power tong manufacturers price

Our experienced and skilled power tong technicians play a major role in the safety and efficiency of a casing run. This makes the selection of your power tong service company a key component of overall performance.

ProTorque attracts and employs some of the industry’s most talented and experienced casing running technicians. Every detail of a casing run must be considered when looking for cost savings and efficiency; particularly on long production strings where every second counts while maintaining a safe operation. When making-up hundreds of connections, filling on the fly and selecting the correct handling equipment (air or hydraulic powered slips); we save time and effort on long challenging casing runs. ProTorque can meet handling requirements of up to 500 tons of hoist capability.

The tong should be secured for both make-up or break-out operation, by utilizing the snub line. If this is not done, the tong may be thrown against operator causing physical harm.

When using the mechanical shift lever to change speeds, the power tong must first come to a complete stop before shifting. When using tongs hydraulic shift two-speed motor to change speeds, the tong may be shifted "On the Run."

Eckel tongs have proven to basically to last forever with minimal maintenance as all they are manufactured with the highest quality of steel. Using Eckel equipment tells your customer that you have the highest quality equipment on the market.

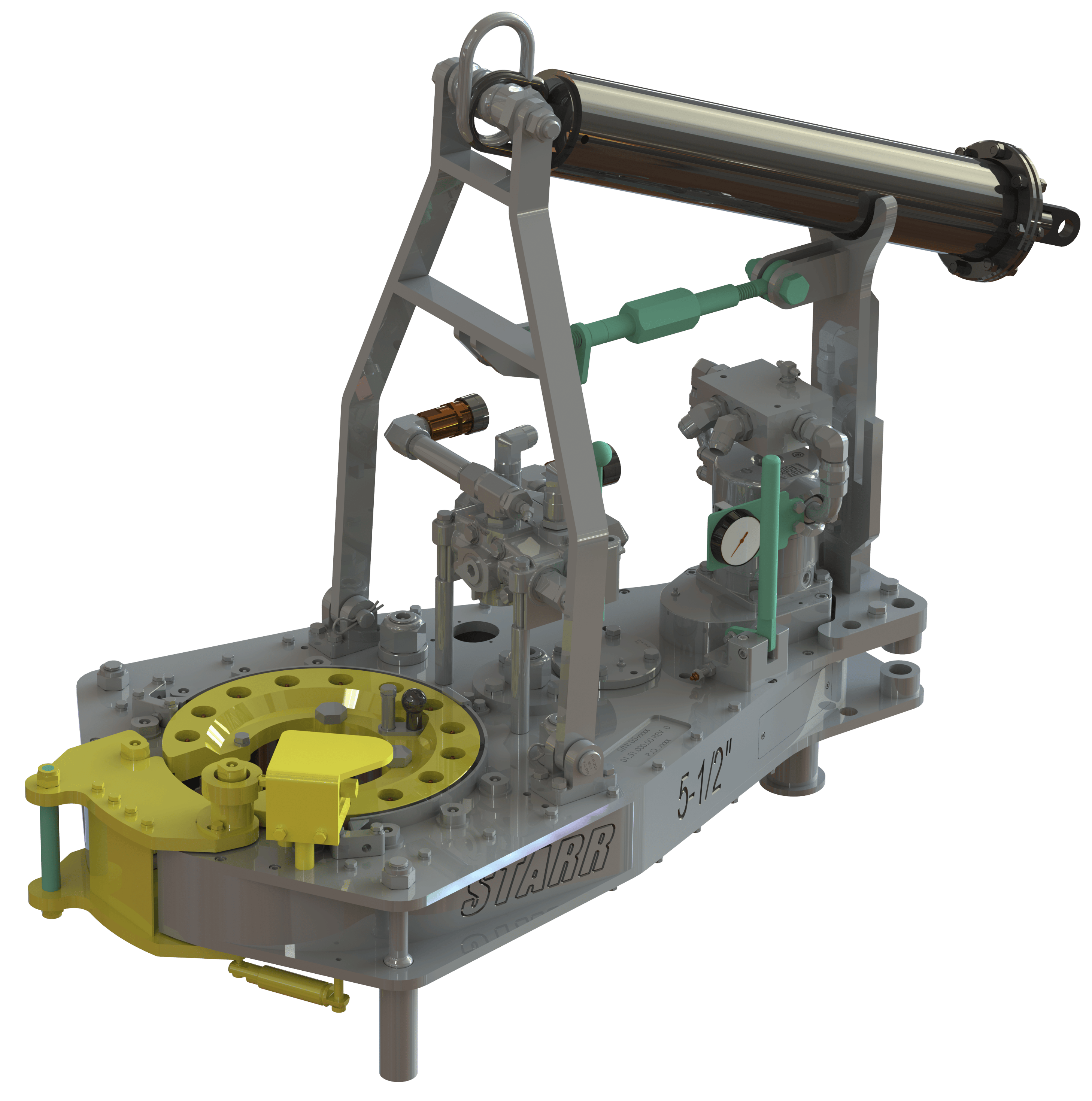

Tong size is determined by range of tubulars you will run. For example a 5-1/2 Hydra-Shift® is capable of running tubulars 5-1/2-inches and smaller while the 14 UHT is capable of running tubulars 14-inches and smaller. It is important not to use a large range of sizes with just one tong. If you have a 10-3/4 Standard and you regularly run 4-1/2-inch tubing with this tong, you might consider using a smaller tong.

PSI pressure determines the maximum torque the tong will safely be able to reach. Eckel rates all their tongs at the industry standard 2500 PSI. A competitor with a similar size tong may show more or the same torque as an Eckel tong due to a higher PSI from the power unit (which is in fine print) in an effort to fool you, thinking there tong is equal to the industry standard (Eckel tong.)

