oilfield power tong rebuilders and repairs manufacturer

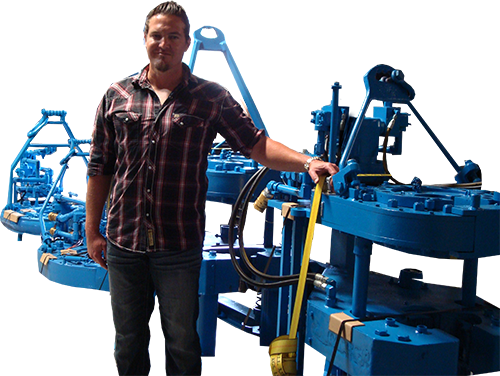

The quote is the core of GOM Energy Services LLC philosophy and the services provided. Cory Forbes has over 20 years in the Power Tong industry in Sales at a leading manufacturer before starting his own company in REMAN and Repair to Power Tongs.

Our staff consists of professionals from the industry in services, sales and repair. Each service technician has at least 9 years experience in power tong repairs. Our new Shot Peening service has been a great addition to blast the tong casing bodies while we take your existing product and make it as new it was when it was purchased. Click the process below to find out what you can expect in the GOM Energy Services LLC REMAN services.

With our 20,000 sqft facillity and over a century in combined experience, we have been a leading supplier of well servicing equipment and supplies for over 40 years.

We at Maverick Oilfield Specialties understand your needs and are ready to assist you in any way we can. We can handle all your needs, from repairs and general maintainence, to complete rig-up packages. We stock everything from pliers and pipe wrenches, to BOP"s and Power Tongs.

World Petroleum Supply, Inc stocks a wide selection of West International Consulting, Inc. Power Tongs & Hydraulic Power Units to suit every application. All power tongs products of which are API Certified.

Wil-Tech provides maintenance, repair, and complete overhaul services for tubing tongs. We stock components for all major brands of pipe handling product, and a variety of not so common components. Our technicians are extremely capable and well equipped to maintain and refurbish your pipe tongs, they offer seal replacements, bearing replacements, gear replacements, backup repair, motor replacements and repair, jaw replacements, and preventative maintenance to reduce the frequency for complete overhaul.

We encourage our customers with pipe handling equipment to regularly maintain their asset, because a properly maintained pipe tubing tong tends to operate longer, more efficiently and safer. Operating pipe handling equipment can be dangerous as it is, don’t let neglect add to the danger.

Wil-Tech provides inspection services for open and closed tubing tongs, our pipe handling department are well equipped and provided thorough inspections on all componentry including; gears, hydraulic motors, fittings, jaws, cylinders, backups, and structural components. Over the course of usage tubing tongs face a barrage of punishment that can reduce efficiency; regular inspections can increase the longevity of your asset, keeping it operating smoothly and safely. Properly functioning tongs reduce operator frustration, reducing risk of injury while improving productivity; as an asset owner that is what you want.

Wil-Tech provides tubing tong rental services. While your tongs are being repaired you don’t have to worry about downtime. Not all malfunctions can be quickly remedied in the field, if your tongs experience a failure during production rest assured our set of rental tongs can get you out of the bind. We offer delivery to site and can pick up your malfunctioning tongs to be brought back to our shop for repair. We hope it doesn’t come to this for our clients but these situations occur and we want to offer our clients the right solution.

Wil-Tech provides paint preparation and painting services for tubing tongs. Wil-Tech houses an industrial part washing unit, sandblasting cabinet and paint booth for full service component paint preparation and painting. Our technicians take pride in sending our client’s tongs out the door working and looking as close to as new as possible.

Wil-Tech provides performance testing service on all tubing tongs prior to leaving our shop as a quality assurance measure. Our technicians utilize a 50hp test bench to perform a variety of tests on the tubing tongs to ensure functionality, sealing, relief and performance.

Wil-Tech provides troubleshooting services for hydraulic tubing tongs. Whether in our shop or on-site, our technicians and facilities and mobile units are equipped to troubleshoot your tubing tong. If your asset isn’t operating as expected let our technicians identify and resolve the problem.

