hydraulic power tong made in korea manufacturer

A two-speed Hydra-Shift® motor coupled with a two-speed gear train provides (4) torque levels and (4) RPM speeds. Easily shift the hydraulic motor in low speed to high speed without stopping the tong or tublar rotation, saving rig time.

Used on corrosion resistant alloys (CRA) and fiberglass tubulars where reduced markings on the tubular is desired. Eckel"s Coated True Grit® Dies utilize Tungsten Carbide grit which provides many more points of contact on the surface of the tubular than our Pyramid Fine Tooth dies.

A patented door locking system (US Patent 6,279,426) for Eckel tongs that allows for latchless locking of the tong door. The tong door swings easily open and closed and locks when torque

is applied to the tong. When safety is important this locking mechanism combined with our safety door interlock provides unparalleled safety while speeding up the turn around time between connections. The Radial Door Lock is patented protected in the following countries: Canada, Germany, Norway, United Kingdom, and the United States.

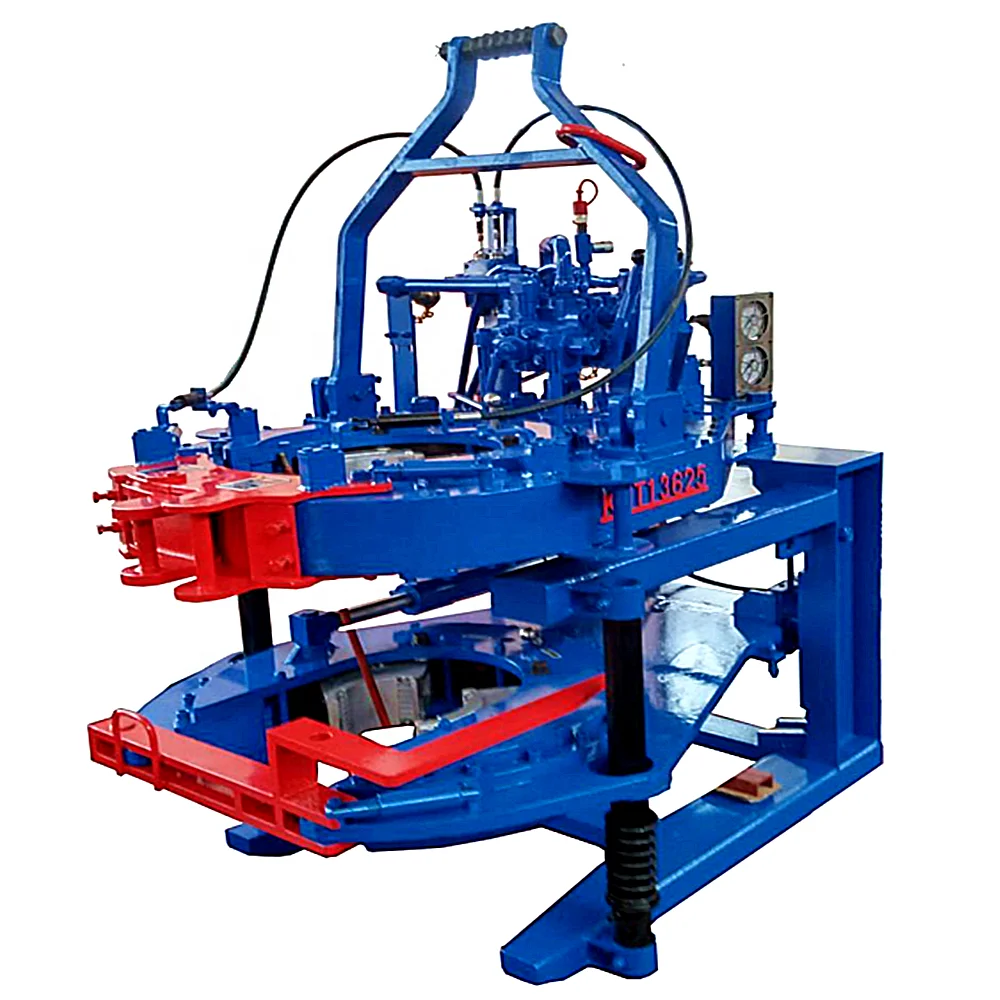

The WD Tri-Grip® Backup is a high performance no compromise backup that is suitable for make-up and break-out of the most demanding connections. The WD Tri-Grip®Backup features a three head design that encompasses the tubular that applies an evenly distributed gripping force. The WD Tri-Grip®is a high performance backup with no compromises that is available for specific applications that provdies exceptional gripping capabilities with either Eckel True Grit® dies or Pyramid Fine Tooth dies.