Gallons Per Minute determines the rotational speed of the tong. A low GPM will cause the tong to operate at a lower speed while a high GPM will result in the tong to rotate at a higher speed. Eckel offers an RPM (Revolutions per minute) Control which is a flow divider to decrease the amount of hydraulic fluid that reaches the tong if needed, the remaining fluid is returned to the power unit reservoir. By decreasing the amount of fluid reaching the tong the operator is able to control the maximum RPM of the tong.

Field tests have shown depending on several factors most power units used in above 32 degrees Fahrenheit conditions no matter if your hydraulic oil tank holds 200 gallons of oil, will exceed 150 degrees during a short 8 hour job. Most power units without hydraulic oil coolers exceed 170 degrees which is way past the recommended guide lines.

The quote is the core of GOM Energy Services LLC philosophy and the services provided. Cory Forbes has over 20 years in the Power Tong industry in Sales at a leading manufacturer before starting his own company in REMAN and Repair to Power Tongs.

Our staff consists of professionals from the industry in services, sales and repair. Each service technician has at least 9 years experience in power tong repairs. Our new Shot Peening service has been a great addition to blast the tong casing bodies while we take your existing product and make it as new it was when it was purchased. Click the process below to find out what you can expect in the GOM Energy Services LLC REMAN services.

The GOM"s technicians trained on the top Power Tong manufacturers products. One last thing ... if the power tong has old technology - It will be upgraded.

The global Hydraulic Power Tongs market was valued at USD million in 2020 and it is expected to reach USD million by the end of 2027, growing at a CAGR of % during the forecast period 2022-2027.

The report also focuses on global major leading industry players of Global Hydraulic Power Tongs market providing information such as company profiles, product picture and specification, capacity, production, price, cost, revenue and contact information. Upstream raw materials and equipment and downstream demand analysis is also carried out.

