power tong operator price

Texas International Oilfield Tools (TIOT) offers a free standing test stand for testing of hydraulic casing and tubing power tongs. The test stand is designed to resist torque applied by a power tong through a test mandrel.

The test stand is an air operated device that utilizes a hydraulic active dual spring disc brake chamber in order to apply friction force (“brake” action) to the rotating (or stationary) test mandrel mechanism. The power tong is tested by applying torque to the test stand’s mandrel. The test stand’s brake is activated by pushing and twisting clockwise the red control box button on the control box. A brake foot pedal is supplied as backup for the mini power unit. Using the control box mounted on the test stand, the black knob regulates pressure.

include but are not limited to: Safely and efficiently performing all tasks on the rig floor and B.O.P. area under the direction and supervision of the Driller. Operating the tongs, slips, and spinners ...

2 or more years related field experience in the of the following disciplines Torque Turn Systems Power Tong Systems Handling Tool Systems High School diploma (or Secondary School Diploma or equivalent) ...

The Field Specialist IV will rig up, rig down and run TRS (Tubular Running Services) equipment at location with no supervision, lead and train less experienced Operators. Prepare accurate tickets, job ...

of the Floorhand include: Assisting the Derrickhand, Motorhand and Driller on the drill floor while making trips; Operating manual tongs and slips to connect and disconnect drilling pipe and drilling ...

of the Floorhand include: Assisting the Derrickhand, Motorhand and Driller on the drill floor while making trips; Operating manual tongs and slips to connect and disconnect drilling pipe and drilling ...

Power Tong and Pressure Testing business for sale. Perfect set up for ambitious owner/operator. 3 sets of tongs, Farr 9 5/8, Mighty Mite 9 5/8, Mighty Mite 11 3/4. Slips & Elevators from 11 3/4 to 4 1/2 with recent certs. Cat 3507 pressure test pump. 2 ton picker, Electric reels on combo unit.

The tong should be secured for both make-up or break-out operation, by utilizing the snub line. If this is not done, the tong may be thrown against operator causing physical harm.

When using the mechanical shift lever to change speeds, the power tong must first come to a complete stop before shifting. When using tongs hydraulic shift two-speed motor to change speeds, the tong may be shifted "On the Run."

Eckel tongs have proven to basically to last forever with minimal maintenance as all they are manufactured with the highest quality of steel. Using Eckel equipment tells your customer that you have the highest quality equipment on the market.

Tong size is determined by range of tubulars you will run. For example a 5-1/2 Hydra-Shift® is capable of running tubulars 5-1/2-inches and smaller while the 14 UHT is capable of running tubulars 14-inches and smaller. It is important not to use a large range of sizes with just one tong. If you have a 10-3/4 Standard and you regularly run 4-1/2-inch tubing with this tong, you might consider using a smaller tong.

PSI pressure determines the maximum torque the tong will safely be able to reach. Eckel rates all their tongs at the industry standard 2500 PSI. A competitor with a similar size tong may show more or the same torque as an Eckel tong due to a higher PSI from the power unit (which is in fine print) in an effort to fool you, thinking there tong is equal to the industry standard (Eckel tong.)

Gallons Per Minute determines the rotational speed of the tong. A low GPM will cause the tong to operate at a lower speed while a high GPM will result in the tong to rotate at a higher speed. Eckel offers an RPM (Revolutions per minute) Control which is a flow divider to decrease the amount of hydraulic fluid that reaches the tong if needed, the remaining fluid is returned to the power unit reservoir. By decreasing the amount of fluid reaching the tong the operator is able to control the maximum RPM of the tong.

Field tests have shown depending on several factors most power units used in above 32 degrees Fahrenheit conditions no matter if your hydraulic oil tank holds 200 gallons of oil, will exceed 150 degrees during a short 8 hour job. Most power units without hydraulic oil coolers exceed 170 degrees which is way past the recommended guide lines.

