power tong companies in alberta factory

Pathmaker is an expanding Tubular Running Service company developed Industry professionals with remarkable TRS experience and expertise. We are family owned and operated and have been proudly serving Alberta and British Columbia Industry for over 40 years.

Dash Energy Services Ltd. provides complete tubular services, integral and conventional power tongs, CRT"s, computer torque monitoring, thread washing, 12 GPS equipped units and more, all provided with professional, competent service.;Dash Energy Services Ltd. has been in busine…

An oilfield service company, Hybrid Energy Services relies on the latest technology to create accountability and reduce liability for its clients. They offer a wide range of services, including the following: computer-analyzed torque monitoring, wireless torque sub, electroni…

Drifters Casing Service is a local leader for drilling and completions work in Grande Prairie, Whitecourt, and other areas in Alberta. You can count on us to provide services 24 hours per day as required.

Tubular Optimization Services has always believed in providing exceptional global casing & tubing field running services while maintaining our customer"s invested tubular interests as our top priority. Specializing in premium connections, fiberglass lined, coated, chrome alloy a…

Universe Machine Corporation"s driving mission is to manufacture, modify or repair steel products for the oilfield, petrochemical and forestry industries. The company has been providing these services since 1965 and owes its success to a highly skilled workforce and a commitm…

At Ed"s Valve Servicing (Red Deer) Ltd., we"re known for quality workmanship. After 25 years of service in the Red Deer area, we understand that there"s no substitute for hard work and accuracy.

Ace Power Tongs & Energy Services serves Western Canada with computer torque monitoring, thread washing, CRT"s, integral and power tongs, GPS equipped units and more. Click our name to learn more about us.;Your choice for a complete tong, casing and tubing program is Ace Power …

When you need to put down or remove pipes for an oil drilling rig, trust Bitz Power Tongs Ltd. to handle the work. We have a variety of power tong trucks in Edson, Alberta, to meet the needs of your project. Our Canadian-owned and locally operated power tong and laydown unit com…

TriMark Tubular Ltd. delivers high-quality oil country tubular goods (OCTG) used for drilling and completions, plus gathering and transmission lines. We hold one of the largest inventories of OCTG and linepipe in Western Canada. TriMark provides complementary engineering experti…

Hill"s Power Tongs has provided Alberta with "First Class Tools All The Way - Any Time Night or Day", since 1975. Offering: Integral tongs and Computer torque monitoring We are certified: ISnetworld, ComplyWorks and COR. Offering 24 hour service. Please call or email.

Pro Torque Connection Technologies Ltd. offers a full line of casing running services: conventional and integral power tong equipment, Volant casing running tools, computer torque monitoring, casing crews, and thread supervision and inspection. We also offer top drive and iron r…

Universe Machine Corporation"s driving mission is to manufacture, modify or repair steel products for the oilfield, petrochemical and forestry industries. The company has been providing these services since 1965 and owes its success to a highly skilled workforce and a commitm…

At Ed"s Valve Servicing (Red Deer) Ltd., we"re known for quality workmanship. After 25 years of service in the Red Deer area, we understand that there"s no substitute for hard work and accuracy.

Pathmaker is an expanding Tubular Running Service company developed Industry professionals with remarkable TRS experience and expertise. We are family owned and operated and have been proudly serving Alberta and British Columbia Industry for over 40 years.

Dash Energy Services Ltd. provides complete tubular services, integral and conventional power tongs, CRT"s, computer torque monitoring, thread washing, 12 GPS equipped units and more, all provided with professional, competent service.;Dash Energy Services Ltd. has been in busine…

Ace Power Tongs & Energy Services serves Western Canada with computer torque monitoring, thread washing, CRT"s, integral and power tongs, GPS equipped units and more. Click our name to learn more about us.;Your choice for a complete tong, casing and tubing program is Ace Power …

When you need to put down or remove pipes for an oil drilling rig, trust Bitz Power Tongs Ltd. to handle the work. We have a variety of power tong trucks in Edson, Alberta, to meet the needs of your project. Our Canadian-owned and locally operated power tong and laydown unit com…

TriMark Tubular Ltd. delivers high-quality oil country tubular goods (OCTG) used for drilling and completions, plus gathering and transmission lines. We hold one of the largest inventories of OCTG and linepipe in Western Canada. TriMark provides complementary engineering experti…

Hill"s Power Tongs has provided Alberta with "First Class Tools All The Way - Any Time Night or Day", since 1975. Offering: Integral tongs and Computer torque monitoring We are certified: ISnetworld, ComplyWorks and COR. Offering 24 hour service. Please call or email.

Pro Torque Connection Technologies Ltd. offers a full line of casing running services: conventional and integral power tong equipment, Volant casing running tools, computer torque monitoring, casing crews, and thread supervision and inspection. We also offer top drive and iron r…

An oilfield service company, Hybrid Energy Services relies on the latest technology to create accountability and reduce liability for its clients. They offer a wide range of services, including the following: computer-analyzed torque monitoring, wireless torque sub, electroni…

Drifters Casing Service is a local leader for drilling and completions work in Grande Prairie, Whitecourt, and other areas in Alberta. You can count on us to provide services 24 hours per day as required.

In your work you rely on having suppliers who use the best equipment to complete your jobs. Among the most important pieces of equipment required for oil drilling and completions are power tongs. Drifters Casing Service is a local provider of power tongs services in Grande Prairie and Whitecourt areas with a reputation for expertise and reliability.