Hydraulic Power Tongs market competitive landscape provides details and data information by vendors. The report offers comprehensive analysis and accurate statistics on revenue by the player for the period 2016-2021. It also offers detailed analysis supported by reliable statistics on revenue (global and regional level) by players for the period 2016-2021. Details included are company description, major business, company total revenue and revenue generated in Hydraulic Power Tongs business, the date to enter into the Hydraulic Power Tongs market, Hydraulic Power Tongs product introduction, recent developments, etc.

Based on product, this report displays the production, revenue, price, Hydraulic Power Tongs market share and growth rate of Hydraulic Power Tongs Market types split into:

On the basis on the end users/applications, this report focuses on the status and outlook for major applications/end users, sales volume, share and Hydraulic Power Tongs market growth rate with applications, includes:

The Hydraulic Power Tongs market report presents pinpoint breakdown of Industry based on type, applications, and research regions. Growth strategies adopted by these companies are studied in detail in the report. The report also includes several valuable information on the Hydraulic Power Tongs market, derived from various industrial sources.

On a regional level, North America is the largest market for Hydraulic Power Tongs, accounting for the bulk of sales. This is due to the availability of a diverse range of Hydraulic Power Tongs solutions in the country. Western Europe, Asia Pacific, Latin America, Eastern Europe, and the Middle East and Africa are the other main markets.

Reasons why you should buy this report: ● Understand the current and future of the Hydraulic Power Tongs Market in both developed and emerging markets.

Some of The Key Questions Answered in This Report: ● What is the global (North America, Europe, Asia-Pacific, South America, Middle East and Africa) sales value, production value, consumption value, import and export of Hydraulic Power Tongs?

● Who are the global key manufacturers of the Hydraulic Power Tongs Industry? How is their operating situation (capacity, production, sales, price, cost, gross, and revenue)?

● What are the upstream raw materials and manufacturing equipment of Hydraulic Power Tongs along with the manufacturing process of Hydraulic Power Tongs?

MOT"s Hydraulic Power Tongs are used for running or pulling tubular strings during well repair, workover, snubbing, drilling and casing operations to extract oil and gas from wells. MOT’s

Our TEDA Style power tongs apply correct, uniform torque, reducing costly rod and tubing failures, delivering ample power to make up and break out rods and tubulars from 5/8” rod to 5-1/2” casing. Our series of XQ power tongs come with Bi-Directional jaw systems that save time and enhance safety, and go from make to break with the flip of a knob.

Tongs offer a variety of upgrades from our standard XQ series of TEDA Style models featuring Eaton hydraulic motors for extra torque and reliability, two or three spool directional control valves for more efficient hydraulic operations, and modified structures for higher strength, durability and adaptability to specific job requirements.