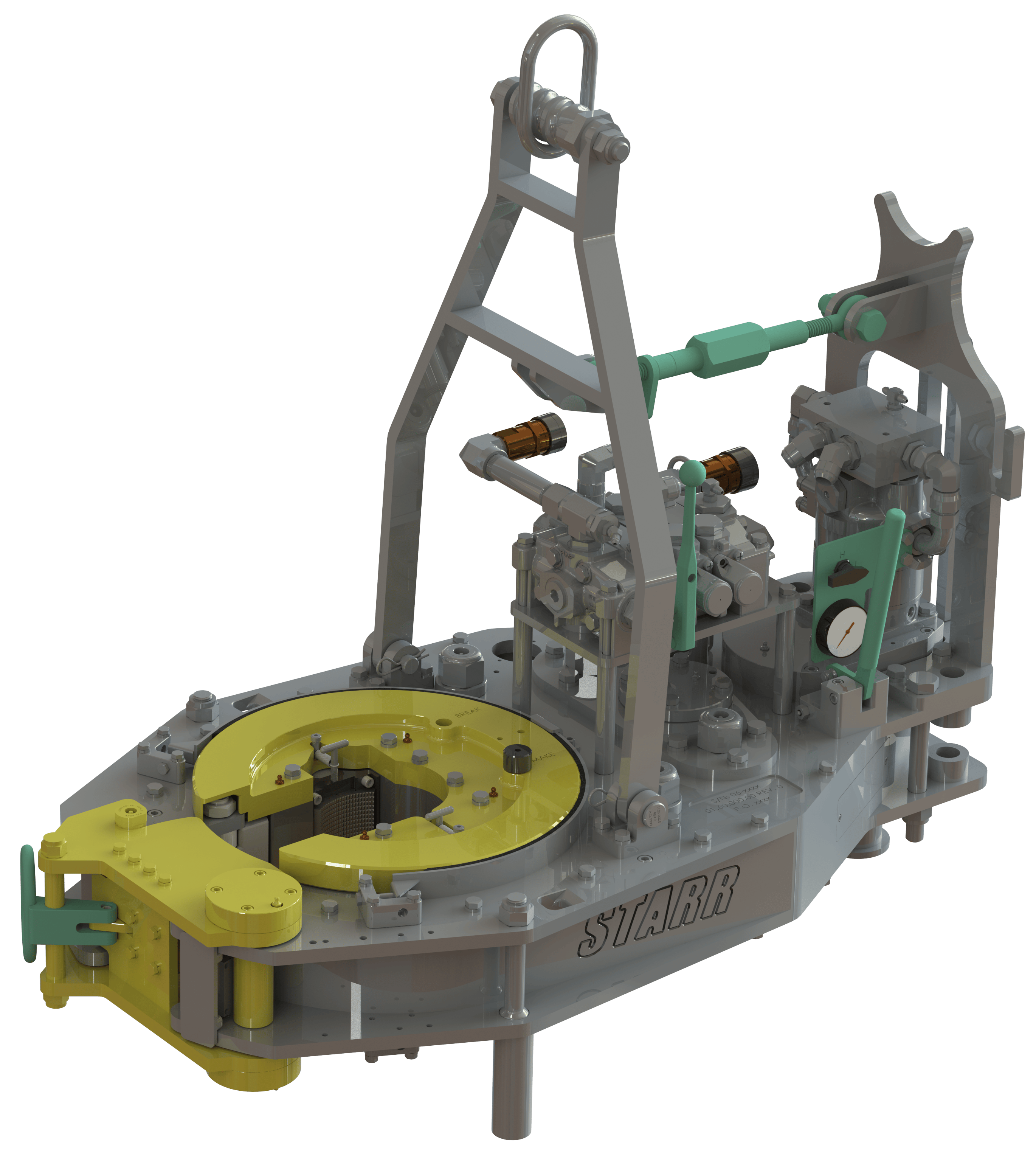

A viable alternative that improves safety and efficiency during snubbing operations consists of a power tong set, with lead and back-up tongs that are mounted on the slip bowl of the traveling jack head of a snubbing unit and rotates with the slip bowl. Service lines for the tong set are not connected during string rotation.

In another version of this type of device, a fluid feed-through swivel is mounted on the tong set, secured to the necessary tong operating and control service fluid lines, such that the tong set can rotate with tong service lines between the tong set and the snubbing unit attached during rotation.

In an alternate form, the tong set is mounted on the jack head, independent of the rotary table, and the tong set does not rotate when the rotary table rotates.

A snubbing unit consists basically of a pipe-handling system, a wellhead safety system, a hydraulic power unit and the downhole accessories incorporated into the snubbing string.

The pipe is brought up from the pipe rack by a set of elevators, sheaves and a handling cable attached to the gin pole, and the connections are made by using a set of power tongs that remain hanging by cable at the height of the work area. The tong may also be attached to a tong arm fixed to the basket.

