gill 600 power tong manual for sale

Contact our expert sales staff for pricing, availability and product specifications for the Gill Power Tong right for your application at the link provided on this page.

The Model 300 Sucker Rod Tongs made to make getting on and off the rods easier and to reduce weariness and mishaps. The Model 300 accelerates tripping the pipe, protects rods, and all while simply using the same power unit as a tubing tong. The Model 300 comes with a modifiable relief valve to set the torque; 95 RPM and 850ft/lbs. of torque at high range. Situated by a firm torque arm, this tong can engage automatically and release automatically by a reversing tong.

The Model 300M Sucker Rod Tongs made to make getting on and off the rods easier and to reduce weariness and mishaps. The Model 300 accelerates tripping the pipe, protects rods, and all while simply using the same power unit as a tubing tong. The Model 300 comes with a modifiable relief valve to set the torque; 95 RPM and 850ft/lbs. of torque at high range. Situated by a firm torque arm, this tong can engage automatically and release automatically by a reversing tong. A feature unique to this model is the ability to breakout and make-up 1-1/8” rods without over torqueing.

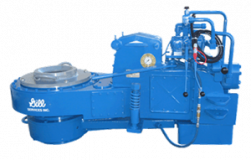

The Model 500 Power Tubing Tong has a size range of 1-5/16” to 7”, joint make-up in 5 seconds, and joint break-out in 7 seconds. With a split glide ring, both safer and more convenient access to jaws and final drive gear components is attainable, while pressurized oil baths ensure that the Model 500 is properly lubricated. The Model 500 also features an adjustable clutch and air or hydraulic assist for the back-up tool. Also fitted with a “Power Shift” Transmission, the operator is able to adjust gears during operation while the Improved Drive Alignment minimizes wasted power.

The Model 600 Power Tubing Tongs feature an adjustable clutch and is available in either air or hydraulic assist for the back-up tool. Also fitted with a “Power Shift” Transmission, the operator is able to adjust gears during operation while the Improved Drive Alignment minimizes wasted power. The Model 600 permits joint make-up in 5 seconds and joint break-out in 7 seconds. With a split glide ring, both safer and more convenient access to jaws and final drive gear components is attainable, while pressurized oil baths ensure that the Model 500 is properly lubricated.

The Model RSHD Power Tubing Tongs are truly a heavy duty piece of equipment that is for the tough jobs. The Model RSHD has more steel weight and gussets added to the bottom in order to diminish chance of case spreading. This model features a customary chain-driven design, integral sprocket, and outer ring. Lastly, the Model RSHD utilizes a familiar jaw-and-bushing biting system.

The Model 700 features the highest torque of all the Power Tubing/Casing Tongs at 20,000 ft./lbs. at 2000 PSI. This model consists of a light drill pipe, tubing, and casing.

