power tong hand quotation

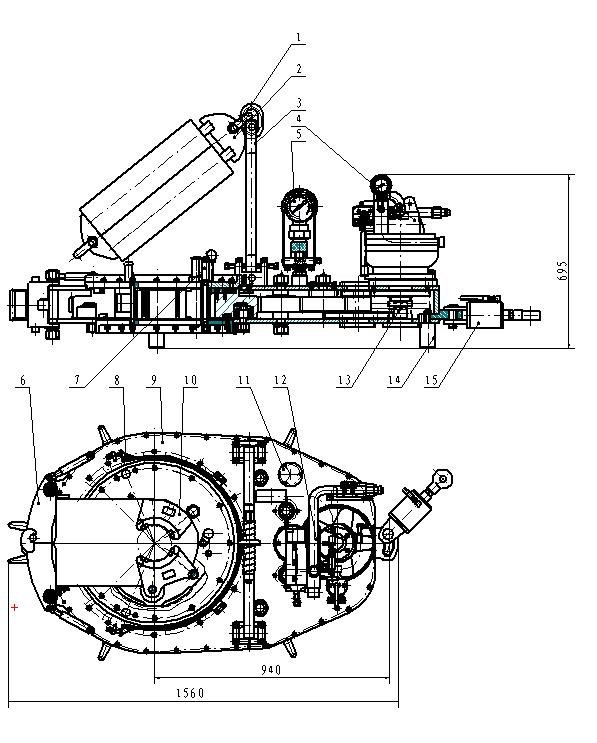

Model XQ28/2.6 hydraulic power tong is an improved type of XYQ1.8 which is used to make up and break out sucker rod thread in Well Service. This product has the following features:

A. The structure is compact, concise and light. Master tong is driven by a low-speed large torque hydraulic motor that matches with a manual control valve. The backup tong is just like a spanner. The total weight is approximately equal to XYQ1.8.

B. The operating is briefness and convenience with high efficiency. Put the respondence size jaw set into master tong and the respondence size glutting into backup tong, turning the reset knob incorrect direction then can make up and break out sucker rod by operating manual control valve. Two speed, snapping at low speed, spinning at high speed.

The KT13625 casing tong can handle tubulars as small as 3-1/2″ and as large as 13-5/8″ in diameter. Wraparound jaw and die technology for the two tong jaws is available. Tong can be mounted on either a CLINCHER® or a FARR hydraulic backup. Available with McCoy’s patented WinCatt® data acquisition and torque control system for the make-up of tubular connections.

Straight Tong Die Driver: Used for die slot redressing, the straight tong die driver is the simplest of type of rig tong. Though it is also the simplest type of rig tong to use, it is also the least safe of the three. Its handle and handguard protect hammer blows from falling onto the grip. Straight tong die drivers are lightweight—under eight pounds—and measure in at around 1”.

Angled Tong Die Driver: The angled tong die driver has a grip that’s angled away from the perpendicular tong as well as brass guards for the tong tip and handle, making this rig tong safer than the straight tong die driver. While this tong is safer, however, it’s actually harder to keep the angle tong die driver in place. This driver is similar in length to the straight tong die driver, but is about two pounds heavier, weighing in at over nine pounds.

Hammerless Tong Die Driver: This variety of tong die driver is made up of a hand pipe that can be used to apply pressure to the tong’s tip without using a hammer at all. This option is the safest of the three driver types because there’s no hammer required, it’s also the slowest driver for this same reason. The hammerless tong die driver is about as long and weighs as much as the straight tong die driver.

What oilfield tools does your operation need? Keystone Energy Tools has atool to fit your bill.Contact us today to learn more about how rig tongs can make your work environment safer, and to learn more our other oil and gas industry products.

These gauges (CTT101 Series) display the amount of torque in foot pounds per joint when using power tongs to run oilfield tubular. They are available for all makes and models of power tongs and even dual scale variations are available. The systems come with either compression or tension-type load cells, which provide precision checks of make up torque for all oilfield tubular.

The CTT100 Series Tong Line Pull Systems are available from 10,000 to 30,000 single line pull for use in all torquing applications. The universal tong line pull system can be used with a veriety of tong systems and can be moved from rig to rig as needed. When you need a gauge to work in most of your tong applications with a variety of tong handle lenghts, you can trust taht the CTT100 series will provide the best measurement you can get.