Operating in this manner requires specialized people, usually consisting of a foreman and three or four people per shift. The space in the snubbing basket is usually very limited and unstable, which magnifies the hazards associated with the manipulation of pipe, elevators and power tongs.

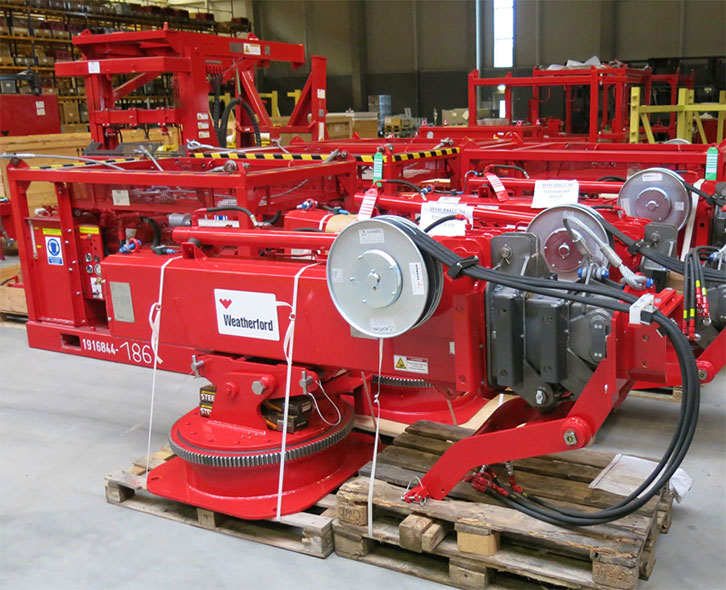

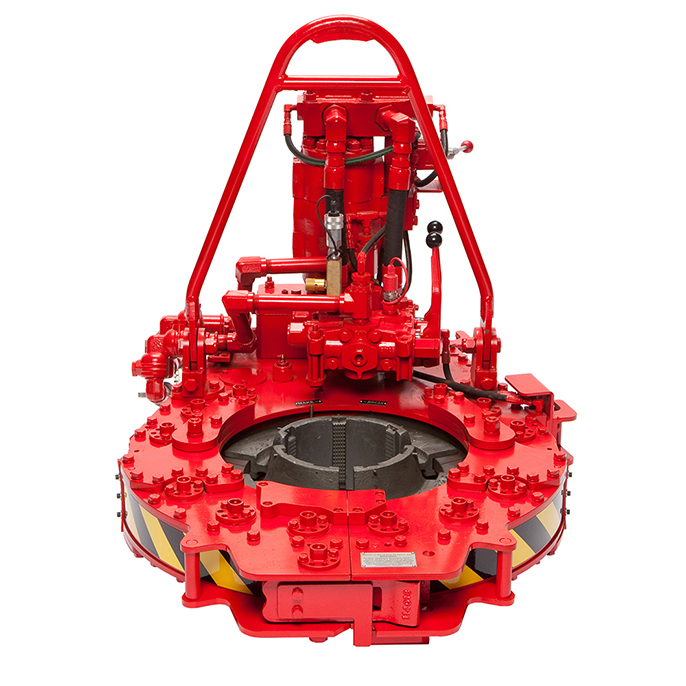

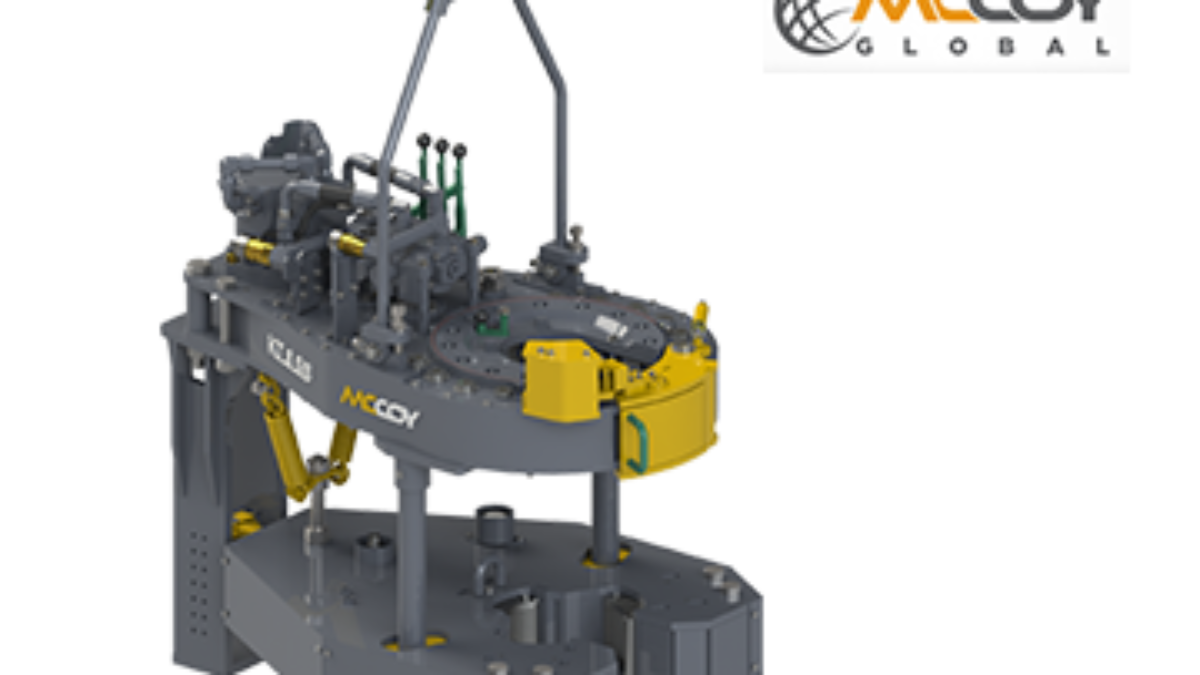

ODS International and Rogers Oil Tools (ROT) have developed a patented power tong built specifically for snubbing and well control applications (Figure 1). It is the only tong designed to ride the jack incorporated with a swinging basket.

No tong pole and no pushing or pulling of the tong on and off the pipe is necessary, which eliminates nagging injuries (broken or mashed fingers, twisted or strained backs, shoulder damage) and significantly improves the efficiency of the operation.

The jack head tong carries the provision of having a three-section cage plate system that can be removed to allow the jack head tong to be open for full wellbore capabilities, matching the BOP’s bore. This is the fastest and safest way to trip pipe with a snubbing unit.

The snubbing power tong introduced in this article is a viable alternative, making operations safer by eliminating movement of the tong on and off the pipe. This eliminates nagging injuries and increases the operational efficiency, which ultimately impacts the overall costs of well servicing programs in benefit of operator and drilling contractors.

Radial Lock Door: A patented door locking system (US Patent 6,279,426) for Eckel tongs that allows for latchless locking of the tong door. The tong door swings easily open and closed and locks when torque is applied to the tong. When safety is important this locking mechanism combined with our safety door interlock provides unparalleled safety while speeding up the turn around time between connections. The Radial Door Lock is patented protected in the following countries: Canada, Germany, Norway, United Kingdom, and the United States.