Eckel.Eckel is the one of the world’s leading power tong manufacturers. Each Eckel tong must pass a comprehensive compliance checklist so it’s ready to meet requirements in the field.

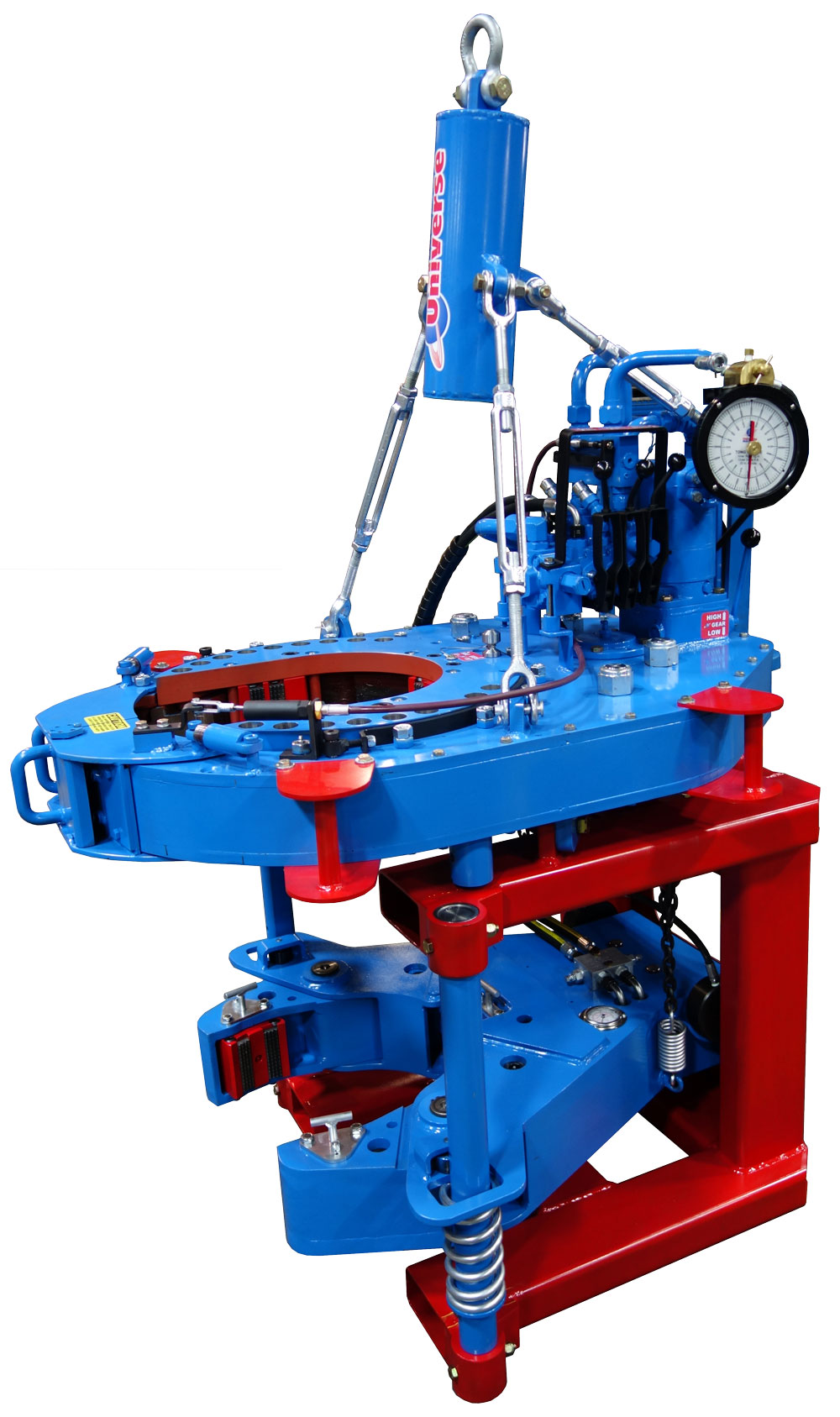

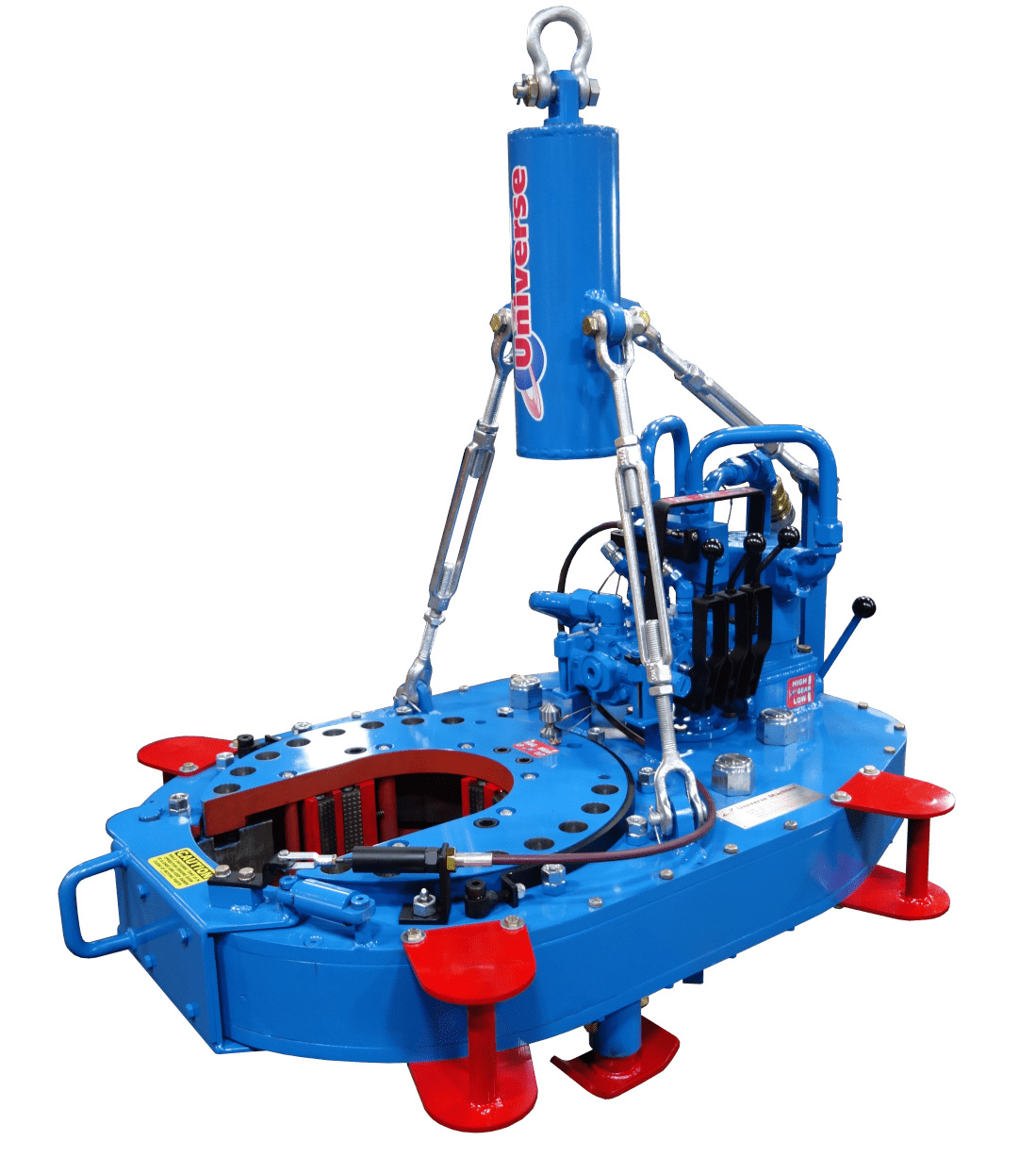

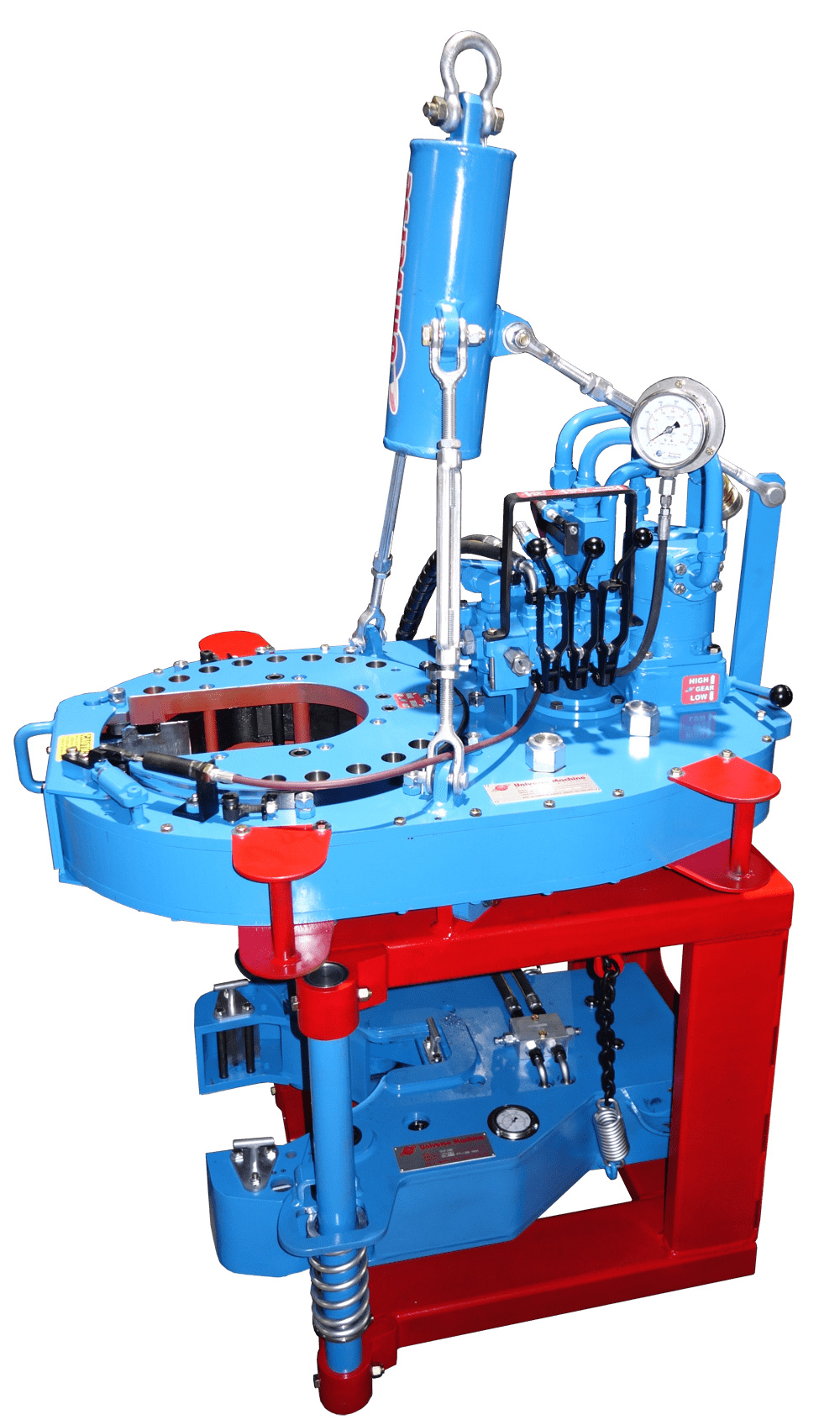

Universe. Since 1965, Universe Machine Corporation has supplied trustworthy steel products for the oilfield industry. Their quality standard system ensures that each power tong meets your application requirements.

We have many sizes of power tongs to fit the size of your pipe, from 2-3/8″ to 13- 3/8″. And our power tongs equipment offers a wide torque range to suit the job.

In addition to power tongs in Grande Prairie, we provide all other casing and tubing services you may need, including integral tubing tongs. You can also monitor your equipment with WinCatt Computer Torque Monitoring that we can provide and monitor on your behalf. All equipment can be used in drilling and completions work.

We’re your provider of oil field drilling and completions services that require power tongs and related oilfield equipment. Since 2000, our locally-owned and operated company has helped companies like yours get the work done right. Contact us for more information.

Edcon Power Tongs and Oilfield Services Ltd. is an Alberta owned company comprised of local, experience and committed individuals who work as a team to provide services to the oil and gas industry.

Our purpose shall be to consistently provide value added reliable services by performing the following for our customers; casing and tubular running with integral power tongs and Casing Running Tools, computer torque monitoring, thread washing and inspection services.

The foundation of our services’ capabilities is based on a total committed safety program. We will not compromise the safety of our employees or others for the sake of corporate and personal gain.