Afghanistan - AFGAlbania - ALBAlgeria - DZAAmerican Samoa - ASMAndorra - ANDAngola - AGOAnguilla - AIAAntigua and Barbuda - ATGArgentina - ARGArmenia - ARMAruba - ABWAustralia - AUSAustria - AUTAzerbaijan Republic - AZEBahamas - BHSBahrain - BHRBangladesh - BGDBarbados - BRBBelarus - BLRBelgium - BELBelize - BLZBenin - BENBermuda - BMUBhutan - BTNBolivia - BOLBosnia and Herzegovina - BIHBotswana - BWABrazil - BRABritish Virgin Islands - VGBBrunei Darussalam - BRNBulgaria - BGRBurkina Faso - BFABurma - MMRBurundi - BDICambodia - KHMCameroon - CMRCanada - CANCape Verde Islands - CPVCayman Islands - CYMCentral African Republic - CAFChad - TCDChile - CHLChina - CHNColombia - COLComoros - COMCongo, Democratic Republic of the - CODCongo, Republic of the - COGCook Islands - COKCosta Rica - CRICote d Ivoire (Ivory Coast) - CIVCroatia, Republic of - HRVCyprus - CYPCzech Republic - CZEDenmark - DNKDjibouti - DJIDominica - DMADominican Republic - DOMEcuador - ECUEgypt - EGYEl Salvador - SLVEquatorial Guinea - GNQEritrea - ERIEstonia - ESTEthiopia - ETHFalkland Islands (Islas Malvinas) - FLKFiji - FJIFinland - FINFrance - FRAFrench Guiana - GUFFrench Polynesia - PYFGabon Republic - GABGambia - GMBGeorgia - GEOGermany - DEUGhana - GHAGibraltar - GIBGreece - GRCGreenland - GRLGrenada - GRDGuadeloupe - GLPGuam - GUMGuatemala - GTMGuernsey - GGGuinea - GINGuinea-Bissau - GNBGuyana - GUYHaiti - HTIHonduras - HNDHong Kong - HKGHungary - HUNIceland - ISLIndia - INDIndonesia - IDNIreland - IRLIsrael - ISRItaly - ITAJamaica - JAMJapan - JPNJersey - JEJordan - JORKazakhstan - KAZKenya - KENKiribati - KIRKorea, South - KORKuwait - KWTKyrgyzstan - KGZLaos - LAOLatvia - LVALebanon - LBNLiechtenstein - LIELithuania - LTULuxembourg - LUXMacau - MACMacedonia - MKDMadagascar - MDGMalawi - MWIMalaysia - MYSMaldives - MDVMali - MLIMalta - MLTMarshall Islands - MHLMartinique - MTQMauritania - MRTMauritius - MUSMayotte - MYTMexico - MEXMicronesia - FSMMoldova - MDAMonaco - MCOMongolia - MNGMontenegro - MNEMontserrat - MSRMorocco - MARMozambique - MOZNamibia - NAMNauru - NRUNepal - NPLNetherlands - NLDNetherlands Antilles - ANTNew Caledonia - NCLNew Zealand - NZLNicaragua - NICNiger - NERNigeria - NGANiue - NIUNorway - NOROman - OMNPakistan - PAKPalau - PLWPanama - PANPapua New Guinea - PNGParaguay - PRYPeru - PERPhilippines - PHLPoland - POLPortugal - PRTPuerto Rico - PRIQatar - QATReunion - REURomania - ROURussian Federation - RUSRwanda - RWASaint Helena - SHNSaint Kitts-Nevis - KNASaint Lucia - LCASaint Pierre and Miquelon - SPMSaint Vincent and the Grenadines - VCTSan Marino - SMRSaudi Arabia - SAUSenegal - SENSerbia - SRBSeychelles - SYCSierra Leone - SLESingapore - SGPSlovakia - SVKSlovenia - SVNSolomon Islands - SLBSomalia - SOMSouth Africa - ZAFSpain - ESPSri Lanka - LKASuriname - SURSwaziland - SWZSweden - SWESwitzerland - CHETaiwan - TWNTajikistan - TJKTanzania - TZAThailand - THATogo - TGOTonga - TONTrinidad and Tobago - TTOTunisia - TUNTurkey - TURTurkmenistan - TKMTurks and Caicos Islands - TCATuvalu - TUVUganda - UGAUkraine - UKRUnited Arab Emirates - AREUnited Kingdom - GBRUnited States - USAUruguay - URUUzbekistan - UZBVanuatu - VUTVatican City State - VATVenezuela - VENVietnam - VNMVirgin Islands (U.S) - VIRWallis and Futuna - WLFWestern Sahara - ESHWestern Samoa - WSMYemen - YEMZambia - ZMBZimbabwe - ZWE

Model 500 Serial No.________________________Customer Reference No._____________________Gill Services, Inc. 650 Aldine Bender, Houston, TX 77060Phone: 281-820-5400 Fax: 281-820-0034 Website: www.gillservicesinc.com