Tong Line Pull Gauges and Tong Torque Gauges both tell the operator the amount of torque being applied to oilfield tongs; however, they perform this necessary task differently. Although they both measure the force applied to the pipe in make up and break out situations, how they measure this force is what makes these two gauges different. Knowing which tong gaugewill work best for your application and employees is all important in selecting a tong gauge.

The biggest difference between these two gauges is how and what they measure. A tong line pull gauge measures true force (force/pounds), so what you see on the gauge is exactly what’s being applied to the pipe. Basically, it’s the what-you-see-is-what-you-get gauge. A tong torque gauge, on the other hand, measures the force that is being applied to the load cell and reads this force in foot/pounds. A more detailed explanation of both gauges follows.

A tong line pull gauge is universal. As long as the tong is a manual tong, a tong line pull gauge will fit on any hydraulic tong system. No matter what the tong’s handle length, a tong line pull gauge will measure force/pounds. The advantage to these gauges is that because they are universal, they can be used on any manual tong system. For example, you have two tongs, one with a 48 inch handle, and one with a 36 inch handle. You can use a tong line pull gauge with each tong, either the 48 inch handle or 36 inch handle, and measure the force pounds being applied to the drill pipe. Having this gauge on hand can be very useful when you have to move from different manual tong systems with different handle lengths. These systems, consisting of gauge, hose, and load cell, are great for the driller who wants to measure force/pounds on a variety of manual tongs.

Handle lengths are measured from the center of the tong to the end of the handle. If this measurement is in inches, it will need to be converted to feet in order to find max torque.

Once you have the max torque needed and the handle length in feet, you can complete the formula. The example below shows the formula in action. If you want to measure the maximum torque of 18,000 foot/pounds and you have a handle length of 34 inches, the calculations will look like this:

In this instance, when trying to determine foot/pounds and the reading he needs on the gauge, the driller will need to multiply 2.83 by the reading on the gauge (in this instance 6360.42) to make sure he’s reaching the torque required. Alternately, the drilling can use the maximum torque required, divide it by the handle length to determine what the optimal reading will be.

Tong torque gauges can be used on manual tongs or power tongs, but the handle length must never change because these gauges are not universal. A tong torque gauge is calibrated to a specific tong handle length and thus reads in foot/pounds instead of force/pounds. The advantage to the gauge readings being foot/pounds is that the driller does not have to convert the gauge measurement in order to know the foot pounds being imposed on the drill string. By doing the math beforehand, the driller will avoid any miscalculations that could cause possible twistoffs. The calculations are completed when the system is calibrated, taking the worry out of the driller’s hands and making the measurement of torque easier in the field. These systems, consisting of gauge, hose, and load cell, are great for the driller who wants to measure foot pounds without calculations in the field.

A wide variety of power tong tools options are available to you, You can also choose from electric drill, sander power tong tools,As well as from 3 years, {2}, and {3}. And whether power tong tools is ul, {2}, or {3}.

Find parts you need to repair or maintain your machines. At Alibaba.com, you can shop for power tongs used at affordable rates to tackle new obstacles and challenges. In the ever-changing industry, you can find what you need and speak to the supplier directly. Thanks to Alibaba’s collection of wholesale power tongs used you also get to buy these parts at lower prices, which means you can explore new levels every day more comfortably. From bulldozers to dragline excavators, wheel tractor scrapers to shotcrete machines, any part you need for a heavy-duty mining machinery; you can find it at Alibaba.com.

Looking for purpose-built machine parts? Find them at Alibaba.com. From new components to used parts straight from the manufacturers. Plus, if you need custom-made pieces, you can chat with the supplier, give specifications and wait on delivery. From stone crushers to excavator undercarriage parts, buckets, and even drill bits to get you through the rocks, the power tongs used from Alibaba offers you the chance to continue operating without a hitch. Whether you are looking to introduce concrete into the rock walls for more consistency and safety during mining, then power tongs used that goes at wholesale prices at Alibaba will be an excellent addition to your machinery.