The owners and employees of Edcon Power Tongs and Oilfield Services Ltd will always operate with the highest of integrity and honesty. High values, personal service and ethics are the cornerstone of our company as we provide for our families and our community.

For over 30 years, Clarkes Power Tong Service andClarkes Oilfield Services has been providing tubular running services to the oil & gas industry. We specialize in casing and tubing work primarily in Alberta and Western Saskatchewan. With new ownership in 2005, Clarkes continues to build on that solid foundation with an equal amount of new strength and energy. Progressive initiatives combined with an extensive maintenance and new equipment purchase program have ensured that Clarkes is at the forefront of the industry. Whether conventional oil and gas, tight shale or SAGD programs, we have the experience and equipment to get it done right.

Not just power tongs� in addition to maintenance and new equipment purchases of power tongs, integral tongs, handling, circulating, and all of the equipment used in our traditional business of running tubulars, Clarkes provides a number of complimentary services that include: BOP Pressure Testing, Computer Torque Monitoring, Threadwashing and new in 2013...Volant Casing Running Tools �CRTi�s�. These mechanical CRTi�s have 4-1/2� to 20� OD capabilities and are utilized on ADR Super Single rigs to perform the complete job of running and pulling casing; and/or conventional top drive double and triple rigs to fill, circulate and push casing in combination with power tongs for making up the casing.

Our personnel, fully equipped power tong and pressure testing trucks and CRTi�s are located throughout Alberta and Western Saskatchewan. Temporary and permanent relocation based on the ideal place to be based from for a project, is always accommodated. All locations are dispatched through our Calgary office which is contacted 24 hours a day.