Wil-Tech services and installs torque gauge and sensing equipment on tubing tongs. Our technicians repair, calibrate and certify gauges. Our component technicians work in tandem with our pipe handling department to ensure your gauges are reporting accurate measurements.

Additionally, we offer an aftermarket torque monitoring systems to create a smart torqueing system. Our mobile IQAN torqueing package, is versatile, mobile, accurate, and easy to both install and use. The IQAN records torque at each connection in a string of tubing, it’s easy and produces reports that drive accountability and quality assurance. Don’t leave any question in your clients mind as to whether the job was done right.

Wil-Tech provides pipe, rod and tubing elevator repair and maintenance services. Our technicians thoroughly refurbish elevators to as close of an as-new product as possible. We stock a variety of elevator components and products to keep them function smoothly and latching securely.

We encourage our customers with pipe handling equipment to regularly maintain their asset, because as with any device securing an overhead load, safety is of the utmost concern.. Operating pipe handling equipment can be dangerous as it is, don’t let neglect add to the danger.

Wil-Tech provides paint preparation and painting services for pipe, rod and tubing elevators. Wil-Tech houses an industrial part washing unit, sandblasting cabinet and paint booth for full service component paint preparation and painting. Our technicians take pride in sending our client’s elevators out the door working and looking as close to as new as possible.

Wil-Tech provides hydraulic top-drive repair and maintenance services. Our technicians thoroughly repair and replace components to ensure your top-drive is as close of an as-new product as possible. We stock a variety of top-drive components and products to keep them function safely and efficiently.

We encourage our customers with pipe handling equipment to regularly maintain their asset, due to the size of top-drives and being an overhead load during operation, safety is of the utmost concern. Operating pipe handling equipment can be dangerous as it is, don’t let neglect add to the danger.

Wil-Tech provides hydraulic top-drive inspection services. Our technicians meticulously inspect and document condition of the hydraulic top-drive and provide a thorough review of their findings. We offer our clients the convenience of performing our inspection services on site and in the field.

Wil-Tech provides maintenance and repair services for hydraulic kelly spinners. Our technicians perform general maintenance tasks, including seal replacements, bearing replacements, fitting replacements, greasing, chain replacements as well as component replacements and complete overhauls. We encourage our customers with pipe handling equipment to regularly maintain their asset, because a properly maintained pipe Kelly spinner tends to operate longer, more efficiently and safer. Operating pipe handling equipment can be dangerous as it is, don’t let neglect add to the danger.

Wil-Tech provides inspection services for hydraulic kelly spinners, our technicians perform a thorough review of the hydraulic motor, gears, fittings and connections, jaws, bearings and structural components. Regular inspections can identify problems before they end up causing damage and/or injury and should be included in the asset’s preventative maintenance schedule to protect both the asset and its operators.

Wil-Tech provides troubleshooting services for hydraulic kelly spinners. Whether in our shop or on-site, our technicians and facilities and mobile units are equipped to troubleshoot your kelly spinner. If your asset isn’t operating as expected let our technicians identify and resolve the problem.

Wil-Tech provides maintenance, repair, and complete overhaul services for rod tongs. We stock components for all major brands of pipe handling product, and a variety of not so common components. Our technicians are extremely capable and well equipped to maintain and refurbish your pipe tongs, they offer seal replacements, bearing replacements, gear replacements, backup repair, motor replacements and repair, jaw replacements, and preventative maintenance to reduce the frequency for complete overhaul.

We encourage our customers with pipe handling equipment to regularly maintain their asset, because a properly maintained pipe rod tong tends to operate longer, more efficiently and safer. Operating pipe handling equipment can be dangerous as it is, don’t let neglect add to the danger.

Wil-Tech provides inspection services for open and closed rod tongs, our pipe handling department are well equipped and provided thorough inspections on all componentry including; gears, hydraulic motors, fittings, jaws, cylinders, backups, and structural components. Over the course of usage rod tongs face a barrage of punishment that can reduce efficiency; regular inspections can increase the longevity of your asset, keeping it operating smoothly and safely. Properly functioning tongs reduce operator frustration, reducing risk of injury while improving productivity; as an asset owner that is what you want.