IMPORTANT SAFETY NOTICEProper service and repair is important to the safe, reliable operation of all GILL SERVICESequipment. The service procedures recommended by GILL SERVICES and described in thetechnical manuals are recommended methods of performing service operations. Some of theseservice operations require the use of tools especially designed for the purpose. The special toolsshould be used when and as recommended.It is important to note that some warnings against the use of specific service methods that candamage the equipment or render it unsafe are stated in the manuals. It is also important tounderstand that these warnings are not exclusive. GILL SERVICES could not possibly know,evaluate, and advise the service people of all conceivable ways in which service might be done orof the possible hazardous consequences of each way. Accordingly, anyone who uses serviceprocedures or tools which are not recommended by GILL SERVICES must first satisfy himselfthoroughly that neither his safety nor his equipments safety will be jeopardized by the methodselected.

WARRANTY AND GUARANTEEGILL SERVICES, INC. warrants and guarantees that all equipment furnished hereunder andmanufactured or reconditioned by GILL SERVICES, INC. (hereinafter called Vendor) iswarranted to be free from defects in workmanship and material for a warranty period of six (6)months from date of receipt of the original retail purchaser. If, under normal use and service, anyfailure of any parts by reason of a defect in workmanship or material shall appear within suchwarranty period, Purchaser shall notify Vendor thereof immediately, and if so requested byVendor, shall return the defective part to Vendor, transportation charges prepaid, and Vendorshall, upon verifying that the cause of the failure is within the terms hereof, correct any suchdefects by repairing the defective part at its works or by supplying a replacement thereof F.O.B.Vendors works or warehouse. This guarantee does not apply to any parts or items thereof whichshall have been repaired or altered by other than Vendor in any way so as, in Vendors judgment,to affect same or which has been subjected to negligence, accident or other than normal use andservice. The liability of Vendor arising out of the supplying of any material hereunder or its use,whether on warranties or otherwise, shall not exceed the cost of correcting defects as hereinprovided, and shall not include transportation charges, Purchasers labor or materials (except asauthorized in wiring in advance), loss of use or revenue, or any indirect or consequentialdamages. Upon expiration of said warranty period, all such liability shall terminate. Vendorshall have no liability, other than as specifically herein provided, upon warranties, expressed orimplied, of any nature whatsoever, (exclusive, however, of its warranty of title) including, butwithout limitation, warranties with respect to workmanship, material performance and fitness foruse. Upon the expiration of said six (6) month period after the original receipt to retail purchaserof the machinery, all liability hereunder with respect to the machinery or any part or parts thereofrepaired or replaced by reason of this guarantee shall terminate. Any parts or material not ofVendors manufacture is covered only to the extent of any guarantee given to the Vendor by theseller of said material and enforceable by the Vendor against said seller.

WARNINGDO NOT OPERATE, ADJUST, OR REPAIR THIS TONGWITHOUT PROPER TRAINING. READ AND UNDERSTAND ALLOPERATING AND MAINTENANCE INSTRUCTIONS AND ALLOTHER WARNINGS CONCERNING SAFETY BEFORE USINGTHIS TONG. DO NOT REMOVE OR PAINT OVER WARNINGLABELS.

1. DO NOT OPERATE TONG UNTIL ANCHOR ARM ISATTACHED TO THE TONG AND ANCHOR POST.2. DO NOT CRAWL OR STAND UNDER TONG.3. CAUTION: KEEP HANDS CLEAR OF TONG HEADWHILE TONG IS IN OPERATION, AS PARTS INSIDETONG HEAD ROTATE. KEEP ALL PARTS OF THEBODY AND CLOTHING AWAY FROM MOVINGPARTS.4. SHUT OFF POWER SUPPLY TO THIS UNIT BEFOREPERFORMING ANY WORK, (i.e., CHANGING TONGDIES OR JAWS, ADJUSTMENTS, MAINTENANCE,OR LUBRICATION).5. FAILURE TO COMPY WITH WARNINGS COULDRESULT IN EQUIPMENT DAMAGE ANDPERSONAL INJURY.