Whether we provide all of our available services or a single service in combination with other service providers, Clarkes Power Tong Service / Clarkes Oilfield Services is serious about doing it right and takes pride in providing safe, reliable and quality service to our valued customers!

(From left) Ron Feigel, business development, and Fred Aleksic, product development manager, show off the company’s flagship power tong equipment. Images: Universe Machine

In 1960 a then 18-year-old Kurt Feigel Sr. immigrated to Canada with plans only to stay for a year or two. To earn a living he capitalized on his skills, and in 1965 established Universe Machine Corp. with two other people within a 2,000-sq.-ft. building in the Edmonton area. What started out as a small machine shop with a plan to move on shifted, and Feigel Sr. grew both his business and his family in Canada for decades to come. To this day Universe Machine remains in the hands of the Feigel family.

From its humble beginnings, the shop has always focused on heavy industry, including oil and gas. Today the shop has expanded both its operations and services to include more than 200 employees during peak times, and a more than 100,000-sq.-ft. facility. In decades past depending on market conditions, the company has branched out from a singular focus to include three divisions.

General manufacturing was the shop’s strength. However, in the late 1980s Universe machine found itself focused on product development. The shop designed and engineered a high-quality line of power tongs—a machine used on drilling rigs to screw and unscrew tubing or casing to a specific torque. It was this development that really pushed the shop to branch out into this new area of opportunity. Today Universe Machine’s power tongs and other related products are sold globally.