Before buying a component, you’d want the equipment to suit your application and offer value. The list of power tongs used at Alibaba.com lets you dig into earth deposits, and the compare tool checks out other similar parts to give you the information you need to make a purchasing decision. You’ll get wholesale power tongs used that specializes in mining, with reinforced chassis, and run on more powerful engines. Whether you want to transport minerals or the workers to the mining site, introduce explosives or arms to help you remove materials from your mine pits, Alibaba.com has it all.

Tubing tongs may have a simple design compared to other types of drilling equipment, but don’t let that fool you—they are powerful and essential tools that provide critical support to drilling operations on a daily basis. important

Essentially, tubing tongs provide stability and allow workers to better handle tubular components. All drilling operations should be equipped with specialized tubing tongs appropriate for the size of equipment and scope of the work onsite.

While the tools are functionally identical, drilling sites typically have designated tongs for makeup and breakout. Makeup tongs are used to tighten joints and components of the drill string to keep them secure once they are active. Breakout tongs, on the other hand, are used for loosening operations when pieces or components need to be unscrewed or detached from the string.

Tongs look and function much like ordinary wrenches, although there are several design considerations to account for the extreme forces involved such as:

Just like opposing wrenches, tubing tongs are used in pairs when handling tubing or other drilling components. The “lead tongs” are connected directly to the derrick, while the second set is handled separately. The two tongs work together to provide enough

When it comes to tongs or wrenches, torque is the most important measurement to keep in mind. Tongs used in drilling operations are typically rated for a certain amount of torque, which is the rotational force required to turn an object about its longitudinal axis. From a mathematical perspective, torque is calculated by multiplying applied force by the length of the tong’s handle. This means that force applied at the end of the handle is magnified at the eye, so the people or equipment applying the force expend less energy to accomplish the same task.

Tongs are essentially levers that magnify applied force when generating torque, which greatly reduces the force needed to perform the operation. This improves efficiency by cutting down on power costs, as well as reducing the strain placed on the derrick’s infrastructure. Tongs also make the entire work environment safer by helping workers reliably stabilize and handle the equipment, making basic drilling processes more consistent and controllable.

The most important qualities of tubing tongs are strength, reliability, and usability. The best designs attempt to address all three of these needs by balancing them according to operators’ needs. Just like many other drilling tools, tongs should only be used for approved torque levels and functions. Operators should also monitor their tongs regularly to ensure they are properly maintained and in good repair before use.

We offer a full range of high quality casing and tubing, drill pipe tongs for use in all types of oil and gas drilling, well completion and well servicing activities. Our tongs have been engineered for the high operational torques today"s that premium connections require. Eckel tongs continue to advance the technology of tool service and setting industry standards.

Our proprietary True Grit® have set NEW industry standards in handling Corrosion Resistant Allows (CRA) tubular goods. True Grit® are used on chrome tubulars where reduced die penetration and die marking is desired. TRUE GRIT® dies are long lasting 3 times longer than competing technologies and perform better than any steel tooth die when running (SUPER or HYPER) Chrome. Tubular penetration of the True Grit® is less than half of API allowable surface defect area.

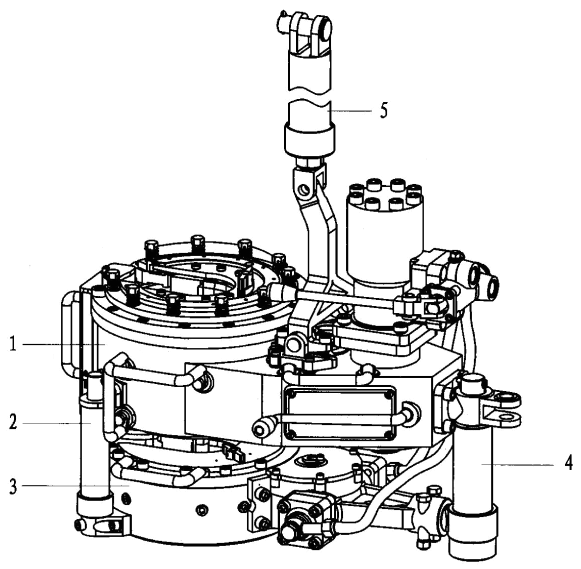

Our renowned free floating Tri-Grip®hydraulic backup provides unparalleled backup performance and is one of the industry"s closest tong mounting backups that minimize pipe bending. The backup utilizes three biting surfaces to insure a secure grip on the tubular to prevent tubular rotation.