1. INTRODUCTIONThis manual contains information regarding the GILL Model 500 Power Tong. Full benefitof long life and dependability of this unit can only be realized by proper operation andmaintenance. The operator should familiarize himself thoroughly with informationcontained in this manual before operating this tong. GILL SERVICES, INC. provides theinformation, data, and recommendations contained in this manual as a customer service. Allare believed accurate. However, GILL SERVICES, INC. assumes no responsibility, impliedor otherwise, for errors in or for the application of the Information, data, andrecommendations presented herein.The right is reserved to make changes in this manual at any time, without obligation.

WARRANTY..WARNING INTRODUCTION .GENERAL DESCRIPTION TORQUE CURVE ...SPECIFICATIONS ..INSTALLATION AND OPERATION INSTRUCTIONS ..VICKERS HYDRAULIC FLUID RECOMMENDATIONSLUBRICATION AND MAINTENANCE .FINAL DRIVE ASSEMBLY TRANSMISSION ASSEMBLY ..JAW SETS LISTS ...TONG DRAG RING ASSEMBLY .CLUTCH ASSEMBLY .HYDRAULIC LIFT ASSEMBLY ..COMMERCIAL HYDRAULICS ..HYDRAULIC TORQUE GAUGE ASSEMBLY ..BACKUP TOOL ...AIR CONTROLS FOR BACKUP TOOL ....MAINTENANCE LOG..

2. GENERAL DESCRIPTIONGILL MODEL 500 Power Tong is a safe and accurate unit for the makeup andbreakout of tubing and casing 1-5/16 in O.D. through 7 in O.D. These power tongfeatures include: closed head design, allowing tong to remain in position duringthe entire trip, reducing makeup and break-out time; pressure oil bathlubrication; positive case seal; direct motor drive; roller chain final drive; twospeed operation; controlled torque; and stiff torque arm for safety.

RPMHigh Gear.*126Low Gear...*27Hydraulic Requirement..33 GPM at 2,000 psiTong Length.51Space Required on PipeTong.9-1/2 inWith backup.....16-1/2 inMaximum Elevator Diameter Clearance...30Approximate WeightTong...1,000 lb* (RPM based on published requirements of motor manufacturer: 33.5GPM to tong motor5. INSTALLATION AND OPERATION INSTRUCTIONS5.1 INSTALLING WITH SPRING CUSHIONED HYDRAULIC LIFT1. Move tong to convenient position near well.2. Lift hydraulic cylinder, set in position on tong, attach with pins, and connecthydraulic line from control valve to cylinder.3. Lift tong with line approximately 3 feet above well head. (Cylinder has 6 foottravel.) The hydraulic lift is ready to operate by means of controls. The linesupporting the tong should be located so the tong head will hang over the center ofthe well.4. Weld anchor bracket on right rear corner of rig approximately 4 feet aboveground. Additional anchor brackets can be purchased for use of this tong on morethan one rig. See Figure 5-1.5. Connect torque arm to rear of tong and to anchor bracket on rig. The torquearm Is adjustable, so adjust the torque arm so that the tong will be at a right angle totorque arm. See Figure 5-2. Tong should then have about 4 feet of free verticaltravel. Lower tong over tubing.6. Attach hoses from hydraulic power source. Be sure all self-sealing hosecouplings are tight before starting engine. Tighten firmly by hand. Failure to do thiswill cause engine to run at full speed when tong is not in use.7. To level tong, use the leveling screws and compression spring nuts. If tong isnot level, it will cause excessive wear to tong jaws and Inserts. See Figure 5-3.

1. For breaking out and/or making up joints, place jaws on pins withlong side of jaw against gear teeth.2. Inserts are reversible and should be turned around when theybecome worn or replaced if reversing fails to bring sharp teethIn contact with pipe.5.3 SETTING HYDRAULICS FOR PROPER OPERATION1. Check all hose connections before engaging hydraulic powersource.2.