The 1980s also saw another significant shift for the shop. The company expanded into valve servicing, specializing in the service, modification, and repair of valves for many industries. Universe Machine boasts that this valve service division has grown to be one of the largest of its kind in all of Canada.

Throughout all the changes and iterations, the company took on, it continues to remain a family-owned business. In 2014 Kurt Sr. passed the reins to his son Kurt Jr., who became president of the company. A third generation of Feigels, including Kurt Jr.’s sons, are helping to continue the family legacy.

“We’ve been really fortunate to see steady growth over all these years,” said Ron Feigel, business development, Universe Machine. “We’ve spent 57 years in business, and while we’ve had some low points and struggled with market conditions, we’ve always come through stronger. We’ve chosen a slow and steady path, unlike other operations that just grew too fast and are no longer around anymore. We’ve remained and continue to thrive.”

The shop has spent decades honing its skills and expertise, focusing on the three divisions that have helped it grow: manufacturing, valve services, and products development. In that time the shop has taken on many unique projects, including machining the first heart implant valve for the University of Alberta, designing valves used in the NASA launch facilities, and producing valves for pipelines throughout Canada.

The shop started out as a job shop with manual machining, drilling, and welding capabilities. These core competencies have continued to this day while expanding to include extensive CNC machining, grinding, heat treatment, laser cladding, and plasma cutting services. The diversity in equipment and services allows the company to take on a range of challenging projects.

“Having highly skilled and dedicated workers, stringent quality control standards, and large equipment capacities has really set us apart from the competition,” said Feigel. “Our largest CNC machines can handle 50-ton workpieces. Our large, high-quality machines allow us to regularly work on massive, complex components.”

Universe’s manufacturing division focuses on modifying or repairing some of the biggest and most unique components in Canada. Because of this the shop requires extremely large and diverse machining equipment, including CNC machining centers and lathes, horizontal and vertical boring mills, milling machines, drill presses, surface grinders and shapers. It also provides full in-house engineering support, and its certifications include ISO 9001:2015, APEGA, ABSA, and COR. Beyond machining, the manufacturing division also provides laser PTA heat treating and cladding, robotic and B-pressure welding, fabricating, and millwrighting services.

The company is an authorized repair and modification center for numerous valve manufacturers and is the only Canadian-based member of the Valve Repair Council. This division provides specialized services ranging from hydro-testing, and trim changes and extensions to full valve refurbishing back to OEM specifications. The shop specializes in valves ranging from ½ to 72 in. in diameter. For valve modifications the shop provides CRN numbers and certified processes accordingly.

And while much of the shop’s work focuses on oilfield products and servicing, the company has expanded to also include other heavy industries like mining and forestry. Universe products require extreme and rugged testing by staff to ensure they can withstand the harsh conditions found in these sectors.

There is much discussion surrounding the nation’s reliance on fossil fuels and the significant push towards renewable energy. However, many reports including the International Energy Outlook by the U.S. Energy Information Administration show that while renewable energy is the largest growing segment across North America, petroleum and natural gas are the most-consumed sources of energy. In essence, fossil fuels will continue to dominate for much of the next half century.

“If we are to ensure secure, reliable, and affordable energy for the world’s increasing population, it would be prudent to shape energy policy with this in mind,” said Feigel. “While Universe Machine does a lot of work for the oil and gas sector, we also have diversified into forestry, mining, and other heavy industry segments.”

However, the oil and gas sector has always been extremely volatile. Local and global conditions can have significant impact on manufacturers, and companies that survive the market’s ups and downs of the market often are those with grit, determination, and innovation.

“Leaders must maintain growth no matter what phase of boom or bust the industry is in,” said Feigel. “Global competition and remaining competitive is a challenge. But another challenge is right here in our own back yard. When our own federal government is not truly interested in efficiently utilizing our vast natural resources to help stabilize our economy, but instead creates roadblocks like increased taxes and changing rules for businesses, that is an even bigger problem. Investment dollars will flow elsewhere.”

“However, the opportunities, creativity, and satisfaction the energy industry provides, thankfully, still seems to outweigh the negatives,” said Feigel. “Our highly skilled staff take great pride and find it rewarding to design, manufacture, repair, or modify the many interesting, challenging, and complex components we work on.”

And while Feigel acknowledged the importance of improving energy efficiency, including the mindful utilization of renewable energy, a realistic, wise, and balanced long-term transition plan that takes risk, reward, cost, and benefit into equal consideration is necessary.

“We need provincial and federal governments to actually support our oil and gas industry in Alberta and across Canada,” said Feigel. “This approach has been proven to create stability, instill confidence, and spur investment, which creates more jobs and economic growth over the long term. Natural resource wealth should be utilized on a parallel platform, creating long-term diversification, energy efficiency, and sustainability without slowing growth or causing economic hardship.”

Universe Machine specializes in valves ranging from ½ to 72 in. in diameter. This extremely large 42 in. valve body can easily be machined on its equipment.

The constant flux of the oil and gas industry has forced Universe’s management to find new ways to generate revenue and keep business as steady as possible. Investing in training, apprenticeships, and improving employee skills are a few ways the shop has remained competitive.