Wil-Tech provides rod tong rental services. While your tongs are being repaired you don’t have to worry about downtime. Not all malfunctions can be quickly remedied in the field, if your tongs experience a failure during production rest assured our set of rental tongs can get you out of the bind. We offer delivery to site and can pick up your malfunctioning tongs to be brought back to our shop for repair. We hope it doesn’t come to this for our clients but these situations occur and we want to offer our clients the right solution.

Wil-Tech provides paint preparation and painting services for rod tongs. Wil-Tech houses an industrial part washing unit, sandblasting cabinet and paint booth for full service component paint preparation and painting. Our technicians take pride in sending our client’s tongs out the door working and looking as close to as new as possible.

Wil-Tech provides performance testing service on all rod tongs prior to leaving our shop as a quality assurance measure. Our technicians utilize a 50hp test bench to perform a variety of tests on the rod tongs to ensure functionality, sealing, relief and performance.

Wil-Tech provides troubleshooting services for hydraulic rod tongs. Whether in our shop or on-site, our technicians and facilities and mobile units are equipped to troubleshoot your rod tong. If your asset isn’t operating as expected let our technicians identify and resolve the problem.

Wil-Tech services and installs torque gauge and sensing equipment on rod tongs. Our technicians repair, calibrate and certify gauges. Our component technicians work in tandem with our pipe handling department to ensure your gauges are reporting accurate measurements.

Additionally, we offer an aftermarket torque monitoring systems to create a smart torqueing system. Our mobile IQAN torqueing package, is versatile, mobile, accurate, and easy to both install and use. The IQAN records torque at each connection in a string of rod, it’s easy and produces reports that drive accountability and quality assurance. Don’t leave any question in your clients mind as to whether the job was done right.

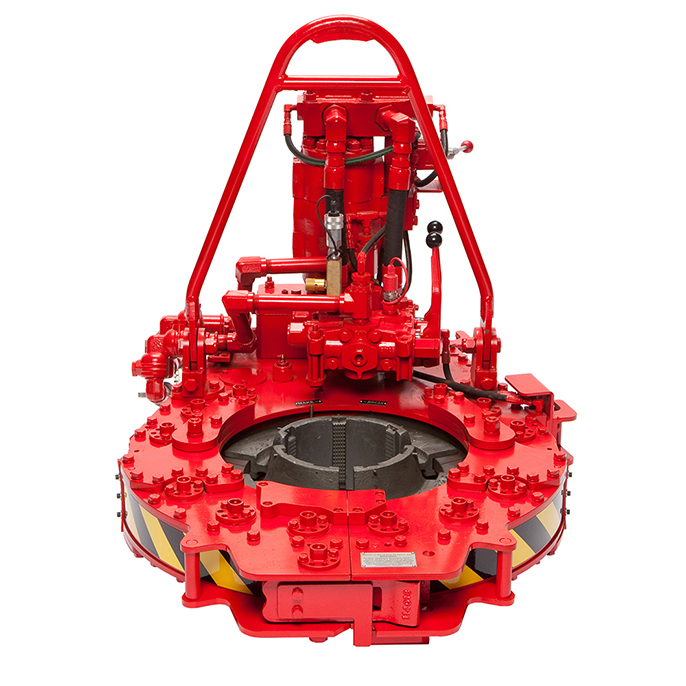

Wil-Tech provides maintenance and repair services for hydraulic spiders. Our technicians thoroughly refurbish tubing spiders to as close of an as-new product as possible. We stock a variety of components and products to keep them gripping and latching securely.

We encourage our customers with pipe handling equipment to regularly maintain their asset, because as with any device securing downhole tools, safety is of the utmost concern. Operating pipe handling equipment can be dangerous as it is, don’t let neglect add to the danger. Save yourself the cost of the damages and fishing tools and ensure you’re properly maintain your hydraulic spiders.