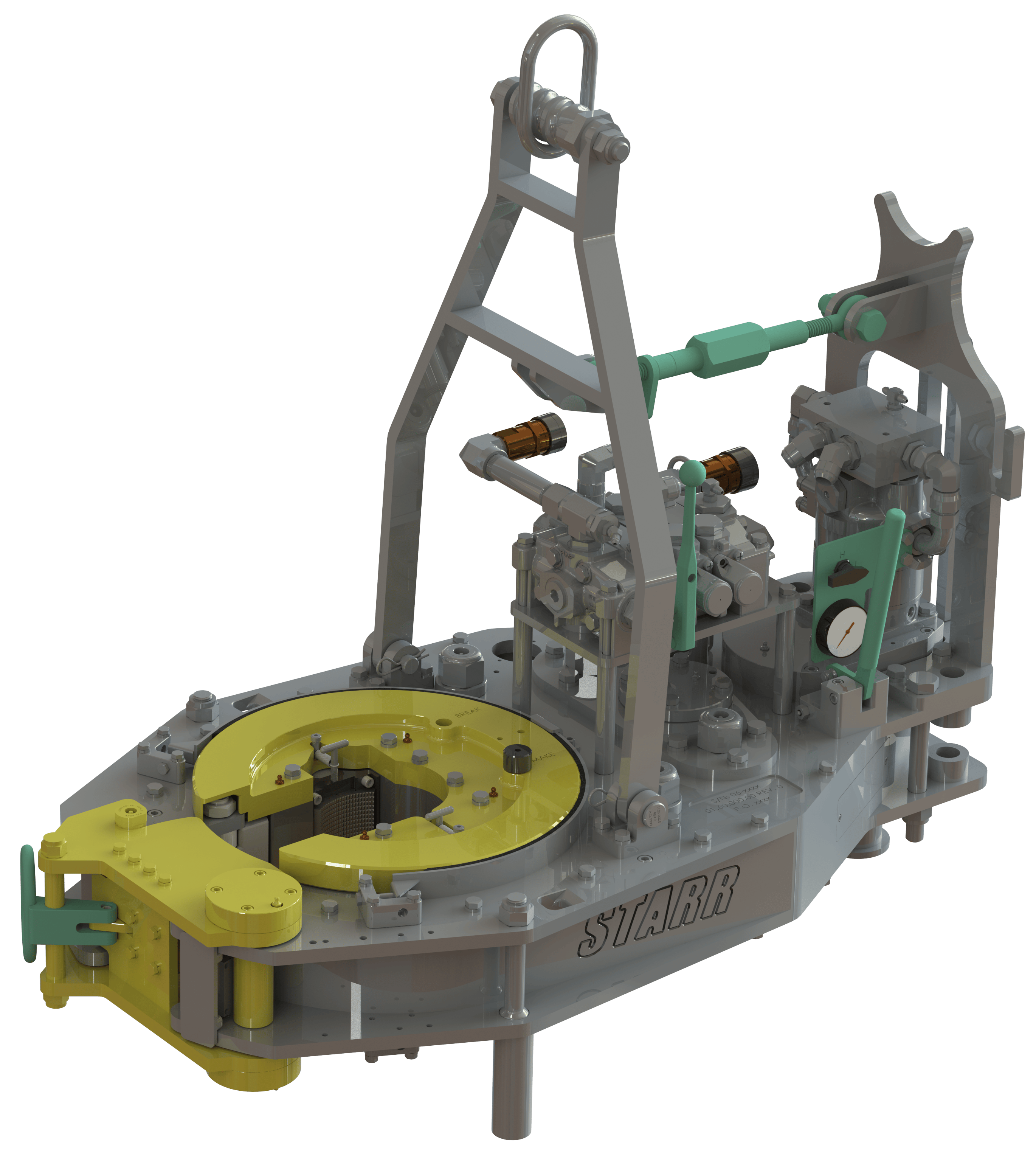

Are available from 5-1/2” to 20” pipe and are able to handle both API Standard and PREMIUM (Proprietary Steel Grade) casing connections which require higher torque. Available in a variety of models with hydraulic back-up tongs optional: “KMA", “KHT”, “TQ", “KJD”, “KD” and SE 16-25 with torques ranging from 15,000 ft-lbs up to 55,000 ft-lbs.

Are designed for quick and safe making up and breaking out of drill pipe and drill collars. Our “ZQ” series of hydraulic power drill pipe tongs are widely used in oil and gas drilling, in land and offshore operations around the world. The integrated torque tong and bucking tong eliminate the need for manual tongs and spinning chains, able to handle pipe from2-3/8” up to 8” drill collars, providing torques of up to 92,000 Lbs-Ft.

AUTOBAHN make Manual Tongs (ABMT - 65) are made as per the latest APL-7K standard and is designed for making up and braking connection of Drill Pipes, Drill Collars and Tubings with a range from 3 1/2" to 17" by means of easily change of lug jaws. Autobahn makes Manual Tongs are designed to handle the torque capacity up toread more...

"udt make" manual tongs/snap on tubing tongs are used to cover joints upto 3 ½" od and provide a 360 degree non-slip grip around the tubing. Our tongs are constructed from alloy steel, heat-treated and magnetic-particle tested. All steel specifications are certified. The tubing tong is a light weight design and operable withread more...

8613371530291

8613371530291