Sliding Head: A type of head used in specific Eckel tongs that slides out from a pocket within the tong. This head biting system utilizes our wide angle wrap-around type dies and is considered the best choice of power tong biting systems for use on small tubular and drill pipe.

Magnum Manufacturing. has successfully mastered the design and manufacturing processes of creating a better hydraulic tong. By decreasing the weight of the tong and increasing the power, Magnum Power Tongs out perform the torque to weight ratio of any competitor. Constructed of premium quality materials, Magnum"s unique system delivers safe, efficient, and reliable performance on every job. Find out more..

Premiere, Inc. CRT / PRT Casing Equipment includes patent pending efficient equipment as Single and Dual Stage Diesel Power Units (DPU), the Magnum Manufacturing exclusive Multi-Grip Bowl and more. Technology at the Intersection of Obsession & Innovation. Find out more..

Magnum Manufacturing has released its latest invention in cutting edge tubular running technology. The Magnum Alignment Tool connects to any top drive and allows the operator to remotelyadjust the position of each joint of casing or tubing directly over the well bore.... Find out more..

The Magnum Tubular Flow Tool allows the operator to fill or circulate casing while it is being run into the well. Due to the large flow area it is designed to flow back conditions when float equipment is not being utilized. Our oilfield equipment is designed with safety in mind. Find out more..

Contact our expert sales staff for pricing, availability and product specifications for the Gill Power Tong right for your application at the link provided on this page.

8613371530291

8613371530291