Wil-Tech provides inspection services for hydraulic tubing spiders, our technicians perform a thorough review of the hydraulic cylinders, jaws and structural components. Regular inspections can identify problems before they end up causing damage and/or injury and should be included in the asset’s preventative maintenance schedule to protect the asset, its operators and its owner.

Wil-Tech provides paint preparation and painting services for tubing spiders. Wil-Tech houses an industrial part washing unit, sandblasting cabinet and paint booth for full service component paint preparation and painting. Our technicians take pride in sending our client’s spiders out the door working and looking as close to as new as possible.

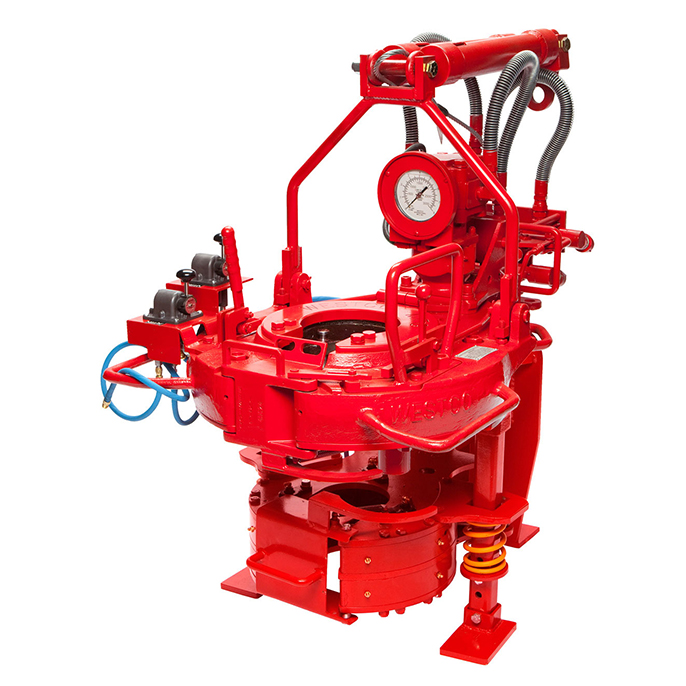

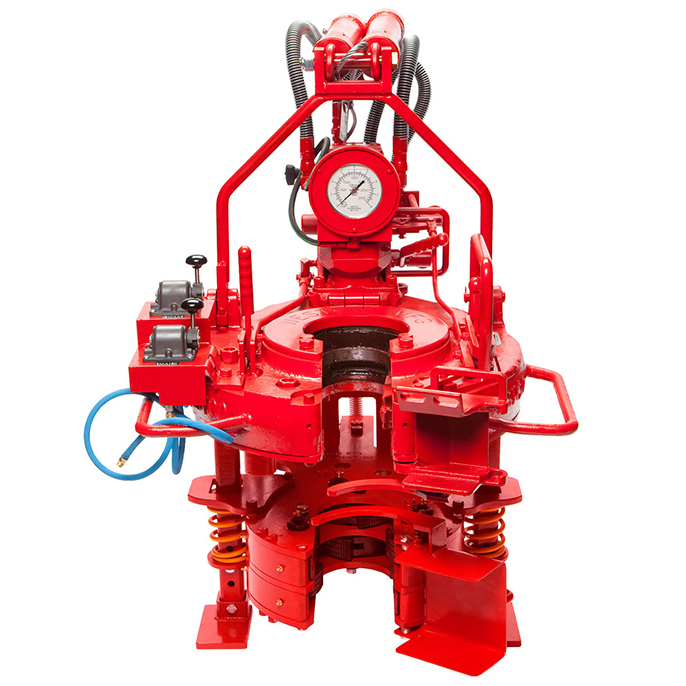

MOT"s Hydraulic Power Tongs are used for running or pulling tubular strings during well repair, workover, snubbing, drilling and casing operations to extract oil and gas from wells. MOT’s

Our TEDA Style power tongs apply correct, uniform torque, reducing costly rod and tubing failures, delivering ample power to make up and break out rods and tubulars from 5/8” rod to 5-1/2” casing. Our series of XQ power tongs come with Bi-Directional jaw systems that save time and enhance safety, and go from make to break with the flip of a knob.