The field proven Tri-Grip® Backup features a three head design that encompasses the tubular that applies an evenly distributed gripping force. The Tri-Grip®Backup provides exceptional gripping capabilities with either Eckel True Grit® dies or Pyramid Fine Tooth dies. The hydraulic backup is suspended at an adjustable level below the power tong by means of three hanger legs and allowing the backup to remain stationary while the power tong moves vertically to compensate for thread travel of the connection.

Eckel offers several models of torque control systems that are used to monitor the torque turn values when making up tubular connections (Tubing, Casing, & Drill Pipe). Any flaws in the make-up process will be readily shown in a graph.

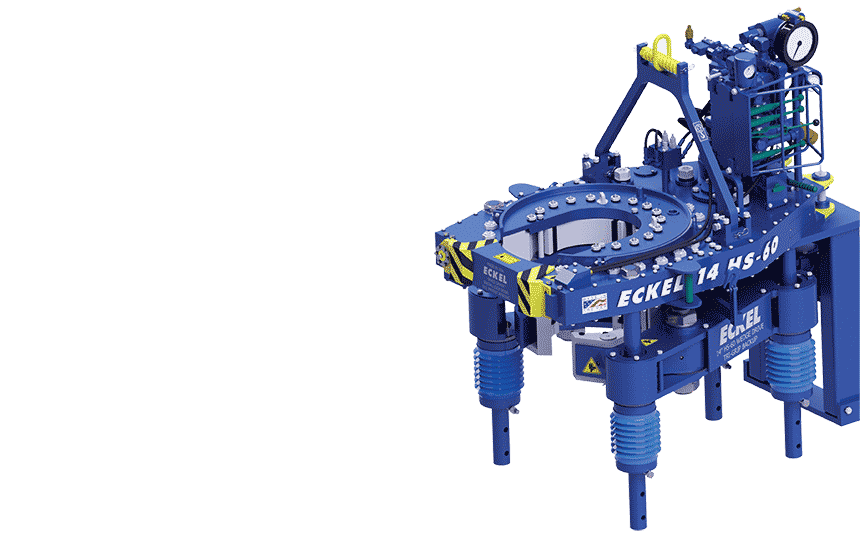

Eckel offers a full range of high-quality casing and tubing, drill pipe tongs for use in all types of oil and gas drilling, well completion, and well-servicing activities. Our tongs have been engineered for the high operational torques today"s that premium connections require. Eckel tongs continue to advance the technology of tool service and setting industry standards. Our tongs have improved crew efficiencies, such as our easy to open and close Radial Lock Door and our Hydra-Shift® speed shifting for speeding up turnaround time between connections. Eckel"s Torque turn control systems that monitor torque turn values when making up the tubular connection with any flaws in the make-up process are displayed.

The 14-100 hydraulic power tong provides 100,000 ft-lb (135,600 N∙m) of torque capacity for running and pulling 7- to 14-in. casing. The tong has a unique gated rotary, a free-floating backup, and a hydraulic door interlock.

Our 14-50 high-torque casing tong provides 50,000 ft-lb (67,790 N∙m) of torque capacity for running and pulling 6 5/8- to 14-in. casing. The tong has a unique gated rotary, a free floating backup, and a hydraulic door interlock.

The 16-25 hydraulic casing tong provides 25,000 ft-lb (33,900 N∙m) of torque capacity for running and pulling 6 5/8- to 16-in. casing. The tong features a unique gated rotary and as many as seven contact points that create a positive grip without damaging the casing.

Rigged up without rig modifications, our 21-300 riser tong is the only tong capable of producing 300,000 ft-lb (406,746 N∙m) of continuous rotational torque in both makeup and breakout mode. The power it achieves in a compact size compares with a conventional 24-in. casing tong.