“Investing and incorporating new technology and focusing on research and development during the pandemic has led to extensive testing and improvements of our existing products,” said Feigel. “We’ve engineered a new line of compact, high-torque power tong equipment, which is currently being introduced to market. We also added a Toshiba TUE-200(S) vertical lathe with live tooling. All of this investment, including retaining skilled, long-term employees, signals to our employees and customers that we can be trusted to continue moving forward, even during difficult times.”

Universe Machine has taken the difficulties and economic downturns in stride. Rather than letting these times bring them down, management has always focused on investing in strengthening employees’ skills and in new equipment and services. This mindset has allowed the company to weather tough times and take advantage of opportunities during economic upswings.

“It appears that industry confidence is slowly returning. Along with higher energy prices, this is driving a sustained improvement and more positive tone for our industry, but it’s not without its challenges,” said Feigel.

Today Universe Machine is moving forward in the best way possible. Kurt Sr., with his decades of experience and wisdom, does his best to pass on that knowledge to his children, grandchildren, and shop employees. Mentoring young people has always been his passion. You can still find him in the office teaching anyone interested in learning tricks of the trade.

“With wise and dedicated mentors like Kurt Sr., the future looks bright as we transition to the next generation,” said Feigel. “We are fortunate to have many intelligent, educated, and hard-working young people in the business. We are continuing to see improvements in the oil and gas sector and hope that this will continue through 2022 and into 2023. As a business, we are not just surviving but thriving and look forward to continuing this trend.”

Making and breaking threaded joints of tubulars used in oil and gas drilling and production is typically accomplished using a backup tong and a power tong.

Lateral and axial forces on the threaded joints imparted by the power tong or the backup tong may cause damage to them. The power tong system described here provides reduction of lateral and axial forces on the joints.

In a first power tong system, lateral forces on joints are reduced by providing the power tong with a guide system that constrains the power tong against movement.

There is thus provided according to an aspect of the invention, a power tong system, comprising a frame having a rear support and a front support, the front support comprising a first front leg and a second front leg; and a power tong mounted in the frame with the power tong extending transversely between the first front leg and the second front leg, the first front leg and the second front leg forming a guide preventing transverse motion of the power tong while allowing vertical movement of the power tong. The system is also preferably provided with a backup tong. The constraint is preferably provided by using a roller on the sides of the power tong, to prevent excessive wear on the power tong and reduce friction between the tong and the guide. Supporting the power tong in a guide with roller bearings reduces bending or shear forces, while providing accurate torque readings and improved thread connections.

In a second power tong system, a load cell assembly is provided in which a load cell is linked by a series of links to the power tong such that movement by the power tong in either of two transverse directions loads the load cell. Two ways of accomplishing this are also provided, though others are possible.

In a third power tong system, an improved backup tong is provided in which jaws, preferably symmetrically disposed on the backup tong and each carrying dies, are moved about pivots by a rigid link between the jaws and a linear actuator. The dies are preferably provided with more than one die seat for locating the dies at different positions on the jaws. This makes the power tong capable of biting casing and a coupling with the same jaws, thus eliminating the need to change jaw sizes, or using additional jaw sets. A third die may be provided, preferably symmetrically arranged with the dies on the jaws. The third die may be located on the linear actuator.

There will now be described preferred embodiments of the invention, with reference to the drawings, by way of illustration only and not with the intention of limiting the scope of the invention, in which like numerals denote like elements and in which:

FIG. 2 is a top plan view, partly in section, of backup tong for use in the power tong system of FIG. 1, showing two positions of the dies on the jaws, with the jaws open;

In this patent document, the word “comprising” is used in its non-limiting sense to mean that items following the word in the sentence are included and that items not specifically mentioned are not excluded. The use of the indefinite article “a” in the claims before an element means that one of the elements is specified, but does not specifically exclude others of the elements being present, unless the context clearly requires that there be one and only one of the elements. A rigid rod or link is a rod or link that can transmit forces in both directions along the rod or link. By contrast, a loose link is a link in which forces are transmitted in only one direction along the link, as in the case of a wire, chain or rope.

Referring to FIG. 1, a power tong system is shown with a frame 10, power tong 12 and backup tong 14. The frame 10 is formed of a pair of rear legs 16, 18 forming a rear support and front legs 20, 22 forming a front support. Conventional handles 19 are provided on the legs 16-22 for ease of handling. The rear legs 16, 18 are connected together by cross-members 24, and the front and rear legs are connected by cross-members 26. A further pair of cross-members 28 complete the frame 10 by connecting between the members 26. These legs and cross-members 16-28 are conveniently formed of square or rectangular irons welded together with suitable wedge reinforcements 30. The entire frame 10 is designed to be hung in conventional manner in operation on a rig by a chain (not shown) connected to the connector mechanism 32.

The power tong 12 is mounted in the frame 10 so that it extends transversely between the two front legs 20, 22. The power tong 12 is conventionally mounted by hanging with chains (not shown) connected to the hook attachments 34. The front legs 20, 22 form a guide preventing transverse motion of the power tong 12 while allowing vertical movement of the power tong 12. To accomplish the guide function, there must be clearance between the sides of the power tong 12 and the legs 20, 22, and the clearance cannot be so great that during operation of the power tong 12 in normal use the sides of the power tong 12 do not come into contact with the legs 20, 22, since it is the contact with the legs 20, 22 that creates the guide function. This is illustrated in FIGS. 5, 6, 7 and 10.

