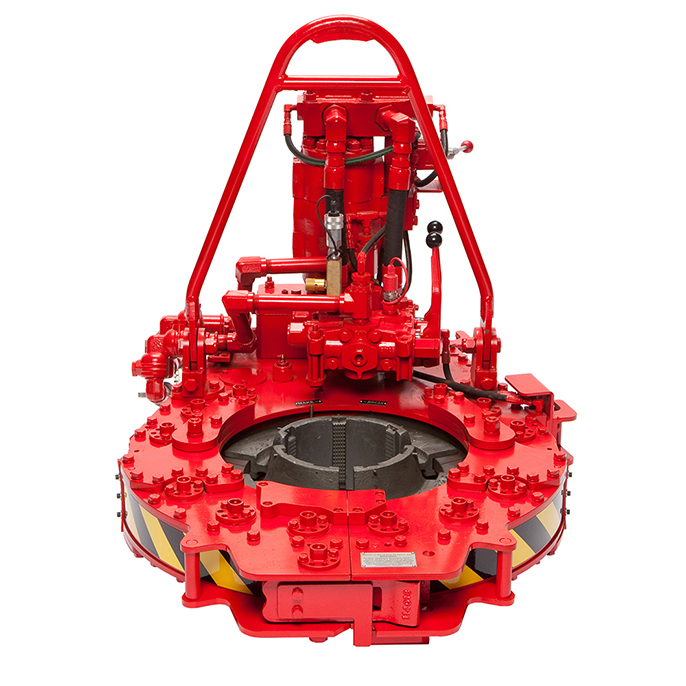

Frank’s engineers and manufactures power tongs to meet the strict criteria of our customers. Frank’s inventories over 3,000 hydraulic power tongs in different models, sizes and torque capacities, ranging from tubing sizes up through 36-inch casing size. All Frank’s tongs are equipped to work in conjunction with the DATA TREK® Advantage, our torque turn monitoring system, as well as the interlock system for safety, and may be equipped with integral back-ups.

Segmented By Type (Hydraulic, Pneumatic), By Product Type (Chisel Tong, Casing Tong, Rotary Tong, Manual Tong, Others), By Function (Breakout Tong, Makeup Tong), By Location (Offshore, Onshore), By Region.

New York, Dec. 05, 2022 (GLOBE NEWSWIRE) -- Reportlinker.com announces the release of the report "Power Tong Market - Global Industry Size, Share, Trends, Opportunity, and Forecast, 2017-2027" - https://www.reportlinker.com/p06370197/?utm_source=GNW

Global power tong market value is anticipated to grow with an impressive CAGR during the forecast years on the backbone of growing demands for efficient and effective equipment for oil excavation and reservoir drilling activities.Surge in the demand for oil and natural gas from the various end use sectors also drives the growth of the global power tong market in the upcoming five years.

Rising concerns regarding the safety of the reserve workers and drilling site workers in case of functional at a complicated site, upsurges the demand for better and efficient drilling equipment and safety equipment also supports the growth of the global power tong market in the next five years.

Increasing consumption of oil & gas in the various end use industries, drive the growth of the global power tong market in the upcoming five years.With higher consumption, consistent increase in the production of the oil and gas through oil wells is also experienced.

Growing number of oil reserves and higher drilling activities further facilitates the growth of the global power tong market in the future five years.The demand for the power tongs is also increasing due to drilling for oil in the complicated and difficult terrain.

Excavation activities in the difficult terrain makes it impossible for the workers to access the location physically. In those terms, efficient drilling equipment and safety tools are required for the drilling, thereby aiding the growth of the global power tong market in the next five years.

Global oil production in the year 2020 was recorded to be 4165.1 million tonnes and its consumption was about 88477 thousand barrels per day. The United States oil production capacity was 712.7 million tonnes in the year 2020. Demands from the end use industries are exhaustive. Increasing number of passenger cars and commercial vehicles further upsurge the demand for higher production of oil and thus aids the growth of the global power tong market in the forecast years.

The global power tong market segmentation is based on type, product type, function, location, regional distribution, and competitive landscape.Based on type, the market is differentiated between hydraulic and pneumatic.

By product type, the market is further segmented into chisel tong, casing tong, rotary tong, manual tong, and others.Based on function, the market is distinguished between breakout tong and makeup tong.

Keystone Energy Tools, Texas International Oilfield Tools Limited, Eckel, Weatherford International, ProTorque, Edcon Power Tongs and Oilfield Services Ltd., TNT Power Tongs, Starr Power Tongs, Besdrill Machinery, McCoy Global Inc., are enlisted in a partial list of major market players of the global power tong market.