The 24-50 high-torque casing tong provides 50,000 ft-lb (67,790 N∙m) of torque capacity for running and pulling 10 3/4- to 24-in. casing. The tong features a unique gated rotary, a free-floating backup, and a hydraulic door interlock.

The 30-100 high-torque casing tong provides 100,000 ft-lb (135,600 N∙m) of torque capacity for running and pulling 16- to 30-in. casing. The tong features a unique gated rotary, a free-floating backup, and a hydraulic door interlock.

The 5.5-15 hydraulic tubing tong provides 15,000 ft-lb (20,340 N∙m) of torque capability for makeup and breakout of 1.66- to 5.5-in. tubing and premium or standard connections on corrosion‑resistant alloy tubulars. The tong features an ergonomic, lightweight design with a free-floating hydraulic backup.

The 7.6-30 hydraulic tubing tong provides 30,000 ft-lb (40,670 N∙m) of torque capability for makeup and breakout of 2 3/8- to 7 5/8-in. tubing and premium or standard connections on corrosion‑resistant alloy tubulars. The tong features an ergonomic, lightweight design with a free-floating hydraulic backup.

Our SpeedTork 8.0-70 tong provides torques up to 70,000 ft-lb (94,900 N∙m) and 360° rotation in makeup and breakout operations. It can torque drillpipe connections, drillstring components, drilling tools, packers, couplings, and valves.

A hydraulic power tong is a type of equipment used for work. Experienced hydraulic power tongs, also called as hydraulic power tanks, are different types of equipment that is used to work on pressure-sensitive surfaces.

Explore different kinds of hydraulic power tongs on Alibaba.com, including wholesale hydraulic power tongs for excavator power tongs for sale, include hydraulic power tongs for small, medium, and large-scale work.

We provided licensing of technology Tong Myung Heavy Industries Co., Ltd., Korea with our technology of the Electro Hydraulic Steering Gear since 1976 and supplying the key parts of hydraulic pump (the LV series) and Flutek Ltd. took over the business. We have also been providing with the technology of the Electro Hydraulic Steering Gear CSIC/Wuhan Marine Machineries Plant, China since 1981 and they have started the production since then. Furthermore we have recently, tied up each other concerning the Deck Machinery and Deck Crane and have been expanding the range of cooperation in production.