Our remotely operated tongs provides a mean to control the tong for make-up and break-out operations. The tong is based upon the standard tong and backup configuration with the exception of hydraulic cylinders on the unit for remote control of the operations of the tong and backup. The functions include the tong door, backing pin, mechanical gear shift, power tong rotation, motor speed and backup gripping. Totally hydraulic with no electrical or electronic devices.

Eckel"s standard diesel or electric power packages at 65 GPM and 2,500 psi (246 LPM / 172 bar) are widely recognized for dependability and long, trouble-free service. Eckel will customize hydraulic power systems in the shortest possible time to meet "nonstandard" requirements for space, fluid flow, auxiliary power, and portability. Diesel driven units are optionally supplied with automatic shutdown systems to prevent engine run away when explosive gases are present. Additional shut downs include engine oil temperature, oil pressure, and fan belt breakage. All controls are either air, mechanical or electrical.

Our trained specialists are on hand in all areas of Russia for technical support during the commissioning of new equipment and when technical issues arise with running and handling of our products.

The present invention relates to open-head power tongs used in drilling operations, and more particularly, is directed to an improved means of actuating and deactuating the operation of the power tong drive means in response to the opened and closed positions of an access door.

As well known in the drilling industry, power tongs are employed in making-up and breaking-out operations of casings, tubings, rods, pipes and the like. More particularly, power tongs are used to grip and rotate lengths of drill pipe or the like to connect or join several lengths of pipe together to thereby form a drill string in a make-up operation, and in the alternative, to grip and rotate a length of drill pipe to disconnect it from the drill string in a break-out operation.

One type of power tong commonly used today is the open-head tong, such as the one shown and described in U.S. Pat. No. 4,060,014. The open-head tong has a bifrucated frame defining a central opening and a side opening communicating with the central opening for the passing therethrough of a drill pipe or the like. Due to the extreme costs of drilling, open-head tongs have become very popular, in that, they can easily and readily be moved into and out of an operative position when they are needed in the making up and breaking out of drill strings.

In operation, the open-head power tong exerts large rotational torques on the drill pipes, usually the larger the tong, the larger the torque output. Due to these large torque outputs and the resulting forces generated therefrom, the open-head tongs have been provided with an access door that bridges the gap between the bifrucated ends of the tong. The primary purpose of such an access door is to strengthen the tong structure so as to prevent, during the operation of the tong, the bifrucated ends from separating or springing apart, which not only results in damage to the tong, but could also inflict injury to the operating personnel. The access door, in addition to providing structural rigidity to the tong, also provides the operator with safety in bodily protecting him from the rotating pipe gripping and engaging jaws.

Such access doors perform very satisfactorily in providing structural rigidity to the tong and do provide protection to the operators from the rotating components of the tong when the door is properly latched in position during the make-up and break-out operations; however, in an effort to save time, operators have been known to operate the tong with the access door open, and in some instances, the operators have even removed the access door from the tong. Such operator"s carelessness not only causes costly structural damage to the tong, but also results in personal injury to the operator.

In U.S. Pat. No. 2,705,614 there is shown an open-head power tong having an automatic hydraulically powered access door, operably interconnected to the hydraulic cylinders that actuate the jaw gripping mechanism, which must be closed before the jaws can be actuated so as to rotate a drill pipe. Such door interlock mechanism has been specifically designed for the type of tong disclosed and is not readily adaptable to other types of power tongs, such as the one shown in the above-mentioned U.S. Pat. No. 4,060,014. Further, the hydraulic circuitry that is involved with such a powered access door is not only complicated, having expensive components, but is also, costly to maintain and repair. Still further, such door interlock mechanism does not provide adequate safety to an operator, in that, although the operator is protected from the pipe gripping and engaging mechanism when the door is closed, he is also subjected to the risk of having the power operated door being automatically swung into him as it is being closed, thus, creating a potentially dangerous and unsafe condition under which the operator must work.

