ekle power tong factory

A two-speed Hydra-Shift® motor coupled with a two-speed gear train provides (4) torque levels and (4) RPM speeds. Easily shift the hydraulic motor in low speed to high speed without stopping the tong or tublar rotation, saving rig time.

A patented door locking system (US Patent 6,279,426) for Eckel tongs that allows for latchless locking of the tong door. The tong door swings easily open and closed and locks when torque

is applied to the tong. When safety is important this locking mechanism combined with our safety door interlock provides unparalleled safety while speeding up the turn around time between connections. The Radial Door Lock is patented protected in the following countries: Canada, Germany, Norway, United Kingdom, and the United States.

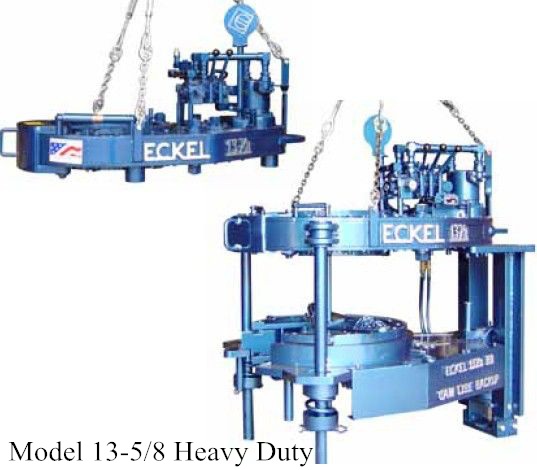

The field proven Tri-Grip® Backup features a three head design that encompasses the tubular that applies an evenly distributed gripping force. The Tri-Grip®Backup provides exceptional gripping capabilities with either Eckel True Grit® dies or Pyramid Fine Tooth dies. The hydraulic backup is suspended at an adjustable level below the power tong by means of three hanger legs and allowing the backup to remain stationary while the power tong moves vertically to compensate for thread travel of the connection.

We offer a full range of high quality casing and tubing, drill pipe tongs for use in all types of oil and gas drilling, well completion and well servicing activities. Our tongs have been engineered for the high operational torques today"s that premium connections require. Eckel tongs continue to advance the technology of tool service and setting industry standards.

Our renowned free floating Tri-Grip®hydraulic backup provides unparalleled backup performance and is one of the industry"s closest tong mounting backups that minimize pipe bending. The backup utilizes three biting surfaces to insure a secure grip on the tubular to prevent tubular rotation.

Our remotely operated tongs provides a mean to control the tong for make-up and break-out operations. The tong is based upon the standard tong and backup configuration with the exception of hydraulic cylinders on the unit for remote control of the operations of the tong and backup. The functions include the tong door, backing pin, mechanical gear shift, power tong rotation, motor speed and backup gripping. Totally hydraulic with no electrical or electronic devices.

Eckel"s standard diesel or electric power packages at 65 GPM and 2,500 psi (246 LPM / 172 bar) are widely recognized for dependability and long, trouble-free service. Eckel will customize hydraulic power systems in the shortest possible time to meet "nonstandard" requirements for space, fluid flow, auxiliary power, and portability. Diesel driven units are optionally supplied with automatic shutdown systems to prevent engine run away when explosive gases are present. Additional shut downs include engine oil temperature, oil pressure, and fan belt breakage. All controls are either air, mechanical or electrical.

Established in 1958, Eckel is globally recognized as the leading manufacturer of hydraulic power tongs and hydraulic power units for the world’s oil and gas industries. We offer a full line of hydraulically operated drill pipe tongs, casing tongs, tubing tongs, hydraulic backups, hydraulic power units, and tong positioning equipment. Eckel delivers a comprehensive range of tongs from 2-1/16 through 36 in. for the most demanding onshore and offshore environments. Eckel Tri-Grip® backup is an industry standard for reliable make-up and break-out of tubular connections. Eckel’s cutting-edge designs, quality, and rugged durability have won us a world-wide reputation of a first-class product that insures years of trouble free service.

Eckel high-performance tongs operate in some of the toughest operating environments around the world performing drill pipe, casing and work-over activities on onshore and offshore locations. Eckel is highly involved in drilling, well servicing, and work-over operations.

We offer a full range of high quality casing and tubing, drill pipe tongs for use in all types of oil and gas drilling, well completion and well servicing activities. Our tongs have been engineered for the high operational torques today’s that premium connections require. Eckel tongs continue to advance the technology of tool service and setting industry standards.

Our renowned free floating Tri-Grip® hydraulic backup provides unparalleled backup performance and is one of the industry’s closest tong mounting backups that minimize pipe bending. The backup utilizes three biting surfaces to insure a secure grip on the tubular to prevent tubular rotation.

Our remotely operated tongs provides a mean to control the tong for make-up and break-out operations. The tong is based upon the standard tong and backup configuration with the exception of hydraulic cylinders on the unit for remote control of the operations of the tong and backup. The functions include the tong door, backing pin, mechanical gear shift, power tong rotation, motor speed and backup gripping. Totally hydraulic with no electrical or electronic devices.