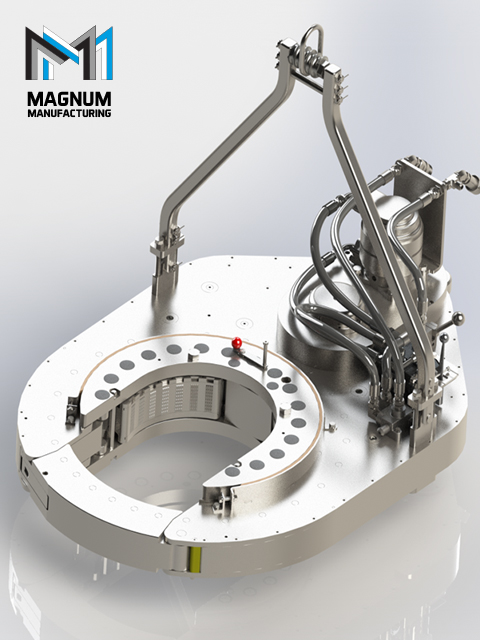

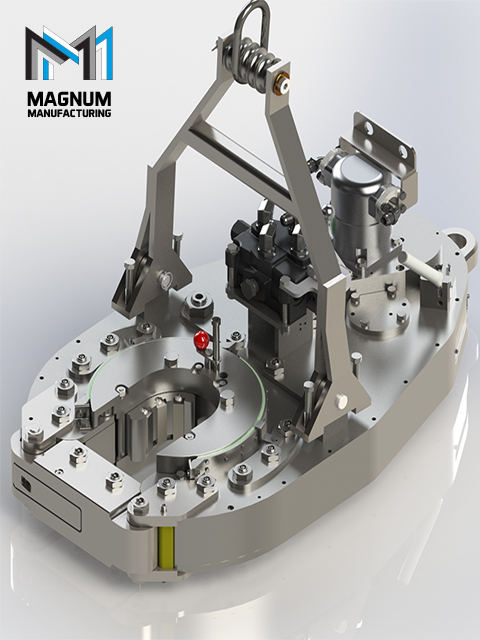

Magnum Manufacturing is a team of experienced casing running engineers and industry-leading professionals tired of working with existing substandard equipment. We have spent decades developing equipment to the highest industry standards, and we personally have been using the equipment we’ve developed. After 30+ years of partnering with a leading American TRS company to ensure optimal performance, we are prepared to stake our reputation on Performance, Longevity, & Safety.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

API 7K Tq340 Casing/ Hydraulic Power Tong Sucker Rod Power Tubing ,Made in China Supplier of Durable Military Quality U-Pipe Tongs, Aluminum Rod Handle,Sucker Rod Power Tong supplier

API standard BXJ Lubricated Fishing Bumper Sub for Drilling Jar,XQ series sucker rod tong,mud pump parts valve parts bonnet gasket,Oil gas Well Wellhead Christmas Tree,hydraulic tong ZQ 203 100 oil pipe power tong,API Conventional and Unconventional Pumping Unit and Pumpjack,API 5CT 2 78 eue N80 L80 tubing coupling on sale,Oil Well Used Float Collar Float Shoe,8 1 2 215 9mm hard formation PDC Drill Bit,Plain end 316L Johnson type v wire water well screens,YKDF 150 Truck mounted reverse circulation drilling rig,Fast Delivery Tricone Bit List,tungsten carbide mining picks coal cutter pick U85 u85hd,cheap price Heavy Weight Drill Pipes,johnson v wire water well screens

Segmented By Type (Hydraulic, Pneumatic), By Product Type (Chisel Tong, Casing Tong, Rotary Tong, Manual Tong, Others), By Function (Breakout Tong, Makeup Tong), By Location (Offshore, Onshore), By Region.

New York, Dec. 05, 2022 (GLOBE NEWSWIRE) -- Reportlinker.com announces the release of the report "Power Tong Market - Global Industry Size, Share, Trends, Opportunity, and Forecast, 2017-2027" - https://www.reportlinker.com/p06370197/?utm_source=GNW

Global power tong market value is anticipated to grow with an impressive CAGR during the forecast years on the backbone of growing demands for efficient and effective equipment for oil excavation and reservoir drilling activities.Surge in the demand for oil and natural gas from the various end use sectors also drives the growth of the global power tong market in the upcoming five years.

Rising concerns regarding the safety of the reserve workers and drilling site workers in case of functional at a complicated site, upsurges the demand for better and efficient drilling equipment and safety equipment also supports the growth of the global power tong market in the next five years.

Increasing consumption of oil & gas in the various end use industries, drive the growth of the global power tong market in the upcoming five years.With higher consumption, consistent increase in the production of the oil and gas through oil wells is also experienced.

Growing number of oil reserves and higher drilling activities further facilitates the growth of the global power tong market in the future five years.The demand for the power tongs is also increasing due to drilling for oil in the complicated and difficult terrain.

Excavation activities in the difficult terrain makes it impossible for the workers to access the location physically. In those terms, efficient drilling equipment and safety tools are required for the drilling, thereby aiding the growth of the global power tong market in the next five years.

Global oil production in the year 2020 was recorded to be 4165.1 million tonnes and its consumption was about 88477 thousand barrels per day. The United States oil production capacity was 712.7 million tonnes in the year 2020. Demands from the end use industries are exhaustive. Increasing number of passenger cars and commercial vehicles further upsurge the demand for higher production of oil and thus aids the growth of the global power tong market in the forecast years.

Demand for higher performance, efficiency, and cost effectiveness demands for the consistent research and technological advancement in the oil drilling equipment and safety equipment.It is highly mandatory that these equipment are safe switched and are easily manageable by the remote network based control to the equipment.