Conveniently, the power tong 12 is provided with stabilizers 36 mounted on either side of the power tong 12, with the stabilizers 36 providing the contact point between the legs 20, 22 and the sides of the power tong 12. The stabilizers 36 may be formed of a hard wearing roller 38 on a shaft 39 held between a pair of flanges 40 welded to the sides of the power tong 12. Although a semi-circular wedge could be used in place of the roller 38, it is preferred to use a roller since this reduces friction between the power tong 12 and the legs 20, 22, and thus helps reduce errors in readings on the load cell 44.

The operation of the torque stabilization system is illustrated in FIGS. 6, 7 and 10. As the ring gear 64 of the power tong 12 rotates to make up or break a threaded joint, either by clockwise movement (FIG. 6) or anti-clockwise (FIG. 7) movement, a lateral or transverse force F is imparted to the power tong 12 which tends to make the tong move laterally in the direction of the force F. In addition, the power tong 12 also tends to rotate about a central longitudinal axis as shown in FIG. 10. The legs 20, 22 prevent lateral motion of the power tong 12 beyond the amount of clearance between the stabilizers 36 and the legs 20, 22, and this has the effect of reducing the amount of rotation. For a power tong about three feet wide, the reduction of movement, with a typical amount of force for making up a threaded joint, is in the order of 87%, corresponding to a reduction of rotational movement at the stabilizers 36 from a total movement of about 2 inches to ¼ in.

Referring now to FIGS. 1, 8 and 9, the power tong system also preferably includes a load cell assembly 42 mounted between the rear legs 16 and 18. The load cell assembly 42 is formed of a load cell frame which is mounted between the rear legs 16 and 18 of the power tong frame and a load cell 44 linked by a series of links to the power tong 12 such that movement by the power tong 12 in either of two transverse directions (towards or away from the respective legs 16, 18) loads the load cell 44.

In one embodiment, shown in FIG. 8, the links comprise bars 48 and 54 pivotally mounted respectively on walls 66, 68 of the frame of cell assembly 42. The power tong 12 is connected by a link 50 which attaches to end 51 of the bar 48, and on the other side of the power tong 12 by a link 52 to an end 53 of the bar 54. Each of the links 50 and 52 should be loosely connected so that they only pull one way on the bars 48, 54. Thus, the links 50 and 52 may be made of chains or wires, which may pull on the ends 51, 53, but which cannot push on them. Other one way links of this type may be used such as rods with slots in them. A load cell end 55 of the bar 48 is coupled by link 46 (which may also be a one way link) to the load cell 44 and by link 47 to leg 18. Link 47 anchors the load cell 44. The power tong end 51 of the bar 48 is pivotally connected by a rigid rod 56 to the end 55 of the bar 54.

The load cell assembly of FIG. 8 operates as follows. Upon movement of the power tong 12 towards leg 18, link 50 pulls on bar 48, without pushing on bar 54. Bar 48 rotates about its pivot and loads the load cell 44 through link 46. Upon movement of the power tong 12 towards leg 16, link 52 pulls on bar 54, without pushing on bar 48. Bar 54 rotates about its pivot and cross-link 56 pulls on bar 48, which rotates on its pivot to load the load cell 44 through link 46.

An alternative embodiment of load cell assembly is shown in FIG. 9. In this case, load cell ends 55 and 60 of both the bars 48 and 54 respectively are coupled to the load cell 44 by links 46 and 58 respectively. In addition, cross-link 56 is removed. Stops 61 and 62 limit rotation of the bars 54 and 48 respectively. The embodiment of FIG. 9 works as follows. Upon movement of the power tong 12 towards leg 18, link 50 pulls on bar 48, without pushing on bar 54. Bar 48 rotates about its pivot and loads the load cell 44 through link 46. The link 58 forms an anchor for the load cell 44 since rotation of bar 54 in this instance is prevented by stop 61. Upon movement of the power tong 12 towards leg 16, link 52 pulls on bar 54, without pushing on bar 48. Bar 54 rotates about its pivot to load the load cell 44 through link 58. The link 46 forms an anchor for the load cell 44 since rotation of bar 48 in this instance is prevented by stop 62.

The power tong system also provides an improved backup tong 14. The backup tong 14 are mounted on the frame 10 by conventional manner, as by bolts, to the cross-members 24 and 28. Referring to FIGS. 2-4, the backup tong may be formed of an upper mounting plate 70 and a lower mounting plate 72 connected together in conventional manner to form a housing. Each of the upper mounting plate 70 and lower mounting plate 72 have a bight defining a throat 74 for receiving a tubular 73 (FIG. 10). The upper mounting plate 70 is spaced from the lower mounting plate 72 with the bights aligned.

A jaw 76 is pivotally mounted on a pivot 78 between the upper mounting plate 70 and the lower mounting plate 72 on one side of the throat 74 for pivotal movement about an axis perpendicular to the upper and lower mounting plates 70, 72. Another jaw 80 is pivotally mounted on a pivot 82 between the upper mounting plate 70 and the lower mounting plate 72 on the other side of the throat 74 for pivotal movement about an axis perpendicular to the upper and lower mounting plates 70, 72.

Each jaw 76, 80 includes a die end 84, 86 respectively, on which die carriers 88 carrying dies 89 are mounted. Each jaw 76, 80 also has a link end 90, 92 respectively, the die ends 84, 86 and the link ends 90, 92 being on opposed sides of the respective pivots 78, 82.