The present invention obviates the problems experienced with access doors and disadvantages associated with the prior art door-interlock mechanisms by providing, as one of its principle objects, an improved door-interlock mechanism for an open-head power tong that ensures the access door is in a closed position before the tong can be operated, thereby preventing possible structural damage to the tong from operating the tong with the door open, as well as, preventing personal injury to the operators by protecting them from the various rotating components of the tong.

Another object of the present invention is to provide a door-interlock mechanism for an open-head power tong that is simple in structure and adaptable to all types of open-head power tongs.

Accordingly, the present invention, sets forth in an open-head power tong having an access door mounted on the tong and moveable between opened and closed positions, an improved door-interlock mechanism that includes means for controlling the operation of the tong in response to the opened and closed position of the door. More particularly, the control means preferably includes a pneumatic contact valve interconnected with a pneumatically piloted diverter valve operably associated with the power means of the tong such that the power means is placed in either an operative or inoperative condition in response to respective closed and opened positions of the door. Specifically, the pneumatic contact valve is so positioned in the vicinity of the side opening that the door, in its closed position, engages the contact valve thereby actuating the diverter valve to permit operation of the power means, and when, the door is moved from its closed position out of engagement with the contact valve, the contact valve causes the diverter valve to deactuate the power means, thus stopping the operation thereof.

FIG. 1 is a top plan view of an open-head power tong incorporating the improved door-interlock mechanism of the present invention with the access door being in its closed position in engagement with the contact valve which actuates the diverter valve.

FIG. 2 is a diagrammatic fragmentary view of the power tong showing the side edge portion of the access door with the door latch removed and with the contact valve being in disengagement with the door which is partly open.

Referring to the drawings, and particularly, to FIG. 1, there is shown, for illustration purposes only, an open-head power tong, being generally indicated by the numeral 10, incorporating the principles of the present invention. The tong illustrated in FIG. 1 is of the type shown and described in U.S. Pat. No. 4,060,014, and thus, for the sake of brevity, since the tong itself forms no part of this invention, only a brief description of the tong will follow.

Briefly, as best seen in FIG. 1, the power tong 10 is comprised of a bifrucated frame structure 12 defining a central drill pipe receiving opening, and a side opening that communicates to the central opening for laterally passing a drill pipe therewithin. Rotatably supported within the frame structure 12 is a pipe engaging and gripping means that includes jaws 14 that swing into and out of the central opening for gripping and rotating a drill pipe disposed within the central opening during make-up and break-out operations of a drill string. The pipe engaging and gripping means with its associated jaws 14 are rotatably driven through a suitable drive train (not shown) by power means such as the hydraulic motor 16 which receives fluid under pressure from a suitable hydraulic pump (not shown) and through a hydraulic control valve 17. The valve 17 is conventional, being moveable between three spool positions; one position being such that the fluid drives the motor in a forward clockwise direction, another position being such that the hydraulic fluid drives the motor in a reverse counterclockwise direction, and the third position being a neutral position wherein fluid passes through the valve to the return line that returns the fluid to a reservoir (not shown) for recirculation thereof.

Also supported on the frame structure 12 is an access door 18, adapted to span or bridge the access opening defined between the bifrucated end portions so as to provide structural rigidity to the power tong 10, as well as, to protect the operator from the various moving components, such as the jaws 14. One end of the access door 18 is hinged to an end of one of the frame bifrucations by a pivot pin 20 whereas the free end of the door is provided with a self-latching arm 22 that engages a latch member 24 mounted on the other bifrucation so as to positively latch the door when it is closed. The door and the door latching mechanism are of the type shown and described in a pending U.S. application, bearing U.S. Ser. No. 791,752; filed Apr. 28, 1977; and entitled TONG LOCKING MECHANISM. The door and the latching mechanism forms no part of this invention and thus a further description will not be given.

To ensure that the tong 10 is only operated when the door 18 is closed, closing the access opening, the tong 10 is provided with an interlock mechanism which basically includes a contact valve 26, engageable by the door 18, and a hydraulic diverter valve 28, operably associated with the hydraulic motor 16 so as to permit flow of hydraulic fluid to the motor, or, in the alternative position, to bypass the flow of hydraulic fluid around the motor.