Tongs offer a variety of upgrades from our standard XQ series of TEDA Style models featuring Eaton hydraulic motors for extra torque and reliability, two or three spool directional control valves for more efficient hydraulic operations, and modified structures for higher strength, durability and adaptability to specific job requirements.

Are available from 5-1/2” to 20” pipe and are able to handle both API Standard and PREMIUM (Proprietary Steel Grade) casing connections which require higher torque. Available in a variety of models with hydraulic back-up tongs optional: “KMA", “KHT”, “TQ", “KJD”, “KD” and SE 16-25 with torques ranging from 15,000 ft-lbs up to 55,000 ft-lbs.

With our years of manufacturing experience of bridging the gap between quality and service, customers and distributors, and performance and economy, Keystone understands the critical requirements of the oil and gas industry, from on-time delivery to competitive pricing and product availability.

By using the latest in 3D modeling for product design and by staying current with the rapid advances in manufacturing technology and quality-assurance standards, Keystone is able to manufacture and produce the most reliable products on the market today.

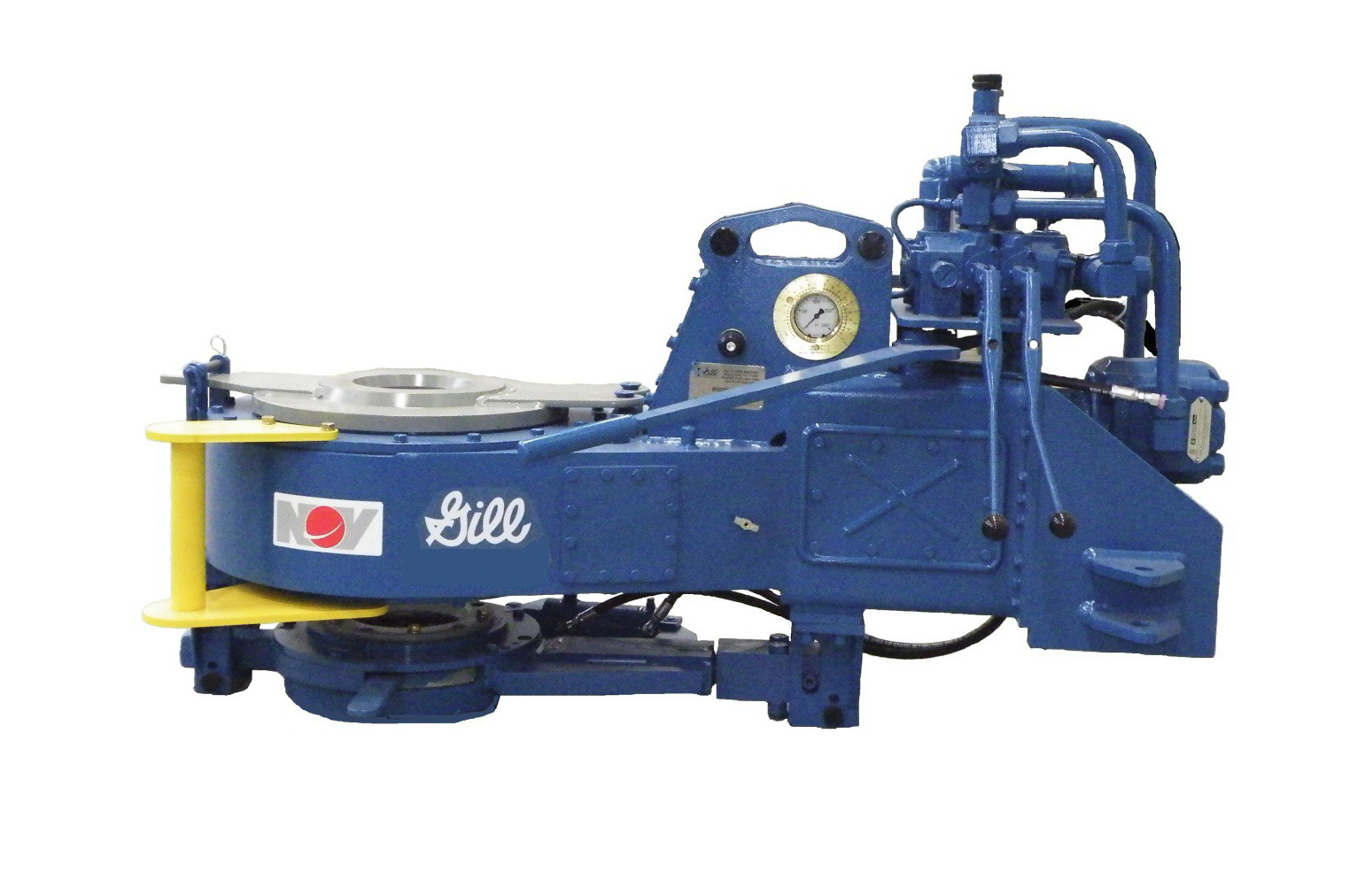

The 14-100 hydraulic power tong provides 100,000 ft-lb (135,600 N∙m) of torque capacity for running and pulling 7- to 14-in. casing. The tong has a unique gated rotary, a free-floating backup, and a hydraulic door interlock.

Our 14-50 high-torque casing tong provides 50,000 ft-lb (67,790 N∙m) of torque capacity for running and pulling 6 5/8- to 14-in. casing. The tong has a unique gated rotary, a free floating backup, and a hydraulic door interlock.

The 16-25 hydraulic casing tong provides 25,000 ft-lb (33,900 N∙m) of torque capacity for running and pulling 6 5/8- to 16-in. casing. The tong features a unique gated rotary and as many as seven contact points that create a positive grip without damaging the casing.

Rigged up without rig modifications, our 21-300 riser tong is the only tong capable of producing 300,000 ft-lb (406,746 N∙m) of continuous rotational torque in both makeup and breakout mode. The power it achieves in a compact size compares with a conventional 24-in. casing tong.