A linear actuator 94 is mounted on the housing to actuate the jaws 76, 80. The linear actuator 94 may be a hydraulic actuator, many of which are known in the art, with fixed piston 106 inside movable cylinder 108. A rigid link 96 is pivotally connected to the link end 90 of the jaw 76 and is pivotally connected at pivot 100 to a head 103 on the cylinder 108 of the linear actuator 94. A rigid link 102 is pivotally connected to the link end 92 of the jaw 80 and is pivotally connected to the head 103 on the cylinder 108 of the linear actuator by pivot 104.

Two die carrier seats are preferably provided on each jaw 76, 80. Both die positions are shown in FIG. 2. In FIG. 3, a die position is shown for a tubular of nominal diameter. The die carrier seat is defined by holes in the jaws that receive pins 110. In FIG. 4, a die position is shown for a tubular of nominal plus 1 inch diameter. The die position is further inward in the throat 74 of the housing, and is defined by holes in the jaws that receive pins 112. Further die carrier seats, also in different positions, may also be provided. Several dies may also be used at the same time on each jaw, so as to provide wrap-around dies.

A further die carrier 114 carrying dies 115 is mounted on a side of the throat 74 opposed to both the die carriers 88. This die carrier 114 may be mounted on the housing adjacent the linear actuator 94 or may be mounted on the linear actuator 94 as shown and the dies 115 brought into contact with a tubular when the linear actuator 94 pushes on the jaws 76, 80 to close them. A conventional hydraulic power supply is provided for the hydraulic actuator. Preferably, the hydraulic actuator 94 is aligned with the throat 74 (the longitudinal axis of the actuator passes through the center line of the throat 74), and the die carriers 88 disposed symmetrically on either side of the throat 74 so that the die carriers 76, 80 and 114 are approximately separated by 120° of arc.

Any of various conventional load cells may be used for the load cell. Also, any of various conventional power tongs may be used for the power tong, such as the power tong made by Universe Machine Corporation of Edmonton, Alberta, Canada.

A person skilled in the art could make immaterial modifications to the invention described in this patent document without departing from the essence of the invention that is intended to be covered by the scope of the claims that follow.

Industry & Engineering in Red earth creek, Alberta is all about choices - it is the engineering discipline that offers the most wide-ranging array of opportunities, and it is distinguished by its flexibility. Industry & Engineering involve disciplines that are devoted to the design, installation, improvement and control of integrated systems of people, materials and facilities in a wide range of organizations that produce goods or render services. Industry is the production of a good or service within an economy. It can include disciplines and products like building fixtures, anchor bolts, contingency operations or other services like management engineering, energy & chemicals. Industry & Engineering is also the creative application of scientific principles to design or develop structures, machines, apparatus, or manufacturing processes, its underlying concepts overlap considerably with certain business-oriented disciplines such as operations management.

There are 2715 different subcategories in the Industry & Engineering category here at Find-Us-here.com, like Plastics - Toolmakers & Engineers, Baling Equipment & Supls-Manufacturers, Gasket Cutting Equipment (Manufacturers), Cables - Manufacture. Wholesale. Retail. Installation. Maintenance, Shot Blasting & Sand Blasting - Services, Equipment and many more. Ray"s Power Tongs Ltd is an expert based at Red earth creek, Alberta, T0G1X0 where they specialize in Oil and Gas Extraction. When you need a professional in this field, be sure to give the experts at Find-Us-Here.com a try. With a whole breadth of experience in all sorts of Industry & Engineering disciplines our many listed businesses can fulfil all your needs, no matter how complex. If you specifically need Oil and Gas Extraction skills in Red earth creek you"ll find them here at Ray"s Power Tongs Ltd - a well-established business that can provide you with all your Oil and Gas Extraction needs. So don"t hesitate to contact Ray"s Power Tongs Ltd today on 7806493744 no matter what your Oil and Gas Extraction requirements.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

You’re the one with the power – the power tongs, that is. You control the equipment that threads sections of drill casing to form the pipe that is placed hundreds of metres into the ground. When you arrive at site, the rig crew knows it’s time to get to work. Your strength and dexterity serve you well in this occupation.

Power tong operators control the equipment that threads sections of drill casing into the wellbore. As a member of the oilfield well services team, they are responsible for operating power tongs, torque measuring equipment and tube/casing handling equipment at the well site. Casing is required to maintain an oil or gas well’s structural integrity, prevent the cross-contamination of water with other fluids and control well pressure during the drilling, production and maintenance of the well. Power tong operators must be able to transport equipment to and from the well location, safely rig in and operate the equipment, perform day-to-day inspections, servicing and maintenance of equipment, and complete all required paperwork accurately and on time.

A2: We will have our engineers teach you how to operate it,you can just inform us some details of the product you need then we can customize as your special order.

A3: We has been regard quality as the priority. We always attach great importance to quality controlling from the very beginning to the very end ,so our press can match all the CE and ISO standard also more strict standard .

A4: Generally, it will take 35 working days after receiving your deposit payment. The specific delivery time depends on the items and the quantity of your order. Sometimes we have standard machines in stock.

A5: We can supply 1 year warranty for our machines, We can send engineer to customer place if big quality problem. We can provide internet or calling service at any time.

2. Personnel training: Our engineers will give your employees free machine training when they come to your company to assemble the machines, and welcome to our factory to learn how to operate our machineQ1. How to get an accurate quotation?.

8613371530291

8613371530291