Adjust tong relief valve. The relief valve on the tong operatesin makeup direction only.a. Turn relief valve adjusting screw to left toreduce pressure until tong reduces speed.b. Place tong on tubing to be made up andgradually increase the pressure to reach make uprequired. Check manufacturers recommendedmakeup torque for type of joint beingmade up.c. Lock relief valve adjusting screw and make upsecond joint checking torque where tong stalls.d. Make minor corrections as necessary untiltorque readings are satisfactory.e. If tong grips and slips, increase pressure ondrag plugs by screwing in drag screws in dragring. Adjust screws evenly. See Figure 5-4.NOTE: It is not necessary to change makeup torque to

break-out. Tong operates at system pressure for breakout.System pressure is controlled by a relief valve set at 2200PSI in power unit tank. PSI should not exceed 2500 PSL4. If pump fails to pick up oil after hoses have been connected orif tong runs in surges, screw out relief valve all the way and letpressure back to tank. Circulate to remove air. Screw In pressurescrew until tong operates. Repeat if necessary.5. In operating tong, stop operating lever in center position onesecond before reversing motor. This reduces fluid shock Inmotor.

5.4 STEPS TO DISMANTLE1. Raise tong to top of hydraulic lift travel.2. Use a line to lower tong and hydraulic lift to ground.3. Shut off hydraulic source to tong. Engage lever on control valve for lift to release pressure off lifthose.4. Disconnect hoses and prepare unit for transporting.

6. VICKERS HYDRAULIC FLUID RECOMMENDATIONS6.1 OIL-TYPEOils used in hydraulic systems perform the dual function of lubrication and transmission of power.Oil must be selected with care and with the assistance of a reputable supplier.Crankcase oils meeting or exceeding the Five Engine Test Sequence for evaluating oils for API(American Petroleum Institute) service MS (Maximum Severity) best serve the needs of mobilehydraulic systems. These engine sequence tests were adopted by the Society of AutomotiveEngineers, American Society for Testing Materials, and automotive engine builders. The MSclassification is the key to selection of oils containing the type of compounding that will extend theoperating life of the hydraulic system. Oils meeting Diesel engine requirements, DG through DSclassifications, may or may not have the type of compounding desired for high performancehydraulic systems.HYDRAULIC SYSTEMOPERATING RANGE(Mm. to Max.)0F to 180F15F to 210F32F to 230F0F to 210F

Automatic Transmission Fluid, Type A, is usually satisfactory for power steeringsystems or those systems operating under moderate hydraulic service.6.2 OPERATING TEMPERATURESThese temperature ranges for each grade of oil are satisfactory If suitable proceduresare followed for low temperature start-up conditions and if sustained operation isavoided at the upper temperature limits. Operation in excess of these temperaturesresults in increased wear of the system components and causes more rapiddeterioration of the oil. For optimum operation, a maximum oil viscosity of 4,000 SSUat the low temperature start-up condition and a minimum oil viscosity of 60 SSU for thesustained high temperature operating condition are recommended.Good oils are the most economical. Specifications can be set up which will indicate, toa limited degree, the characteristics essential in a good hydraulic oil. These are listedherein and should be checked with the oil manufacturer prior to the use of theirproduct.

7.2 OPERATIONAL MAINTENANCE1. Grease lube fittings weekly, (Fig. 7-1).2. Check the transmission after every trip. If water or dirt is found in transmission, change oil. Undernormal conditions, oil should be changed every 100 work-hours.3. Clean and grease tong head and backup tool after every trip. Use kerosene or solvent and a wirebrush for cleaning. After cleaning, applycup grease to jaws, pins, ring gear, and top seal.4. Do not steam clean tong head. Steam cleaning tong head will force water by the top seal Into thetransmission, removing all of the lubricants from top seal and causing It to harden. If steam cleaning isused, guide bell should be pinned in place. After cleaning, check the transmission for the presence ofwater.7.3 SAFETY POINTS AND WARNINGSCAUTION: Keep hands clear of Tong Head while Tongs are in operation. Caution should be taken whi!e operating thisequipment, as parts inside the Tong Head rotate.1. Do not crawl or stand under Tongs as hydraulic line could be cut or broken, and Tongs will fall.2. Do not operate Power Tongs until the Anchor Arm is attached to the Tong and Anchor Post.3. Power should be OFF before any size equipment change, maintenance, or any work Is done to thisequipment.

