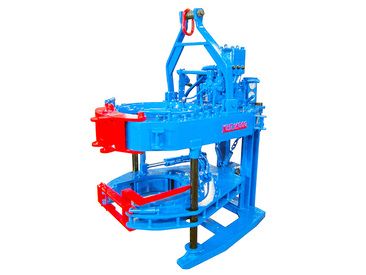

model kht14000 casing power tong with backup quotation

KHT14000 Casing Power Tong is used to make up and break out for casing operation in oil fields. It has greatly reduced the labor of worker, enhanced connection quality of thread and diminished accidents in inappropriate casing operation. The power tong has the following features as well:

They are exported to Russia, America, Middle East, South America, Southeast Asia, Central Asia , African, Australia,Europe etc.Our company is willing to cooperate and make common progress with friends at home and abroad with first-class products, first-class service and reasonable prices.

The McCoy Global FARR® KT14-75K casing tong can handle tubulars as small as 4-1/2″ and as large as 14-3/8″ in diameter. Tong can be mounted on a CHROMEMASTER™ CM15000-75,000 ft/lbs hydraulic backup.

Our power tongs are built to last. With 1 motor options for the 6 1/4” hydraulic power tong, you crew can reach rated torque at 2500 psi. Which means, the tools can reach their rated torque dependably on ever single joint, every day.

With an investment like this, you don’t want one malfunctioning part to be the reason why your equipment isn’t performing. That’s why we build our tongs to be serviceable, high in quality. By using an ISO 9001:2015 quality system, we maintain a close eye on our products.

TTMC ProTM oil/casing torque measuring instrument can be applied for the pipe operations, monitoring and controlling the operation quality of both offshore and land drilling platforms. The device provides two operation modes and four measuring methods, which can monitor and control the standard makeup torque in real time, so that the oil and casing pipe can reach the standard setting value, and can monitor the oil and casing pipe with special makeups to achieve the best sealing state. TTMC Pro monitoring system consists of a host machine, a data signal line, a tension/turn sensor, and an electromagnetic relief valve. After the several wells operation, it is proved that this instrument has high practical value for ensuring the operation quality of the oil and casing job, and reducing accidents and improving work efficiency.

Compact Size and Big Torque! If this is what you are looking for in a power tong, look no further. Our 5½ Hydra-Shift® is sized smaller in width than our 5½ Standard model. Like all of our newly developed tongs, the 5½ incorporates the Hydra-Shift® technology, allowing the operator to shift from high speed to low speed without having to shift the tong manually. You will see many years of trouble-free operation, not to mention the smoother hydraulic shifting. With two models to choose from, Eckel has the right 5½ Hydra-Shift® for your needs. The 5½ Hydra-Shift® (VS) with a two-speed motor and a two-speed gear train offers the operator a more flexible choice of torque/RPM"s to work with during make-up or break-out. At the beginning of the job, the operator will choose which tong gear ratio is most appropriate for the current tubular connections and adjust the mechanical shifting lever. During make-up or break-out, further adjustments are actuated through the two-speed motor. Slide heads with rig dies are available for handling drill pipe tool joints.

The WD Tri-Grip® Backup is a high performance no compromise backup that is suitable for make-up and break-out of the most resilient connections. The WD Tri-Grip® Backup features a three head design that encompasses the tubular that applies an evenly distributed gripping force. The backup is capable of handling tubulars from 3½ in. to 6&ffac12; in. (88.9 - 165.1 mm). A constant radial load is applied with a single wedge drive to actuate the front two pivot heads with a third stationary head providing a reactionary force to provide a superior gripping performance. Wedge Drive Tri-Grip®Backup has exceptional gripping capabilities with Eckel Wrap-Around, True-Grit® dies or Pyramid Fine Tooth dies for making up other types of tubulars.

Eckel customarily provides compression style hydraulic backups to measure the torque exerted in make-up and break-out operations. A load cell bracket is located at the rear of the backup which a compression load cell is inserted.

Eckel also provides tension type backups when operator preferences require a tension configuration. Tension backups unlike compression have identical handle lengths as the tong. This allows the torque gauge assembly to be calibrated for proper torque readings in both tong and tong & backup configurations. The tension load cell is mounted on the rear of the backup between the roller bracket yoke and load cell mount.

Magnum Manufacturing is a team of experienced casing running engineers and industry-leading professionals tired of working with existing substandard equipment. We have spent decades developing equipment to the highest industry standards, and we personally have been using the equipment we’ve developed. After 30+ years of partnering with a leading American TRS company to ensure optimal performance, we are prepared to stake our reputation on Performance, Longevity, & Safety.

The Model 300 Sucker Rod Tongs made to make getting on and off the rods easier and to reduce weariness and mishaps. The Model 300 accelerates tripping the pipe, protects rods, and all while simply using the same power unit as a tubing tong. The Model 300 comes with a modifiable relief valve to set the torque; 95 RPM and 850ft/lbs. of torque at high range. Situated by a firm torque arm, this tong can engage automatically and release automatically by a reversing tong.

The Model 300M Sucker Rod Tongs made to make getting on and off the rods easier and to reduce weariness and mishaps. The Model 300 accelerates tripping the pipe, protects rods, and all while simply using the same power unit as a tubing tong. The Model 300 comes with a modifiable relief valve to set the torque; 95 RPM and 850ft/lbs. of torque at high range. Situated by a firm torque arm, this tong can engage automatically and release automatically by a reversing tong. A feature unique to this model is the ability to breakout and make-up 1-1/8” rods without over torqueing.

The Model 500 Power Tubing Tong has a size range of 1-5/16” to 7”, joint make-up in 5 seconds, and joint break-out in 7 seconds. With a split glide ring, both safer and more convenient access to jaws and final drive gear components is attainable, while pressurized oil baths ensure that the Model 500 is properly lubricated. The Model 500 also features an adjustable clutch and air or hydraulic assist for the back-up tool. Also fitted with a “Power Shift” Transmission, the operator is able to adjust gears during operation while the Improved Drive Alignment minimizes wasted power.

The Model 600 Power Tubing Tongs feature an adjustable clutch and is available in either air or hydraulic assist for the back-up tool. Also fitted with a “Power Shift” Transmission, the operator is able to adjust gears during operation while the Improved Drive Alignment minimizes wasted power. The Model 600 permits joint make-up in 5 seconds and joint break-out in 7 seconds. With a split glide ring, both safer and more convenient access to jaws and final drive gear components is attainable, while pressurized oil baths ensure that the Model 500 is properly lubricated.

The Model RSHD Power Tubing Tongs are truly a heavy duty piece of equipment that is for the tough jobs. The Model RSHD has more steel weight and gussets added to the bottom in order to diminish chance of case spreading. This model features a customary chain-driven design, integral sprocket, and outer ring. Lastly, the Model RSHD utilizes a familiar jaw-and-bushing biting system.

The Model 700 features the highest torque of all the Power Tubing/Casing Tongs at 20,000 ft./lbs. at 2000 PSI. This model consists of a light drill pipe, tubing, and casing.

8613371530291

8613371530291