Also, higher production of the oil and gas demands for the advanced and evolved equipment that has better performance as well as can be equipped for longer duration of time and is fail safe. The cost of production, distribution and supply of oil and oil products is very expensive, and still, the demands for this energy produced is increasing rapidly, thus creating further demand for efficient methods of oil excavation, drilling, and supply.

The global power tong market segmentation is based on type, product type, function, location, regional distribution, and competitive landscape.Based on type, the market is differentiated between hydraulic and pneumatic.

By product type, the market is further segmented into chisel tong, casing tong, rotary tong, manual tong, and others.Based on function, the market is distinguished between breakout tong and makeup tong.

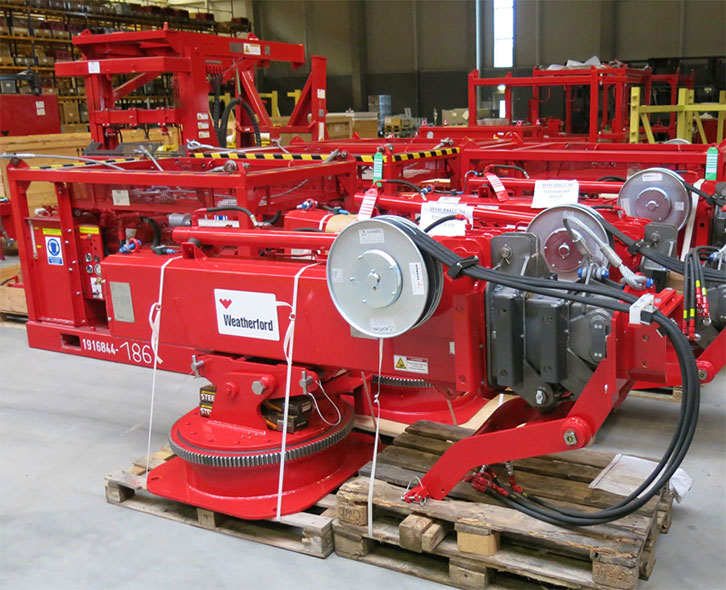

Keystone Energy Tools, Texas International Oilfield Tools Limited, Eckel, Weatherford International, ProTorque, Edcon Power Tongs and Oilfield Services Ltd., TNT Power Tongs, Starr Power Tongs, Besdrill Machinery, McCoy Global Inc., are enlisted in a partial list of major market players of the global power tong market.

In this report, global power tong market has been segmented into following categories, in addition to the industry trends which have also been detailed below:

With the given market data, we offers customizations according to a company’s specific needs. The following customization options are available for the report:

ReportLinker is an award-winning market research solution. Reportlinker finds and organizes the latest industry data so you get all the market research you need - instantly, in one place.

If you’ve worked with us before, you’ll know what we mean. We are remarkably dedicated to the success of our customers. That’s what drives us and everything we do. From the bottom up, we’ve built our company to deliver the highest quality hydraulic tongs faster than anyone else.

JND HYDRAULICS is a manufacturer and distributor of hydraulic power packs based in Korea. As specialists in the hydraulic industry, our customers have confidence in the reliability of our products and our technical expertise. Since its inception in 2003, JND Hydraulics has been a domestic industry- and market-leader while also experiencing strong growth in overseas markets due to our superior quality at competitive prices. To remain as an industry-leader, we continuously take steps to further our technological development while pursuing the highest standards in product quality and service to our clients.

The SsangYong Motor Company (Korean: 쌍용자동차 주식회사) is a South Korea–based automobile manufacturer. It traces its origins back to a manufacturer established in 1954. The name SsangYong appeared in 1988, after its acquisition by the chaebol SsangYong Group. SsangYong Motor was then acquired by Daewoo Motors, SAIC Motor, and then Mahindra & Mahindra. In 2022, the company was acquired by the KG Group. The SsangYong name is planned to be dropped by the company in March 2023.

SsangYong originally started out as two separate companies; Ha Dong-hwan Motor Workshop (established in 1954) and Dongbang Motor Co (established in 1962). In mid-1963, the two companies merged into Ha Dong-hwan Motor Co.Korean: 하동환자동차공업주식회사). In 1964, Hadonghwan Motor Company started building jeeps for the US Army as well as trucks and buses. Beginning in 1976, Hadonghwan produced a variety of special purpose vehicles. After changing its name to Dong-A Motor (Korean: 동아자동차공업주식회사) in 1977 and taking control of Keohwa in 1984, it was taken over by SsangYong Business Group in 1986.