The 24-50 high-torque casing tong provides 50,000 ft-lb (67,790 N∙m) of torque capacity for running and pulling 10 3/4- to 24-in. casing. The tong features a unique gated rotary, a free-floating backup, and a hydraulic door interlock.

The 30-100 high-torque casing tong provides 100,000 ft-lb (135,600 N∙m) of torque capacity for running and pulling 16- to 30-in. casing. The tong features a unique gated rotary, a free-floating backup, and a hydraulic door interlock.

The 5.5-15 hydraulic tubing tong provides 15,000 ft-lb (20,340 N∙m) of torque capability for makeup and breakout of 1.66- to 5.5-in. tubing and premium or standard connections on corrosion‑resistant alloy tubulars. The tong features an ergonomic, lightweight design with a free-floating hydraulic backup.

The 7.6-30 hydraulic tubing tong provides 30,000 ft-lb (40,670 N∙m) of torque capability for makeup and breakout of 2 3/8- to 7 5/8-in. tubing and premium or standard connections on corrosion‑resistant alloy tubulars. The tong features an ergonomic, lightweight design with a free-floating hydraulic backup.

Our SpeedTork 8.0-70 tong provides torques up to 70,000 ft-lb (94,900 N∙m) and 360° rotation in makeup and breakout operations. It can torque drillpipe connections, drillstring components, drilling tools, packers, couplings, and valves.

For over 30 years Bourque Sales & Service has provided high-performance equipment to the oil and gas industry, suited to both workover and drilling applications on land-based and offshore rigs. As your one-stop shop for energy products and services, we specialize in Foster hydraulic power tongs, catheads, bucking units, Kelly spinners and more.

Progressive initiatives combined with extensive maintenance and new equipment purchase programs have ensured that BSS is at the forefront industry minds when the words reliability, durability and trustworthiness are spoken.

Our power tongs meet all industry standards and are engineered for the operational demands they will encounter during use. Use of these products will improve productivity by simplifying operations and ensuring a safer working environment.