Eckel’s standard diesel or electric power packages at 65 GPM and 2,500 psi (246 LPM / 172 bar) are widely recognized for dependability and long, trouble-free service. Eckel will customize hydraulic power systems in the shortest possible time to meet “nonstandard” requirements for space, fluid flow, auxiliary power, and portability. Diesel driven units are optionally supplied with automatic shutdown systems to prevent engine run away when explosive gases are present. Additional shut downs include engine oil temperature, oil pressure, and fan belt breakage. All controls are either air, mechanical or electrical.

We offer modular spring hangers, which attach to the tong bridle and act as a hanger for the tong. In-turn, providing thread compensation to limit stresses during makeup. Give us a call today for pricing and shipping details.

We are committed to delivering innovative designs and high performance powers tongs for the oil and gas industry. With 90% of all tong components manufactured and heat treated in-house, you are assured reliability and confidence on your next job with an Eckel tong!

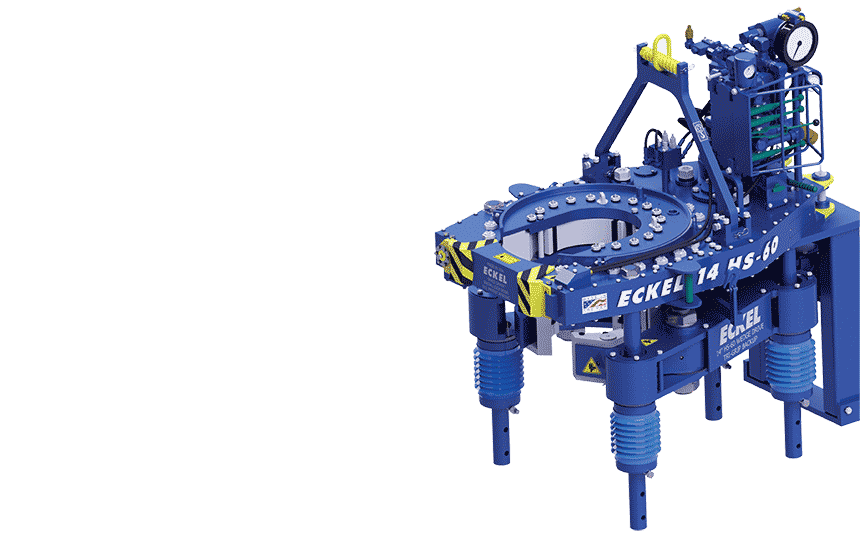

The 14-100 hydraulic power tong provides 100,000 ft-lb (135,600 N∙m) of torque capacity for running and pulling 7- to 14-in. casing. The tong has a unique gated rotary, a free-floating backup, and a hydraulic door interlock.

Our 14-50 high-torque casing tong provides 50,000 ft-lb (67,790 N∙m) of torque capacity for running and pulling 6 5/8- to 14-in. casing. The tong has a unique gated rotary, a free floating backup, and a hydraulic door interlock.

The 16-25 hydraulic casing tong provides 25,000 ft-lb (33,900 N∙m) of torque capacity for running and pulling 6 5/8- to 16-in. casing. The tong features a unique gated rotary and as many as seven contact points that create a positive grip without damaging the casing.

Rigged up without rig modifications, our 21-300 riser tong is the only tong capable of producing 300,000 ft-lb (406,746 N∙m) of continuous rotational torque in both makeup and breakout mode. The power it achieves in a compact size compares with a conventional 24-in. casing tong.

The 24-50 high-torque casing tong provides 50,000 ft-lb (67,790 N∙m) of torque capacity for running and pulling 10 3/4- to 24-in. casing. The tong features a unique gated rotary, a free-floating backup, and a hydraulic door interlock.

The 30-100 high-torque casing tong provides 100,000 ft-lb (135,600 N∙m) of torque capacity for running and pulling 16- to 30-in. casing. The tong features a unique gated rotary, a free-floating backup, and a hydraulic door interlock.

The 5.5-15 hydraulic tubing tong provides 15,000 ft-lb (20,340 N∙m) of torque capability for makeup and breakout of 1.66- to 5.5-in. tubing and premium or standard connections on corrosion‑resistant alloy tubulars. The tong features an ergonomic, lightweight design with a free-floating hydraulic backup.

The 7.6-30 hydraulic tubing tong provides 30,000 ft-lb (40,670 N∙m) of torque capability for makeup and breakout of 2 3/8- to 7 5/8-in. tubing and premium or standard connections on corrosion‑resistant alloy tubulars. The tong features an ergonomic, lightweight design with a free-floating hydraulic backup.

Our SpeedTork 8.0-70 tong provides torques up to 70,000 ft-lb (94,900 N∙m) and 360° rotation in makeup and breakout operations. It can torque drillpipe connections, drillstring components, drilling tools, packers, couplings, and valves.

The quote is the core of GOM Energy Services LLC philosophy and the services provided. Cory Forbes has over 20 years in the Power Tong industry in Sales at a leading manufacturer before starting his own company in REMAN and Repair to Power Tongs.

Our staff consists of professionals from the industry in services, sales and repair. Each service technician has at least 9 years experience in power tong repairs. Our new Shot Peening service has been a great addition to blast the tong casing bodies while we take your existing product and make it as new it was when it was purchased. Click the process below to find out what you can expect in the GOM Energy Services LLC REMAN services.

8613371530291

8613371530291