Now turning to FIG. 3 which schematically represents the various operating components as well as the hydraulic and pneumatic circuitry associated therewith, the operation of the door interlock will be further described. First, it should be noted that both the hydraulic source and the pneumatic source are fully operating with respective fluids being under pressure in inlet lines, the access door 18 being closed, engaged with the actuating arm of the contact valve 26, the piloted diverter valve 28 being detented so as to pass the flow of hydraulic fluid around the motor 16, and with the hydraulic spool control valve 17 being in its neutral position such that fluid passes directly therethrough to the reservoir tank via inlet line 34, passageway 36, return line 38. Thus, as the spool valve 17 is shifted to its forward drive position, hydraulic fluid passes from the inlet line 34, through passageway 40, to line 42, through passageway 44 (of diverter valve 28), to line 46 which directs fluid into the left-hand side of the motor 16, and then via lines 48,49 to passageway 50 of valve 18 which is internally connected to the hydraulic return line 38. If the spool valve 17 is shifted in an opposite direction so as to reverse the direction of the motor 16, fluid flows via line 34, through passageway 52 to line 49 and line 48 to the right side of the motor 16, and then returns via lines 46, passageway 44, line 42 to passageway 54 which is internally connected to return line 38. It can be thus seen that when pressure is applied on the diverter valve 28, it is so positioned to pass hydraulic fluid either to one or the other sides of the motor 16 to thereby drive the rotating components of the tong 10 in either forward or reverse directions depending on the forward or reverse positions of the control valve 17. However, when the pneumatic pressure is relieved from the diverter valve 28, the internal spring forces the valve to the right, thus changing the flow path of the hydraulic fluid so as to bypass the motor 16. In such pressure relief position of the diverter valve 28, the fluid flow path is via lines 49,58, passageway 56 and line 42, thereby bypassing the flow of fluid to the motor 16. Since the flow of fluid through line 46 is blocked, no fluid passes to the motor 16, thus rendering it inoperative.

It can be understood from the foregoing that the described interlock-mechanism controls the operation of the hydraulic motor 16, and thus the operation of the tong 10, in response to the open and closed positions of the access door 18, such that the tong 10 can only be operated with the access door 18 in its closed position, and thereby eliminating the possibility of structural damage to the tong from operating same with the door open, as well as, providing safety to the operator from exposure to the various operating components of the tong.

Falls from 100 feet or more are not uncommon on oil rigs, and that is why fall protection equipment is so important, especially for derrick hands, who work on small, elevated platforms. Body harnesses, positioning lanyards, anchors, and connectors are a few of the crucial pieces of equipment that can protect workers. Falling objects are another danger. Hard hats should be worn at all times, and tools should be attached to the worker’s belts or the platform structure.

Hand injuries make up nearly half of all incidents in the oil industry. They range from the crush and pinching injuries to abrasions and lacerations. Crush accidents, particularly involving the hands, are an especially serious risk when handling objects such as drill pipe tongs and power tongs.

Tongs are a type of tool used to grip and lift objects instead of holding them directly with hands. There are many forms of tongs adapted to their specific use.

The first pair of tongs belongs to the Egyptians. Tongs likely started off as basic wooden tongs and then over time progressed to bronze bars as early as 3000BC. Over time they progressed to what we now know as modern-day tongs.

An Egyptian wall painting from 1450 BCE shows a crucible supported between two metal bars. The same painting shows someone holding a small object over a fire with a tong-like instrument. Bronze loops capable of handling heavy crucibles also happened to appear at this time.

Tongs that have long arms terminating in small flat circular ends of tongs and are pivoted at a joint close to the handle used to handle delicate objects. Common fire-tongs, used for picking up pieces of coal and placing them on a fire without burning fingers or getting them dirty are of this type. Tongs for grilling, tongs for serving salad or spaghetti are kitchen utensils of the same type. They provide a way to move, rotate and turn the food with delicate precision, or fetch a full serving in one grab.

Tongs in which the pivot or joint is placed close to the gripping ends are used to handle hard and heavy objects. Driller"s round tongs, blacksmith"s tongs or crucible tongs are of this type.

A myth contained in the classical Jewish text Pirkei Avot states that the first pair of tongs were created by God right before God rested on the Seventh Day. The reasoning is that a blacksmith must use a pair of tongs in order to fashion a new pair of tongs. Accordingly, God must have provided humankind with the first pair of tongs.

8613371530291

8613371530291