We are extremely dependable and always available to meet your needs with 24/7 service and repair, ensuring your equipment is never at risk. Whether you are looking to purchase a new tong, service your existing one, or utilize a rental to keep your operations running, the BSS team of in-house specialists provide the highest-quality drilling and completion equipment as cost-efficiently as possible.

It’s a straightforward situation that most businesses have dealt with at one point or another: operations are halted due to equipment failure, and money is being lost by the hour. That is exactly why the BSS cathead exchange program was developed. Simply send in your Foster cathead for repair, and we’ll send a rebuilt one to your location to keep you running. It saves downtime on the jobsite therefore saving you money!

There are times when the best solution to tong troubles is to have a service technician go on location. That’s why BSS has a team of mechanics specially trained and available 24/7 to do repairs in the field. From the Gulf Coast to the Alaskan coast and beyond, our professional crew can have your equipment operational in no time at all.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

New & rebuilt oilfield equipment, including power tubing, casings & rod tongs & distributor of power slips/spiders & elevators, including repair services & rental of power tongs

A Field Service Supervisorwill monitor the makeup of accessories in the yard and ensure all connections are properly prepared for running in the field or to be stored. They will be sure that the makeup graphs meet the acceptance criteria of the pipe manufacturer. A Field Service Supervisor will also ensure the proper makeup torque is applied to each connection and that makeup graphs are acceptable.

Our Field Service Supervisors also make sure all completed assemblies have thread protectors re-installed prior to being loaded into the basket for shipment to the rig. If requested, our professionals will also supervise bolstering, loading and unloading of tubulars.

Our thread supervisors ensure the manufacturers specifications and API standards are being performed thus maximizing long term performance and preventing tubular damage.

Wolverine Group provides the best thread inspection processes in the industry. Not only are our field hands highly trained and experienced, they carry a great deal of pride in their work. Our thread supervisors, through our triple check process ensure the manufacturers specifications and API standards are being performed thus maximizing long term performance and preventing tubular damage.

ABE Corp, Calgary based mechanical repair shop, specializes in 24/7 emergency repairs at point of breakdown and mobile on-site repair done at your location.

Amos Machine & Manufacturing Ltd from Nisku, AB. Company specialized in: oilfield equipment repair. Please call us for more information - (780) 955-9383

Canadian Block Manufacturing Ltd. is a manufacturer of overhead lifting equipment. We specialize in building traveling blocks to the specification API 8C for oil drilling structures. We are Located in Edmonton, Alberta, Canada. We provide general machining and welding services a…

As one of the world’s leading specialty chemical companies, Clariant contributes to value creation with innovative and sustainable solutions for customers from many industries. Our focus areas include: Care Chemicals, Natural Resources, Catalysis & Energy and Plastics & Coatings.

Garfield Equipment Repair from Lloydminster, AB. Company specialized in: oilfield equipment repair. Please call us for more information - (780) 875-5167

Goldmark Diesel International Ltd. provides quality New, Rebuilt, and Refurbished diesel engines, generator sets, and generator ends. Specialize in Caterpillar, Cummins, and Detroit Diesel engines and stock a full line of replacement parts. Have an extensive inventory of oilfiel…

Since our inception in Edmonton, Alberta in 1983, GRB College of Welding has acquired a reputation for excellence that is reflected by our continued success and the success of our clients. GRB College of Welding is a private welding school, welder training facility as well as a …

Leon"S Heavy Equipment Ltd from Ft McMurray, AB. Company specialized in: oilfield equipment repair. Please call us for more information - (780) 715-0648

An experienced service rig/oilfield supply store & power tong repair shop that will ensure your rig & equipment are operating at their highest efficiency.

Revolution Equipment Manufacturing Inc from Leduc, AB. Company specialized in: oilfield equipment repair. Please call us for more information - (780) 980-9212

Werner Heavy Equipment Repair Ltd from Hinton, AB. Company specialized in: oilfield equipment repair. Please call us for more information - (780) 817-2271

Marshall Oilfield Services from Red Earth Creek, AB. Company specialized in: oilfield equipment repair. Please call us for more information - (780) 649-2644

8613371530291

8613371530291