13. CLUTCH13.1 Adjustment For Clutch1. Remove side panel from operators side of tong.2. Be sure tong is in neutral position.3. Rotate clutch with hand until slot in adjusting collar is facing toward the opening in tong.4. Insert screwdriver or similar object in slot in the adjusting collar.5. Pry the adjusting collar away from pressure plate so that the teeth are free from each other.6. Rotate adjusting collar in the direction shown to adjust clutch.7. Follow the above procedure for both ends of the clutch.8. Adjust left end of clutch for high gear.9. Adjust right end of clutch for low gear.10. If the clutch slips or the disc stack heats up, adjustment is required.

A two-speed Hydra-Shift® motor coupled with a two-speed gear train provides (4) torque levels and (4) RPM speeds. Easily shift the hydraulic motor in low speed to high speed without stopping the tong or tublar rotation, saving rig time.

A patented door locking system (US Patent 6,279,426) for Eckel tongs that allows for latchless locking of the tong door. The tong door swings easily open and closed and locks when torque

is applied to the tong. When safety is important this locking mechanism combined with our safety door interlock provides unparalleled safety while speeding up the turn around time between connections. The Radial Door Lock is patented protected in the following countries: Canada, Germany, Norway, United Kingdom, and the United States.

The field proven Tri-Grip® Backup features a three head design that encompasses the tubular that applies an evenly distributed gripping force. The Tri-Grip®Backup provides exceptional gripping capabilities with either Eckel True Grit® dies or Pyramid Fine Tooth dies. The hydraulic backup is suspended at an adjustable level below the power tong by means of three hanger legs and allowing the backup to remain stationary while the power tong moves vertically to compensate for thread travel of the connection.

R.D.O.T is a small but ambitious Company specializing in Hydraulic Handling Tools. Our core business is the Sales, Supply & Service of Hydraulic Power Tongs.

GILL POWER TONGS TEDA POWER TONGS SHENLIDA POWER TONGS GILL POWER TONGS TEDA POWER TONGS SHENLIDA POWER TONGS GILL POWER TONGS TEDA P[OWER TONGS SHENLIDA POWER TONGS GILL POWER TONGS TEDA POWER TONGS SHENLIDA POWER TONGS GILL POWER TONGS TEDA POWER TONGS SHENLIDA POWER TONGS GILL POWER TONGS TEDA POWER TONGS SHENLIDA POWER TONGS GILL POWER TONGS TEDA POWER TONGS SHENLIDA POWER TONGS GILL POWER TONGS TEDA POWER TONGS SHENLIDA POWER TONGS GILL POWER TONGS TEDA POWER TONGS SHENLIDA POWER TONGS GILL POWER TONGS TEDA POWER TONGS SHENLIDA POWER TONGS GILL POWER TONGS TEDA POWER TONGS SHENLIDA POWER TONGS GILL POWER TONGS TEDA POWER TONGS SHENLIDA POWER TONGS GILL POWER TONGS TEDA POWER TONGS SHENLIDA POWER TONGS GILL POWER TONGS TEDA POWER TONGS SHENLIDA POWER TONGS GILL POWER TONGS TEDA POWER TONGS SHENLIDA POWER TONGS GILL POWER TONGS GILL

At R.D.O.T we are uniquely able to work on everything from Sucker Rod Tongs, the familiar 58-93R up to and including Snubbing and Casing Tongs. From a simple service to a complete custom Slant Rig Configuration R.D.O.T has the experience and skill to fulfill your requirements. Our in house test bench allows us to test up to 3500 psi @ 36 gallons a minute.

8613371530291

8613371530291