In this report, global power tong market has been segmented into following categories, in addition to the industry trends which have also been detailed below:

MOT"s Hydraulic Power Tongs are used for running or pulling tubular strings during well repair, workover, snubbing, drilling and casing operations to extract oil and gas from wells. MOT’s

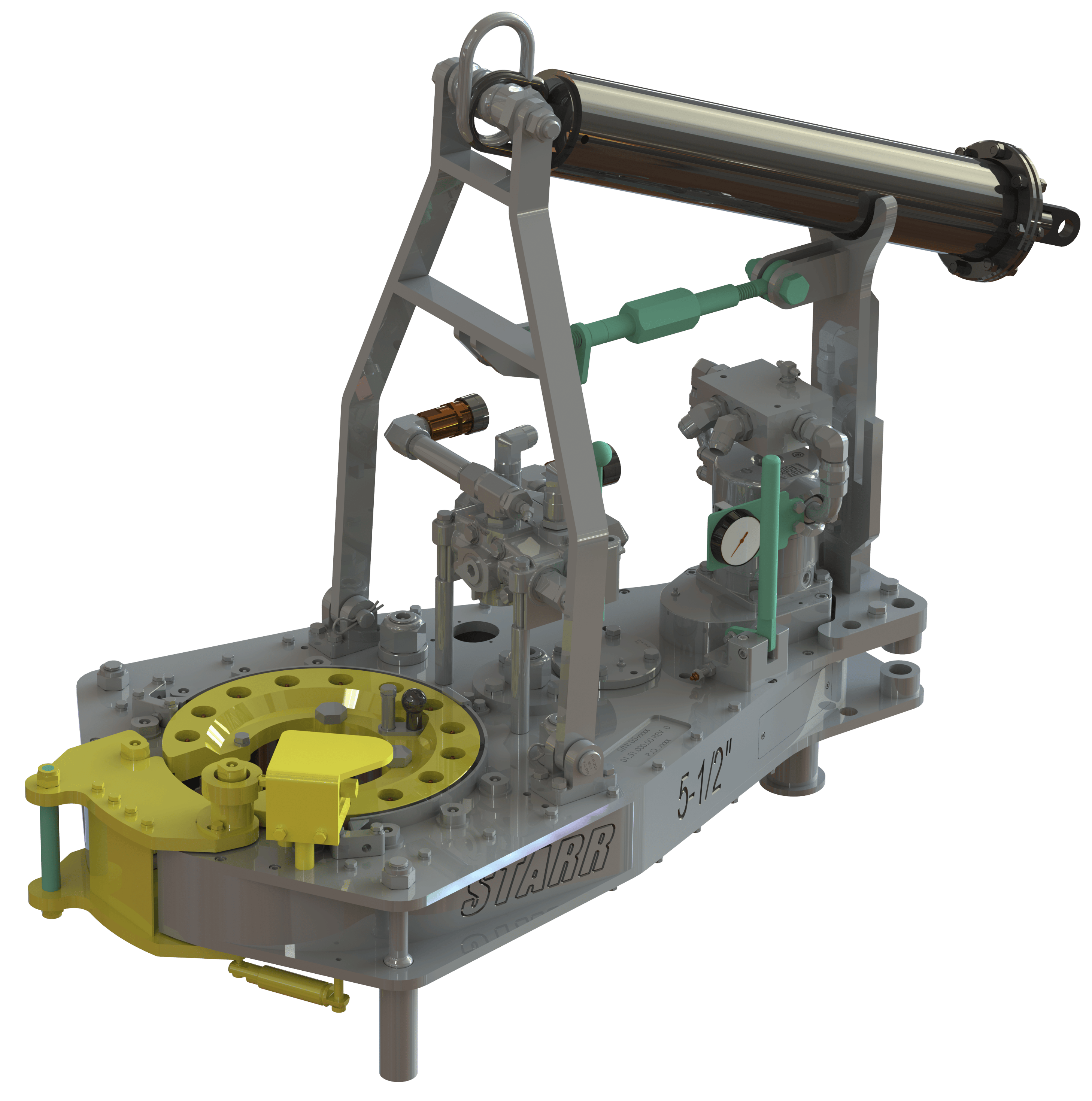

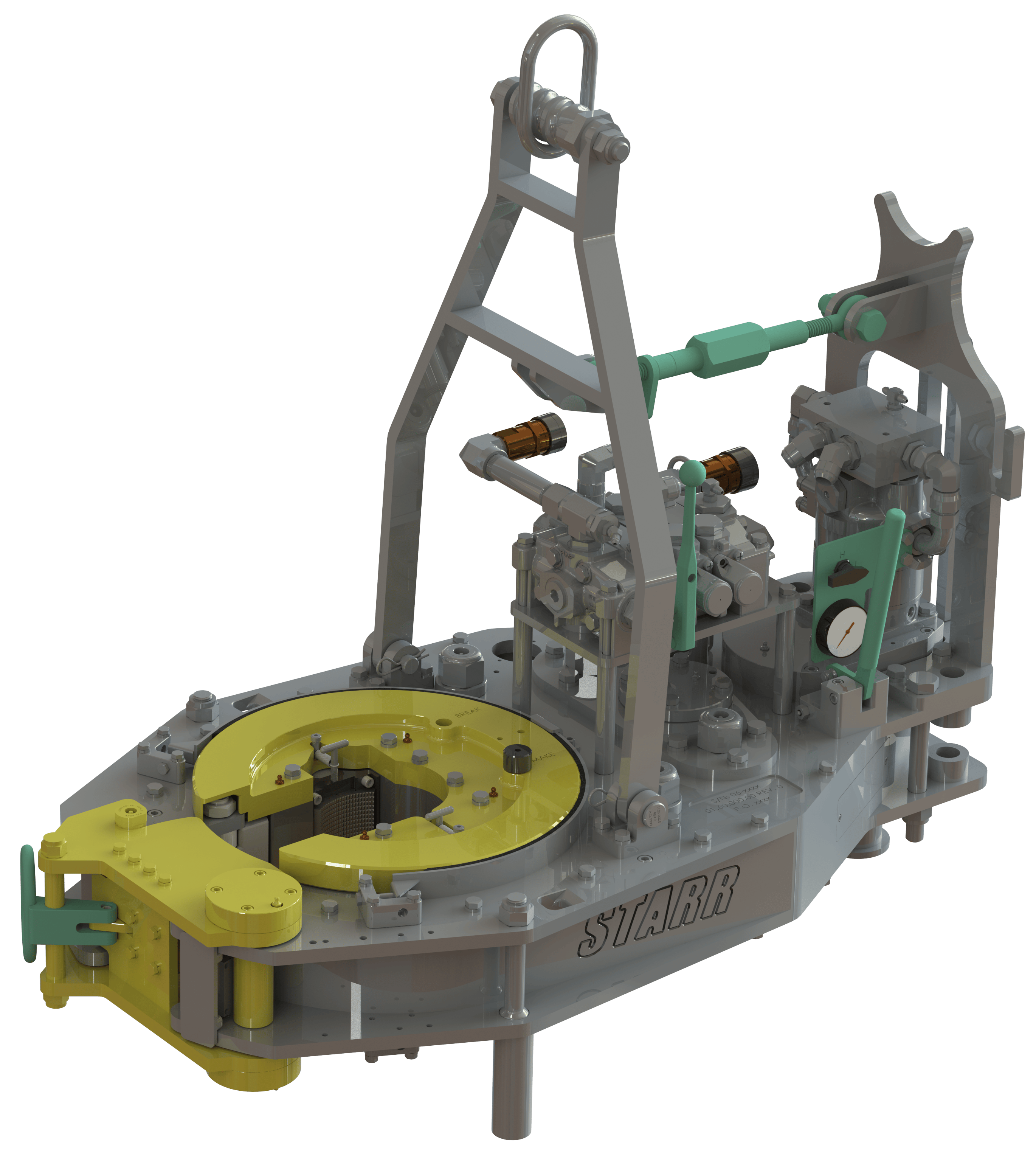

Our TEDA Style power tongs apply correct, uniform torque, reducing costly rod and tubing failures, delivering ample power to make up and break out rods and tubulars from 5/8” rod to 5-1/2” casing. Our series of XQ power tongs come with Bi-Directional jaw systems that save time and enhance safety, and go from make to break with the flip of a knob.

Tongs offer a variety of upgrades from our standard XQ series of TEDA Style models featuring Eaton hydraulic motors for extra torque and reliability, two or three spool directional control valves for more efficient hydraulic operations, and modified structures for higher strength, durability and adaptability to specific job requirements.

Are available from 5-1/2” to 20” pipe and are able to handle both API Standard and PREMIUM (Proprietary Steel Grade) casing connections which require higher torque. Available in a variety of models with hydraulic back-up tongs optional: “KMA", “KHT”, “TQ", “KJD”, “KD” and SE 16-25 with torques ranging from 15,000 ft-lbs up to 55,000 ft-lbs.

8613371530291

8613371530291