Keohwa, Ltd. (Korean: 주식회사 거화; RR: Jusighoesa Geohwa) was a South Korean assembler of Jeeps under licence, mainly for export markets.Shinjin Motors and American Motor Corporation (AMC), established in 1974.

In 1991, SsangYong started a technology partnership with Daimler-Benz. The deal was for SsangYong to develop a sport utility vehicle (SUV) with Mercedes-Benz technology. This was supposedly to allow SsangYong to gain footholds in new markets without having to build their own infrastructure (utilizing existing Mercedes-Benz networks) while giving Mercedes a competitor in the then-booming SUV market.Musso, which was sold first by Mercedes-Benz and later by SsangYong.

SsangYong further benefited from this alliance, long after Daimler-Benz stopped selling the Musso, producing a badge engineered version of the Mercedes-Benz MB100, the Istana and using Daimler designs in many other models, including the second-generation Korando (engine and transmission), the Rexton (transmission),Chairman H (chassis and transmission)Kyron (transmission).

In 1997, Daewoo Motors, now GM Korea, bought a controlling stake from the SsangYong Group, only to sell it off again in 2000, because the conglomerate ran into deep financial troubles. In late 2004, the Chinese automobile manufacturer SAIC took a 51% stake of SsangYong Motor Company. In July - August 2006, workers went on strike for 7 weeks to protest SAIC"s plans to lay off 554 employees.

In January 2009, after recording a $75.42 million loss, the company was put into receivership. This may have been due to the global economic crisis and shrinking demand.South Korean law when it ordered and carried out the transfer of SsangYong"s proprietary technology developed with South Korean government funding over to SAIC researchers.

In 2010, Daewoo Motor Sales was dropped by General Motors. The long-time dealership partner then signed a deal with the SsangYong Motor Company to supply new vehicles to sell (specifically the Rodius, Chairman W and Chairman H), in return for the injection of ₩20,000,000,000 ($17.6 million) into the car maker still recovering from bankruptcy. The deal is non-exclusive, meaning SsangYong will also sell vehicles through private dealers.

In April 2010, the company released a statement citing interest of three to four local and foreign companies in acquiring SsangYong Motor Company, resulting in shares rising by 15%.Mahindra & Mahindra, Ruia Group, SM Aluminum, Seoul Investments and French-owned Renault Samsung Motors of South Korea.

In 2015, SsangYong launched the Tivoli, its first car after Mahindra acquisition.Mahindra XUV300, which was later launched in 2019 is built on Tivoli"s platform, sharing many parts including several metal sheets.

In October 2021, it was reported that SsangYong was set to be acquired by electric bus and truck maker Edison Motors which would lead to SsangYong exiting receivership. Edison Motors planned to introduce SsangYong vehicles into the United States, Mexico, and Canada markets by the mid-2020s. Edison Motors also intended to phase-out production and new car sales of fossil fuel-powered SsangYong vehicles by 2030, in favor of producing and selling only electric-powered vehicles by the latter, if acquired.

In December 2021, SsangYong signed an agreement with the Chinese BYD Auto to co-develop battery systems for its first electric car (called U100) which would be launched in 2023.

In June 2022, the Seoul Bankruptcy Court opted for a consortium (KG Mobility) led by the KG Group as the final bidder to take over SsangYong Motor. The consortium planned to pay 900 billion won ($699.5 million) for SsangYong.

In December 2022, SsangYong"s chairman Kwak Jae-sun said it plans to remove the "SsangYong" name entirely in March 2023 by modifying the articles of association. The company is set to be renamed as "KG Mobility", adopting a new branding and using KG as its marque, to avoid the negative perception of the present name,

SsangYoung Head Office - The Head office located in Pyeongtaek, South Korea. R&D Centre, Design Centre, and other departments are located in the Pyeongtaek office

지프 하나로 아·중동공략…130배 신장 [Jeeps exports surge in the Middle East, 130 times more]. article.joins.com (in Korean). JoongAng Ilbo. 25 November 1981. Retrieved 17 March 2018.

Kim, Joon (22 March 2015). 신진차 ‘지프’가 국내 첫 SUV… 현대차 ‘싼타페’로 열풍 선도 [Shinjin Motors" Jeep is Korea"s first SUV, leading to Hyundai Santa Fe]. biz.khan.co.kr (in Korean). The Kyunghyang Shinmun. Retrieved 17 March 2018.

아재차 히스토리 - 코란도(korando)편 [History again - History of Korando]. Encar Magazine (in Korean). Archived from the original on 29 June 2020. Retrieved 17 March 2018 – via Magazine.kakao.com.

"Mahindra chosen preferred bidder for Ssangyong Motors". Sify.com. 12 August 2010. Archived from the original on 11 August 2011. Retrieved 25 February 2011.

Nandini Sen Gupta, TNN, Feb 16, 2011, 12.56am IST (16 February 2011). "M&M seals $470m Ssangyong deal - The Times of India". Timesofindia.indiatimes.com. Retrieved 25 February 2011.link)

GaadiWaadi, Team (11 December 2017). "Mahindra To Help SsangYong In Developing Electrified Vehicles". Gaadiwaadi.com - Car News, Bike News, Reviews. Retrieved 28 December 2018.

Posted on October 20, 2021October 22, 2021 (20 October 2021). "SsangYong Set To Be Acquired By Edison Motors". Carscoops. Retrieved 11 April 2022.link)

Seo, Jin-woo; Lee, Ha-yeon (22 December 2021). "SsangYong Motor joins forces with BYD to gain power to go electric". Pulse. Retrieved 24 December 2021.

Lee, Sang-hyun (31 October 2022). "쌍용차, 서울회생법원에 회생절차 종결 신청" [Ssangyong Motor applies for termination of receivership with the Seoul Bankruptcy Court]. Daily Impact. Retrieved 31 October 2022.

Choi, Seong-hook (11 November 2022). "쌍용자동차 19개월 만에 회생절차 종결" [Ssangyong Motor Company"s receivership ends after nineteen months]. Seoul Economic Daily. Retrieved 12 November 2022.

Park, Seong-ho (22 December 2022). ""쌍용차 역사 빼고 다 바꾼다"...36년 만에 "KG 모빌리티"로 재탄생" ["We will change everything, except for Ssangyong Motor"s history". To be reborn as "KG Mobility" after 36 years]. EBN. Retrieved 22 December 2022.

MOT"s Hydraulic Power Tongs are used for running or pulling tubular strings during well repair, workover, snubbing, drilling and casing operations to extract oil and gas from wells. MOT’s

Our TEDA Style power tongs apply correct, uniform torque, reducing costly rod and tubing failures, delivering ample power to make up and break out rods and tubulars from 5/8” rod to 5-1/2” casing. Our series of XQ power tongs come with Bi-Directional jaw systems that save time and enhance safety, and go from make to break with the flip of a knob.

Tongs offer a variety of upgrades from our standard XQ series of TEDA Style models featuring Eaton hydraulic motors for extra torque and reliability, two or three spool directional control valves for more efficient hydraulic operations, and modified structures for higher strength, durability and adaptability to specific job requirements.

Are available from 5-1/2” to 20” pipe and are able to handle both API Standard and PREMIUM (Proprietary Steel Grade) casing connections which require higher torque. Available in a variety of models with hydraulic back-up tongs optional: “KMA", “KHT”, “TQ", “KJD”, “KD” and SE 16-25 with torques ranging from 15,000 ft-lbs up to 55,000 ft-lbs.

For few years until 1994, we realized that most of hydraulic power unit customers complained unstable working power units, high percent of defectives in shipment, late response and late

Therefore, we started creating, designing of our own production system and educating the sales people to provide perfect satisfaction to global customers.

During short time, our brand name has been delivered to many countries by users" mouths to mouths and we are now exporting power units & parts along with perfect satisfaction to Japan, the USA, Canada, South America, Europe union, China & South East Asia.

8613371530291

8613371530291